Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Boeing-Stearman Kaydet PT13 - 17

Caricato da

Mihaela ApostolDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Boeing-Stearman Kaydet PT13 - 17

Caricato da

Mihaela ApostolCopyright:

Formati disponibili

Boeing-Stearman

Kaydet PT13/17

US Airforce / Navy Primary Trainer

Assembly and finishing Manual

for ARF stand-off scale model

in 1:5 scale.

Historical data and presentation.

Model design and construction drawing by

Gran Kaldern

Rev. 2002-08-15

Stearman Kaydet PT17 ARF 2

Stearman Kaydet PT17 ARF 3

Stearman Kaydet PT17 ARF 4

Stearman Kaydet PT17 ARF 5

Boieng Stearman PT-17 Kaydet

Nicknamed the Yellow Peril thanks to its

somewhat tricky ground handling characteristics, the

Stearman is one of the most easily recognized air-

craft. Its simple construction, rugged dependability and

nimble handling made the Stearman much loved by

those who flew and trained on it. The Stearman Kaydet,

as it was officially named, was the only American air-

craft used during World War II that was completely

standardized for both Army and Navy use as the PT

13D (Army) and N255 (Navy). Sold by the thousands

after World War II, the Stearman has had a long and

full career as a trainer, crop duster and air show per-

former.

The famed Stearman Model 75 has its roots

in the earlier Model 70, which was chosen in 1934 as

the U.S. Navys primary trainer. At a time when bi-

planes were becoming a thing of the past, the Model

70 offered the fledgling pilot a steady and sturdy steed.

Designed and built in only 60 days, the prototype Model

70 could withstand load factors much higher than were

expected to occur in normal flight training. The U.S.

Army and Navy tested the prototype in 1934. At the

conclusion of these tests, the Navy ordered the air-

craft while the Army decided to wait for the introduc-

tion of the improved Model 75 appearing in 1936. Over

the next decade, the Armydecided to wait for the in-

troduction of the improved Model 75 appearing in 1936.

Over the next decade, the Army received nearly 8,500

Stearmans in five different variants. The difference

among these versions were the engines fitted; Kaydets

were fitted with Lycoming (PT 13), Continental (PT

17) or Jacobs (PT 18) radial engines. The U.S. Navy

took delivery of their first Stearman (called the NS-1 )

in 1934. Powered with the obsolete but readily avail-

able Wright R-790-8 engine, the NS-1 proved its worth

as a primary trainer. The Navy purchased several thou-

sand of an improved model, the N2S. The N2S was

built in five sub variants, each variant being equipped

with a different model engine. Additionally, the Cana-

dian armed forces took delivery of 300 PT 27s, a win-

terized version of the PT 17.

A later, more powerful version of the Stearman,

the Model 76, was purchased by Argentina, Brazil and

the Philippines.

Stearman Kaydet PT17 ARF 6

Stearman PT-17 Kaydet

Length: 25' 7.62 M

Height: 9' 2" 2.79 M

Wingspan: 32' 2" 9.80 M

Wingarea: 297.00 Sq Ft 27.59 Sq M

Empty Weight: 1936.00 lbs 878.00 Kg

Gross Weight: 2717.00 lbs 1232.00 Kg

Powerplant: Continental R-670-5, 220 hp

Stearman Kaydet PT17 ARF 7

The Model

We have chosen the scale of 1:5 rendering

a model size that i easy to fly but also relatively

easy to transport. Both the upper and the lower

wing panels can be removed for transportation

whi ch gi ves very l i mi ted requi rement for

transportation size. With a .1.20 4-stroke engine

the airplane is capable of most of the manoeuvers

in the book but still as docile as you can demand

from a n advanced trainer.

The finished model is painted in 1939 livery

and further detailing can be made as per

documentation.

Specifications:

Wingspan cm 193

Wingspan inches 77.2

Length cm 149

Length inches 59.6

Weight grams 6600

Weight Lb/oz 14lb. 8 oz.

