Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cavitation - An Introduction

Caricato da

Paijo TejoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cavitation - An Introduction

Caricato da

Paijo TejoCopyright:

Formati disponibili

4/14/13

Cavitation - an Introduction

Resources, Tools and Basic Information for Engineering and Design of Technical Applications!

Ads by Google

Flow Measurement

Water Pump Cost

Centrifugal Pump

Search

Home

Share

Recommend

Custom Search

Cavitation

Share this on Google+

Tw eet

Acoustics

Air Psychrometrics

Basics

Combustion

Drawing Tools

Sponsored Links

Cavitation - an Introduction

Cavitation may occur in fluid flow systems where local static pressure is below the vapor

pressure

Sponsored Links

Dynamics

Economics

Temperature Calibration

Electrical

www.flukecal.com

Environment

Fluid Mechanics

Fluke Provides a Wide Range of Temperature Calibrators Get a Demo!

Gas and Compressed Air

HVAC Systems

Hydraulics and

Pneumatics

Insulation

Material Properties

Mathematics

Mechanics

Miscellaneous

Physiology

Piping Systems

Process Control

Pumps

Standards Organizations

Steam and Condensate

Thermodynamics

Water Systems

Ads by Google

Introduction

Fluid Pumps

Pump Part

Convert Units

Temperature

0

oC

oF

Convert!

Length

1

m

km

in

ft

yards

miles

nautical miles

Convert!

Volume

1

m3

liters

in3

Cavitation is a common problem in pumps and control valves - causing serious wear and tear and damage. Under

the wrong conditions, cavitation reduces the component life time dramatically.

What is Cavitation?

Cavitation may occur when the local static pressure in a fluid reach a level below the vapor pressure of the liquid

at the actual temperature.

According to the Bernoulli Equation this may happen when the fluid accelerates in a control valve or around a

pump impeller.

The vaporization itself does not cause the damage - the damage happens when the vapor almost immediately

collapses after evaporation when the velocity is decreased and pressure increased.

Water & Air

Flowmeters

www.erdco.com

Rotameter, Turbine &

Thermal types for

process, environmental

& OEM's!

Stainless Steel

Materials

www.chiafar.com

We Provide High Quality

Stainless Steel

Materials. Welcome To

Us!

Vertical Turbine

Pumps

www.kkpumps.com

Manufacturer:Pumps &

RA gear drive, Process

Pumps. ISO 9001:2008

Hydro Power

Consultants

www.scg-india.com

DPR, Feasibility Study,

Detailed Engineering,

Buy/sell Projects

Avoiding Cavitation

Cavitation can in general be avoided by

increasing the distance between the actual local static pressure in the fluid - and the vapor pressure of the

fluid at the actual temperature

This can be done by:

reengineering components initiating high speed velocities and low static pressures

increasing the total or local static pressure in the system

reducing the temperature of the fluid

Reengineering of Components Initiating High Speed Velocity and Low Static Pressure

Cavitation and damage can be avoided by using special components designed for the actual rough conditions.

conditions as huge pressure drops can - with limitations - be handled by Multi Stage Control Valves

challenging pumping conditions - with fluid temperatures close to the vaporization temperature - can be

handled with special pumps - working after other principles than centrifugal pumps

Cooling Water

Treatment

www.merusonline.com

Merus Rings green

solution to treat entire

cooling water systems

Free Industry

Magazines

Machinery Lubrication

Increasing the Total or Local Pressure in the System

By increasing the total or local pressure in the system the distance between the static pressure and the

vaporization pressure is increased and vaporization and cavitation can be avoided.

The ratio between static pressure and the vaporization pressure - an indication of the possibility of vaporization, is

often expressed by the Cavitation Number.

Unfortunately it may not always be possible to increase total static pressure due to systems classifications or other

limitations. Local static pressure in components may be increased by lowering the component in the system.

Control valves and pumps should in general be positioned in the lowest part of the systems to maximize static

head.

Asia Electronics

Industry

This is common solution for boiler feeding pumps receiving hot condensate (water close to 100 oC) from

condensate receivers.

Reducing the Temperature of the Fluid

The vaporization pressure depends of fluid temperature. Vapor pressure of Water, our most common fluid, is

indicated below:

ft3

us gal

Convert!

Velocity

1

m/s

km/h

ft/min

ft/s

mph

knots

Convert!

www.engineeringtoolbox.com/cavitation-d_407.html

Temperature

(oC)

0

5

10

15

20

25

30

35

40

45

Vapor Pressure

(kN/m2)

0.6

0.9

1.2

1.7

2.3

3.2

4.3

5.6

7.7

9.6

World Industrial

Reporter

Engineering

Standards

1/2

4/14/13

Cavitation - an Introduction

Pa (N/m 2 )

50

55

60

b ar

65

25

mm H2 O

70

32.1

kg/cm 2

psi

75

80

38.6

47.5

inches H2 O

85

57.8

Pressure

90

Flow

1

m 3 /h

US gpm

cfm

Convert!

