Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

En 14399 (Informazioni Tecniche Per L'utilizzo - EN 1090-2 - Rev2-En)

Caricato da

Adnan KaraahmetovicTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

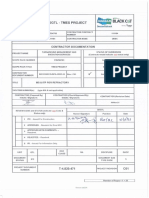

En 14399 (Informazioni Tecniche Per L'utilizzo - EN 1090-2 - Rev2-En)

Caricato da

Adnan KaraahmetovicCopyright:

Formati disponibili

High strength structural bolting assemblies for preloading,

according to EN 14399.

Technical information for use.

Contents

1. Scope

2. Normative References

3. General

4. Symbols and units

5. Assembly method

5.1 Bolts

5.2 Nuts

5.3 Washers

6. Tightening of preloaded bolts: HV system.

6.1 Nominal minimum preloading force

6.2 Tightening method, class K1

6.3 Tightening method, class K0

7. Inspection and testing of preloaded bolted connections

7.1 Before tightening

7.2 During and after tightening

7.2.1 Inspection of tightening by the combined method

8. Recommendations

Annex A - Prescribed clamp lengths

1. Scope

The information in this technical documentation are referred to high strength structural bolting assemblies

for preloading, according to the standards EN 14399-1, system HV, classes K0 e K1.

General technical information about tightening of preloaded bolted joints, in E category, according to the

standards EN 1993-1-8: 2005 " Design of steel structures. Part 1-8: Design of joints ", are specified.

2. Normative References

- EN 1090-2: 2008 "Execution of steel structures and aluminium structures - Part 2: Technical

requirements for steel structures";

- EN 1993-1-8: 2005 "Design of steel structures. Part 1-8: Design of joints";

- EN 14399-1:2005 "High-strength structural bolting assemblies for preloading - Part 1: General

requirements";

- EN 14399-2:2005 "High-strength structural bolting assemblies for preloading - Part 2: Suitability test

for preloading";

- EN 14399-4:2005 "High-strength structural bolting assemblies for preloading - Part 4: System HV.

Hexagon bolt and nut assemblies";

- EN 14399-6:2005 "High-strength structural bolting assemblies for preloading - Part 6: Plain chamfered

washers".

3. General

Structural bolting assemblies (bolt/nut/washers) manufactured by Agrati are complying with the

requirements of the mandate M/120 (Structural metallic products and ancillaries) given under the EU

Construction Products Directive 89/106/EEC. This entitles the manufacturer to affix the CE marking.

CE marking certifies:

- the compliance of the assemblies bolt/nut/washers with the harmonized European standards for metallic

constructions;

- the execution of a structured, controlled and certificated, by a notified external body, production

process;

- the presence of a quality management system able to guarantee a continuous surveillance, assessment

and approval of production process.

Every single Agrati HV assembly, ready to use, is a set comprising:

- a bolt, in compliance with the standard EN 14399-4;

- a properly lubricated nut, in compliance with the standard EN 14399-4;

- two washers, in compliance with the standards EN 14399-6;

- possible direct or indirect measurement of bolt preload device.

Agrati supplies assemblies in these two versions:

- hot dip galvanized;

- as processed (the normal finish resulting from manufacture with a light coating of oil).

Other coatings may be negotiated between the purchaser and the manufacturer.

4. Symbols and units

References: EN 1993-1-8; EN 14399-2.

nominal stress area of the bolts, [mm

2

]

nominal thread diameter, [mm]

,

nominal minimum preloading force , [kN]

nominal tensile strength, [MPa]

individual value of the k-factor, (for K1 class: 0,10

0,16; for K0 class: not specified)

k-factor value for the calculation of the tightening torque, (for class K1:

= 0,13 unless

otherwise specified - ref. EN 1090-2, 8.5.4)

,

reference value for tightening torque, [Nm]

t clamp length, between the nut bearing surface and bolt bearing surface, [mm]

5. Assembly method

Reference: EN 1090-2, 8.2: Use of bolting assemblies.

