Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

JIT Term Paper

Caricato da

Shaon Banerjee0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

143 visualizzazioni21 pagineJIT Term Paper

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoJIT Term Paper

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

143 visualizzazioni21 pagineJIT Term Paper

Caricato da

Shaon BanerjeeJIT Term Paper

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 21

Shaon Banerjee, Shilpi Saxsena (UH13044),

Shobhita Dikshit, Shruti Jain, Shruti Prashant,

Sib Sankar Datta

Xavier Institute of Management,

Bhubaneswar

Just-in-Time and Lean

Manufacturing

Page | 2

CONTENTS

1. Preface ................................................................................................................................................. 4

2. Acknowledgment ................................................................................................................................. 5

3. Abstract ................................................................................................................................................ 6

4. Introduction to Literature Review ........................................................................................................ 6

4.1. Literature Review ............................................................................................................................. 6

4.2. Literature review on JIT in India ....................................................................................................... 8

5. Implementing JIT effectively in a company Resolving Issues related to JIT Implementation ........... 9

5.1. Introduction ..................................................................................................................................... 9

5.2. High Supplier Dependency ............................................................................................................. 10

5.2.1. How HP handled the issue ......................................................................................................... 10

5.3. Software implementation to aid JIT ............................................................................................... 11

5.4. Late productions ............................................................................................................................ 11

5.5. Inventory Control ........................................................................................................................... 11

5.5.1. How HP handled the situation ................................................................................................... 11

5.6. Implementing JIT in an environment of Low Value Operations..................................................... 12

5.6.1. Observations from HP ............................................................................................................... 12

5.7. JIT for a job shop ............................................................................................................................ 12

5.8. Involvement of the Management .................................................................................................. 12

5.9. Workforce Participation An HR Perspective ............................................................................... 12

5.9.1. Assessing the Training and Development needs ....................................................................... 12

5.9.2. Observation from HP ................................................................................................................. 13

5.10. Conclusion: How to implement JIT ................................................................................................ 14

6. Certain important aspects related to JIT ................................................Error! Bookmark not defined.

6.1. Lean Manufacturing ...........................................................................Error! Bookmark not defined.

6.1.1. Categories of waste ................................................................................................................... 14

6.1.2. Stages of Lean Manufacturing ................................................................................................... 14

6.2. Kanban System ...................................................................................Error! Bookmark not defined.

6.2.1. Benefits of using Kanban ...............................................................Error! Bookmark not defined.

6.2.2. Shortcomings of Kanban ................................................................Error! Bookmark not defined.

6.3. Set-Up Reduction ...............................................................................Error! Bookmark not defined.

6.3.1. Importance of Set-Up Reduction ...................................................Error! Bookmark not defined.

6.3.2. Effect of Set-Up Reduction on Production Lot Size .......................Error! Bookmark not defined.

6.3.3. Set-Up Reduction Process..............................................................Error! Bookmark not defined.

6.3.4. Benefits of Set-Up Reduction Implementation .............................Error! Bookmark not defined.

6.4. Repetitive Manufacturing .............................................................................................................. 15

Page | 3

6.4.1. Repetitive Manufacturing Methodology ................................................................................... 15

6.4.2. Prerequisites for Repetitive Manufacturing .............................................................................. 15

6.4.3. Key Steps in Repetitive Manufacturing ..................................................................................... 15

6.4.4. Benefits of Implementation ....................................................................................................... 15

7. JIT in various companies ..................................................................................................................... 16

7.1. JIT in Toyota ................................................................................................................................... 16

7.1.1. JIT Practices followed in Toyota ................................................................................................ 16

7.1.2. Steps of production ................................................................................................................... 16

7.1.3. Conclusion ................................................................................................................................. 16

7.2. JIT in IBM ........................................................................................................................................ 17

7.2.1. A Phased Approach .................................................................................................................... 17

7.2.2. Education and involvement ....................................................................................................... 17

7.2.3. Suppliers Relations .................................................................................................................... 17

7.3. JIT in Motorola ............................................................................................................................... 18

7.4. JIT in Dell ........................................................................................................................................ 18

7.5. JIT in GE .......................................................................................................................................... 19

7.5.1. Objectives of TSBO .................................................................................................................... 19

7.5.2. Issues in JIT Implementation ..................................................................................................... 19

7.5.3. Conclusion ................................................................................................................................. 20

8. Concluding Remarks and directions for future research .................................................................... 20

9. References .......................................................................................................................................... 20

Page | 4

1. PREFACE

Companies from Japan have revolutionized Manufacturing industry at one point of time with the help of a

new philosophy named Just-in-Time. Its impact was so substantial in the US market that it forced the US

companies to at least try and understand what they were doing.

Initial studies in this arena proved to be unsuccessful where most researchers reported that the

manufacturing excellence seen in Japan was actually rooted in the Japanese culture itself. The

individualistic western culture would be far stretched to adopt the Japanese principles where the need of

the few gave way to the need of the many and discipline coupled with an inherent attention to details was

something that was ingrained in their culture.

Richard Schonberger and Robert Hall were among the firsts to actually challenge the view that US could

indeed catch up to the Japanese or at the very least could emulate their strategies to a certain extent.

Japanese Manufacturing Techniques by Schonberger, 1982, and Halls Zero Inventories, which followed a

year later argued that the Japanese had indeed developed a new approach to manufacturing, one that

involved reducing inventories and waste. While these methods were indeed rooted in the Japanese culture

they were indeed executable.

JIT was enthusiastically embraced by a great many companies, including such prominent manufacturers as

Ford, General Electric, General Motors, Hewlett-Packard, IBM, and Xerox. wrote Paul. H. Zipkin, Armand G.

Erpf Professor of Business at the Graduate School of Business, Columbia University in 1991.

This paper tries to capture the various essences of implementing JIT in various manufacturing setup. We

have tried to capture how the implementation of JIT has been enhanced over the years. Along with the

basic concepts and studying the implementation of JIT in various manufacturing sectors, we have tried to

review articles and research papers on JIT that span the time period from 1986 to recent past. The purpose

of adopting such an approach was to attempt to chronicle how JIT has been handled over all these years.

Finally, we hope that the reader finds this paper helpful and beneficial. We have had a great time

researching and putting this article together. Our purpose would be well served if this paper benefits you in

any way.

Page | 5

2. ACKNOWLEDGMENT

Our research on the topic of Just-in-Time is attuned with the inputs we received from our esteemed faculty,

Prof. Santosh K Bishwal. We would like to thank our professor for giving us such an opportunity to study

such a celebrated concept in Operations Management in order to get a glimpse of the real life JIT practices

prevalent in the industry. If not for this project we would have missed a brilliant opportunity to learn and

develop our knowledge base.

Page | 6

3. ABSTRACT

The Manufacturing companies of todays world is no longer restricted to a localized market. They are facing

the heat of global competition through the development of faster means of communication, extensive use

of IT and IT-enabled services in manufacturing industry and improved transportation system. So, each and

every manufacturing company, on one hand, has to be become ready for this global competition for its

survival and on the other hand, has to deliver quality products with reduced delivery time. Furthermore,

customers have become more conscious about their needs. This has resulted in the need of product

catalogue diversification, which needs reduced batch sizes and high flexibility in operations. Moreover,

manpower accounting costs have increased to a large extent in the last few decades. All these factors

ideally should have resulted in higher production costs. However, the companies have to maintain their

cost advantage within their market segment to be relevant and competitive. In order to overcome these

huge challenges, manufacturing companies are trying to find innovative ways to reduce costs, improve

quality and meet the ever-changing needs of their customers. One way of accomplishing all these targets

together is to adopt the Just-in-Time (JIT) and Lean manufacturing strategies. JIT and Lean manufacturing

concepts are relevant to almost all the functional areas of a company i.e. manufacturing, engineering,

marketing, purchasing etc. The objective of the paper is to review relevant literature on JIT, with emphasis

on JIT in India, the process of implementing JIT in a firm, to overcome operational issues while

implementing the same and how JIT strategies are implemented in various companies.