70

95

100

Convert!

m 3 /s

12.5

15.7

20

84.5

101.33

Note! - the possibility of evaporation and cavitation increases dramatically with the water temperature.

Cavitation can also be avoided by locating components to the coldest part of a system. It is common to locate

pumps in heating systems in the "cold" return lines.

This is the same for control valves. If it is possible control valves should be located on the cold sides of heat

exchangers.

Sponsored Links

Free Industry

Magazines

Davey 5255H firefighter

www.qualitypumps.com.au

Machinery Lubrication

Honda 5.5HP twin imp' 350 lpm. 3yr engine - 2yr pump wty. $850

Search the Engineering ToolBox

Search

Custom Search

Related Topics

Asia Electronics

Industry

Fluid Mechanics - The study of fluids - liquids and gases. Involves various properties of the fluid, such as

velocity, pressure, density and temperature, as functions of space and time.

Pumps - Piping systems and pumps - centrifugal pumps, displacement pumps - cavitation, viscosity, head

and pressure, power consumption and more

Related Documents

World Industrial

Reporter

Boiling Fluids - Recommended Suction Flow Velocity - Recommended flow velocity for the pump suction

side

Cavitations Number - An introduction to and a definition of the Cavitations Number

Condensate Pumping - High temperatures and danger of impeller cavitation is the major challenge of

condensate pumping

Control Valves and Cavitation - Control valves and cavitation, application ratio and multi stage control

valves

Feeding Pumps - the Suction Lift in Steam Systems - The danger of impeller cavitations increases with

water temperature

Light Oils - Recommended Suction Flow Velocity - Recommended flow velocity for the pump suction side

Suction Flow Velocities of Water - Recommended water flow velocity on suction side of pump

Engineering ToolBox - SketchUp Edition - Online 3D modeling!

Engineering

Standards

Engineering ToolBox - SketchUp Edition - enabled for use with the amazing, fun and free Google SketchUp

Translate the ToolBox

Arabic - Chinese (Simplified) - Chinese (Traditional) - Dutch - French - German - Italian - Japanese - Korean Portuguese - Russian - Spanish - - Select Your own language . .

About the ToolBox

We appreciate any comments and tips on how to make The Engineering ToolBox a better information source.

Please contact us by email

editor.engineeringtoolbox@gmail.com

if You find any faults, inaccuracies, or otherwise unacceptable information.

The content in The Engineering ToolBox is copyrighted but can be used with NO WARRANTY or LIABILITY.

Important information should always be double checked with alternative sources. All applicable national and local

regulations and practices concerning this aspects must be strictly followed and adhered to.

Advertise in the ToolBox

If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords.

www.engineeringtoolbox.com/cavitation-d_407.html

2/2

Potrebbero piacerti anche

- DD DNV Gardu PLN Alt1 ModelDocumento1 paginaDD DNV Gardu PLN Alt1 ModelPaijo TejoNessuna valutazione finora

- Input EchoDocumento42 pagineInput EchoPaijo TejoNessuna valutazione finora

- T-L R, (,li U $: LrillllDocumento4 pagineT-L R, (,li U $: LrillllPaijo TejoNessuna valutazione finora

- Pages From Piusi Cube 70mc EspDocumento1 paginaPages From Piusi Cube 70mc EspPaijo TejoNessuna valutazione finora

- Coefficient of Friction,..Documento2 pagineCoefficient of Friction,..Paijo TejoNessuna valutazione finora

- ST 3000 KLiter New SettingDocumento3 pagineST 3000 KLiter New SettingPaijo TejoNessuna valutazione finora

- ICD EPC Volume 2 Final-ToCDocumento6 pagineICD EPC Volume 2 Final-ToCPaijo TejoNessuna valutazione finora

- Valve ScheduleDocumento2 pagineValve SchedulePaijo TejoNessuna valutazione finora

- LCC PumpDocumento2 pagineLCC PumpPaijo TejoNessuna valutazione finora

- ICD EPC Volume 2 FinalDocumento1 paginaICD EPC Volume 2 FinalPaijo TejoNessuna valutazione finora

- Tte033 7403 01 Filling Station DetailDocumento1 paginaTte033 7403 01 Filling Station DetailPaijo TejoNessuna valutazione finora

- Fire PumpDocumento1 paginaFire PumpPaijo TejoNessuna valutazione finora

- Water CadDocumento29 pagineWater CadPaijo TejoNessuna valutazione finora

- Form LCC PumpDocumento1 paginaForm LCC PumpPaijo TejoNessuna valutazione finora