Bolts and nuts shall not be welded, unless otherwise specified.

Preloaded assemblies do not need additional locking device, unless otherwise specified.

5.1 Bolts

The nominal fastener diameter used for structural bolting shall be at least M12.

The bolt length shall be chosen to such that after tightening the length of bolt end protrusion shall be at least

the length of one thread pitch measured from the outer face of the nut to the end of the bolt.

Clamp lengths (t ) shall be in accordance with those specified in table A.1 of EN 14399-4, attached to this

document.

5.2 Nuts

Nuts shall run freely on their partnering bolt, which is easily checked during hand assembly. Any nut and

bolt assembly where the nut does not run freely shall be discarded.

If a power tool is used, either of the following two checks may be used:

- for each new batch of nuts or bolts their compatibility may be checked by hand assembly before

installation;

- for mounted bolt assemblies but prior to tightening, sample nuts may be checked for free-running

by hand after initial loosening.

Nuts shall be assembled so that their designation markings are visible for inspection after assembly.

5.3 Washers

Washers shall be used under both the bolt head and the nut.

For preloaded bolts, used washer shall be chamfered according to EN 14399-6.

Washer used under head shall be positioned with the chamfer towards the bolt head.

Washer used under nuts shall be positioned with the chamfer towards the nut.

6. Tightening of preloaded bolts: HV system.

References:

- EN 1993-1-8, 3.4: Categories of bolted connections.

- EN 1090-2, 8.5: Tightening of preloaded bolts.

Requirements concerning tightening parameters for system HV, classes K1 and K0, are described hereafter.

6.1 Nominal minimum preloading force

Unless otherwise specified, the nominal minimum preloading force,

,

, shall be taken as:

,

0,7

In the case when a lower level of preload is specified, the bolt assemblies, the tightening method, the

tightening parameters and the inspection requirements shall also be specified.

6.2 Tightening method, class K1

Assemblies according to HV system, class K1, combined tightening method (initial torque + angle) is

required.

- Combined method (initial torque + angle)

Tightening by the combined method comprises two steps: first applying a specified initial torque, and then

applying a proper rotation to the turned part of the assembly:

1 - Initial torque

to tighten, using a torque wrench offering a suitable range (capable of an accuracy of 4%,

according to EN ISO 6789), up to a value of the initial torque of about

0,75

,

This first step shall be completed for all bolts in one connections before starting the second step.

The torque reference values,

,

, to be used for a nominal minimum preloading force,

,

, based

on k-class K1 declared by Agrati, according to the standards EN 14399, are determined using this

equation:

,

with

= factor included in the prescribed limits for k-class K1 (0,10

0,16).

For simplification, unless otherwise specified, this value of

,

could be considered:

,

0,13

,

The values of nominal minimum preloading force,

,

, and reference value for the initial

tightening torque,

,

, are shown in Table 1.

1 2 3

Thread

Nominal

minimum

preloading force,

,

[kN]

Initial tightening

torque,

0,75

,

[Nm],

for

= 0,13

M12 59 69

M16 110 171

M20 172 334

M22 212 455

M24 247 578

M27 321 846

M30 393 1149

M36 572 2007

Table 1: combined method. Initial tightening torque values.

2 - angle

to rotate the turned part of the assembly (the nut, excluding exceptions that require special

precautions) of an angle specified in Table 2. The final rotation of the nut relative to the bolt thread

shall be easily determined at the end of the tightening, using, for example, a marking crayon or a

marking paint.

Clamp length t

d = nominal thread diameter

Further rotation to be applied, during the

second step of tightening

Degrees Part turn

t < 2d 60 1/6

2d t < 6d 90 1/4

6d t < 10d 90 1/4

NOTE: where the surface under bolt head or nut is not perpendicular to the bolt axis, the required

angle should be determined by testing.

Table 2: Combined method. Further rotation.

Note

For the family of clamping lengths 6d t < 10d, the rotation angle, shown in table 2, has been

reduced compared to the value recommended by EN 1090-2.

