Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

D 1400 - 94

Caricato da

Salah Jallali0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

251 visualizzazioni3 pagineThis standard covers the nondestructive measurement of the dry film thickness of electrically nonconductive coatings applied over a Nonferrous Metal Base. This Test Method does not purport to address all of the safety concerns associated with its use. The extent of such changes varies with the distance between the probe and the metal.

Descrizione originale:

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis standard covers the nondestructive measurement of the dry film thickness of electrically nonconductive coatings applied over a Nonferrous Metal Base. This Test Method does not purport to address all of the safety concerns associated with its use. The extent of such changes varies with the distance between the probe and the metal.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

251 visualizzazioni3 pagineD 1400 - 94

Caricato da

Salah JallaliThis standard covers the nondestructive measurement of the dry film thickness of electrically nonconductive coatings applied over a Nonferrous Metal Base. This Test Method does not purport to address all of the safety concerns associated with its use. The extent of such changes varies with the distance between the probe and the metal.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Designation: D 1400 94

Standard Test Method for

Nondestructive Measurement of Dry Film Thickness of

Nonconductive Coatings Applied to a Nonferrous Metal

Base

1

This standard is issued under the xed designation D 1400; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the nondestructive measure-

ment of the dry lm thickness of electrically nonconductive

coatings applied over a nonferrous metal base using commer-

cially available eddy current instruments.

1.2 This test method is not applicable to coatings that are

readily deformable under the load of the measuring instru-

ments, as the instrument probe must be placed directly on the

coating surface to take a reading.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 823 Practices for Producing Films of Uniform Thickness

of Paint, Varnish, and Related Products on Test Panels

2

D 1005 Test Method for Measurement of Dry-Film Thick-

ness of Organic Coatings Using Micrometers

2

D 1730 Practices for Preparation of Aluminum and

Aluminum-Alloy Surfaces for Painting

3

D 3980 Practice for Interlaboratory Testing of Paint and

Related Materials

2

3. Summary of Test Method

3.1 After calibrating the instrument using shims of known

thickness and either a bare part of the metal object or metal of

the same kind, the instrument probe is placed in contact with

the coated metal. In instruments of this type, electrical char-

acteristics of a coil and the probe are changed by the eddy

currents created in substrates by the alternating ux of the coil.

The extent of such changes varies with the distance between

the probe and the metal, the distance being the thickness of the

dry coating lm.

3.2 It should be recognized that the accuracy of the mea-

surements can be inuenced or affected when measurements

are made closer than 1 in. (25 mm) to an edge or 3 in. (75 mm)

to another mass of metal.

4. Signicance and Use

4.1 The results of many test methods applicable to coatings

are markedly affected by the lm thickness of the dry lm,

some examples being adhesion, exibility, and hardness to

name a few. To be able to compare results obtained by different

operators, it is essential to measure lm thickness closely.

4.2 Most protective and high performance coatings are

applied to meet a requirement or a specication for the dry lm

thickness of each coat, or for the complete system, or both.

Coatings must be applied within certain minimum and maxi-

mum thickness tolerances in order that they can fulll their

intended function. In addition to potential performance de-

ciencies, it is uneconomical to apply more material than

necessary when coating large areas such as metal structures

and coils. This test method is used to measure lm thickness of

coatings on nonferrous metals.

5. Apparatus

5.1 Eddy Current Thickness Gages, commercially available,

suitable to measure coating thickness accurately.

4

5.2 Nonconductive Thickness Shims for Calibration

Shims with assigned values traceable to National Standards are

available, but when shims are used that are not traceable to

National Standards, thickness must be measured to the nearest

0.1 mil (2.5 m) using a micrometer using a method such as

Procedure D in Test Method D 1005.

6. Test Specimens

6.1 When this test method is used in the eld, the specimen

is the coated structure or article on which the thickness is to be

evaluated.

6.2 For laboratory use apply the materials to be tested to

panels of the composition and surface conditions on which it is

desired to determine the thickness.

NOTE 1Applicable test panel description and surface preparation

1

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved Aug. 15, 1994. Published October 1994. Originally

published as D 1400 56. Last previous edition D 1400 87.

2

Annual Book of ASTM Standards, Vol 06.01.

3

Annual Book of ASTM Standards, Vol 02.05.

4

Apparatus found to be typical are shown in Table 1. Sources for the instruments

are available from ASTM, 1916 Race St., Philadelphia, PA 19103.

1

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

methods are given in Practices D 1730.

NOTE 2Coatings should be applied in accordance with Practices

D 823, or as agreed upon between the purchaser and the seller.

7. Calibration of Apparatus

7.1 Calibrate the instrument in an area free of stray mag-

netic elds, such as power lines, generators, or welding

equipment. There shall be no vibration apparent on the test

piece when the instrument is being calibrated.