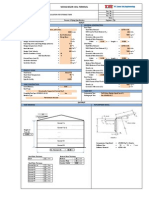

- Miang Besar Coal Terminal: Calculation For Diesel Oil Transfer PumpDocumento1 paginaMiang Besar Coal Terminal: Calculation For Diesel Oil Transfer PumpPaijo TejoNessuna valutazione finora

- Final Sum ADocumento2 pagineFinal Sum APaijo TejoNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- KT62 ManualDocumento30 pagineKT62 ManualandyjwatsonNessuna valutazione finora

- VTT R 05984 12Documento72 pagineVTT R 05984 12Soma Shekar ANessuna valutazione finora

- SOP Reach Stacker01Documento7 pagineSOP Reach Stacker01vozefjadav100% (1)

- Procurement & Distribution Logistics: Tutor: Mr. Michael KleinDocumento14 pagineProcurement & Distribution Logistics: Tutor: Mr. Michael KleinRiya OberoiNessuna valutazione finora

- Berta BlastingDocumento13 pagineBerta Blastingkandrian76100% (1)

- Addressing Some Issues in Drop Weight Testing - A Material Science ApproachDocumento16 pagineAddressing Some Issues in Drop Weight Testing - A Material Science ApproachManish BhadauriaNessuna valutazione finora

- Automated Car Jack PDFDocumento3 pagineAutomated Car Jack PDFakashlogic100% (1)

- Whirlpool Awe 6515 WDocumento41 pagineWhirlpool Awe 6515 WCoryl BlueNessuna valutazione finora

- HTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Documento4 pagineHTTP Bulletins - Wartsila.com Bulletins File WCH RTA-79 2Riddhi DasNessuna valutazione finora

- Cement PPT-BMC PDFDocumento120 pagineCement PPT-BMC PDFAdhyyan JoshiNessuna valutazione finora

- px5879 Pantex Product Weld Inspection Form (Visual) PDFDocumento2 paginepx5879 Pantex Product Weld Inspection Form (Visual) PDFbambaeeroNessuna valutazione finora

- ROHS Compliance TestingDocumento13 pagineROHS Compliance TestingVedang BhagwatNessuna valutazione finora

- Bar TrussDocumento18 pagineBar TrussJithinGeorgeNessuna valutazione finora

- Chemical Spill Response GuideDocumento7 pagineChemical Spill Response GuideDaniel BobbittNessuna valutazione finora

- 05 Fuel SystemDocumento109 pagine05 Fuel SystemUtomo BudidarmoNessuna valutazione finora

- Waste in Paper ProductionDocumento10 pagineWaste in Paper Productiongo2_sumitNessuna valutazione finora

- Sika PDS - E - Icosit KC 340-65 PDFDocumento2 pagineSika PDS - E - Icosit KC 340-65 PDFlwin_oo2435Nessuna valutazione finora

- FMDS 03 10 - Installation & Maintenance of Fire Service MainsDocumento59 pagineFMDS 03 10 - Installation & Maintenance of Fire Service MainsNazri Nawi100% (1)

- فتح Lecture 8-1Documento7 pagineفتح Lecture 8-1Ali aliraqiNessuna valutazione finora

- Synthesis of Ketamine PDFDocumento4 pagineSynthesis of Ketamine PDFJohn Haas100% (3)

- Shape Memory ShubhamDocumento11 pagineShape Memory Shubhamtimroddick24Nessuna valutazione finora

- 21 49 PlansDocumento7 pagine21 49 PlansShehab Abu AhmadNessuna valutazione finora

- BASF Process For Producing 1Documento4 pagineBASF Process For Producing 1Tasneem MNessuna valutazione finora

- High School Clay For WeeblyDocumento71 pagineHigh School Clay For Weeblyapi-293964578100% (6)

- Solar Thermal TechnologiesDocumento48 pagineSolar Thermal TechnologiesVinoth MalaikaniNessuna valutazione finora

- Cable Selection and Wiring SystemDocumento34 pagineCable Selection and Wiring SystemMuhammad Faiz bin Ahmad Shafi0% (1)

- Pakyaw RatesDocumento36 paginePakyaw RatesKesMercado100% (5)

- Grouting Work and Jet-Grouting - ENDocumento92 pagineGrouting Work and Jet-Grouting - ENLucki Yohan GunawanNessuna valutazione finora

- Mechanical Properties of Modified Low Cobalt Powder Metallurgy UDIMET 700 Type AlloysDocumento30 pagineMechanical Properties of Modified Low Cobalt Powder Metallurgy UDIMET 700 Type AlloysEnary SalernoNessuna valutazione finora

- 4 Way Reversing Valve Series SHF L Data PDFDocumento3 pagine4 Way Reversing Valve Series SHF L Data PDFDharani PathyNessuna valutazione finora