Wing surface dm 118 dm

Wing surface Sq.inch 1888 sq

Wing load g/dm 56 g/dm

Wing load oz/Sq 24 oz/sq

Engine 2-cycle .60 - .90

Engine 4-cycle .90 - 1.20

C/G fr. Lead.edge upper wing 15cm / 6

Covering and finish

The model is covered and painted from the

factory. Where the original had aluminum covering

panels, the model has the same. This also means

excellent acces to the various compartments in

the fuselage when installing or servicing the radio

equipment. When you have made changes in the

fire wall and adapted the dummy engine to fit in

front of the engine, you will have to cover the open

areas with fuel proof paint.

Installation of engine.

Our prototype was tried with an OS 1.20 FS

surcharge 4-stroke which gave more than ample

thrust. The engine mounts have been installed

for this size of engine and in an upright position

for several reasons.

The need for adequate cooling. The access

to the glow plug easily and finally to get the

carburator in line with the center of the tank.

1. Drill the holed for the engine in the "

plywood ingine mount. Install blind nuts underside

of the plywood aligned with the holes

2. Drill the holes from the tank to the

carburator, pressure tap and the filling cap.

3. Install the engine and connect the throttle

servo.

No side or down thrust is deemed necessary. You

can use an flexible exhaust manifold to lead the

exhaust out under the center bottom panel to give

a better apperance.

Installation of servos, tank, battery and

receiver.

The aileron servo is installed in the cockpit

flooring. The elevator servo and the rudder

servo are also installed in the cockpit flooring.

The trottle servo is installed behind the

engine as well as the tank, booth on the

engineboard.

Battery pack and receiver are positioned

in the upper part of the tray.

The switch can be mounted on the front

cockpit instrument panel.

1. Attach a ball link head to joystick and

rudder bar in the appropriate holes. You may have

to enlarge the holes to take the screw from the

ball link (Dubro #189 set of 2).

2. Install the servos for rudder and elevator

and temporarily connect the servo arms to the

ball links. Deflection for elevator is 20 up and

down and for rudder 30 right and left..

3. Install and connect the throttle servo in

the fashion you prefer.

4. Install the tank in the available space at

the right side next to the rudder and throttle

servos..

5. Install the aileron servo in the bulkhead.

The aileron connecting rods attaches to the servo

arm. Deflection of the ailerons should be 20 up

and down. The servo arm should be fashioned to

take 2 clevices approx 1/8" apart.

6. Install the radio switch on the dash board.

7. Place the receiver in the upper part of the

tray and the battery pack in front of the lower

firewall, wrapped in foam rubber and secured with

rubber bands.

Assembly of the PT17

All parts have been assembled at the factory

and only disassembled for transportation.

Rudder wires and elevator pushrod are

factory adjusted but may need some tensioning

adjustment after a while. Aileron bellcranks are

permanently adjusted to the connecting rod.

Assembly of the tail unit

See detail drawing.

1. Attach horizontal tail(3) to fuselage using 3 pcs

4 mm nylon countersunk screws. Make sure that

stabilizer is flat against fuselage.

2. connect the elevator control rod to the elevator

horn.

3. Insert vertical fin and secure to tailpost bracket

and front of stabilizer. Attach rudder on to the fin

with hinge pins.

4. Secure the assembly with screws to the

stabilizer and to the tailpost. Attach the top

stabilizer fairing and secure with screws.

5. Attach fin and stabilixer support wires to top of

fin using 2 mm screw and nut (from top side of

Stearman Kaydet PT17 ARF 8

Stearman Kaydet PT17 ARF 9

Stearman Kaydet PT17 ARF 10

an integrated part of the fuselage. The wheels

are secured with locking rings and the wheel caps

are pushed onto the wheel hubs.

Balancing

The center of gravity / balancing point should be

approx. 15 cm (6") measured from the leading

edge on the upper wing. Make adjustments if

necessary.

Flying

The prototype was flown with a OS 1.20

4-stroke FS which provides ample thrust. Let the

engine swing a 18x6 propeller if possible. This

gives better thrust outside the big dummy engine

and reduces sound to a more realistic level.

Flying characteristics are very forgiving

and will fly hapily on half trottle. Set the elevator

at zero angle for the first flight but be prepared

to give down elevator if the model climbs out too

steep. During the initial take off run you have to

compensate for the torque with right rudder but

as the speed builds up the rudder is returned to

neutrual. This model should fly of the ground and

not be pulled.

