Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ets Ust 3 Update 14 Screen

Caricato da

Faizan MotiwalaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ets Ust 3 Update 14 Screen

Caricato da

Faizan MotiwalaCopyright:

Formati disponibili

efficient, durable, reliable

Long service intervals, maintenance-friendly engine design and low fuel consumption ensure maximum efficiency in our type 3 engines. Optimized components

prolong service life even when using non-pipeline gases such as landfill gas. The new type 3D generation offers an outstanding service interval with up to 80,000

operating hours until the major overhaul. This engine type stands out in its 500 to 1,100 kW power range due to its technical maturity and high degree of

reliability.

Jenbacher

type 3

reference installations

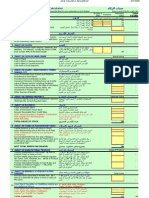

model, plant key technical data description

J312

Containerized

solution

Landfill site;

Cavenago, Italy

J316

Profusa,

producer of coke;

Bilbao, Spain

J320

Ecoparc I;

Barcelona, Spain

J320

Amtex Spinning Mills;

Faisalabad, Pakistan

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Landfill gas

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x J312

Electrical output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,202 kW

Thermal output . . . . . . . . . . . . . . . . . . . . . . . . . . 5,102 MBTU/hr

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . September 1999

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . Coke gas and natural gas

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 x J316

Electrical output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

a) with 100% coke gas . . . . . . . . . . . . . . . . . . . . . . . . 5,642 kW

b) with 60% coke gas and 40% natural gas,

or 100% natural gas . . . . . . . . . . . . . . . . . . . . . . . . . . . 6,528 kW

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . November 1995

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Biogas and natural gas

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 x J320

Electrical output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5,240 kW

Thermal output

a) with biogas . . . . . . . . . . . . . . . . . . . . . . . . . . . 10,040 MBTU/hr

b) with natural gas . . . . . . . . . . . . . . . . . . . . 10,263 MBTU/hr

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . December 2001

to January 2002

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Natural gas

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 x J320

Electrical output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12,072 kW

Commissioning . . . . November 2002 (1

st

, 2

nd

engine),

April 2003 (3

rd

engine),

May 2003 (4

th

- 7

th

engine),

April 2004 (8

th

engine),

April 2005 (9

th

, 10

th

engine),

March 2008 (11

th

, 12

th

engine)

Every system has its own landfill gas feeder line and exhaust

gas treatment line. The generated electricity is used on-site,

excess power is fed into the public grid. The employ ment of

the CL.AIR* system ensures the purification of the exhaust

gas to meet stringent Italian emission requirements. As a

special feature, at this plant the thermal energy is used for

landfill leachate treatment, as well as for greenhouse heating.

This installation designed by GEs Jenbacher product team

enables Profusa to convert the residual coke gas with a

hydrogen content of approximately 50% into valuable

electrical energy.

Beginning 2008, the 12 engines reached a combined

total of one million operating hours.

In Ecoparc I, organic waste is processed into biogas, which

serves as energy source for our gas engines. The gener-

ated electricity is used on-site as well as fed into the public

power grid. A portion of the thermal energy is used as pro-

cess heat in the digesters, and the excess heat is bled off in

the air coolers.

The natural gas-driven units generate electricity for spin-

ning mills in one of Pakistans most important textile cen-

ters. Special features of this Jenbacher plant allow for high

ambient temperature, dusty inlet air, and operation in island

mode.