7.2 Use a bare section of the substrate after the specied

surface preparation method has been accomplished. If an

uncoated section of the substrate is not available, uncoated test

panels similar to the type on which the specied preparation

has been performed may be used.

7.3 Select calibration shims in the expected thickness range

to be measured. For example, a coating is approximately 3 mils

(75 m) in thickness, calibrate the instrument at 3 mils. Then

check the calibration using shims of both a lesser and greater

thickness to determine the thickness range over which the

instrument is calibrated. The limits of this range are set at the

points where the gage no longer registers the shim thicknesses

within the manufacturers stated accuracy (for example,

610 %).

7.4 Follow the manufacturers instructions for the specic

adjustment of the instrument.

8. Procedure

8.1 Use the instrument only after it has been calibrated in

accordance with Section 7.

8.2 Ensure that the coating is dry prior to use of the

instrument.

8.3 Inspect the probe tip and surface to be measured to

assure that they are clean, otherwise erroneous readings can

result.

8.4 Take readings in areas free of vibration, electrical, or

magnetic elds.

8.5 If thickness readings are found to be outside the cali-

bration range established in 7.3, repeat the calibration proce-

dure in the appropriate range. Check the calibration before,

during, and after each use to ensure that the instrument

continues to read properly. If the instrument is found to be out

of adjustment, remeasure the thicknesses taken since the last

satisfactory calibration check was made.

8.6 Take a sufficient number of readings to characterize the

surface.

8.6.1 For laboratory measurements a recommended mini-

mum is three for a 3 by 6 in. (75 by 150 mm) panel and more

in proportion to size.

8.6.2 For eld measurements a recommended minimum is

ve determinations at random for every 100 ft

2

(10 m

2

) of the

surface area. Each of the ve determinations should be the

mean of three separate gage readings within the area of a

1

2 in.

(12 mm) diameter circle.

8.7 Take measurements no closer than 1 in. (25 mm) to an

edge or 3 in. (75 mm) to another mass of metal. If such

measurements are necessary, recheck the calibration in the

specic area to determine the effect the edge or mass of metal

has on the instrument reading.

9. Report

9.1 Report the following information: the instrument used,

serial numbers range, and mean of the thickness readings

found. Depending upon the application, it may be useful to

record the individual readings as well.

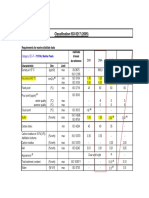

10. Precision and Bias

10.1 PrecisionOn the basis of an interlaboratory study of

this test method, conducted to determine the precision of

several types of instrument in measuring a moderate range of

coating thicknesses, the intralaboratory and interlaboratory

coefficients of variation, calculated using procedures described

in Practice D 3980, were found to be those shown in Table 1

for the instrument evaluated. Based upon these coefficients the

following criteria should be used for judging, at the 95 %

condence level the acceptability of results:

10.1.1 RepeatabilityTwo results, each the mean of four

measurements, obtained by the same operator using instru-

ments from the same category should be considered suspect if

they differ by more than the maximum allowable difference

values given in Table 1 for the appropriate lm thickness.

10.1.2 ReproducibilityTwo results, each the mean of four

measurements, obtained by operators in different laboratories

using instruments from the same category should be considered

suspect if they differ by more than the maximum allowable

difference values given in Table 1 for the appropriate lm

thickness.

10.2 BiasThe bias for this test method for measuring dry

lm thickness cannot be measured at this time, because each

instrument has its own bias.

11. Keywords

11.1 coating thickness; dry lm thickness; Eddy current

thickness gages; nondestructive thickness; paint thickness

D 1400

2

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, 100 Barr Harbor Drive, West Conshohocken, PA 19428.

TABLE 1 Precision of Film Thickness Measurements

Intralaboratory

Coating Thickness 0.5 to 1.5 mils 3 to 3.5 mils

Degrees of

Freedom

(df)

Coefficient

of Variation

(v

w

), %

Maximum

Allowable

Difference

(MAD), %

Degrees of

Freedom

(df)

Coefficient

of Variation

(v

w

), %

Maximum

Allowable

Difference

(MAD), %

Instrument:

A

Permascope EC 28 3 8.7 14 2

Minitest FN 250 ... ... ... 2 2

16 2

Minitest FN 250 4 6 ... ... 6

Elcometer 150 FN 38 8

B B

Dermitron 16 8

B B

Pooled 58 7.9 22.3

Interlaboratory

Coating Thickness 0.5 to 1.5 mils 3 to 3.5 mils

Degrees of

Freedom

(DF)

Coefficient

of Variation

(v

b

), %

Maximum

Allowable

Difference

(MAD), %

Degrees of

Freedom

(DF)

Coefficient

of Variation

(v

b

), %

Maximum

Allowable

Difference

(MAD), %

Instrument:

A

Permascope EC 8 3 8 5

C

Elcometer 150 FN 6 5

D

4 3

Pooled 14 3.98 12.1 12 4.44 13.7

C

Minitest FN 250

B B B

Dermitron

B B B

A

Results obtained using the models shown. Note that some instruments are available as newer models, which are not included.