This new definition, permitted by EN 1090-2 ( 8.5.4), allows an additional safety margin against

the failure of the joint, while ensuring the minimum nominal preload required by the harmonized

standards.

(An alternative method for the calibration of high strength structural bolting assembly for preloading is

indicated in the Annex H of the standard EN 1090-2:2008.)

6.3 Tightening method, class K0

Several methods of tightening, subjected to the utilization of appropriate systems of measurement (direct or

indirect) of the preload, could be used.

Minimum preload values are shown in table 1, column 2.

Tightening methods (procedures and measuring system) should be defined and developed every time.

7. Inspections and testing of preloading bolted connections

Reference: EN 1090-2, chapter 12.5.2: Inspection and testing of preloaded bolted connections.

7.1 Before tightening

All connections with preloaded mechanical fasteners shall be visually checked after they are initially bolted

up with the structure aligned locally and before starting the preloading.

If chamfered washers are installed, they shall be visually checked to ensure that, during assembly, their

positioning is correct (ref. 5.3 of this document).

The torque wrench used in the first step of the combined method shall be correctly calibrated: the tool

calibration certification shall be checked yearly and its accuracy shall be 4%, according to EN ISO 6789.

7.2 During and after tightening

General requirements for the inspection of the correct tightening of the assemblies:

a) inspection of installed fasteners and/or method of installation shall be undertaken depending on the

tightening method used. The location selected shall be on a random basis ensuring that the sampling

covers the following variables as appropriate:

- connection type;

- bolt group;

- fastener lot;

- components type and size;

- equipment used;

- operatives.

b) for the purposes of the inspection, a "bolt group" is defined as bolt assemblies of the same origin, in

similar connections, with the bolt assemblies of the same size and class. A large bolt group may be

subdivided into a number of subgroups for inspection purposes.

c) the pre-tightening step shall be checked by visual inspection of connection to ensure they are fully

packed. Under-tightening conditions shall also be checked.

d) for final tightening inspection, the same bolt assembly shall be used for checking both under-

tightening and, if specified, over-tightening.

e) if the inspection leads to a rejection, all the bolting assemblies in the bolt subgroup shall be checked

and corrective actions shall be taken.

If fasteners are not applied in accordance with the method defined in standard EN 1090-2 and by Agrati, the

removal and the replacement of the whole bolt group shall be witnessed.

The criteria that define the non-compliance and the corrective actions that shall be taken in case of

tightening by combined method are specified below.

7.2.1 Inspection of tightening by the combined method

Both steps of combined method (torque and angle) shall be checked during the assembling on the structure.

If the connections are not fully packed, the calibrations of the torque wrenches in combination with the

applied loads shall be controlled by supplementary test to achieve the correct initial pre-tightening load. If

necessary, the first step has to be repeated with the corrected torque values.

Before starting the second step, the marking of all the nuts relative to the bolts threads shall be visually

inspected. Any mark missing shall be corrected.

After the second step, the marks shall be inspected with the following requirements:

a) if the rotation angle is more than 15 below the specified value, this angle shall be corrected;

b) if the rotation angle is more than 30 over the specified angle, or the bolt or the nut has failed, the

bolt assembly shall be replaced by new one.

A complete overview of inspections that shall been carried out during tightening by combined method is

shown in the chapter 12.5.2.5 of the standard EN 1090-2.

8. Recommendations

Functional characteristics, especially those influenced by the lubricant performance, may change if:

- the components of the assembly are left exposed to weathering in the construction site awaiting the

mounting;

- the components, during storage or transport, are subjected to surface damage or permanent

deformations.

Tightening performances defined by K1 class are guaranteed only if:

- components in compliance with EN 14399, supplied by Agrati, are used;

- all components have the same coating;

- the lubrication of bolts, nuts and washers is not modified;

- tightening is executed by the rotation of the nut;

- assembly components are tightened only one time (components shall not be re-used).

- used assemblies are drawn directly from the individual packages and all the expedient to avoid the

mixing of lots have to be carried out.