GE Power & Water

Distributed Power

*Trademark of General Electric Company

Natural gas 1,800 rpm | 60 Hz

NOx < Type Pel (kW) el (%) Pth (MBTU/hr) th (%) tot (%)

312 633 38.1 2,836 50.0 88.1

1.1 g/bhp.hr 316 848 38.3 3,431 45.4 83.6

320 1,059 39.0 4,655 50.2 89.2

312 633 36.8 3,052 51.9 88.7

0.6 g/bhp.hr 316 848 36.9 4,043 51.6 88.5

320 1,059 38.1 4,832 51.0 89.1

Biogas 1,800 rpm | 60 Hz

NOx < Type Pel (kW) el (%) Pth (MBTU/hr) th (%) tot (%)

312 633 38.1 2,764 48.8 86.9

1.1 g/bhp.hr 316 848 38.3 3,549 47.0 85.2

320 1,059 39.0 4,507 48.6 87.6

312 633 36.8 2,934 49.9 86.7

0.6 g/bhp.hr 316 848 36.9 3,743 47.8 84.7

320 1,059 36.9 4,954 50.6 87.5

2

0

1

4

G

E

J

e

n

b

a

c

h

e

r

G

m

b

H

&

C

o

O

G

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

G

E

A

-

1

3

6

9

0

U

S

Dimensions l x w x h (inch)

Generator set J312 190 x 70 x 90

J316 210 x 70 x 90

J320 230 x 70 x 90

Cogeneration system J312 190 x 90 x 90

J316 210 x 90 x 90

J320 230 x 80 x 90

Container J312 490 x 100 x 110

J316 490 x 100 x 110

J320 490 x 100 x 110

Weights empty (lbs)

J312 J316 J320

Generator set 16,480 19,480 22,520

Cogeneration system 19,560 21,900 23,620

Container (generator set) 43,400 49,930 56,500

Container (cogeneration) 44,700 51,230 57,800

Configuration V 70

Bore (inch) 5.31

Stroke (inch) 6.69

Displacement/cylinder (cu.in) 148.5

Speed (rpm) 1,800 (60 Hz)

Mean piston speed (in/s) 402

Scope of supply Generator set, cogeneration system,

generator set/cogeneration in container

Applicable gas types Natural gas, flare gas, propane, biogas,

landfill gas, sewage gas. Special gases

(e.g., coal mine gas, coke gas, wood gas, pyrolysis gas)

Engine type J312 J316 J320

No. of cylinders 12 16 20

Total displacement (cu.in) 1,782 2,376 2,970

technical data

1) Technical data according to ISO 3046

2) Total heat output with a tolerance of +/- 8%, exhaust gas outlet temperature 120C, for biogas exhaust gas outlet temperature 180C

All data according to full load and subject to technical development and modification.

Further engines versions available on request.

outputs and efficiencies

1

1

1

1

2

2

2

2

GE Power & Water Jenbacher gas engines North America Houston, TX 77032 T +1 832 2955600 F +1 281 4429994 jenbacher.us@ge.com www.ge-distributedpower.com

Potrebbero piacerti anche

- Jenbacher Type 3: Efficient, Durable, Reliable Reference InstallationsDocumento2 pagineJenbacher Type 3: Efficient, Durable, Reliable Reference InstallationsSohailAKramNessuna valutazione finora

- Jenbacher Type 3: Efficient, Durable, Reliable Reference InstallationsDocumento2 pagineJenbacher Type 3: Efficient, Durable, Reliable Reference InstallationsMUHAMMAD EHSAN-UL-HAQUE L1F17MSME0003Nessuna valutazione finora

- Et Set 4 Update 14 ScreenDocumento2 pagineEt Set 4 Update 14 ScreenFaizan MotiwalaNessuna valutazione finora

- The Engine For Agricultural Equipment.: 32 - 128 KW at 2500 RPMDocumento6 pagineThe Engine For Agricultural Equipment.: 32 - 128 KW at 2500 RPMMohammed Amine KenedNessuna valutazione finora

- 1104D-E44Tag1 Electropak: SeriesDocumento8 pagine1104D-E44Tag1 Electropak: Seriesmahmoud khtaNessuna valutazione finora

- Cat cG132: Series Gas Generator SetsDocumento8 pagineCat cG132: Series Gas Generator SetsCesário GuimarãesNessuna valutazione finora

- Perkins 2206c E13tag2 en ItDocumento20 paginePerkins 2206c E13tag2 en Itganesh_d2k6100% (1)