The landing approach can be rather

steep as per prototype but the flare out needs

almost full up elevator. Maintain directional

heading and remember, the aircraft has a

stearable tailwheel.

Happy landings!

stabilizer to top of fin).

6. Secure and tighten all screws and nuts.

Check the action of elevator and rudder. The

elevator is actuated with the joy-stick and the

rudder with the rudder bar.

Assembly of wing panels

1. Push the lower wing halves into the holes

in the fuselage.

2. Attach the upper wing center section using

the 4 Allen 6-32 screws supplied (note that the

front screws are longer and the rear screws

shorter). Attach ball links or clevices to the aileron

push rods. Connect the aileron push rods to the

servo in the fuselage.. Check the movement of

the ailerons. 20 up and 15 down throw.

3. Install the interplane struts. Connect the

flying wires and the landing wires. Attach the fly-

ing wires in place. Attach the landing wires in

place. Adjust if necessary, the rear lower

incidence adjustment screw and the fasten this

assembly to the bracket on the lower wing using

2 mm screw and locknut.

Should you need to replace a wire, use the

attachment method indicated in the picture. When

crimping the cerulet (sleeve) use a flat plier, press

firmly and don't cut through the wire.

Landing gear

Install the wheel shafts and secure with the

Allen socket locking screws. The landing gear is

completely built up with oleo spring action and is

Stearman Kaydet PT17 ARF 11

Rudder and elevator servos in the flooring

of front cockpit

Aileron servo in the

flooring of rear

cockpit. Note the

servo arm with 2

attachment point

for the clevices of

the aileron push

rods.

Push rods from the servos attach to the

rudder bar and the control column.

The tailwheel is

coupled to the

rudder bar and has

50% throw of the

rudder

The OS 1.2 engine blends nicely with the

dummy engine

Stearman Kaydet PT17 ARF 12

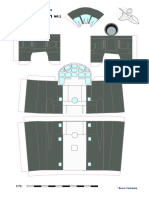

What is in the box:

The ARF kit contains the parts shown in the picture.

All the parts are covered and painted. All the rigging

wires are supplied in the correct lengths and need

only to be clipped to their positions.

1. Fuselage with wing cabane

2. Landing gear

3. Scale wheels

4. Dummy engine with mount

5. Scale propeller

6. Tail wheel assy (stearable).

7. Fin with tailfairing /rudder

8. Stabilizer / elevator

9. Upper wing panels

10. Lower wing panels

11. Interplane struts

12. Wires, turnbuckles and hardware for assembly

(not shown)

13. Assembly manual with scale

documentation

1

2

3

5

6

7

9

8

10

11

4

P.O.Box 1229, Cebu City Centrl. Postoffice

Cebu City 6000, Philippines

Visiting address:

3343 Gun-Ob, Kinalumsan,

Lapu-Lapu City 6015, PHILIPPINES

Phone +63 32-340 0772, Cellular +63 917-3200 985

Telefax +63 32-340 7131, E-mail: kwmairpl@gsilink.com

Website http://www.kwmairpl.com.ph

K&W

Model

Airplanes Inc.

13

Potrebbero piacerti anche

- THM 135 ALL VERSION - Enc.2019 02 05.4729Documento628 pagineTHM 135 ALL VERSION - Enc.2019 02 05.4729João Corrêa100% (7)

- BIAS 2016 - Inventory of Participant AircraftDocumento1 paginaBIAS 2016 - Inventory of Participant AircraftJohn WilkonsonNessuna valutazione finora

- (1921) Operating Equipment For U.S. Army Observation BalloonsDocumento28 pagine(1921) Operating Equipment For U.S. Army Observation BalloonsHerbert Hillary Booker 2nd100% (1)

- Boeing 707: Advanced Passenger Jet Specs & RecordsDocumento2 pagineBoeing 707: Advanced Passenger Jet Specs & RecordsErta ShinoNessuna valutazione finora

- The Santos-Dumont DemoiselleDocumento7 pagineThe Santos-Dumont DemoiselleAntônio CastroNessuna valutazione finora