In the case of manipulation of supply conditions and non compliance with the operative instructions, any

complaints will be dismissed.

Annex A - Prescribed clamp lengths

Diameter of thread M12 M16 M20 M22 M24 M27 M30 M36*

Nominal length l HV assemblies - Clamping length t

35 16-21

40 21-26 17-22

45 26-31 22-27 18-23

50 31-36 27-32 23-28 22-27

55 36-41 32-37 28-33 27-32

60 41-46 37-42 33-38 32-37 29-34

65 46-51 42-47 38-43 37-42 34-39

70 51-56 47-52 43-48 42-47 39-44 36-41

75 56-61 52-57 48-53 47-52 44-49 41-46 39-44

80 61-66 57-62 53-58 52-57 49-54 46-51 44-49

85 66-71 62-67 58-63 57-62 54-59 51-56 49-54 43-48

90 71-76 67-72 63-68 62-67 59-64 56-61 54-59 48-53

95 76-81 72-77 68-73 67-72 64-69 61-66 59-64 53-58

100

77-82 73-78 72-77 69-74 66-71 64-69 58-63

105 82-87 78-83 77-82 74-79 71-76 69-74 63-68

110 87-92 83-88 82-87 79-84 76-81 74-79 68-73

115 92-97 88-93 87-92 84-89 81-86 79-84 73-78

120 97-102 93-98 92-97 89-94 86-91 84-89 78-83

125 102-107 98-103 97-102 94-99 91-96 89-94 83-88

130 107-112 103-108 102-107 99-104 96-101 94-99 88-93

135

108-113 107-112 104-109 101-106 99-104 93-98

140 113-118 112-117 109-114 106-111 104-109 98-103

145 118-123 117-122 114-119 111-116 109-114 103-108

150 123-128 122-127 119-124 116-121 114-119 108-113

155 128-133 127-132 124-129 121-126 119-124 113-118

160

132-137 129-134 126-131 124-129 118-123

165 137-142 134.139 131-136 129-134 123-128

170

139-144 136-141 134.139 128-133

175 144-149 141-146 139-144 133-138

180 149-154 146-151 144-149 138-143

185 154-159 151-156 149-154 143-148

190 159-164 156-161 154-159 148-153

195 164-169 161-166 159-164 153-158

200

166-171 164-169 158-163

*only on request

Potrebbero piacerti anche

- EN14399-HS Bolted Assemblies For PreloadingDocumento8 pagineEN14399-HS Bolted Assemblies For Preloadinggabimaier31Nessuna valutazione finora

- Assembly and Tensioning of High Strength Bolts andDocumento14 pagineAssembly and Tensioning of High Strength Bolts andKirtichandraKomarrajuNessuna valutazione finora

- International StandardDocumento6 pagineInternational Standardmurat arda KOCACİĞERNessuna valutazione finora

- Data Sheet HV-HR ItDocumento3 pagineData Sheet HV-HR ItKemo TufoNessuna valutazione finora

- Is 1367 Part 8Documento24 pagineIs 1367 Part 8Otavio1230% (2)

- CJ Generalrequirementsfor Vibratorsformassconcreting, ImmersiontypeDocumento5 pagineCJ Generalrequirementsfor Vibratorsformassconcreting, ImmersiontypeRahul ChaudharyNessuna valutazione finora

- ETAG001 Part3Documento13 pagineETAG001 Part3Serban RaduNessuna valutazione finora

- Iso 898 7 1992Documento8 pagineIso 898 7 1992Quality & EngineeringNessuna valutazione finora

- TCB Installation Booklet HRCDocumento11 pagineTCB Installation Booklet HRCAlexandre FonsecaNessuna valutazione finora

- IJCRT2305283Documento6 pagineIJCRT2305283rrpatil1221Nessuna valutazione finora

- Trunnion Support ClampDocumento10 pagineTrunnion Support ClampMosa Elnaid ElnaidNessuna valutazione finora