- Technical Data: 4000 Series 4008TAG 4008TAG1 4008TAG2Documento8 pagineTechnical Data: 4000 Series 4008TAG 4008TAG1 4008TAG2Ulma HudinNessuna valutazione finora

- 4006-23tag2a - Tag3aDocumento14 pagine4006-23tag2a - Tag3aImran MazharNessuna valutazione finora

- Perkins 1300 Technical DataDocumento12 paginePerkins 1300 Technical DataAbdul Khaliq100% (1)

- Technical Specifications: CAMDA Perkins Diesel Genset at 60HZ, 1800Rpm, 3ph, 0.8pfDocumento16 pagineTechnical Specifications: CAMDA Perkins Diesel Genset at 60HZ, 1800Rpm, 3ph, 0.8pfNisar AhmedNessuna valutazione finora

- Technical Data: @perkinsDocumento6 pagineTechnical Data: @perkinsHendra SyalalaNessuna valutazione finora

- TBG 620Documento4 pagineTBG 620sdiamanNessuna valutazione finora

- 2206c-E13tag2&3 Tpd1688e4Documento20 pagine2206c-E13tag2&3 Tpd1688e4Daniel Graterol100% (2)

- TBG 616Documento4 pagineTBG 616sdiaman50% (2)

- Performance CurveDocumento2 paginePerformance CurveNiten GuptaNessuna valutazione finora

- Perkins 4000 SeriesDocumento16 paginePerkins 4000 SeriesFuqqi Bhai100% (3)

- Perkins 1104 44tg1 Spec SheetDocumento8 paginePerkins 1104 44tg1 Spec SheetRodrigoThuLokithoPkmzNessuna valutazione finora

- 4012-46TWG2A 4012-46TWGA DieselDocumento24 pagine4012-46TWG2A 4012-46TWGA DieselJDBORDNessuna valutazione finora

- 1104D-44Tg2 1104D-44Tg3 Electropak: SeriesDocumento10 pagine1104D-44Tg2 1104D-44Tg3 Electropak: SeriesDede R KurniawanNessuna valutazione finora

- 2806A-E18TAG2A Technical DataDocumento10 pagine2806A-E18TAG2A Technical DatabereketNessuna valutazione finora

- Manual Motor Perkins PDFDocumento8 pagineManual Motor Perkins PDFRobertoSoares0% (1)

- Jenbacher Type 6: Cutting-Edge TechnologyDocumento2 pagineJenbacher Type 6: Cutting-Edge TechnologySergiuPolNessuna valutazione finora

- 2206A Series PerkinsDocumento20 pagine2206A Series Perkinskodor sinno100% (1)

- 5-1 Technical DatasheetDocumento10 pagine5-1 Technical DatasheetJegadeshwaran RNessuna valutazione finora

- 2506C E15tag2 PDFDocumento14 pagine2506C E15tag2 PDFIvan Dumont67% (3)

- TPD2158E2Documento4 pagineTPD2158E2MohamedJaberKutkutMjkNessuna valutazione finora

- 2506-A E15tag1 Datos TecnicosDocumento14 pagine2506-A E15tag1 Datos TecnicosValeddia Beatriz Gutierrez Nina100% (1)

- Perkins 4012 - 46twg2a Briz MotorsDocumento18 paginePerkins 4012 - 46twg2a Briz MotorsRafiee AdityaNessuna valutazione finora

- Perkins 1106A-70TAG2 PDFDocumento10 paginePerkins 1106A-70TAG2 PDFAna Nurul WakhidahNessuna valutazione finora

- PD50-01 Engine Data SheetDocumento10 paginePD50-01 Engine Data SheetManuela AsmatNessuna valutazione finora

- TBD 616Documento6 pagineTBD 616sdiamanNessuna valutazione finora

- 1104C-44T IOPU Technical Data Sheet PDFDocumento8 pagine1104C-44T IOPU Technical Data Sheet PDFBob100% (2)

