Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Instruments in Aircraft Cockpit

Caricato da

rohit2r0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

347 visualizzazioni33 pagineThe document provides an overview of Hindustan Aeronautics Limited (HAL), an Indian state-owned aerospace and defense company. It discusses HAL's history beginning in 1940, production including licensed production from countries like Russia and indigenous designs. It also outlines HAL's customers which include the Indian military as well as export customers like Airbus and Boeing. The document serves to introduce HAL and provide background information on its role in India's aerospace industry.

Descrizione originale:

Training report on all the major instruments inside an aircraft cockpit produced/overhauled in HAL ADL(accessories division lucknow)...

Titolo originale

training report on aircraft instrument systems

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document provides an overview of Hindustan Aeronautics Limited (HAL), an Indian state-owned aerospace and defense company. It discusses HAL's history beginning in 1940, production including licensed production from countries like Russia and indigenous designs. It also outlines HAL's customers which include the Indian military as well as export customers like Airbus and Boeing. The document serves to introduce HAL and provide background information on its role in India's aerospace industry.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

347 visualizzazioni33 pagineInstruments in Aircraft Cockpit

Caricato da

rohit2rThe document provides an overview of Hindustan Aeronautics Limited (HAL), an Indian state-owned aerospace and defense company. It discusses HAL's history beginning in 1940, production including licensed production from countries like Russia and indigenous designs. It also outlines HAL's customers which include the Indian military as well as export customers like Airbus and Boeing. The document serves to introduce HAL and provide background information on its role in India's aerospace industry.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 33

HINDUSTAN AERONAUTICS LIMITED

Accessories Division, Lucknow

PROJECT REPORT

ON

Instruments used in Cockpit of Aircraft

SUBMITTED TO:- SUBMITTED BY:-

Mr. S.P. Singh VARUN MISHRA,

Sr. Manager (Trg.) Branch- E.C.E

(HAL-ADL)

ACKNOWLEDGEMENT

I am very thankful to everyone who all supported me, for i have

completed my project effectively and moreover on time.

I would like to express my special thanks of gratitude to my teachers who

given the valuable knowledge at HAL-ADL training center as well as

Manager Mr. S.P. Singh who gave me the golden opportunity to do this

wonderful project on the topic Instruments used in Cockpit of Aircrafts,

which also helped me in doing a lot of Research and i came to know

about so many new things.

Last but not the least, I would like to thank my parents who helped me a

lot in gathering different information, collecting data and guiding me

from time to time in making this project .despite of their busy schedules

,they gave me different ideas in making this project unique.

I am making this project not only for professional academics but to also

increase my knowledge.

Content

Introduction.

History.

Evolution of H.A.L.

Production

Licensed production

Indigenous production

Costumers & Services.

Divisions.

Introduction to HAL ADL

Products by HAL - ADL

Factories in HAL ADL

Mechanical System factory.

Fuel System Factory.

Instrument/Electrical System Factory.

Cockpit Instruments

Barometric Instruments.

Gyroscopic Instruments.

Fuel Measurement.

Conclusion

Bibliography

Introduction

H.A.L. one of the most significant and prestigious aeronautical and its accessories

company from the country of varied culture and traditions, INDIA. As H.A.L. acronym

for Hindustan Aeronautics Limited. And having Sales Turnover of Rs.14,204 crores

during the Financial Year 2011-12. The Profit of the Company (Profit Before Tax)

soared to Rs.3,329 crores.

H.A.L. has is registered office based in Bangalore, India, is one of Asia's largest

aerospace companies. Under the management of the Indian Ministry of Defence, this

state-owned company is mainly involved in aerospace industry, which includes

manufacturing and assembling aircraft, navigation and related communication

equipment, as well as operating airports.

H.A.L. built the first military aircraft in South Asia and is currently involved in the

design, fabrication and assembly of aircraft, jet engines, and helicopters, as well as

their components and spares. It has several facilities spread across several states in

India including Nasik, Korwa, Kanpur, Koraput, Lucknow, Bangalore and Hyderabad.

H.A.L. made and assembled many types of fighter aircrafts, helicopters, civil aviation

aircrafts, etc. like Sukhoi (SU 30-MKI), Jaguar, Kirat, Cheetah, Tejas(L.C.A.), MiG Series

Aircrafts, Mirage 2000, etc. under licensed and indigenous production both.

Today, HAL has 19 Production Units and 10 Research & Design Centers in 8 locations

in India. The Company has an impressive product track record - 15 types of

Aircraft/Helicopters manufactured with in-house R & D and 14 types produced under

license. HAL has manufactured over 3658 Aircraft/Helicopters, 4178 Engines,

Upgraded 272 Aircraft and overhauled over 9643 Aircraft and 29775 Engines.

History

HAL was established as Hindustan Aircraft in Bangalore in 1940 by Seth Walchand

Hirachand to produce military aircraft for the Royal Indian Air Force. The initiative

was actively encouraged by the Kingdom of Mysore, especially by the Diwan, Sir

Mirza Ismail and it also had financial help from the Indian Government. Mysore was

favored because of the availability of cheap electricity.

[2]

The organization and

equipment for the factory at Bangalore was set up by William D. Pawley of the

Intercontinental Aircraft Corporation of New York, an exporter of American aircraft to

the region. Pawley managed to obtain a large number of machine-tools and

equipment from the United States.