- Technical Manual Anchor Mooring Winch AMW 111-E-44-U3 Dwg. 34729-1 (PS-SB) DMT 219138Documento145 pagineTechnical Manual Anchor Mooring Winch AMW 111-E-44-U3 Dwg. 34729-1 (PS-SB) DMT 219138Ciprian MariusNessuna valutazione finora

- Cut82hr Manual Parts (Cr9b-) 130712siDocumento43 pagineCut82hr Manual Parts (Cr9b-) 130712si2222222222222-242735Nessuna valutazione finora

- ETAG No 001: Edition July 1998Documento18 pagineETAG No 001: Edition July 1998GnabBangNessuna valutazione finora

- Assignment 1 (Unit 1 and 2)Documento5 pagineAssignment 1 (Unit 1 and 2)Atharva ChoudhariNessuna valutazione finora

- Assembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62Documento12 pagineAssembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62rajuajiNessuna valutazione finora

- Inplant Training ReportDocumento56 pagineInplant Training Reportsankey11286Nessuna valutazione finora

- International StandardDocumento6 pagineInternational Standardsagadevan100% (1)

- TCB Installation BookletDocumento12 pagineTCB Installation BookletAsherNessuna valutazione finora

- Informe - Diseño de EjeDocumento12 pagineInforme - Diseño de EjeCristian ArizaNessuna valutazione finora

- ISO 898-6-1994, OCR Mechanical Properties of Fasteners-2nd EdDocumento12 pagineISO 898-6-1994, OCR Mechanical Properties of Fasteners-2nd EdRenatoGolinNessuna valutazione finora

- IGS-M-PL-027 (0) 1388 : ApprovedDocumento9 pagineIGS-M-PL-027 (0) 1388 : ApprovedMamadNessuna valutazione finora

- Bolt Torq 0309Documento3 pagineBolt Torq 0309jakkakiransNessuna valutazione finora

- GMW16215 PDFDocumento7 pagineGMW16215 PDFJuanPeriquitanNessuna valutazione finora

- Technical Manual Mooring Winch Type MW 022-44c-E117 (KN) Dwg. 32164-1 DMT 219138Documento119 pagineTechnical Manual Mooring Winch Type MW 022-44c-E117 (KN) Dwg. 32164-1 DMT 219138Ciprian MariusNessuna valutazione finora

- 36-68-07 Machined End Tolerances For Drum Nozzles& Nipples, Header, Pipe, FittingsDocumento4 pagine36-68-07 Machined End Tolerances For Drum Nozzles& Nipples, Header, Pipe, FittingsJKKNessuna valutazione finora

- Registro Italiano Navale Rules For Classification of Ship, January 2016Documento6 pagineRegistro Italiano Navale Rules For Classification of Ship, January 2016David MestanzaNessuna valutazione finora

- DLD2 User ManualDocumento10 pagineDLD2 User ManualTechnical OfficeNessuna valutazione finora

- Bs en 14399 Parts 1 To 8Documento7 pagineBs en 14399 Parts 1 To 8ramonyk_003558100% (1)

- 1 25MWDocumento33 pagine1 25MWmadivala nagarajaNessuna valutazione finora

- Rebar Coupler Test StandartDocumento6 pagineRebar Coupler Test StandartSaurav KumarNessuna valutazione finora

- ETAG 001 Part5-Amendment-080201 PDFDocumento34 pagineETAG 001 Part5-Amendment-080201 PDFanon_484117881Nessuna valutazione finora

- ESS Katalog 5 enDocumento10 pagineESS Katalog 5 enANKUSH PARMARNessuna valutazione finora

- Is 12943 Brass Cable GlandsDocumento10 pagineIs 12943 Brass Cable Glandsnirbhay111Nessuna valutazione finora

- 22Documento4 pagine22Dasith SithiraNessuna valutazione finora

- Ferrometal Steel Construction FastenersDocumento48 pagineFerrometal Steel Construction FastenersMilos VukobratNessuna valutazione finora

- Acoplamientos para EjesDocumento15 pagineAcoplamientos para EjesCapacitacion TodocatNessuna valutazione finora