B

Results are not provided.

C

Coefficient of variation is usually lower for thicker lms.

D

Interlaboratory MAD is usually larger than intralaboratory MAD.

D 1400

3

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Shop Manual WA380-3LE SN A50001Documento758 pagineShop Manual WA380-3LE SN A50001Eliecer godoy100% (2)

- Procedure BASE LINE SURVEY of Pipework & PV EqpmtDocumento9 pagineProcedure BASE LINE SURVEY of Pipework & PV EqpmtSalah Jallali100% (1)

- Cs15 Gas Tank Cleaning Degassing 1997Documento12 pagineCs15 Gas Tank Cleaning Degassing 1997kirandevi1981100% (2)

- Catalogue de Formation BookletDocumento12 pagineCatalogue de Formation BookletSalah JallaliNessuna valutazione finora

- 6 - Ut Scan Report Separator #v-3001Documento19 pagine6 - Ut Scan Report Separator #v-3001Salah JallaliNessuna valutazione finora

- Valco Group's dedication to flexible wedge gate valve deliveryDocumento15 pagineValco Group's dedication to flexible wedge gate valve deliverySalah JallaliNessuna valutazione finora

- Dedication To Delivery: Valco GroupDocumento15 pagineDedication To Delivery: Valco GroupSalah JallaliNessuna valutazione finora

- Fixed storage tanks requirements for volume measurementDocumento22 pagineFixed storage tanks requirements for volume measurementnknicoNessuna valutazione finora

- Vérification Des Évent T7CDocumento1 paginaVérification Des Évent T7CSalah JallaliNessuna valutazione finora

- Pipeline Integrity Management Systems ": LEVEL FoundationDocumento3 paginePipeline Integrity Management Systems ": LEVEL FoundationSalah JallaliNessuna valutazione finora

- Classification ISO 8217 (2005)Documento5 pagineClassification ISO 8217 (2005)Salah JallaliNessuna valutazione finora

- Storage Tank Design Calculation - Api 650: Close Cone-RoofDocumento14 pagineStorage Tank Design Calculation - Api 650: Close Cone-RoofSalah JallaliNessuna valutazione finora

- Evaluation of Losses of Gasoline Storrage TanksDocumento31 pagineEvaluation of Losses of Gasoline Storrage TanksSalah JallaliNessuna valutazione finora

- Jensen Mixer Series 400 CatalogDocumento12 pagineJensen Mixer Series 400 CatalogSalah JallaliNessuna valutazione finora

- 2 PDFDocumento51 pagine2 PDFSalah JallaliNessuna valutazione finora

- LNG As Marine Fuel: Merchant Vessels - ConversionsDocumento27 pagineLNG As Marine Fuel: Merchant Vessels - ConversionsSalah JallaliNessuna valutazione finora

- Spec Peinture BacDocumento2 pagineSpec Peinture BacSalah JallaliNessuna valutazione finora

- CV Salah Jallali - English New RevDocumento8 pagineCV Salah Jallali - English New RevSalah JallaliNessuna valutazione finora

- Truck Loading System PDFDocumento3 pagineTruck Loading System PDFSalah JallaliNessuna valutazione finora

- CV Salah Jallali - English New RevDocumento2 pagineCV Salah Jallali - English New RevSalah JallaliNessuna valutazione finora

- Materials Testing Lab, Corrosion Study, RBI, Failure Analysis, Advanced NDT Services, Training and ConsultingDocumento23 pagineMaterials Testing Lab, Corrosion Study, RBI, Failure Analysis, Advanced NDT Services, Training and ConsultingahmedawadallaNessuna valutazione finora

- Cuadro Comparativo AcerosDocumento1 paginaCuadro Comparativo Acerosfateruler51Nessuna valutazione finora

- API 650 & API 653 TrainingDocumento56 pagineAPI 650 & API 653 TrainingSalah JallaliNessuna valutazione finora

- Fixed storage tanks requirements for volume measurementDocumento22 pagineFixed storage tanks requirements for volume measurementnknicoNessuna valutazione finora

- Steel TanksDocumento75 pagineSteel TanksAnonymous b3NKZUbNessuna valutazione finora