The Indian Government bought a one-third stake in the company and by April 1941

as it believed this to be a strategic imperative. The decision by the government was

primarily motivated to boost British military hardware supplies in Asia to counter the

increasing threat posed by Imperial Japan during Second World War. The Kingdom of

Mysore supplied two directors, Air Marshal John Higgins was resident director. The

first aircraft built was a Harlow PC-5

[3]

On 2 April 1942, the government announced

that the company had been nationalized when it had bought out the stakes of Seth

Walchand Hirachand and other promoters so that it could act freely. The Mysore

Kingdom refused to sell its stake in the company but yielded the management

control over to the Indian Government.

Hindustan Aeronautics Limited (HAL) was formed on 1 October 1964 when Hindustan

Aircraft Limited joined the consortium formed in June by the IAF Aircraft

Manufacturing Depot, Kanpur (at the time manufacturing HS.748 under license) and

the group recently set up to manufacture Mig-21 under license (with its new factories

planned in Koraput, Nasik and Hyderabad).

[4]

Though HAL was not used actively for

developing newer models of fighter jets, the company has played a crucial role in

modernization of the Indian Air Force. In 1957 company started manufacturing Bristol

Siddeley Orpheus jet engines under license at new factory located in Bangalore.

During the 1980s, HAL's operations saw a rapid increase which resulted in the

development of new indigenous aircraft such as HAL Tejas and HAL Dhruv. HAL also

developed an advanced version of the MiG-21, known as MiG-21 Bison, which

increased its life-span by more than 20 years. HAL has also obtained several multi-

million dollar contracts from leading international aerospace firms such as Airbus,

Boeing and Honeywell to manufacture aircraft spare parts and engines.

By 2012, HAL was reportedly been bogged down in the details of production and has

been slipping on its schedules.

Production

Licensed Production

Under licensed production India and H.A.L. withdrawn many designs from different countries

like:-

Sukhoi (SU 30-MKI) , MiG variant aircrafts from Russia,

SUKHOI (SU 30-MKI)

Twin - seater, Multi-role, Long range Fighter / Bomber / Air Superiority Aircraft.

MIG 27 M

Single - seater Tactical Fighter / Bomber with variable sweep wings.

MIG 21

Single - seater Front line Tactical Interceptor / Fighter Aircraft.

Jaguar and Hawk Advance Jet Trainer from western origins

Jaguar

single-seat, swept-wing, Rolls-Royce Adour Turbofan twin-engine.

Hawk Advance Jet Trainer

Two-man tandem cockpit, a low-mounted cantilever wing, single turbofan engine

Other licensed aircraft and engines production

Harlow PC-5 first aircraft assembled by HAL

Percival Prentice 66 built by HAL

Folland Gnat

HAL Ajeet improved version of the Folland Gnat

Mikoyan-Gurevich MiG-27 M variant

SEPECAT Jaguar IS, IB and IM variants

Dornier Do 228 Also providing equipment for production of the upgraded

Mirage 2000 (france)

Aerospatiale SA 315B Lama HAL Cheetah, Lancer, Cheetal Variants

Aerospatiale SA 316B Alouette III HAL Chetak, Chetan Variants

HAL HS 748 Avro Modified for military usage, includes Series 2M variant

with large freight door

Rolls-Royce Turbomeca Adour Mk 811 Engine for SEPECAT Jaguar

Rolls-Royce Turbomeca Adour Mk 871 Engine for BAE Hawk Mk 132

Garrett TPE331-5 Engine for Dornier Do 228

Turbomeca TM 333 Engine for HAL Dhruv

Indigenous Production

HF 24 MARUT

Indias First fighter aircraft

IJT HAL(HJT-36 SITARA)

HAL BASANT(agri-utility aircraft)

Light Combat Aircraft(HAL TEJAS)

Light Combat Helicopter

HAL dhruv

Other types of Production indigenously

Engines

GTRE GTX-35VS Kaveri- Co-developed with GTRE (DRDO)(under development)

PTAE-7- For indigenously designed Lakshya PTA

GTSU-110 - For starting main engine GE404 or Kaveri of LCA Tejas

HAL/Turbomeca Shakti - Co-developed with Turbomeca for HAL Dhruv Helicopter

Gliders

HAL G-1 - HAL's first original design, dating from 1941. Only one was built.

Ardhra training glider

Rohini

Transport Aircrafts

Saras under joint development with the National Aerospace Laboratories (NAL)

HAL Multirole Transport Aircraft under joint-development with Ilyushin Design

Bureau

Indian Regional Jet (IRJ) of 70-100 seater capacity to be jointly developed with

NAL.

Costumers And Sister Concerns

Sister Concerns

Indian Space Research Organization

Central Aircraft Manufacturing Company

National Aerospace Laboratories

Defense Research and Development Organization

Aeronautical Development Agency

Directorate General Aeronautical Quality Assurance

Directorate General of Civil Aviation

Customers

DOMESTIC

DEFENCE & SPACE:

Indian Air Force

Indian Army

Indian Navy

Indian Coast Guard

Ordnance Factory Board

Border Security Force

CIVIL

Oil & Natural Gas Cooperation of India

Geological Survey of India

Bharat Heavy Electricals Ltd.