4. INTRODUCTION TO LITERATURE REVIEW

Initially, JIT was used only to manage material flow in a factory to reduce the inventory levels. But now,

there is reasonable consensus among existing researchers that there is a lot more to manufacturing than

only inventory control, like process control, level of automation, machine set up times, flexible

manufacturing, labour productivity, supplier management, overhead control, engineering support and

quality of products delivered to customers. A modern organization has to deal efficiently with all these

issues to operate in a smooth and productive environment delivering quality products.

4.1. LITERATURE REVIEW

According to researchers, JIT is not just a mere manufacturing strategy which helps manufactures to

lower cost but a philosophy of continuous improvement in which non-value adding activities are

identified and removed. This helps in reducing costs, improving product quality, performance and

delivery. The core objective is adding manufacturing flexibility and stimulating innovation at workplace.

Many companies after implementing JIT practices have reported significant reduction in manufacturing

cost and improved quality of both product and process by continuous elimination of waste and

consistent improvement of productivity.

Advocates of JIT consider inventory as a waste and the source of all-evil in a manufacturing company as

inventory build-ups tend to hide production problems rather than solving them. JIT works best when

raw materials to be consumed arrive just in time, resulting in savings and reduction in inventory.

Researches show that the philosophy of JIT increases both organizational efficiency and effectiveness.

On the other hand if JIT is not properly implemented, desirable benefits are not realized. Researchers

have also brought the fact in front that though it is easy to understand the concepts of JIT, but, in

reality, they are very difficult to implement because of the need for fundamental organizational

changes.

Page | 7

Operationally, JIT production requires waste to be identified in all the steps of manufacturing a

product: overproduction waste, idle time/waiting waste, motion waste, transportation waste,

inventory waste, processing waste and product defects waste. The essentials required for a successful

JIT production facility are as follows:

1. Minimization of inventory in supply chains efficiency is gained from frequent deliveries of small

quantities to meet immediate demand.

2. Application of Kanban a pull system of production and material control.

3. Employee participation and involvement strategy to encourage worker input, which ultimately

helps in elimination of waste. Moreover, awareness of quality among employees results in

generation of ideas for controlling defects and improves delivery.

In a JIT set-up, workers hold the authority to stop the line when problems are identified. So, its

critical for the success of JIT to train and motivate the workforce.

If JIT principles are successfully implemented across an organization, following benefits can be

enjoyed as per our findings:

1. Elimination of waste in production and materials.

2. Improving communication internally (within organization) and externally (between the

organization and its customers and vendors)

3. Reduction of purchasing cost.

4. Reduction of lead-time and throughput time, improving production quality and productivity and

enhancing customer responsiveness.

5. Increased involvement of higher management

6. Develop discipline in organization.

7. Reduction of gaps between production and accounting departments

8. Integration of all functional areas of the organization.

In order to enjoy the benefits of JIT, a company must accept JIT as an organizational philosophy. This

requires the organization to change/modify its operating procedures, production system and

organizational culture which can be done by:

1. Adjustments are needed in plant layouts

2. Modifications are needed in the relationships with suppliers and customers

3. Maintaining Quality Circles

4. Achieving accurate demand forecasts

According to the findings in previous research works on JIT, following factors may make or break the

implementation process of JIT:

1. Proper involvement of Top Management

2. Proper employee training and education (both administrative and production workers)

3. Proper Logistic Planning System

4. Availability of accurate data especially w.r.t. demand forecasts

5. Strong working relationship with vendors

According to a case study on JIT implementation in a small company in Taiwan producing different

kinds of automobile lamps, it is observed with JIT system, the company survived with lower

manufacturing costs and higher quality. The company placed emphasis on continuous improvement,

involvement of all people in the organization, reductions in throughput time, elimination of non-value

adding activities and simplification of essential activities.

Research done on human resource practices of firms in Canada which practice JIT reveals that working

hours flexibility, ability to work in groups, self-inspection, creating environment in which everybody

Page | 8

having a concern for the firms success, recruitment from within the firm and employee retention

policies by providing better working environment are common practices of these firms. These firms

are committed in upgrading employee skills which get reflected in their increased training budget.

Significant improvement in teamwork, communication and group incentive programs were observed

in these firms. As a result of these practices, productivity and product quality increased significantly

with a significant decrease in the overall inventory, lead time and the labor cost/unit. This helped

these firms to compete successfully in global environment. This research also pointed out the fact that

during JIT implementation, most cited problems faced by the firms were resistance to change from

inside, Union resistance and resistance to production rescheduling.

An empirical study was done to determine the critical success factors of JIT implementation impacting

the variables used in determining organizational performance. Five such success factors were taken as

independent variables. Dependent variables identified were inventory turnover, work-in-progress

inventory, quality, flexibility etc which contributes to the overall organizational success. Multiple

regression models based on dependent and independent variables gave the following results:

1. Communication between production and marketing departments affects inventory turnover in JIT

firms.

2. Employee participation and bottom-up management affects improved quality and flexibility

3. There is a negative correlation between MRP and JIT, sales per employee and inventory turnover.

4. Surprisingly, top management support was not identified as a critical factor affected JIT success.

4.2. LITERATURE REVIEW ON JIT IN INDIA

India is a developing country. It has been identified in previous studies that the manufacturing industry

of India faces the following problems:

1. Underutilization of capacity

2. Low productivity

3. Unreliable and long lead times due to unreliable transportation needs

4. Shortage of raw materials and parts

5. Inferior quality of incoming material

6. Non-recipient of delivery by buyer of exact quantity at exact time

7. Lack of technology transfer and proper management

8. Lack of motivation for workers

In India, manufacturers are mostly concerned about maintaining efficiency rather than reducing cost.

As a result, researchers have suggested JIT and TQM to solve such problems in Indian manufacturing

industry. Researchers are also in the opinion that JIT can be easily implemented in Indian

manufacturing firms as it doesnt involve large investments but requires employee involvement,

mutual trust and unrelenting focus on quality. After the economic reforms of 1992 in India, work

culture in Indian manufacturing firms has significantly changed: multifunctional work force, long term

employment, motivation and trust, top management attitude and commitment, support from union

leaders, effective communication, poka yoke inspection method and incentive schemes have helped

this change to take place. Moreover it is observed that some elements of JIT were already practiced in

Indian automobile industry like quality circles, Kaizan etc. So, JIT could be a great game changer in

Indian context.

A study was conducted in 1996 with the help of a questionnaire send to various industries in India to

understand the importance of JIT purchasing in Indian context. Based on the replies, a t-test was

Page | 9

performed to understand the importance of JIT attributes and expected percentage benefits of JIT

implementation. The study revealed the following:

1. Indian industries were giving importance to JIT attributes but they are facing certain problems

while implementing the same.