- Tutorial-01 2021Documento3 pagineTutorial-01 2021Ishan IndurkarNessuna valutazione finora

- Airborne Doppler Radar Navigation of Jet Transport Aircraft-EftDocumento10 pagineAirborne Doppler Radar Navigation of Jet Transport Aircraft-Eftjulio perezNessuna valutazione finora

- Plane ConnectDocumento4 paginePlane ConnectDarren G. SarvisNessuna valutazione finora

- TO 1C-130H-2-27GS-00-1: General SystemDocumento96 pagineTO 1C-130H-2-27GS-00-1: General SystemLuis Francisco Montenegro Garcia100% (1)

- TOTAL StearmanDocumento10 pagineTOTAL Stearmanmike_hobbs_6Nessuna valutazione finora

- Block 1 - Airframe: Configuration & Major Components General Maintenance Preflight & PostflightDocumento102 pagineBlock 1 - Airframe: Configuration & Major Components General Maintenance Preflight & PostflightKim GomezNessuna valutazione finora

- Flying Paper f22 RaptorDocumento4 pagineFlying Paper f22 Raptorarmando100% (1)

- War Flying by L. F. HutcheonDocumento49 pagineWar Flying by L. F. HutcheonDanKoifmanNessuna valutazione finora

- A Concept of The Vortex Lift of Sharp-Edge Delta Wings Based On A Leading-Edge-Suction AnalogyDocumento18 pagineA Concept of The Vortex Lift of Sharp-Edge Delta Wings Based On A Leading-Edge-Suction AnalogyTimbo81Nessuna valutazione finora

- Demoiselle Original HistoryDocumento52 pagineDemoiselle Original HistoryMDNessuna valutazione finora

- GOERZ-VISIER 219 D BombenrichtgerätDocumento30 pagineGOERZ-VISIER 219 D BombenrichtgerätBranislav PopkonstantinovićNessuna valutazione finora

- Arado Ar-E381Documento4 pagineArado Ar-E38118912170Nessuna valutazione finora

- Squadrons 4Documento2 pagineSquadrons 4ZZBDUNessuna valutazione finora

- Naca TM 1169Documento24 pagineNaca TM 1169Margaret FordNessuna valutazione finora

- Simple Past Tense Harry Potter Worksheet Templates Layouts 102364Documento2 pagineSimple Past Tense Harry Potter Worksheet Templates Layouts 102364Okti Siti Fatimmah0% (1)

- Metoda VLMDocumento6 pagineMetoda VLMGabriel MarinicăNessuna valutazione finora

- Civil Aviation Oriented Aerospace EngineeringDocumento31 pagineCivil Aviation Oriented Aerospace EngineeringGeorgiana UrsachiNessuna valutazione finora

- 10-Blade Flapping Equation of Rigid Body Motion-V01Documento33 pagine10-Blade Flapping Equation of Rigid Body Motion-V01Afshin ManouchehriNessuna valutazione finora

- Army Aviation Digest - Jun 1971Documento68 pagineArmy Aviation Digest - Jun 1971Aviation/Space History Library100% (2)

- Simulating Cannonball Flight in AtmosphereDocumento16 pagineSimulating Cannonball Flight in AtmosphereSandeepNessuna valutazione finora

- Air IntakeDocumento16 pagineAir IntakeDr.S.RamamurthyNessuna valutazione finora

- Drag of Airplane Wheels, Wheel Fairings and Landing Gear I - NACA RPT 485 PDFDocumento35 pagineDrag of Airplane Wheels, Wheel Fairings and Landing Gear I - NACA RPT 485 PDFLysterNessuna valutazione finora

- Army Aviation Digest - Mar 1957Documento40 pagineArmy Aviation Digest - Mar 1957Aviation/Space History LibraryNessuna valutazione finora

- NASA 124162main FS-031-DFRCDocumento7 pagineNASA 124162main FS-031-DFRCNASAdocumentsNessuna valutazione finora

- Sukhoi Su 17Documento14 pagineSukhoi Su 17128mansouriNessuna valutazione finora

- B-17. The C-1 AutopilotDocumento6 pagineB-17. The C-1 AutopilotAnonymous d8N4gq100% (1)