- Installation Manual For Level Control Diaphragm: AddressDocumento11 pagineInstallation Manual For Level Control Diaphragm: AddresspredilettoNessuna valutazione finora

- ESA BAT 0113 Gasket Tightness 3 New EU Standards PDFDocumento2 pagineESA BAT 0113 Gasket Tightness 3 New EU Standards PDFJosmar CristelloNessuna valutazione finora

- Accouplement MecDocumento19 pagineAccouplement MecAli Ben Belgacem MahroukNessuna valutazione finora

- Din 1480 2005Documento6 pagineDin 1480 2005PacoNessuna valutazione finora

- Repair Procedures: Connection Field Repair (Refacing)Documento5 pagineRepair Procedures: Connection Field Repair (Refacing)islam atif100% (1)

- Cabl RealDocumento48 pagineCabl RealMohamed HarbNessuna valutazione finora

- Turbine Eoliene Cu Ax VerticalDocumento15 pagineTurbine Eoliene Cu Ax Verticalmihaela_bobe4555Nessuna valutazione finora

- Bba Certificate MBT Couplers Dec 2005Documento8 pagineBba Certificate MBT Couplers Dec 2005belu diazNessuna valutazione finora

- Oil Free Bushings - Technical InformationDocumento1 paginaOil Free Bushings - Technical InformationStedzavayNessuna valutazione finora

- Iksrfuekz.K Fo - QR Osfymm LVM JFGR, Adj Tathjsa RFKK La KSTH Lkadysa Fof'Kf"VDocumento13 pagineIksrfuekz.K Fo - QR Osfymm LVM JFGR, Adj Tathjsa RFKK La KSTH Lkadysa Fof'Kf"VAhmed HossamNessuna valutazione finora

- Code For Design and Construction For High Strenght BoltDocumento33 pagineCode For Design and Construction For High Strenght BoltTimothy HancockNessuna valutazione finora

- I Nternati NAL Standard: Mechanical Properties of Faster ErsDocumento12 pagineI Nternati NAL Standard: Mechanical Properties of Faster ErsAhmed Hamed ElezabyNessuna valutazione finora

- Dlt 5130-2001 架空送电线路钢管杆设计技术规范 - enDocumento28 pagineDlt 5130-2001 架空送电线路钢管杆设计技术规范 - enguicheng liNessuna valutazione finora

- Av@kii% - : dk7 @i!wlDocumento15 pagineAv@kii% - : dk7 @i!wlDeepak RaturiNessuna valutazione finora

- Wind Turbine Manual English PDFDocumento34 pagineWind Turbine Manual English PDFYasminAngelRojasNessuna valutazione finora

- Toaz - Info Api 617 PRDocumento7 pagineToaz - Info Api 617 PRCường LêNessuna valutazione finora

- Eti Ohe 11 5 89Documento12 pagineEti Ohe 11 5 89Abhishek PandeyNessuna valutazione finora

- Enhance Draw Gear and CuplingDocumento8 pagineEnhance Draw Gear and Cuplinganunay kumarNessuna valutazione finora

- Machine Design Elements and AssembliesDa EverandMachine Design Elements and AssembliesValutazione: 3.5 su 5 stelle3.5/5 (2)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeDa EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeValutazione: 4 su 5 stelle4/5 (9)

- 504H0015 (GS-0015) - Initial Sample Inspection ReportDocumento5 pagine504H0015 (GS-0015) - Initial Sample Inspection ReportsamNessuna valutazione finora

- Satip J 903 01Documento10 pagineSatip J 903 01javed iqbalNessuna valutazione finora

- SAIC-P-3301 Rev 4Documento2 pagineSAIC-P-3301 Rev 4sikandar1234Nessuna valutazione finora

- Cnca C11-09-2014Documento12 pagineCnca C11-09-2014raybchNessuna valutazione finora

- Offshore ContainersDocumento40 pagineOffshore ContainerssalahjallaliNessuna valutazione finora