2. They are expecting an overall benefit of 59.8% if JIT purchasing is implemented correctly

3. Scope of JIT implementation is fair in India and independent of type of industries

4. SMEs were more interested in JIT than large scale ones.

In another observation through Delphi study in 1996, it is indicated that Indian industry just cant

ignore the idea of JIT. The focus for them should be on the following:

1. Poka yoke inspection methods

2. Reduced set-up times

3. 100% quality of incoming materials

4. Kanban system

5. Delivery by vendors at exact quantity on exact time

6. Increased worker motivation and literacy rate

Another survey of 46 Indian industries, conducted in 2002, to look into JIT implementation problems

and benefits in Indian context found the following facts:

1. Perfect JIT implementation in most of the Indian industries may not be feasible due to lack of

resources, technology, multifunctional workers etc.

2. But certain JIT elements like workforce improvement, process and layout improvement, quality

circles, smaller lot size can be easily implemented by Indian industries.

3. Difficult to implement elements in Indian context includes zero defects, Kanban system, set-up

time reduction, JIT purchasing, automation etc.

4. Maximum benefits must be given to the easily implementable elements to reap maximum benefits

in Indian context.

5. High ranked expected benefits of JIT implementation in Indian industries are reduced WIP

inventory, reduced purchase lot size, reduced production lead time and improved competitive

position.

In the same report it has been mentioned that several Indian industries are implementing JIT along

with TQM in fragments with the belief that it would help them to survive the global competition. The

report prescribes that Indian industries must pay attention to implement techniques such as quality

circle, total preventive maintenance, cause and effect diagram, kaizen, JIT purchase etc. Implementing

these will help them to improve the current position of Indian industries w.r.t. quality, cost and

flexibility.

5. IMPLEMENTING JIT EFFECTIVELY IN A COMPANY RESOLVING ISSUES RELATED

TO JIT IMPLEMENTATION

5.1. INTRODUCTION

Most literature on JIT focuses on how it can lead to great cost benefits by way of inventory reduction.

More often than not it is advised by JIT hand-books to ask the suppliers to follow a daily schedule of

supplies. While this is one of the apostles on which the concept of JIT stands on, according to Richard C

Walleigh, author of the article Whats Your Excuse for Not Using JIT? (Published on Harvard Business

Review, March 1986) it is not the right place to start. This section will essentially point out such myths

and pitfalls that come with the territory of implementing a viable and functioning JIT system.

Page | 10

The chief detriment to understanding what JIT is and what it actually stands for is its wide-spread

publicity. Over the course of our research we have come across a multitude of articles which highlight

the difference between JIT and a more traditional batch production system. More often than not

Articles and literature focus on the tremendous cost benefits we now associate JIT with and gloss over

real operational issues like we actually are removing the safety net of having surplus inventory in case

of an exigency.

Large organizations typically have set processes and strategies which they have followed over a long

course of time. Therefore a change perceived to be as disruptive as JIT can meet great inertia in the

form of managing change of such magnitude. It is truly difficult to let go of established albeit old

management policies and practices that associate a large batch sizes with lower setup costs and

backup inventories as a cushion for tougher times to come. The process ultimately represents as much

a Cultural Change within the company as an Operational change.

For an effective implementation of a JIT process the outlook on how we should approach JIT, a demand

pull system should change. The first focus of implementing such a system should be within the

organization where the company can exercise a certain degree of control and could essentially step in

anytime to modify policies and or processes as and when required. It is only after the company

becomes comfortable with the system that they can start working with supplier schedules and lead

times for supply in JIT.

Following is the list of a few bottlenecks that can crop up during implementation of JIT,

recommendations on how to mitigate the same and example of how HP resolved them:

5.2. HIGH SUPPLIER DEPENDENCY

Issues with the supplier crop up generally when managers become a bit too enamored with potential

savings on inventory by asking suppliers to follow and maintain a daily schedule. It simply is not a

viable starting point on the implementation of JIT. The problem here is that the process is perceived as

an inventory reduction technique and not a problem solving methodology. Since its a demand pull

system each part of the manufacturing process produces only what is required by the succeeding

operation. Therefore at its core most of the optimization while moving from a large batch system

happens at the final assembly stage. This process must be rationalized and simplified. Such

standardization and quality will ultimately result in a consistent long term demand for the product.

This phenomenon has to be taken into consideration before engaging JIT suppliers. Because ultimately

in the long run the company would want a single source of supplier and the prospect of having such a

steady demand will help the suppliers to make up their mind on adopting JIT. The process of

implementing JIT with the Suppliers has to be done with the help of the expertise gained by

implementing JIT in the first place, thereby, giving the signal that the company is serious about JIT. The

supplier has to be made aware that one bad batch can stop the production in its entirety.

5.2.1. HOW HP HANDLED THE I SSUE

HP initially implemented JIT with relatively high success before any effort was made to convert the

suppliers to JIT. HP generally helps its suppliers to make JIT deliveries even though most of its vendors

are not JIT enabled. In certain cases HP shifted to suppliers which were closest to its location. It closely

monitors supplier performance and once all the pre-requisites are met they are converted into JIT

suppliers where HP demonstrated the supplier how HP implements JIT in its production line.

Page | 11

A way of bypassing a multi-vendor scenario with most vendors not on JIT is to shorten the annual

production cycle while leaving the material planning intact. This strategy should at least be followed

during the initial phases of implementing JIT. While the immediate benefits of inventory reduction

wont be there, it can be said that there will not be any confusion in the factory floor due to a late

delivery. At worst there will be same kind of impact as there would be for a large batch based system.

As the delivery improves with time materials, planning is matched with the production cycle.

5.3. SOFTWARE IMPLEMENTATION TO AID JIT

Implementing any software in a straight jacketed manner can be a quick fire recipe for disaster. It has

to be understood what process any software is going to support. Therefore an effective

implementation can only happen when a process is in place and the software is synchronized from

experience of actually executing the process in the real world. The pitfall of implementing the software

in a company that has been using traditional methods is that with the absence of a proper structure

more focus will be laid on delivering as per the softwares expectation leading to cutting corners. Till

the operation has been stabilized tracking is better done through simple forms that can be created and

collated easily.

5.4. LATE PRODUCTIONS

JIT results almost 90% decrease in production cycles in which case expediting deliveries ceases to be a

viable option in case of any bottleneck with deliveries. Late deliveries will translate to late shipments.

Therefore the Materials department has to work closely with Production because in a JIT, elimination

of instances of late deliveries will be of the essence. The process by design is going to create a sense of

anxiousness and managers are expected to pool in more effort and resources in ironing out the kinks.

5.5. INVENTORY CONTROL

The author of the article is of the view that objections pertaining to loss of control in managing

inventory are generally voiced by accountants, schedulers and people who have worked on an

elaborate inventory management system.

JIT calls for a simplified kind of control over its predecessors. Ideally the production cycles are short,

there is no inventory to speak of and the flow of materials in production is clear.

5.5.1. HOW HP HANDLED THE SITUATION

The Finance department was concerned that control over inventory and schedulers issue with lack of

tracking with JIT which was deemed necessary for work. To address these issues, HP conducted an

Inventory of work in process at the beginning of each month. The readings were taken very quickly

because the work in process was very low. The initial time taken for such a reading was two hours.

They have been able to reduce the process to a half an hour exercise.

The traditional scheduling method was done away with and since then safety stock is not used to

determine the inventory level.