- Z Parachute PRDocumento4 pagineZ Parachute PRNile_JockeyNessuna valutazione finora

- Army Aviation Digest - Jan 1969Documento68 pagineArmy Aviation Digest - Jan 1969Aviation/Space History LibraryNessuna valutazione finora

- Piston Cooling SystemDocumento31 paginePiston Cooling SystemAfiq ZikriNessuna valutazione finora

- Nato Strap IssueDocumento10 pagineNato Strap IssuepaterdaleNessuna valutazione finora

- Air Force News Jan-Dec 1926Documento447 pagineAir Force News Jan-Dec 1926CAP History LibraryNessuna valutazione finora

- Kampfflieger - Stinson L5 Sentinel 87Documento12 pagineKampfflieger - Stinson L5 Sentinel 87Darren-Edward O'NeillNessuna valutazione finora

- Heinkel He-60 PDFDocumento44 pagineHeinkel He-60 PDFjuanverenguer100% (5)

- AanDocumento9 pagineAanPocs MadarNessuna valutazione finora

- Pilot's Operating Handbook PS-28 CruiserDocumento168 paginePilot's Operating Handbook PS-28 CruiserCruiser Aviation100% (2)

- Soyuz Part2Documento9 pagineSoyuz Part2Angel CarreroNessuna valutazione finora

- Escort Carrier and System Design Naval VesselDocumento9 pagineEscort Carrier and System Design Naval VesselHtain WinNessuna valutazione finora

- Heinkel He 64 C Sport Airplane (German)Documento9 pagineHeinkel He 64 C Sport Airplane (German)SnautzerNessuna valutazione finora

- Tac73 08Documento32 pagineTac73 08TateNessuna valutazione finora

- Naca Report 126Documento62 pagineNaca Report 126PedroSickensNessuna valutazione finora

- European Air Navigation PlanDocumento244 pagineEuropean Air Navigation PlancaraciculaNessuna valutazione finora

- Early Aviation History (1910)Documento1 paginaEarly Aviation History (1910)CAP History Library100% (2)

- Tac77 06Documento32 pagineTac77 06TateNessuna valutazione finora

- Undergraduate Pilot TraininngDocumento53 pagineUndergraduate Pilot TraininngSoepar Nova SyamNessuna valutazione finora

- 02 Airfoil ADocumento23 pagine02 Airfoil Abecool_bcn75Nessuna valutazione finora

- AS3271 Tutorial 1Documento10 pagineAS3271 Tutorial 1Ishan IndurkarNessuna valutazione finora

- Fafnir 3 ViewDocumento1 paginaFafnir 3 ViewDavorinBazijanacNessuna valutazione finora

- Avro Shackleton 1-72 Scissors and PlanesDocumento6 pagineAvro Shackleton 1-72 Scissors and PlanesRabia ReservorioNessuna valutazione finora

- Sailplane and Gliding - Oct-Nov 2000 - 68 PGDocumento68 pagineSailplane and Gliding - Oct-Nov 2000 - 68 PGlaerciofilhoNessuna valutazione finora

- Sopwith TriplaneDocumento12 pagineSopwith TriplaneEduardo CaamañoNessuna valutazione finora

- Mba TornadoDocumento17 pagineMba Tornadojemalves100% (1)

- Interstate Cadet MonoplaneDocumento7 pagineInterstate Cadet MonoplaneAviation/Space History LibraryNessuna valutazione finora

- Pilatus-Pc7 ManualDocumento19 paginePilatus-Pc7 ManualRoderick Diaz MoraNessuna valutazione finora

- Spitfire ARF GB AvionDocumento11 pagineSpitfire ARF GB AvionJuan Carlos AlvaradoNessuna valutazione finora

- Culver Cadet MonoplaneDocumento5 pagineCulver Cadet MonoplaneAviation/Space History LibraryNessuna valutazione finora

- Wing Commander Morningstar Construction Manual: RC Profile PlanesDocumento10 pagineWing Commander Morningstar Construction Manual: RC Profile Planessavall21Nessuna valutazione finora

- DC 9 31 Eastern InstructionsDocumento20 pagineDC 9 31 Eastern InstructionsWoo Hyun ShinNessuna valutazione finora