- Datasheet P2500 PDFDocumento14 pagineDatasheet P2500 PDFElectro JC100% (1)

- 4012-46TWG2A - & - 3A Diesel (1250 Kva)Documento24 pagine4012-46TWG2A - & - 3A Diesel (1250 Kva)Nate PawangNessuna valutazione finora

- 1104A-44TG1 PerkinsDocumento8 pagine1104A-44TG1 PerkinsMario Eduardo Santos MartinsNessuna valutazione finora

- 1104 C44 TAG2 TPD1637 Technical Data SheetDocumento8 pagine1104 C44 TAG2 TPD1637 Technical Data SheetFarhan JuttNessuna valutazione finora

- En Manual GT-500Documento56 pagineEn Manual GT-500Adrian Petre100% (1)

- DPK TDS EN 8M33 0010 22 02 15 - 8M33G800 6 - StdRad - DatasheetDocumento4 pagineDPK TDS EN 8M33 0010 22 02 15 - 8M33G800 6 - StdRad - DatasheetDany_WallyNessuna valutazione finora

- Catalogue Perkins 4012 46TAG1A 46TAG2ADocumento18 pagineCatalogue Perkins 4012 46TAG1A 46TAG2AAbdoul-aziz Ben Ousmanou100% (1)

- 3 1524 (1500)Documento6 pagine3 1524 (1500)mkNessuna valutazione finora

- Series: 973 - 1327 KWM (Gross) at 1500 RPMDocumento18 pagineSeries: 973 - 1327 KWM (Gross) at 1500 RPMlahcen boudaoudNessuna valutazione finora

- 4006-23TRS1&2 Gas EngineDocumento16 pagine4006-23TRS1&2 Gas Enginenanocycle100% (1)

- Thông số Perkins 4008TAG1A PDFDocumento16 pagineThông số Perkins 4008TAG1A PDFBắc NhậtNessuna valutazione finora

- Technical Data: 4000 Series 4012-46TWG2A 4012-46TWG3ADocumento8 pagineTechnical Data: 4000 Series 4012-46TWG2A 4012-46TWG3Aabo omrNessuna valutazione finora

- Perkins 4008tag1a & Tag2a (Tsl4252e-6)Documento16 paginePerkins 4008tag1a & Tag2a (Tsl4252e-6)Cris_eu09Nessuna valutazione finora

- Perkins Engines 1106A-70TAG4Documento10 paginePerkins Engines 1106A-70TAG4dagimNessuna valutazione finora

- New 625kVA 2806D E18 TAG1A PDFDocumento12 pagineNew 625kVA 2806D E18 TAG1A PDFRohit BhattNessuna valutazione finora

- New 625kva 2806d E18 Tag1aDocumento12 pagineNew 625kva 2806d E18 Tag1aRohit BhattNessuna valutazione finora

- Tag 2 ADocumento17 pagineTag 2 AepicenterrulezNessuna valutazione finora

- Full ReporDocumento47 pagineFull RepormuddasirmasoodNessuna valutazione finora

- Perkins 4012-46TWG2-3Documento24 paginePerkins 4012-46TWG2-3Cris_eu09100% (3)

- Electropak: 1206A-E70Ttag2Documento4 pagineElectropak: 1206A-E70Ttag2Andres SorinNessuna valutazione finora

- TPD2127 1206d-E70ttag1Documento4 pagineTPD2127 1206d-E70ttag1marwanqaisi85Nessuna valutazione finora

- Deutz620 50Documento4 pagineDeutz620 50sdiamanNessuna valutazione finora

- 1106a-70tag2 TPD1857Documento10 pagine1106a-70tag2 TPD1857Jan Ahmed100% (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Analysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesDa EverandAnalysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesValutazione: 3 su 5 stelle3/5 (1)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- CMA Positions: Dawn Sunday October 11, 2015 - Page 4Documento27 pagineCMA Positions: Dawn Sunday October 11, 2015 - Page 4Faizan MotiwalaNessuna valutazione finora