Page | 12

5.6. IMPLEMENTING JIT IN AN ENVIRONMENT OF LOW VALUE OPERATIONS

Implementing JIT in an operation that deals with low volumes can be easier and more effective,

contrary to popular belief. The principles of JIT are applicable to all operations regardless of its scale.

The operations in this case already work on small batch sizes.

5.6.1. OBSERVATIONS FROM HP

HPs computer division which used to build less than six computers a day in 1986 implemented JIT with

high efficiency. The setup yielded huge benefits for HP even though the machines themselves consisted

of several parts and production spanned over numerous sub-assemblies.

5.7. JIT FOR A JOB SHOP

Job shops deal with unpredictable and a majority of the orders are unique. However on inspection it

can be observed that Job Shops have more repetitive business than they estimate. The idea of

implementing JIT in a job-shop is to separate the repetitive business and processes. Unproductive

setup costs can be minimized and ultimately eliminated. Opportunities for dedicated equipment for

specific tasks could be identified, thereby, making JIT more efficient than an all-purpose batch

environment. If there are products that has demand not high enough to warrant for a dedicated

equipment then a cluster of such products could be formed which shares some key processes during

the manufacturing sequence. Such grouping based on technology and requirement will enable for

much smaller production batches.

5.8. INVOLVEMENT OF THE MANAGEMENT

More often than not companies are reluctant to implement JIT because they feel that the processes in

place are running without hitches and all effort utilized in implementing such a process would for to

waste. The scenario in 1986 was something akin to a Blue Ocean Strategy in terms of processes. Many

American companies came under the severe pressure of cost effective JIT production techniques. The

author one of the early adopter of JIT was of the view that JIT would at the very least expose

inefficiencies in the processes. Secondly the focus squarely shifts from quick-fix ad-hoc solutions to a

more holistic continuous improvement process. Workers had to be more involved in not only carrying

out an operation but also trying to improve on the same. This issue calls on the management to work

closely with the workers and invest in their training so that the workforce is enabled to make educated

suggestions on improvement. Moreover the initial hiccups on road of implementing JIT have also to be

taken care by the management. The companies which implemented JIT were ones which already had

an effective quality control in place. Documentation of the process was a very pertinent need.

5.9. WORKFORCE PARTICIPATION AN HR PERSPECTIVE

5.9.1. ASSESSING THE TRAINI NG AND DEVELOPMENT NEEDS

The committed management alone cannot bring around the change one expects in a transition to a full

blown JIT process. The level of commitment asked forth from each employee will generally ensure that

he hardly has time from his daily operational work and focus on process improvement, thereby,

slowing the progress of the change-over to a crawl. The author believes that the solution of

overcoming such hurdles is to appoint a full-time project manager whos JD will involve its

implementation.

Page | 13

A common learning experience in its implementation has been suggested by the author because

ultimately each department has a high dependency on the other in both directions. The project

manager will actively collaborate with other departments to suggest ways of implementing the same. A

robust training program has to be put into place as well. Such a training program may be tailored for

different levels of employees. A model framework proposed by the author was designed to be to

involve the work-force and be of inclusive in nature. The suggestions given were:

Attending professional seminars outside the company.

Visiting a site on another company with JIT already in place.

Brainstorming sessions in which participants discuss on JIT implementation.

Simulating a JIT production by creating models of JIT that can be used in the production line.

5.9.2. OBSERVATION FROM HP

The Greenley Division of HP implemented almost all of the strategies mentioned above and the

simulated production line developed by it was disruptive for its time. The model dealt with the

demonstration of the push and pulls material movement and went on to demonstrate its impact on the

production line. The results were videotaped and shared as a common knowledge repository for the

employees of HP.

It was determined that even with everything in place a sudden change to JIT will create frictions and so

pilot projects involving the implementation of JI was done. For a plant with multiple product line the

project should ideally be not implemented on the largest product line. If we are looking at JIT for a

process even then the project should encompass the last two processes.

Therefore in HP, the computer division which only had only one major product at the time namely the

3000 series 68 mini-computer was chosen to adopt JIT in the last two process of its manufacturing. As

with any new technique it is important to learn from mistakes and the small scope of the initial pilot

enabled just that. It served as a great learning resource for the people involved on how the behemoth

that is JIT will behave in the real world.

Conversely, though plant visits on other companies could serve as a great learning experience it is

unlikely that a competitor who has already started stabilizing the process would be too willing to pass

on their competitive edge.

As in case of any new process there will be pockets where the stakeholders would not be able to

anticipate the true impact of a JIT system once implemented. The only feasible solution to the issue

would be to ensure the buy-in of goals at all levels and enlist everyone in the process.

The employees of value will actually be the people who actually operate on the system and not the

people who generally supervise process. Involving that segment of the work-force would create a

sense of ownership that could lead to the creation of a workforce that is more invested in the

company.

The easiest way of achieving the feat would be creation of quality circles and actively encouraging the

organic formation of such groups. Especially for companies that do not have such environment this can

serve as a wonderful opportunity. HP had reaped the benefits of such a structure when the JIT process

was finally implemented. Even though the company had provisions made for expected issues the extra

effort of involving supervisors and the general workforce in application of the managements earlier

plan resulted in a glitch free execution. Employees actively participated and worked out all possible

issues in execution even before its implementation.

Page | 14

Extra resources were in place to help with issues that might creep in during production and solve it on

the fly. One outcome of such an arrangement was actually to reduce the maximum output of the plant

for a while as schedulers worked on the details.

The final step in its execution was removing the transitional inventory between operations to expose

any glaring flaws with the processes in place. This method by design would force departments to

collaborate and move closer. The redesign of the work-space into a U-shape arrangement will also

provide some level of clarity in communication. It will also reduce time lost in handling of materials.

The production line then can come up with suggestions on how to improve the processes and the

quality of feedback will vastly improve.

5.10. CONCLUSION: HOW TO IMPLEMENT JIT

In conclusion one can never truly implement JIT. The basis of this process is continuous improvement

and hinges on the organizations commitment to consistently improve. JIT is a way of making processes

effective and should be looked as such. The organizations should not merely implement the same

because of the future promise it holds. The greatest reward of this process is that it will eventually

create a highly robust and efficient process and pave the way to a world class manufacturing

organization.

6. LEAN MANUFACTURING

Lean manufacturing is a manufacturing philosophy which focuses on minimizing the cost of resources by

eliminating or reducing waste and eliminating the non-value adding processes. It concentrates on

improving the efficiency of the process and finding efficient ways of accomplishing the task.

6.1. CATEGORIES OF WASTE

The 8 categories of wastes that should be monitored in lean manufacturing are:

a. Overproduction Production in excess of demand

b. Waiting Time lag between the production steps

c. Inventory Products not being processed

d. Transportation Inefficient movement of materials i.e. moving products that are not required for

processing

e. Over processing Result of poor quality tool and product design

f. Motion Inefficient movement of people and equipment between the tasks

g. Defects Time spent in finding and fixing the defects

h. Workforce Inefficient use of the workers

6.2. STAGES OF LEAN MANUFACTURING

There are three key stages of lean manufacturing process:

a. Identify waste: Lean manufacturing philosophy says that the waste always exists and there is always

a room for improvement of the processes. This philosophy of continuous improvement is known as

Kaizen.