- Pietenpol Air CamperDocumento16 paginePietenpol Air CamperricardoNessuna valutazione finora

- 34 12 03 RiDocumento2 pagine34 12 03 RiHéctor SánchezNessuna valutazione finora

- Application for Commercial Air Transport Route QualificationDocumento2 pagineApplication for Commercial Air Transport Route QualificationJoanes SyNessuna valutazione finora

- Dgca Ir / LR Check FormDocumento2 pagineDgca Ir / LR Check FormCyril Mathew RoyNessuna valutazione finora

- 690-5 - Helicopter and EquipmentDocumento23 pagine690-5 - Helicopter and EquipmentДмитрий SolodNessuna valutazione finora

- Ata 100 PDFDocumento1 paginaAta 100 PDFLuiz CordeiroNessuna valutazione finora

- FAA 2018 0855 0002 - Attachment - 2Documento15 pagineFAA 2018 0855 0002 - Attachment - 2Andrew OlsonNessuna valutazione finora

- Aeronautika RječnikDocumento6 pagineAeronautika RječnikIvona IvkovicNessuna valutazione finora

- Aircraft Design Project - IDocumento23 pagineAircraft Design Project - Irishitha reddyNessuna valutazione finora

- Fa 330Documento4 pagineFa 330jonjonkelly100% (1)

- Lockon Fc2 Flight Manual enDocumento321 pagineLockon Fc2 Flight Manual encudedog100% (1)

- Reviewer: Engr. R. Renigen: Patts Review Center Patts College of AeronauticsDocumento38 pagineReviewer: Engr. R. Renigen: Patts Review Center Patts College of AeronauticsJasha KimNessuna valutazione finora

- Aircraft Fuel Systems ExplainedDocumento3 pagineAircraft Fuel Systems ExplainedJabez RichardsNessuna valutazione finora

- H900XP Study Guide R1.1Documento28 pagineH900XP Study Guide R1.1Leandro Aquino Dos Santos100% (1)

- Imperfections FAR & EASA CS 23 & 25 by AvioConsult PDFDocumento18 pagineImperfections FAR & EASA CS 23 & 25 by AvioConsult PDFjjannaniNessuna valutazione finora

- QDB 15 PofDocumento142 pagineQDB 15 Pofant100% (1)

- Cessna 210 M SpecificationsDocumento4 pagineCessna 210 M SpecificationsCristiian CamiiloNessuna valutazione finora

- EXPERIMENTER (December 2014)Documento45 pagineEXPERIMENTER (December 2014)Jessie Bechayda100% (4)

- Aerostar Solutions: A Project AssociationDocumento5 pagineAerostar Solutions: A Project AssociationMithun SinghNessuna valutazione finora

- Checklist King Air 350Documento7 pagineChecklist King Air 350Alejo Giraldo VélezNessuna valutazione finora

- Basic Aircraft Maintenance Training - Aviation Legislation For Aircraft Maintenance Course - EASA Part-66 - EASA PART-147 - FL Technics TrainingDocumento3 pagineBasic Aircraft Maintenance Training - Aviation Legislation For Aircraft Maintenance Course - EASA Part-66 - EASA PART-147 - FL Technics TrainingPhil Zimb100% (1)

- SLCA CartasDocumento2 pagineSLCA Cartascorina vargas cocaNessuna valutazione finora

- Cabin Crew Technical EnglishDocumento8 pagineCabin Crew Technical EnglishGabriela SavoneNessuna valutazione finora

- 1999 Q2-Advanced Maintenance Techniques For The 757-300Documento8 pagine1999 Q2-Advanced Maintenance Techniques For The 757-300tlnrsNessuna valutazione finora

- RemoteFlight InstructionsDocumento4 pagineRemoteFlight InstructionsJuanNessuna valutazione finora

- Contents of All Wings of War Boxes and PacksDocumento8 pagineContents of All Wings of War Boxes and Packsairfix1999100% (1)

- Aircraft fuselage structure typesDocumento5 pagineAircraft fuselage structure typesolegprikhodko2809Nessuna valutazione finora

- Document Fms Boeing PDFDocumento4 pagineDocument Fms Boeing PDFtangautaNessuna valutazione finora