- Steve Crimaudo APITank Standards UpdateDocumento36 pagineSteve Crimaudo APITank Standards UpdateSalah JallaliNessuna valutazione finora

- Fiche Programme Doc Asme IxDocumento5 pagineFiche Programme Doc Asme IxSalah JallaliNessuna valutazione finora

- Understanding "Position" in WeldingDocumento116 pagineUnderstanding "Position" in WeldingThaksenNessuna valutazione finora

- Rosoft For TanksDocumento1 paginaRosoft For TanksSalah JallaliNessuna valutazione finora

- ASME A13.1-1996 Identification of Piping SystemsDocumento13 pagineASME A13.1-1996 Identification of Piping SystemsRakesh MenonNessuna valutazione finora

- Floormap3d PDFDocumento4 pagineFloormap3d PDFSalah JallaliNessuna valutazione finora

- Supplier Deviation Request FormDocumento2 pagineSupplier Deviation Request Formjainik shahNessuna valutazione finora

- DatasheetDocumento13 pagineDatasheetebertecnicoNessuna valutazione finora

- Time Table Spring 2017 18Documento10 pagineTime Table Spring 2017 18SuvamNessuna valutazione finora

- Rectify Binary Plate Efficiency BubblesDocumento4 pagineRectify Binary Plate Efficiency BubblesCsaba AndrásNessuna valutazione finora

- Measurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesDocumento11 pagineMeasurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesVedant KodagiNessuna valutazione finora

- PX 9 enDocumento532 paginePX 9 enjjccmmaaNessuna valutazione finora

- Stoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer TabletsDocumento6 pagineStoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer Tabletsgabbal009Nessuna valutazione finora

- GameBoy Programming ManualDocumento298 pagineGameBoy Programming Manualdiceman2037100% (4)

- Catalogo - CATUDocumento132 pagineCatalogo - CATUxis-zeroNessuna valutazione finora

- Wabco Air Suspension Compressor RepairDocumento3 pagineWabco Air Suspension Compressor RepairgarcolNessuna valutazione finora

- Zetron Model 30 Instruction Manual EarlyDocumento58 pagineZetron Model 30 Instruction Manual EarlyOscar EscobarNessuna valutazione finora

- Axle, Front - Differential and Carrier - Jee0123251Documento3 pagineAxle, Front - Differential and Carrier - Jee0123251Husi NihaNessuna valutazione finora

- Introduction to Generators, Protection Schemes, Relays and MaintenanceDocumento44 pagineIntroduction to Generators, Protection Schemes, Relays and MaintenancerahulNrana100% (1)

- Instruction Manual STR 155 RL-1Documento24 pagineInstruction Manual STR 155 RL-1VENDI100% (3)

- EI Manifold Pressure ManualDocumento12 pagineEI Manifold Pressure Manualjkloepping_634367970Nessuna valutazione finora

- KALEKİMDocumento18 pagineKALEKİMqaisalkurdyNessuna valutazione finora

- Elective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Documento6 pagineElective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Adesh DeshbhratarNessuna valutazione finora

- Iso Dis 20283-4 2011Documento27 pagineIso Dis 20283-4 2011Ricardo RamirezNessuna valutazione finora

- Trade Skills Assessment GuideDocumento25 pagineTrade Skills Assessment GuideRandz Lampa0% (1)

- Husky Air Assignment 5 and 6Documento15 pagineHusky Air Assignment 5 and 6varunkalra6Nessuna valutazione finora

- Catalogo DeltaDocumento2 pagineCatalogo DeltaHelena ChagasNessuna valutazione finora

- WTS 12 ElectrodynamicsDocumento28 pagineWTS 12 ElectrodynamicsTondani100% (1)

- Nitobond EP 0608Documento2 pagineNitobond EP 0608James PittsNessuna valutazione finora

- Flyer M 10id 12 ENDocumento2 pagineFlyer M 10id 12 ENTrevor SalazarNessuna valutazione finora

- Study of Buffer Overflows and Keyloggers in The Linux Operating SystemDocumento8 pagineStudy of Buffer Overflows and Keyloggers in The Linux Operating Systemrobyrulz100% (1)

- Agentur H. Willems: Tel.: +49-421-52009-0 List of Manufacturers Fax: +49-421-545858Documento5 pagineAgentur H. Willems: Tel.: +49-421-52009-0 List of Manufacturers Fax: +49-421-545858Trần Minh NhậtNessuna valutazione finora

- (1)Documento119 pagine(1)Virginia Rosales OlmosNessuna valutazione finora

- SANTO 72358 KA3: Electronic RefrigeratorDocumento32 pagineSANTO 72358 KA3: Electronic RefrigeratorSakthipriya JeganathanNessuna valutazione finora