A key tool used to identify waste is Value Stream Map (VSM)". VSM shows how material and

processes flows through the organization to bring the product and service to the customer. VSM

Page | 15

analyzes the processes that add value and those which do not add value. Thus it helps in eliminating

the non-value-adding processes.

b. Analyze the Waste, and Find the Root Cause: For each waste that is identified in the first stage, find

out the reason causing the waste by using Root Cause Analysis.

This method is used to identify the cause, i.e. whether the problem is caused by the poor quality of

machines or poorly trained operators or some other causes. Brainstorming and Cause and effect

diagram are the other effective tools used to find out the root cause.

c. Solve the Root Cause, and Repeat the Cycle: The issue is fixed by using an appropriate problem-

solving process.

REPETITIVE MANUFACTURING

According to the APICS (American Production and Inventory Control Society) dictionary, Repetitive

Manufacturing is a process in which the same products or families of products are repeatedly

produced.

6.2.1. REPETITIVE MANUFACTURING METHODOLOGY

A form of Mass Production strategy, Repetitive Manufacturing involves production of a large number

of identical products in a flow. The setup time can be significantly reduced if a single manufacturing

line is dedicated for the production of one product. The production process can then be more

streamlined. It is often used for manufacturing products whose demand is continuous and stable.

6.2.2. PREREQUISITES FOR REPETITIVE MANUFACTURI NG

In order to implement repetitive methodology, the production system must exhibit the following

features:

Production of identical products over a fairly large period

No customization of products individually during manufacturing

Production of total quantity over a defined period at a defined rate per part-period

Product must follow a unique production sequence through all the machines

Simple routings without much variation

6.2.3. KEY STEPS IN REPETITIVE MANUFACTURING

Creation of independent requirements that are planned

Draft of Materials requirement plan at the plant level

In-house manufacturing/ production

Confirmation of Assembling activities

6.2.4. BENEFITS OF IMPLEMENTATION

Repetitive Manufacturing simplifies the handling of manufacturing process along with effective cost

control. It is not mandatory for a unit to implement repetitive manufacturing in all its processes but has

the liberty to convert some of the systems to the repetitive mode. With the help of these small

changes, it is possible for any factory (be it a pure repetitive manufacturer or not) to implement the JIT

production systems.

Page | 16

7. JIT IN VARIOUS COMPANIES

In this section, we will describe how the philosophy of JIT has been implemented in various manufacturing

companies.

7.1. JIT IN TOYOTA

Toyota Production System (TPS) was established with the objective of making vehicles ordered by

customers in the quickest and most efficient way, to deliver the vehicles as quickly as possible.

Two concepts on which TPS was established:

a. Jidoko: Jidoko means automation with a human touch. The production equipment

automatically stops when a problem occurs. Hence, it prevents the production of faulty products.

b. Just-in-time (JIT): Each process produces only those products that are required by the next process

in a continuous flow.

7.1.1. JIT PRACTICES FOLLOWED IN TOYOTA

JIT was introduced by Taiichi Ohno and Shigeo Shingo. Taiichi Ohno was a former Toyota executive and

Shigeo Shingo was an eminent engineer and consultant. Four basic features of Toyota Production

System (TPS), identified by Shigeo Shingo are as follows:

a. It focuses on elimination of waste in order to reduce cost. Toyota places heavy emphasis on

lowering the time and complexity that is required to change a die used in the manufacturing

process. The process of changing the die is wasteful in two ways:

While the process is happening, it causes other production process to standstill, as a result of

which the cycle time and the cost associated with the cycle time increases.

Changing a die does not add any value. Hence the workers time and efforts are wasted on

non-value adding activities.

b. Thus, the major concern at Toyota was to reduce the time taken in changing the die.

c. It maintains low inventory and hence reduces the likelihood of overproduction. It also uses

minimal manpower in order to reduce labour costs.

d. It focuses on reducing the production cycle time with innovations like Single minute exchange of

die (SMED) system.

e. It emphasizes on order based production. The production is guided by actual orders and is not

based on the anticipated demand.

7.1.2. STEPS OF PRODUCTION

a. Customer places an order for the vehicle. The production order is issued to the beginning of the

production line.

b. The assembly line should be stocked with all the needed parts so that the vehicles can be

assembled as soon as the order is received.

c. The Assembly line must replace the parts which are used for the production by retrieving the parts

from the parts-producing process.

d. The parts-producing process must be stocked with all types of parts and production of only those

parts should take place that was retrieved by an operator.

7.1.3. CONCLUSION

Page | 17

Toyota is one of the leading automobile manufacturers in the world. It follows an integrated low cost

business model. Thus, Toyota plans to advance such concepts globally, based on the policy of

purchasing the best parts at the lowest cost with the shortest lead times. Many manufacturing

companies throughout the world follow TPS.

7.2. JIT IN IBM

IBM uses the term Continuous Flow Manufacturing to describe the JIT process it use in its

manufacturing units. In 1985, the Tucson, AZ General Products Division of IBM developed a corporate

culture to foster the principles of Continuous Flow Manufacturing. The Tucson facility used to produce

high-end tape products, optical storage units, control units, laser printers, large storage units and

printed circuit boards.

7.2.1. PHASED APPROACH

Tucson facility identified the following areas for improvement when the CFM implementation project

started:

a. Job shop layout of facility

b. Erratic work flow

c. Very high WIP

d. Employees specialized in one operation

e. Maintenance performed by maintenance personnel only

In the 1

st

phase of the project IBM rearranged its production lines to enable faster product flow,

implemented pull logic into its assembly operation, increased education programs and assigned

rework responsibility to each operation.

In Phase II, IBM reduced lot sizes, integrated in-circuit testers to CFM lines, introducing Kanban

containers, reducing setup time and initiating work station ownership.

In the 3

rd

phase, when CFM was in full swing in Tucson, IBM started developing processes for daily

releases, introduced a more developed pull system and a computer integrated manufacturing (PCIM)

process.

This CFM implementation saw an increase in 45% reduction in cycle time, 100% increase in

productivity, 21% increase in morale of employees, 100% increase in space utilization, 25% drop in

manufacturing non-value add costs along with a significant increase in quality (only one defect per

unit). All these can be attributed to the efficient manufacturing which was possible due to the

introduction of CFM in IBM Tucson.

7.2.2. EDUCATION AND INVOLVEMENT

The time frame in which CFM was implemented in IBM Tucson (1986-88), the company invested

400,000 hours in training and education of its employees to make them ready for the new philosophy.

Another change the company brought in was involvement of production workers. They now own the

processes involved in process control, manufacturing line support, maintenance and ordering of parts.

If in any line, defects are found, the workers have the right to stop the line and perform preventive

maintenance and process sampling.

IBM started the good suggestion reward to provide monetary award of $ 80,000 if any suggestion of

a worker is implemented and if it paves the path for further improvement.

7.2.3. SUPPLIERS RELATIONS

Page | 18

The IBM Tucson plant had suppliers which were other IBM plants. Upon implementing CFM, Tucson

started true partnership with external suppliers like Swift-Cor. IBM even trained Swift-Cor in Statistical

Process Control (SPC) and CFM. IBM also reduced its supplier base to 150 and trained most of them in

SPC and CFM. As a result of these activities, stocking and receiving activities got eliminated, inventory

got reduced, planning became unnecessary and cost to process paperwork got reduced by 98%.