EXPORTS:

Airbus Industrie, France

Boeing, USA

Coast Guard, Mauritius

Ecuadorian Air Force, Ecuador

ELTA, Israel

GE Aviation, USA

Hamilton Sundstrand, USA

Honeywell International, USA

Israel Aircraft Industries, Israel

Mauritius Police Force, Mauritius

Moog Inc. USA

Namibian Air Force, Namibia

Nepal Army, Nepal

RAC MIG, Russia

Rolls Royce Plc, UK

Royal Air Force, Oman

Royal Malaysian Air Force, Malaysia

Royal Thai Air Force, Thailand

Ruag, Germany

Rosoboron export, Russia

Divisions

Research & Design Centers

Aircraft Research and Design Center, Bangalore

Rotatory Wing Research and Design Center, Bangalore

Aircraft Upgrade Research and Design Center, Nasik

Transport Aircraft Research and Design Center, Kanpur

Mission and Combat System Research and Design Center, Bangalore

Engine and Test bed Research and Design Center, Bangalore

Strategic Electronics Research and Design Center, Hyderabad

Aerospace Systems & Equipments Research & Design Center, Lucknow

Gas Turbine Research and Design Center

Central Materials & Processes Laboratory & NDT ,Bangalore

Introduction to HAL ADL

Accessories Division of HAL was established in 1970 with the primary objective of

manufacturing systems and accessories for various aircraft and engines and attains

self-sufficiency in this area. Its facilities are spread over 116,000 sq. /m of built area

set in sylvan surroundings. At present it is turning out over 1300 different types of

accessories. The Division started with manufacturing various Systems and Accessories

viz, Hydraulics, Engine Fuel System, Air-conditioning and Pressurization, Flight

Control, Wheel and Brake, Gyro & Barometric Instruments, Electrical and Power

Generation & Control System, Undercarriages, Oxygen System and Electronic System

all under one roof to meet the requirements of the aircraft, helicopters and engines

being produced by HAL like MiG series of aircrafts, Dornier, Jaguar, Advanced Light

Helicopters(ALH), PTA, Cheetah & Su-30 and repair / Overhaul of Avro, AN-32, HPT-

32, Mirage-2000 & Sea-Harrier aircrafts, Cheetah and Chetak helicopters.

The Division undertakes manufacturing and servicing of accessories under Transfer of

Technology (Tot) from more than 40 licensor from different countries. In addition, a

lot of emphasis has been given on developing indigenous capability for Design and

Development of various systems and accessories. This capability has culminated in

indigenous design and development of over 350 types of accessories for the Light

Combat Aircraft (LCA) (Air force and Navy version), Advanced Light Helicopter (all

versions i.e. Army, Air force, Navy & Civil), SARAS and IJT (Intermediate Jet Trainer).

The Division has also developed and has made successful strides into the area of

Microprocessor based control systems for the LCA Engine as well as other systems.

The Division has been in the forefront of accessories development and supply not

only to Indian Force but to Army, Navy, Coast Guard and various Defense

Laboratories as well as for Space applications.

The Division is networked with all sister Divisions and R& D Centers by LAN/WAN.

Lean manufacturing and ERP have been implemented to create an efficient

manufacturing system. The Division today has a prime name in the Aviation market

and various international companies are interested to join hands with it for future

projects. The Division has also made steady progress in the area of Export.

Products by HAL - ADL

HYDRAULIC SYSTEM AND POWER CONTROL

Hydraulic Pumps, Accumulators, Actuators, Electro-selectors, Bootstrap

Reservoirs and various types of valves

ENVIRONMENTAL CONTROL SYSTEM

Cold Air Unit, Water Extractors, Non Return Valves and Venturies

ENGINE FUEL CONTROL SYSTEM

Fuel after Burner regulator and distributor, Main Fuel Distributor, Regulator

and After Burner Pump, Plunger Pumps, Fuel Metering Device

INSTRUMENTS

Electrical Indicators, Fuel quantity and flow metering instruments, Flight

instruments, Sensors and Switches.

ELECTRICAL POWER GENERATION AND CONTROL SYSTEM

AC/DC Generator, Control and Protection Units, AC and DC Master Box,

Inverters, Transformer Rectifier Unit, Actuators.

UNDERCARRIAGE, WHEELS AND BRAKES

Main and Nose Undercarriage, Main and Nose Wheel, Brake System LRUs.

TEST RIGS

Dedicated Test Rigs, custom-built Fuel/Hydraulic Test Rigs and Electrical Test

Rigs.

Factories in HAL ADL

Mechanical System factory

Hydraulics and Pumps

Servo-Actuators

Flight Control system

Environment System

Assembly Test

Fuel System Factory

Gas Turbine

Fuel Flow Metering and Gauging

Assembly Test

Instrument & Electrical System Factory

Cockpit Instruments

Oxygen System

Sensors

Starter/Generator

Static Inverter

Gyroscopic Instruments

Barometric Instruments

Fuel Content Gauging Probes.