- Custom Tambola Housie Tickets PDFDocumento5 pagineCustom Tambola Housie Tickets PDFFaizan MotiwalaNessuna valutazione finora

- 1-25 BINGO: Safety First!Documento17 pagine1-25 BINGO: Safety First!Faizan MotiwalaNessuna valutazione finora

- License PremiumDocumento1 paginaLicense PremiumNguyen Viet Trung (FPL HCMK13.3)100% (1)

- Iris - Help by FBRDocumento5 pagineIris - Help by FBRGulzar Ahmad RawnNessuna valutazione finora

- Pre Post TestDocumento7 paginePre Post TestFaizan MotiwalaNessuna valutazione finora

- CBE Shedule Quarterly Winter 2015 FinalDocumento1 paginaCBE Shedule Quarterly Winter 2015 FinalFaizan MotiwalaNessuna valutazione finora

- Internship Report MTMDocumento45 pagineInternship Report MTMusmanaltafNessuna valutazione finora

- برنامج حساب زكاه المالDocumento3 pagineبرنامج حساب زكاه المالnewlife4me100% (10)

- Business Finance SyllabusDocumento68 pagineBusiness Finance SyllabusKhalid Mahmood0% (1)

- MPF Card FormDocumento2 pagineMPF Card FormFaizan MotiwalaNessuna valutazione finora

- Limiting Factor AnalysisDocumento5 pagineLimiting Factor AnalysisFaizan MotiwalaNessuna valutazione finora

- Jumbo Touch Remote ImDocumento18 pagineJumbo Touch Remote ImFaizan MotiwalaNessuna valutazione finora

- Maintenance Schedule For Gas Genset - GE JENBACHERDocumento5 pagineMaintenance Schedule For Gas Genset - GE JENBACHERrajputashi92% (12)

- Zakat CalculatorDocumento3 pagineZakat CalculatorFaizan MotiwalaNessuna valutazione finora

- Spinning Project Profile FinalDocumento23 pagineSpinning Project Profile FinalFaizan Motiwala67% (3)

- Spinning MillDocumento6 pagineSpinning MillAnand Arumugam0% (1)

- Chairman's Message: Frequently Asked Questions On The Code of Corporate Governance (Revised)Documento26 pagineChairman's Message: Frequently Asked Questions On The Code of Corporate Governance (Revised)Faizan MotiwalaNessuna valutazione finora

- Appointment of AuditorDocumento16 pagineAppointment of Auditorshahnawaz243Nessuna valutazione finora

- Budgeting ExampleDocumento17 pagineBudgeting ExampleBikrOm BaRuaNessuna valutazione finora

- ICSP Company Law Paper Suggested Answer 2013Documento8 pagineICSP Company Law Paper Suggested Answer 2013Faizan MotiwalaNessuna valutazione finora

- Formula SheetDocumento2 pagineFormula SheetFaizan Motiwala100% (1)

- Sohail ResumeDocumento2 pagineSohail ResumeFaizan MotiwalaNessuna valutazione finora

- Sohail ResumeDocumento2 pagineSohail ResumeFaizan MotiwalaNessuna valutazione finora

- Operations Management IsDocumento6 pagineOperations Management IsFaizan MotiwalaNessuna valutazione finora

- Professional CmaDocumento3 pagineProfessional CmarehankhananiNessuna valutazione finora

- Operations Management IsDocumento6 pagineOperations Management IsFaizan MotiwalaNessuna valutazione finora

- Assam Power Distribution Company LTDDocumento7 pagineAssam Power Distribution Company LTDkabuldasNessuna valutazione finora

- School Lawig National High School Grade Level Grade 9 Teacher Vangie P. Manuelo Learning Area T.L.E. - (ICT) Teaching Days and Time Quarter 1stDocumento3 pagineSchool Lawig National High School Grade Level Grade 9 Teacher Vangie P. Manuelo Learning Area T.L.E. - (ICT) Teaching Days and Time Quarter 1stManuelo Vangie100% (1)