7.3. JIT IN MOTOROLA

Motorola, Inc. is known for technology innovation and market visibility. It uses Short Cycle

Management (SCM) as an approach for production of wireless communication devices and technology,

which is also a form of JIT. In this approach Motorola focuses mainly on following attributes:

a. Quality Improvement: Motorola uses six sigma methodologies to improve the overall quality of

the product and reduce defect level to minimum.

b. Total Cycle Time Reduction: Through the well organized process and job design, organization aims

to minimize the cycle time.

c. On-Time Delivery: Motorola is committed to meeting customer expectations by reducing cost,

improving quality and delivering on time.

d. Participative Management: Motorola ensures that all the employees involved in the process

contribute to it and innovative ideas are appreciated.

e. Strategic Investment in People: Motorola emphasizes on training a lot and gives two type of

training to ensure people have necessary skills to contribute towards six sigma qualities.

Following are the trainings:

a. Manufacturing Cycle Management (MCM) is a three-day course which provides the basic concepts

and techniques for increasing productivity through improved materials flow.

b. Motorola Management Institute (MMI) is a two-week program in world-class operations issues.

While following SCM process Motorola invests first few days to correctly identify the problem. They

consider the problem as a start up. Following this the team brainstorms together how to solve the

problem. Later a meeting between the client and a representative from client is done to ensure that

correct problems have been identified and then implementation team starts its work.

To ensure proper working of SCM it is necessary that all parties are involved in the process. Motorola

ensures same.

7.4. JIT IN DELL

Being a faithful implementer of JIT, DELL knew exactly how this concept can be harnessed while giving

the traditional way of production due credit. With careful analysis of the PC market and absorbing all

strategic changes in customer expectations and demand in the emerging market trend, Dell caught

attention of its competitors when it recorded astounding sales of $25 billion in 2000. The direct

business model and the supply chain improvement working in conglomeration have proved to be the

backbone for DELL to achieve this milestone.

Following are main reason of success of JIT in Dell:

Reduction in lead time: The mail-order system and the online sales platform made DELL a direct

seller, reaching out to its customers in no time. Its dependency on retailers and middlemen was

replaced with customized product delivery at discounted prices. This encouraged the customers to

demand a product suiting their specific needs. Therefore, the time for a customer to place an order

and the time taken by Dell to execute it was reduced to a large extent. The customer value was thus

dramatically improved by Dells strategy of distribution making it the market leader.

Page | 19

Supply Chain Virtual Integration: In order to reduce the time needed for Dell to get in touch with its

suppliers of raw materials, Dell devised a way of building strong supplier networks by establishing

the inventory hubs near its own assembly plants. This devised a more economical way for Dell to

meet its demand for precise number of components on short notice. The backlog inventory costs

almost turned nil as it was a one-to-one demand-supply mechanism between Dell and its suppliers.

Open discussions with the suppliers about the planned production, forecasts, and schedules were

easily implemented. Therefore, the promise of Delivering goods in 7 days was thereby achievable.

Assembly process improvement: Multi-skilled workers were an asset for Dell. Grouping such

workers into what they call manufacturing cells reduced the assembly times by 75%. A group of

workers were grouped together around a workstation to assemble entire PCs.

Kanban Analogy: Dell asks for any component or part only when it has a customer order to meet. A

Kanban methodology is established between Dell and its suppliers. The floors of the manufacturing

plants have a series of thin white lines that encircle the factory. When a signal goes out from an

assembly line when it runs out of components for building PCs, a forklift pulls out the snatched

component on to the floor. A scanner records the barcode and thus the component is owned by Dell

for its usage in the assembly line. Total inventory time: 2-3 days.

Thus in all, the interaction between the direct business model and the supply chain management

system has proved to be the governing factor for Dells success. The inter-relation and inter-

dependency of these two aspects are the major concerns for Dell to keep the productivity on track, as

any bottleneck in one of these processes will result in Dell losing its momentum bit by bit.

7.5. JIT IN GE

GE uses the term Transportation Systems Business Operations (TSBO) to describe its JIT process.

7.5.1. OBJECTIVES OF TSBO

The firm basically deals with manufacturing locomotives to meet the needs of the customers. Its

objectives include:

Expansion of JIT implementation efforts across the plant

Diminishing supplier base (in line with JIT Philosophy)

7.5.2. ISSUES IN JIT IMPLEMENTATION

While implementing TSBO, GE faced conflicting goals with respect to traditional purchasing methods

and with respect to those of JIT purchase, Supplier reduction, Performance measurement.

In 1977, a new general manager was appointed at GE who successfully convinced the corporate

management that the plant can be salvaged. With this backdrop, the company made efforts to reduce

cost, increase productivity and quality of the product. The first example of this was use of equipments

for fabrication and welding that were controlled numerically and automated. This apart, the

purchasing function was split into four independent parts including diesel, control, cars in transit and

propulsion.

Page | 20

In the next decade, GE focused on improving the materials and purchase division. Programmes for

reducing cost and improving quality were developed. Another important decision was reducing the

number of buyers to one which drastically decreased the labour force level. Single sourcing led to a

significant leap into JIT for TSBO. Evolution of traditional purchasing practice gradually reflected those

of JIT.

7.5.3. CONCLUSION

Being one of the first American companies to implement JIT, GE gained a sustainable competitive

advantage globally as they could conduct extensive research on its methodology before actually

implementing it. Thus, GE was in a position to gain first mover advantage.

8. CONCLUDING REMARKS AND DIRECTIONS FOR FUTURE RESEARCH

JIT concepts have changed the way manufacturing companies use to operate. Since it is natural for people

to resist change, they have done so. But its also important to remember that JIT wont work if it is forced

upon. Voluntary participation of all levels of employees is necessary in JIT to be successfully implemented in

a company.

Being a philosophy, JIT can be implemented in high technology manufacturing environments in the form of

FMS (Flexible Manufacturing Systems) or CIM (Computer Integrated Manufacturing). Similarly, JIT is not

limited to manufacturing industry or doesnt depend on the size of the firm. JIT is successfully implemented

in service-based companies and even in pure administrative work situations. So, future research can be

done on how JIT can help in improving the performance of service sector in developing countries like India,

where it is growing very fast and mostly poorly managed.

9. REFERENCES

[1] Dr. A.K. Gupta, Just-in-Time Revisited: Literature Review and Agenda for Future Research, IJRMET Vol. 2, Issue 1,

April 2012 (http://www.ijrmet.com/vol2/a990.pdf)

*2+ Richard C Walleigh, Whats your excuse for not using JIT, HBR, March 1986 (http://hbr.org/1986/03/whats-your-

excuse-for-not-using-jit/ar/7)

[3] http://www.mindtools.com/pages/article/newSTR_44.htm

[4] http://en.wikipedia.org/wiki/Lean_manufacturing

[5] http://www.epa.gov/lean/environment/methods/kanban.htm

[6] http://www.brighthubpm.com/methods-strategies/71133-weighing-the-disadvantages-of-the-kanban-system/

[7] http://www.processexcellencenetwork.com/lean/articles/what-is-kanban/

[8] http://c2.com/cgi/wiki?KanbanSystem

[9] http://www.everydaykanban.com/what-is-kanban/

[10] http://functionalguy.blogspot.in/2007/04/advantages-and-disadvantages-of-kanban.html#axzz2lwjsKouO

[11] Jason Fretz, Brian Grannan, Aaron Lininger, Jeff Novel, Demand Chain Solutions: Set up Reduction

[12] Repetitive Manufacturing: SAP Best Practices

[13] http://www.wisegeek.org/what-is-repetitive-manufacturing.htm

Page | 21

[14] http://www.toyota-global.com/company/vision_philosophy/toyota_production_system/