PROJECT REPORT ON

INTRUMENTS USED IN COCKPIT

OF AIRCRAFTS

Cockpit Instruments

Cockpit of aircraft

BAROMETRIC INSTRUMENTS

Altimeter

Altitude can be determined based on the measurement of atmospheric pressure. The

greater the altitude the lower the pressure. When a barometer is supplied with a

nonlinear calibration so as to indicate altitude, the instrument is called a pressure

altimeter or barometric altimeter. A pressure altimeter is the altimeter found in most

aircraft, and skydivers use wrist-mounted versions for similar purposes. Hikers and

mountain climbers use wrist-mounted or hand-held altimeters, in addition to other

navigational tools such as a map, magnetic compass, or GPS receiver.

The altimeter shows the aircraft's altitude above sea-level by measuring the

difference between the pressure in a stack of aneroid capsules inside the altimeter

and the atmospheric pressure obtained through the static system. It is adjustable for

local barometric pressure which must be set correctly to obtain accurate altitude

readings. As the aircraft ascends, the capsules expand and the static pressure drops,

causing the altimeter to indicate a higher altitude. The opposite effect occurs when

descending. With the advancement in aviation and increased altitude ceiling the

altimeter dial had to be altered for use both at higher and lower altitudes. Hence

when the needles were indicating lower altitudes i.e. the first 360 degree operation of

the pointers was delineated by the appearance of a small window with oblique lines

warning the pilot that he is nearer to the ground. This modification was introduced in

the early sixties after the recurrence of air accidents caused by the confusion in the

pilot's mind. At higher altitudes the window will dis-appear.

Vertical Speed Indicator or Variometer

Variometer measure the rate of change of altitude by detecting the change in air

pressure (static pressure) as altitude changes. A simple Variometer can be constructed

by adding a large reservoir (a thermos bottle) to augment the storage capacity of a

common aircraft rate-of-climb instrument. In its simplest electronic form, the

instrument consists of an air bottle connected to the external atmosphere through a

sensitive air flow meter. As the aircraft changes altitude, the atmospheric pressure

outside the aircraft changes and air flows into or out of the air bottle to equalize the

pressure inside the bottle and outside the aircraft. The rate and direction of flowing

air is measured by the cooling of one of two self-heating thermistors and the

difference between the thermistor resistances will cause a voltage difference; this is

amplified and displayed to the pilot. The faster the aircraft is ascending (or

descending), the faster the air flows. Air flowing out of the bottle indicates that the

altitude of the aircraft is increasing. Air flowing into the bottle indicates that the

aircraft is descending.

Newer Variometer designs directly measure the static pressure of the atmosphere

using a pressure sensor and detect changes in altitude directly from the change in air

pressure instead of by measuring air flow. These designs tend to be smaller as they

do not need the air bottle. They are more reliable as there is no bottle to be affected

by changes in temperature and less chances for leaks to occur in the connecting

tubes.

The designs described above, which measure the rate of change of altitude by

automatically detecting the change in static pressure as the aircraft changes altitude

are referred to as "uncompensated" Variometer. The term "vertical speed indicator"

or "VSI" is most often used for the instrument when it is installed in a powered

aircraft. The term "Variometer" is most often used when the instrument is installed in

a glider or sailplane.

An "Inertia lead" VSI or ILVSI compensates for relative "g" forces experienced in a

turn (powered aircraft) and provides appropriate mechanical compensation to

remove otherwise erroneous indications of climb or descent.

Air Speed Indicator

The airspeed indicator or airspeed gauge is an instrument used in an aircraft to

display the craft's airspeed, typically in knots, to the pilot. In its simplest form, an ASI

measures the difference in pressure between that which is generally around the craft

and the increased pressure caused by propulsion. The needle tracks pressure

differential but the dial is marked off as airspeed.

Along with the altimeter and vertical speed indicator, the airspeed indicator is a

member of the pitot-static system of aviation instruments, so named because they

operate by measuring pressure in the pitot and static circuits.

Airspeed indicators work by measuring the difference between static pressure,

captured through one or more static ports; and stagnation pressure due to "ram air",

captured through a pitot tube. This difference in pressure due to ram air is called

impact pressure

The static ports are located on the exterior of the aircraft, at a location chosen to

detect the prevailing atmospheric pressure as accurately as possible, that is, with

minimum disturbance from the presence of the aircraft. Some aircraft have static

ports on both sides of the fuselage or empennage, in order to more accurately

measure static pressure during slips and skids. Aerodynamic slips and skids cause

either or both static ports and pitot tube(s) to present themselves to the relative wind

in other than basic forward motion. Thus, the alternative placements on some aircraft.

Icing is a problem for pitot tubes when the air temperature is below freezing and

visible moisture is present in the atmosphere, as when flying through cloud or

precipitation. Electrically heated pitot tubes are used to prevent ice forming over the

tube.

The airspeed indicator and altimeter will be rendered inoperative by blockage in the

static system. To avoid this problem, most aircraft intended for use in instrument

meteorological conditions are equipped with an alternate source of static pressure. In

unpressurised aircraft, the alternate static source is usually achieved by opening the

static pressure system to the air in the cabin. This is less accurate, but is still workable.

In pressurized aircraft, the alternate static source is a second set of static ports on the

skin of the aircraft, but at a different location to the primary source.

GYROSCOPIC INSTRUMENTS

Turn and Slip Indicator

The turn-and-slip indicator provides the only information of either wing's level or

bank attitude if the other gyroscopic instruments should fail. This indicator is

sometimes called the "needle and ball". This instrument, along with the airspeed

indicator, magnetic compass and altimeter, can assist the pilot in flying through

instrument weather conditions, even when it is the only gyro instrument operating.