- S-92 Helicopter: Alert Service BulletinDocumento10 pagineS-92 Helicopter: Alert Service BulletinyiuseppeNessuna valutazione finora

- X Rray Yxlon - Mu2000Documento6 pagineX Rray Yxlon - Mu2000ycchangNessuna valutazione finora

- Mani Store KeeperDocumento3 pagineMani Store KeeperManikandan VpNessuna valutazione finora

- Shaft BBT Installation: Method Statement - 002Documento39 pagineShaft BBT Installation: Method Statement - 002Sufiyan KhedekarNessuna valutazione finora

- PCPA Report-Large Roof Lamp With LEDDocumento3 paginePCPA Report-Large Roof Lamp With LEDawdhut kulkarniNessuna valutazione finora

- Curriculum Vitae: RoustaboutDocumento4 pagineCurriculum Vitae: RoustaboutmaharajanrajanNessuna valutazione finora

- CV Faisal ZAFAR SHAHIDDocumento6 pagineCV Faisal ZAFAR SHAHIDAlam MD SazidNessuna valutazione finora

- ITP Installation of Containments QC REV 2Documento4 pagineITP Installation of Containments QC REV 2irfan vpNessuna valutazione finora

- Naukri RohinLohat (10y 0m) PDFDocumento5 pagineNaukri RohinLohat (10y 0m) PDFayesha siddiqui0% (1)

- 05 Cocu 3 PDFDocumento10 pagine05 Cocu 3 PDFazmanNessuna valutazione finora

- SAFed TC 4 Welding Procedure and Welder Approval Testing 21 Mar 2019 PDFDocumento24 pagineSAFed TC 4 Welding Procedure and Welder Approval Testing 21 Mar 2019 PDFFirdaus NasirNessuna valutazione finora

- Acoustic Emission Testing For Corrosion Monitoring and Deferral of Storage Tank TurnaroundsDocumento9 pagineAcoustic Emission Testing For Corrosion Monitoring and Deferral of Storage Tank TurnaroundsAlzaki AbdullahNessuna valutazione finora

- Nitrogen Tank SM1 Checklist - Controlled PDFDocumento3 pagineNitrogen Tank SM1 Checklist - Controlled PDFMaxim Kanibetov0% (1)

- Terms of Reference ExampleDocumento9 pagineTerms of Reference ExampleVladimir John MacapugayNessuna valutazione finora

- Fabric Defects and Point Grading SystemDocumento32 pagineFabric Defects and Point Grading SystemAnkit Chandorkar100% (7)

- PDCA - Appendix CDocumento20 paginePDCA - Appendix CsamebcNessuna valutazione finora

- Certificates of Competency in The Merchant Navy - Marine Engineer OfficerDocumento4 pagineCertificates of Competency in The Merchant Navy - Marine Engineer OfficersumitNessuna valutazione finora

- Tower Light Almeer 101Documento2 pagineTower Light Almeer 101groshan20Nessuna valutazione finora

- Unit 3, Part 2 - Software Quality AssuranceDocumento19 pagineUnit 3, Part 2 - Software Quality Assurancesanjeewani wimalarathneNessuna valutazione finora

- Adeleke ComfortDocumento17 pagineAdeleke Comfortsheidu ayodeleNessuna valutazione finora

- ITP - Fencing and Gates Installation Works - MAB1Documento24 pagineITP - Fencing and Gates Installation Works - MAB1Vasilica Barbarasa100% (2)

- Quality Manual ISO 9001 2015Documento42 pagineQuality Manual ISO 9001 2015Suresh Kumar100% (6)

- DL Automotive ApplicationsDocumento12 pagineDL Automotive ApplicationsDương TrầnNessuna valutazione finora

- T-4.820.471 - C01 - MS & ITP For Refractory WorkDocumento21 pagineT-4.820.471 - C01 - MS & ITP For Refractory Workshahid imam100% (2)

- Oracle WMS SetupDocumento127 pagineOracle WMS SetupmobakNessuna valutazione finora