[15+ Mr. Kashan Pirzada, Toyota JIT Sytem, April 2010 (http://www.scribd.com/doc/30465374/Toyota-JIT-System)

[16+ Deby Veneziale, Workshop Report: Continuous Flow Manufacturing in IBM Tucson

(http://www.ame.org/sites/default/files/documents/89Q2A3.pdf)

*17+ Mr. Will High, Short Cycle Management (SCM) Implementation: An approach taken at Motorola

(http://www.ame.org/sites/default/files/target_articles/87Q4A4.pdf)

[18] http://opssession.blogspot.in/2008/09/just-in-time-production-dell-way.html

[19] http://www.computerworld.com/s/article/54131/Just_in_Time_Manufacturing?taxonomyId=126&pageNumber=1

[20] http://www.gizmag.com/go/7494/

[21] http://www.marsdd.com/articles/dell-distribution-and-supply-chain-innovation

[22] http://psrcentre.org/images/extraimages/512080.pdf

[23] http://www.ijebf.com/IJEBF_Vol.%201,%20No.%202,%20March%202013/Just-in-

Time%20Manufacturing%20System%20%20Just-in-Time%20Manufacturing%20System.pdf

[24] T. C. Edwin Cheng, S. Podolsky, Just-in-Time Manufacturing: An Introduction

[25] General Electric: JIT Alternative (http://www.allfreepapers.com/Business/General-Electric-JIT-

Alternative/13392.html)

Potrebbero piacerti anche

- Unit 5 Acceptance Sampling Plans: StructureDocumento18 pagineUnit 5 Acceptance Sampling Plans: Structurevinay100% (2)

- Subcontracting in Textile and Clothing Sector in Bangladesh1Documento5 pagineSubcontracting in Textile and Clothing Sector in Bangladesh1Abrar Ahmed ApuNessuna valutazione finora

- Backflush CostingDocumento48 pagineBackflush CostingShubh ShrivastavaNessuna valutazione finora

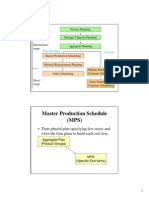

- Master Production Scheduling (MPS) and MRP 1Documento10 pagineMaster Production Scheduling (MPS) and MRP 1Kl OteenNessuna valutazione finora

- Aggregate PlanningDocumento61 pagineAggregate PlanningManisha Jhunjhunwala100% (1)

- Basics of Supply Chain ManagementDocumento34 pagineBasics of Supply Chain ManagementBhuvanes KumarNessuna valutazione finora

- Negotiation in Purchasing MGT (Read-Only)Documento22 pagineNegotiation in Purchasing MGT (Read-Only)Norah NsooliNessuna valutazione finora

- Aggregate Planning and MRPDocumento68 pagineAggregate Planning and MRPJanarthanan Siva KumarNessuna valutazione finora

- WarehouseDocumento15 pagineWarehousesagarika ghosh0% (1)

- Processing Export Finace in A Chemical Export UnitDocumento45 pagineProcessing Export Finace in A Chemical Export UnitBhomik GaurNessuna valutazione finora

- Chap 4 OmDocumento18 pagineChap 4 OmGetie Tiget0% (1)

- Time: 3 Hours Total Marks: 100: Printed Pages: 03 Sub Code: KMB103 Paper Id: 270103 Roll NoDocumento4 pagineTime: 3 Hours Total Marks: 100: Printed Pages: 03 Sub Code: KMB103 Paper Id: 270103 Roll NoAbhishek ChaubeyNessuna valutazione finora

- 08 - Numericals - Process AnalysisDocumento3 pagine08 - Numericals - Process AnalysisRISHA SHETTYNessuna valutazione finora

- Charts Used in Method StudyDocumento13 pagineCharts Used in Method StudyAnonymous 3rajW3TK9Nessuna valutazione finora

- Procedure - GCC - Building Permit PDFDocumento12 pagineProcedure - GCC - Building Permit PDFVijay SaiNessuna valutazione finora

- Implementation of JIT For Achieving The Goal of Customer SatisfactionDocumento5 pagineImplementation of JIT For Achieving The Goal of Customer SatisfactionStefanBelibouNessuna valutazione finora

- Lean Six Sigma (Part A)Documento17 pagineLean Six Sigma (Part A)Punniavel PNessuna valutazione finora

- Material Requirement PlanningDocumento32 pagineMaterial Requirement PlanningNaima RashidNessuna valutazione finora

- Material Requirements PlanningDocumento151 pagineMaterial Requirements PlanningVinod Kumar PatelNessuna valutazione finora

- Operations Mangement 1 - Chapter 16 - Handout 1Documento8 pagineOperations Mangement 1 - Chapter 16 - Handout 1Jessica NgobeniNessuna valutazione finora

- Activity Based CostingDocumento42 pagineActivity Based CostingHaseeb Ali100% (4)

- FCIB Webinar Series: Documentary CollectionsDocumento22 pagineFCIB Webinar Series: Documentary CollectionsYanLi YangNessuna valutazione finora

- WarehousingDocumento16 pagineWarehousingSanil MambullyNessuna valutazione finora

- Inventory ManagementDocumento4 pagineInventory ManagementZain AliNessuna valutazione finora

- Lot Sizing in MRPDocumento5 pagineLot Sizing in MRPMariztine MirandillaNessuna valutazione finora

- 7 TDP Excise DutyDocumento41 pagine7 TDP Excise DutyPranav TubajiNessuna valutazione finora

- QUESTIONNAIREDocumento2 pagineQUESTIONNAIREANJALI A RNessuna valutazione finora

- IFM Chapter 01Documento33 pagineIFM Chapter 01Mahbub TalukderNessuna valutazione finora

- Principles of Material Handling AssignmentDocumento27 paginePrinciples of Material Handling AssignmentMuriithi MichaelsNessuna valutazione finora

- Notes TutorDocumento6 pagineNotes TutorMarie Klaire JNessuna valutazione finora

- Supplier Assesment SCMDocumento22 pagineSupplier Assesment SCMNiranjan ThiruchunapalliNessuna valutazione finora

- 7 WastesDocumento2 pagine7 WastesHemant ChaudharyNessuna valutazione finora

- FM CS - Bom - ExplosionDocumento2 pagineFM CS - Bom - Explosionrahul shendageNessuna valutazione finora

- Process CostingDocumento27 pagineProcess CostingAashika ShahNessuna valutazione finora

- Evaluation of The Role of Inventory Management inDocumento11 pagineEvaluation of The Role of Inventory Management inSumaNessuna valutazione finora

- 402a - Corporate Accounting - I PDFDocumento21 pagine402a - Corporate Accounting - I PDFAnuranjani DhivyaNessuna valutazione finora

- Sop in Enterprise and in Supply Chain - Case Study: Michał Adamczak, Marcin CędrowskiDocumento12 pagineSop in Enterprise and in Supply Chain - Case Study: Michał Adamczak, Marcin CędrowskiNOORUDDINNessuna valutazione finora

- International Purchasing Environment Doc2Documento5 pagineInternational Purchasing Environment Doc2Eric Kipkemoi33% (3)

- 5.0 Order-Winners and Qualifiers 2019 - 2020 PDFDocumento72 pagine5.0 Order-Winners and Qualifiers 2019 - 2020 PDFAizul FaizNessuna valutazione finora