The turn needle of the turn-and-bank indicator gives an indirect indication of the

bank attitude of the aircraft. When the turn needle is exactly centered, the aircraft is

in straight flight. When the needle is displaced from center, the aircraft is turning in

the direction of the displacement. Thus, if the ball is centered, a left displacement of

the turn needle means the left wing is low and the aircraft is in a left turn. Return to

straight flight is accomplished by coordinating aileron and rudder pressures.

The ball of the turn-and-bank indicator is actually a separate instrument, conveniently

located under the turn needle so the two instruments can be used together. This

instrument is best used as an indication of attitude. When the ball is centered within

its glass tube the maneuver is being executed in a coordinated manner. However, if

the ball is out of its center location, the aircraft is either slipping or skidding . The side

to which the ball has rolled indicates the direction of the slip or skid.

In a slip, the rate of turn is too slow for the angle of bank, and the lack of centrifugal

force causes the ball to be displaced to the inside of the turn. (To correct, decrease

the angle of bank, or use rudder to increase the rate of turn, or both). In a skid the

rate of turn is too fast for the angle of bank, and excessive centrifugal force causes

the ball to be displaced to the outside of the turn. (To correct, increase the bank

angle, or use rudder to decrease the rate of turn, or both).

In coordinated flight, the needle may be used to measure the rate of turn; in a

"standard rate turn", the needle is aligned with the left or right marker (dog-house)

and the aircraft will turn at the rate of 3 per second or 180 in one minute. Hence, in

these conditions, the needle indicates both direction and rate of turn.

The answer to controlling and trimming an aircraft in straight and level flight by

means of the turn-and-bank indicator requires a return to basic control principles -

i.e., control yaw with the rudder and keep the wings level with aileron. Therefore,

when flying straight and level through the use of the turn-and-bank indicator,

prevent yawing with appropriate rudder pressure, and keep the wings level with

appropriate aileron pressure. The needle will not deflect while heading is constantly

maintained, since no turn exists.

In other words, control the ball with rudder since the ball moves parallel to a plane

passing through the rudder pedals, and control the needle with aileron since the

ailerons affect bank angle, a primary requirement for a normal turn.

It is important that both the needle and ball are used together. The problem

associated with using these instruments separately is that although the ball will

positively indicate that the aircraft is slipping or skidding, just which one of these the

aircraft is doing can only be determined by reference to the needle. Furthermore, the

needle will not positively indicate a bank attitude. An aircraft could be in a bank

attitude and yet the needle could remain centered or indicate a turn in the opposite

direction, if controls are not coordinated.

Heading Indicator

The heading indicator (also known as the directional gyro, or DG; sometimes also called the

gyrocompass, though usually not in aviation applications) displays the aircraft's heading with

respect to magnetic north. Principle of operation is a spinning gyroscope, and is therefore

subject to drift errors (called precession) which must be periodically corrected by calibrating

the instrument to the magnetic compass. In many advanced aircraft (including almost all jet

aircraft), the heading indicator is replaced by a Horizontal Situation Indicator (HSI) which

provides the same heading information, but also assists with navigation.

The heading indicator works using a gyroscope, tied to the aircraft horizontal, to establish an

inertial platform. As such, any configuration of the aircraft horizontal that does not match the

local Earth horizontal results in gimbal error, essentially leading to a variation in the

predictable "apparent" wander, known in this instance as drift. The heading indicator is

arranged so that only the horizontal axis is used to drive the display, which consists of a

circular compass card calibrated in degrees. The gyroscope is spun either electrically, or using

filtered air from a vacuum pump (sometimes a pressure pump in high altitude aircraft) driven

from the aircraft's engine. Because the Earth rotates (, 15 per hour), and because of small

accumulated errors caused by friction and imperfect balancing of the gyro, the heading

indicator will drift over time, and must be reset from the compass periodically. The apparent

drift is predicted by sin Latitude and will thus be greatest over the poles. Another sort of

apparent drift exist in the form of transport wander, where aircraft movement will essentially

add or subtract to the effect of the Earth's rotation upon a gyroscope. To counter for the

effect of Earth rate drift a latitude nut can be set (on the ground only) which induces a

(hopefully equal and opposite) real wander in the gyroscope. Normal procedure is to realign

the direction indicator once each ten to fifteen minutes during routine in-flight checks.

Failure to do this is a common source of navigation errors among new pilots.

Altitude Indicator

The attitude indicator (also known as an artificial horizon) shows the aircraft's relation

to the horizon. From this the pilot can tell whether the wings are level and if the

aircraft nose is pointing above or below the horizon. This is a primary instrument for

instrument flight and is also useful in conditions of poor visibility. Pilots are trained to

use other instruments in combination should this instrument or its power fail.

Attitude indicators use a gyroscope (powered via vacuum pump or electrical motor)

to establish an inertial platform. The gyroscope is geared to a display that has two

dimensions of freedom, simultaneously displaying pitch and bank. The display may

be colored to indicate the horizon as the division between the two colored segments

(typically blue for sky and brown for ground), and is intended to be intuitive to use.

The actual bank angle is calibrated around the circumference of the instrument. The

pitch angle is indicated by a series of calibration lines, each representing 5 or 10 of

pitch depending on design.