- General Electric (Selector)Documento134 pagineGeneral Electric (Selector)Milton SantoNessuna valutazione finora

- ASNZS1576 Scaffolding+General+RequirementsDocumento69 pagineASNZS1576 Scaffolding+General+RequirementsMuhammad AfiqNessuna valutazione finora

- SP17316 Smartphones RF Front-End Module Sample System Plus ConsultingDocumento23 pagineSP17316 Smartphones RF Front-End Module Sample System Plus ConsultingVasikaran PrabaharanNessuna valutazione finora

- LAUDA Overall Brochure Constant Temperature Equipment en 2020-2021Documento151 pagineLAUDA Overall Brochure Constant Temperature Equipment en 2020-2021FithriyyahningsihNessuna valutazione finora

- Bosch Lambda Sensor LSU 1 & 4.9Documento10 pagineBosch Lambda Sensor LSU 1 & 4.9Al CaracasNessuna valutazione finora

- Technical Sheet of EI2 60 Handed DoorDocumento1 paginaTechnical Sheet of EI2 60 Handed DoorTaoufikAzarkanNessuna valutazione finora

- Analysis PhaseDocumento63 pagineAnalysis PhaseJoseph Josef0% (1)

- Cotton Ginning Machine Plant Quotation Ethopia 23 02 2024Documento2 pagineCotton Ginning Machine Plant Quotation Ethopia 23 02 2024sultannesru2030Nessuna valutazione finora

- Structural Glass Design-BS6399Documento6 pagineStructural Glass Design-BS6399msiddiq1100% (2)

- Engg Colleges in TirunelveliDocumento3 pagineEngg Colleges in Tirunelveligpavi123Nessuna valutazione finora

- Final Project On Digital MarketingDocumento78 pagineFinal Project On Digital Marketinggeer100% (4)

- Qame Form 2Documento6 pagineQame Form 2Gen Li Togy100% (2)

- UTM Security With FortinetDocumento76 pagineUTM Security With FortinetNelson Valente GomesNessuna valutazione finora

- MAXvent OwletDocumento66 pagineMAXvent Owletemanuelluca@yahoo.comNessuna valutazione finora

- Condensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDocumento8 pagineCondensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajNessuna valutazione finora

- STIHL TS410, TS420 Spare PartsDocumento11 pagineSTIHL TS410, TS420 Spare PartsMarinko PetrovićNessuna valutazione finora

- Environmental AwarenessDocumento16 pagineEnvironmental Awarenessvsrajeshvs100% (2)

- Color Difference Measuring InstrumentsDocumento5 pagineColor Difference Measuring InstrumentsJanine Ellyze EvangelistaNessuna valutazione finora

- Eden Garden Vizag BrochureDocumento27 pagineEden Garden Vizag Brochurevamsi1026Nessuna valutazione finora

- Read MeDocumento3 pagineRead MeGhazzanfar Ali KhanNessuna valutazione finora

- Johnson Michelle Resume Business Systems AnalystDocumento3 pagineJohnson Michelle Resume Business Systems Analystmichelle johnson100% (1)

- Siwes Report GoogleDocumento28 pagineSiwes Report GoogleelvisNessuna valutazione finora

- Block Vibration TestDocumento10 pagineBlock Vibration TestMehedi Hasan50% (2)

- Rubber TechDocumento35 pagineRubber TechThang CaoNessuna valutazione finora

- MomentsDocumento4 pagineMomentsontlametse tidimaneNessuna valutazione finora

- International RA472 Front Rear Axle Parts ManualDocumento5 pagineInternational RA472 Front Rear Axle Parts ManualHéctor Perez SNessuna valutazione finora

- Wind Turbine - Control and Monitoring PDFDocumento462 pagineWind Turbine - Control and Monitoring PDFElisete Mota Nascimento100% (3)

- 2801 Pep CL01 10001Documento77 pagine2801 Pep CL01 10001mileperez78100% (2)