- Material and Capacity Requirements Planning (MRP and CRP) Part - 2Documento14 pagineMaterial and Capacity Requirements Planning (MRP and CRP) Part - 2Dr. Mahmoud Abbas Mahmoud Al-NaimiNessuna valutazione finora

- Detailed Steps For Creating Planning BookDocumento6 pagineDetailed Steps For Creating Planning BookShivaram KumarNessuna valutazione finora

- MM WM NotesDocumento37 pagineMM WM NotesRakesh Kumar BeheraNessuna valutazione finora

- Lot SizingDocumento9 pagineLot SizingZerlynda Ganesha IskandarNessuna valutazione finora

- Cost Sheet Project - Hindustan Petroleum Corporation LTDDocumento20 pagineCost Sheet Project - Hindustan Petroleum Corporation LTDkuldeep100% (1)

- Master Production ScheduleDocumento9 pagineMaster Production ScheduleglamboyzNessuna valutazione finora

- Module 3.1 - Inventory ManagementDocumento12 pagineModule 3.1 - Inventory Managementmaheshbendigeri5945Nessuna valutazione finora

- SDRM CaseDocumento3 pagineSDRM Casejawid tabeshNessuna valutazione finora

- Segmentation TablesDocumento3 pagineSegmentation TablessayeeNessuna valutazione finora

- JIT - Case StudyDocumento4 pagineJIT - Case StudyAsif Iqbal 2016289090Nessuna valutazione finora

- Queuing TheoryDocumento10 pagineQueuing TheoryIBHAVRINessuna valutazione finora

- AP - FI-MM Intigration - Complete DocumentDocumento151 pagineAP - FI-MM Intigration - Complete Documentzabiullah1243Nessuna valutazione finora

- Demand ForcastingDocumento24 pagineDemand Forcastingnitish07singhNessuna valutazione finora

- Items and Inventory:: Serial Numbers and BatchesDocumento12 pagineItems and Inventory:: Serial Numbers and BatchesabdeltifNessuna valutazione finora

- A Stakeholder Approach and Business EthicsDocumento16 pagineA Stakeholder Approach and Business EthicsLiora Claire AngelicaNessuna valutazione finora

- AGP-AMDe Ethiopia Warehouse Receipt System A Case For Expansion ReportDocumento35 pagineAGP-AMDe Ethiopia Warehouse Receipt System A Case For Expansion ReportpoorfarmerNessuna valutazione finora

- Global SourcingDocumento22 pagineGlobal SourcingBishnu S. MukherjeeNessuna valutazione finora

- Afm MCQDocumento10 pagineAfm MCQJibu MathewNessuna valutazione finora

- MRP PresentationDocumento22 pagineMRP PresentationJheomari Yumul100% (1)

- PP Material Master ViewsDocumento26 paginePP Material Master ViewsanjitachinkiNessuna valutazione finora

- Oil Seed and Puls ProcessingDocumento55 pagineOil Seed and Puls ProcessingTesfaye Azanie1100% (1)

- Alan Freeman - Ernest - Mandels - Contribution - To - Economic PDFDocumento34 pagineAlan Freeman - Ernest - Mandels - Contribution - To - Economic PDFhajimenozakiNessuna valutazione finora

- Recognition AND AmbivalenceDocumento350 pagineRecognition AND AmbivalenceFrederic ValNessuna valutazione finora

- 1Documento14 pagine1Cecille GuillermoNessuna valutazione finora

- Test 1801 New Holland TS100 DieselDocumento5 pagineTest 1801 New Holland TS100 DieselAPENTOMOTIKI WEST GREECENessuna valutazione finora

- Description About Moon: Earth SatelliteDocumento6 pagineDescription About Moon: Earth SatellitePurva KhatriNessuna valutazione finora

- AJ IntroductionDocumento31 pagineAJ IntroductiontrollergamehuydkNessuna valutazione finora

- Evidence Based Practice in Nursing Healthcare A Guide To Best Practice 3rd Edition Ebook PDFDocumento62 pagineEvidence Based Practice in Nursing Healthcare A Guide To Best Practice 3rd Edition Ebook PDFwilliam.tavares69198% (50)

- C7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesDocumento13 pagineC7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesBhat SaqibNessuna valutazione finora

- Catalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDocumento336 pagineCatalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDr. Dragos CobzariuNessuna valutazione finora

- Fractional Differential Equations: Bangti JinDocumento377 pagineFractional Differential Equations: Bangti JinOmar GuzmanNessuna valutazione finora

- Major Stakeholders in Health Care SystemDocumento5 pagineMajor Stakeholders in Health Care SystemANITTA S100% (1)

- JLPT Application Form Method-December 2023Documento3 pagineJLPT Application Form Method-December 2023Sajiri KamatNessuna valutazione finora

- Tourism and GastronomyDocumento245 pagineTourism and GastronomySakurel ZenzeiNessuna valutazione finora

- Dehydration AssessmentDocumento2 pagineDehydration AssessmentzaheerbdsNessuna valutazione finora

- Mastering American EnglishDocumento120 pagineMastering American Englishmarharnwe80% (10)

- Yuzu InstallerDocumento3 pagineYuzu InstallerJohnnel PrietosNessuna valutazione finora

- Week 1-2 Module 1 Chapter 1 Action RseearchDocumento18 pagineWeek 1-2 Module 1 Chapter 1 Action RseearchJustine Kyle BasilanNessuna valutazione finora

- Prosocial Behaviour: Hans W. BierhoffDocumento20 pagineProsocial Behaviour: Hans W. BierhoffSahil Mushaf100% (1)

- How To Build Yam Chips Production PlantDocumento11 pagineHow To Build Yam Chips Production PlantVu Thieu TuanNessuna valutazione finora

- Using MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsDocumento8 pagineUsing MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsJancarlo Mendoza MartínezNessuna valutazione finora

- Isaiah Chapter 6Documento32 pagineIsaiah Chapter 6pastorbbNessuna valutazione finora

- Rfis On Formliners, Cover, and EmbedmentsDocumento36 pagineRfis On Formliners, Cover, and Embedmentsali tahaNessuna valutazione finora

- As I Lay Writing How To Write Law Review ArticleDocumento23 pagineAs I Lay Writing How To Write Law Review ArticleWalter Perez NiñoNessuna valutazione finora

- 7 Ways To Support Your Babys Learning Today Monti KidsDocumento19 pagine7 Ways To Support Your Babys Learning Today Monti KidsMareim A HachiNessuna valutazione finora

- Protected PCM USB Memory Sticks For Pa3X.Documento1 paginaProtected PCM USB Memory Sticks For Pa3X.mariuspantera100% (2)

- Datasheet of STS 6000K H1 GCADocumento1 paginaDatasheet of STS 6000K H1 GCAHome AutomatingNessuna valutazione finora

- Nodal Analysis Collection 2Documento21 pagineNodal Analysis Collection 2Manoj ManmathanNessuna valutazione finora

- 42ld340h Commercial Mode Setup Guide PDFDocumento59 pagine42ld340h Commercial Mode Setup Guide PDFGanesh BabuNessuna valutazione finora

- A List of 142 Adjectives To Learn For Success in The TOEFLDocumento4 pagineA List of 142 Adjectives To Learn For Success in The TOEFLchintyaNessuna valutazione finora

- Interceptor Specifications FinalDocumento7 pagineInterceptor Specifications FinalAchint VermaNessuna valutazione finora