The instrument may develop small "precession" errors, in pitch indication during

extended periods of acceleration or deceleration and, in bank indication during

extended periods in a turn, caused by the mechanism that normally keeps the gyro

rotor properly erected. These errors develop very slowly (usually at not more than 2

or 3 degrees per minute) and are not significant in normal flying. Some attitude

indicators can only tolerate a specific range of bank angles. If the aircraft rolls too

steeply or achieves an extreme pitch attitude while performing aerobatics, for

example the attitude indicator can "tumble" (or "topple") and become temporarily

unusable. For this reason, some attitude indicators are fitted with a "caging

mechanism" (a device to restore the gyroscope to an erect position). Some attitude

indicators can be manually erected once the airplane is in level flight using the caging

mechanism. Most modern instruments are designed to tolerate 360 degrees of

rotation in pitch and roll without tumbling, although periods of violent aerobatics

may tumble any gyro horizon. Once tumbled, an instrument without a caging

mechanism may not be able to re-erect itself until power is removed and the aircraft

is in a level pitch and roll attitude for a long enough period that the gyro rotor comes

to a stop.

Attitude and Heading Reference Systems (AHRS) are able to provide three-axis

information that can be shared with multiple devices in the aircraft, such as "glass

cockpit" primary flight displays (PFDs). Rather than using a spinning rotor for the

horizon reference, modern AHRS use 3-dimension magnetometers and

accelerometers to detect the airplane's pitch and roll attitude, with no moving parts.

AHRS have been proven to be highly reliable and are in wide use in commercial and

business aircraft. Recent advances in MEMS manufacturing have brought the price of

FAA-certified AHRS down to less than $15,000,making them practical for general

aviation aircraft. With most AHRS systems, if an aircraft's AIs have failed there will be

a standby AI located in the center of the instrument panel, where other standby basic

instruments such as the airspeed indicator and altimeter are also available. These

mostly mechanical standby instruments may be available even if the electronic flight

instruments fail, though the standby attitude indicator may be electrically driven and

will, after a short time, fail if its electrical power fails.

Fuel Measurement

Fuel measurement is done by probes dipped in fuel and these probes are high level

and low level pressure of oil tank.

Fuel Content Gauge Probe

Conclusion

By this report and study of this, which concludes that Hindustan

Aeronautics Limited, is one of the most significant aircraft manufacturer

and developer of India and making India self-reliant in the fields of

aerospace and aircrafts, which tending towards the boom of Indian self-

designed aircrafts and helicopters.

And by no means had Hindustan Aeronautics limited, Accessories

Division, Lucknow, playing vital and magnificent role to make H.A.L. more

prosperous as well as India.

This report also concludes that instruments which are using in cockpit is

very essential to an aircraft, because it helps pilot to fly aircraft more

precisely.

Bibliography

http://hal-india.com/aircraftdivisionbangalore.asp

http://hal-india.com/products.asp

http://hal-india.com/accessoriesdivision.asp

http://hal-india.com/aircraftdivisionnasik.asp

http://www.slideshare.net

http://www.wikipedia.org

Potrebbero piacerti anche

- Aircraft Economic Life WhitepaperDocumento9 pagineAircraft Economic Life WhitepaperFlankerSparrowNessuna valutazione finora

- Monitoring Systems - Rolls-RoyceDocumento4 pagineMonitoring Systems - Rolls-RoycerenjithaeroNessuna valutazione finora

- Aircraft Financial Evaluation Evidence From The FieldDocumento36 pagineAircraft Financial Evaluation Evidence From The FieldIr. Vinod DamodaranNessuna valutazione finora

- ALR-69A Radar Warning Receiver (RWR)Documento2 pagineALR-69A Radar Warning Receiver (RWR)joma11Nessuna valutazione finora

- The Relationship Between An Aicrafts Value Its Maintenance Status v1 PDFDocumento23 pagineThe Relationship Between An Aicrafts Value Its Maintenance Status v1 PDFChris GilesNessuna valutazione finora

- Breakthrough in SupermaneuverabilityDocumento13 pagineBreakthrough in Supermaneuverabilitykrishnendu_bal100% (1)

- The Economics of Low Cost Airlines - The Key Indian Players and Strategies Adopted For Sustenance.Documento51 pagineThe Economics of Low Cost Airlines - The Key Indian Players and Strategies Adopted For Sustenance.Suyog Funde100% (2)

- 3 Application ARCDocumento9 pagine3 Application ARCHemantkumar TungNessuna valutazione finora

- 737-800 ExtnDocumento6 pagine737-800 ExtnIshmum Monjur NilockNessuna valutazione finora

- Ch.03 Aircraft Specification SASDocumento12 pagineCh.03 Aircraft Specification SASAhmad Faisal Ibrahim100% (1)

- 2009-Final Report B707 - ST-AKW - Report 10 2009Documento96 pagine2009-Final Report B707 - ST-AKW - Report 10 2009AlexShearNessuna valutazione finora

- 3 01 Afdp CounterairDocumento42 pagine3 01 Afdp CounterairThirarot SakulrasrisauyNessuna valutazione finora

- AD management best practicesDocumento10 pagineAD management best practicesYousif Jamal MahboubaNessuna valutazione finora

- Airbus Commercial Aircraft AC A350 900 1000Documento411 pagineAirbus Commercial Aircraft AC A350 900 1000librada diazNessuna valutazione finora

- Pakistan Aeronautical Complex KamraDocumento10 paginePakistan Aeronautical Complex KamraSajad Ijaz100% (1)

- A350 Appraiser OpinionDocumento5 pagineA350 Appraiser OpinionKhushboo VermaNessuna valutazione finora

- De Havilland Canada Dash 8 - Wikipedia PDFDocumento107 pagineDe Havilland Canada Dash 8 - Wikipedia PDFMathieu GiguereNessuna valutazione finora

- ADS-B Sense-and-Avoid System: Automatic Dependent Surveillance BroadcastDocumento38 pagineADS-B Sense-and-Avoid System: Automatic Dependent Surveillance BroadcastMarcvs LewisNessuna valutazione finora

- By Order of The Secretary of The Air Force Air Force Instruction 11-2C-130 23 APRIL 2012 Flying Operations C-130 Operations ProceduresDocumento310 pagineBy Order of The Secretary of The Air Force Air Force Instruction 11-2C-130 23 APRIL 2012 Flying Operations C-130 Operations ProceduresAriawan D RachmantoNessuna valutazione finora

- Afm PDFDocumento26 pagineAfm PDFcf34Nessuna valutazione finora

- CFD in IndiaDocumento14 pagineCFD in IndianileshraneNessuna valutazione finora

- GAO Report On Private Aircraft InsuranceDocumento41 pagineGAO Report On Private Aircraft InsuranceJasonTrahanNessuna valutazione finora

- Sikorsky S76 Brochure 0Documento2 pagineSikorsky S76 Brochure 0Syed Iqmal100% (1)

- Plaaf Elites PilotsDocumento37 paginePlaaf Elites Pilotsneetin vatsya100% (1)

- AP3456 Mathematics & Physics PDFDocumento319 pagineAP3456 Mathematics & Physics PDFLaxmi Krishnadas0% (1)

- Feedback 2 2016 enDocumento40 pagineFeedback 2 2016 enshaotao guoNessuna valutazione finora

- FATIMA SHAFI - Ninety Nines Magazine 20150708Documento2 pagineFATIMA SHAFI - Ninety Nines Magazine 20150708Fatima ShafiNessuna valutazione finora

- Powerplant Level 1rDocumento220 paginePowerplant Level 1rAbil Gilang -Nessuna valutazione finora

- Brochure CFM56 Fiches 2017 PDFDocumento9 pagineBrochure CFM56 Fiches 2017 PDFpbonnetNessuna valutazione finora

- Aircraft Technical Data 2Documento34 pagineAircraft Technical Data 2Gaynor MorganNessuna valutazione finora

- JCS Joint Airspace ControlDocumento115 pagineJCS Joint Airspace Control...tho the name has changed..the pix remains the same.....Nessuna valutazione finora

- Snov1: A Set of Templates For Evaluating WargamesDocumento11 pagineSnov1: A Set of Templates For Evaluating Wargamesanca irinaNessuna valutazione finora

- History of CFD Work in IndiaDocumento10 pagineHistory of CFD Work in IndiajoemonjacobNessuna valutazione finora

- Aeronautical Development Establishment (ADE) (DRDO Institute)Documento9 pagineAeronautical Development Establishment (ADE) (DRDO Institute)LuptongaNessuna valutazione finora

- 1A+2A+4A 11aug2007Documento39 pagine1A+2A+4A 11aug2007RaviSinghNessuna valutazione finora

- A320 maintenance checklistDocumento5 pagineA320 maintenance checklistLandy FebriansyahNessuna valutazione finora

- Booklet N219 REV JAN 2018 PDFDocumento10 pagineBooklet N219 REV JAN 2018 PDFGuntara WigunaNessuna valutazione finora

- Sukhoi Sugc-2007 PDFDocumento27 pagineSukhoi Sugc-2007 PDFPuguh CahyonoNessuna valutazione finora

- The Future of Air SuperiorityDocumento20 pagineThe Future of Air SuperiorityEduardo Weiser100% (1)

- EPAWSSDocumento2 pagineEPAWSSManuel Solis100% (1)

- Approach To High Angle of Attack Testing of Light Combat Aircraft (LCA) TejasDocumento19 pagineApproach To High Angle of Attack Testing of Light Combat Aircraft (LCA) TejasLuptonga100% (4)

- EFB ReportDocumento61 pagineEFB Reportmyrddin55Nessuna valutazione finora

- cmd16 Slideshow14032016 PDFDocumento128 paginecmd16 Slideshow14032016 PDFrsahu_36Nessuna valutazione finora

- 100117CDR MQ-9B SkyGuardian Readly To Deliver JUSTAS PDFDocumento5 pagine100117CDR MQ-9B SkyGuardian Readly To Deliver JUSTAS PDFMorgen GumpNessuna valutazione finora

- Airbus Safety First Magazine 04 PDFDocumento37 pagineAirbus Safety First Magazine 04 PDFhjhjhhNessuna valutazione finora

- Cost ReportDocumento12 pagineCost ReportpistesilNessuna valutazione finora

- The Airframe: Eurofighter Typhoon SpecificationsDocumento16 pagineThe Airframe: Eurofighter Typhoon SpecificationsValentin EmilNessuna valutazione finora

- History of AviationDocumento154 pagineHistory of Aviationrkap0412Nessuna valutazione finora

- China's Emerging 5th Generation Air-To-Air MissilesDocumento14 pagineChina's Emerging 5th Generation Air-To-Air MissilesAzman JantanNessuna valutazione finora

- Sample ReportDocumento15 pagineSample ReportDuong Tong0% (1)

- RFP 737-400Documento11 pagineRFP 737-400aeroalanNessuna valutazione finora

- Is Syria Air SamDocumento96 pagineIs Syria Air Samfox40Nessuna valutazione finora

- CFM56 5B SB Rev 72-1092 TSN.00 N 20201210Documento20 pagineCFM56 5B SB Rev 72-1092 TSN.00 N 20201210Irfan05Nessuna valutazione finora

- 1c-Check Inspection Schedule..............Documento36 pagine1c-Check Inspection Schedule..............Jeffrey DavisNessuna valutazione finora

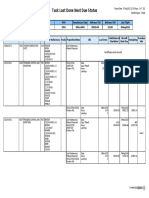

- LAST DONE WLB - 07aug2022 - 122946Documento292 pagineLAST DONE WLB - 07aug2022 - 122946EssamNessuna valutazione finora

- Brochure ATR 600 Series 2014Documento28 pagineBrochure ATR 600 Series 2014Wafi Awf100% (3)

- Rafale Deal PresentationDocumento6 pagineRafale Deal PresentationShounak ChandraNessuna valutazione finora

- Etops 1Documento9 pagineEtops 1CaptainkhosoNessuna valutazione finora

- HAL Accessories Division Summer Training ReportDocumento23 pagineHAL Accessories Division Summer Training ReportRahul YadavNessuna valutazione finora

- Hindustan Aeronautics Limited: Industry Founded Headquarters Key People Ashok Nayak (Chairman)Documento7 pagineHindustan Aeronautics Limited: Industry Founded Headquarters Key People Ashok Nayak (Chairman)Nimmy AravindNessuna valutazione finora

- MyPower S3220&S3320-INSTALLATIONDocumento83 pagineMyPower S3220&S3320-INSTALLATIONJorge GonzalesNessuna valutazione finora

- MC 8051Documento85 pagineMC 8051Sonu SatishNessuna valutazione finora

- 01 U3 Ws 1 Force DiagramsDocumento4 pagine01 U3 Ws 1 Force Diagramsapi-197108354Nessuna valutazione finora

- Axial Shortening of Column in Tall Structure.Documento9 pagineAxial Shortening of Column in Tall Structure.P.K.Mallick100% (1)

- Sample Lab ReportDocumento4 pagineSample Lab ReportHolley WrightNessuna valutazione finora

- Dissertation ErsatzteilmanagementDocumento7 pagineDissertation ErsatzteilmanagementWriteMyEnglishPaperForMeCanada100% (1)

- Slurry Flo BrochureDocumento4 pagineSlurry Flo BrochureChristian Andres Campa HernandezNessuna valutazione finora

- CHEST Workout Structure and Training Log PREVIEWDocumento3 pagineCHEST Workout Structure and Training Log PREVIEWgaurav singhNessuna valutazione finora

- # 6030 PEN OIL: Grade: Industrial Grade Heavy Duty Penetrating OilDocumento3 pagine# 6030 PEN OIL: Grade: Industrial Grade Heavy Duty Penetrating OilPrakash KumarNessuna valutazione finora

- X-Span & Setting ToolsDocumento18 pagineX-Span & Setting ToolsDenier RubianoNessuna valutazione finora

- ALTERNATOR - ST170741: Parts ListDocumento2 pagineALTERNATOR - ST170741: Parts Listkaswade BrianNessuna valutazione finora

- Brigada Eskwela Activities With PicsDocumento6 pagineBrigada Eskwela Activities With PicsCharisse TocmoNessuna valutazione finora

- UFED Solutions Brochure WebDocumento4 pagineUFED Solutions Brochure Webwilly irawanNessuna valutazione finora

- Sample Cover Letter: No Work ExperienceDocumento4 pagineSample Cover Letter: No Work ExperienceMaya ElvisaNessuna valutazione finora

- OD Main Switch & OD OFF Indicator Light CircuitDocumento4 pagineOD Main Switch & OD OFF Indicator Light Circuitcelestino tuliaoNessuna valutazione finora

- Valve Group-Control - AuxiliaryDocumento3 pagineValve Group-Control - AuxiliarythierrylindoNessuna valutazione finora

- Plett DawsonDocumento270 paginePlett DawsonRaghu0% (1)

- Fortumo Mobile Payments API GuideDocumento8 pagineFortumo Mobile Payments API GuideVladimir UtješinovićNessuna valutazione finora

- Tda 1526Documento15 pagineTda 1526Adilcio Melo0% (1)

- Advances in Remediation-eBookDocumento88 pagineAdvances in Remediation-eBookalinerlfNessuna valutazione finora

- Masterseal 550Documento4 pagineMasterseal 550Arjun MulluNessuna valutazione finora

- Associating Numbers With Sets Having 51 Up To 100 Objects or ThingsDocumento4 pagineAssociating Numbers With Sets Having 51 Up To 100 Objects or ThingssweetienasexypaNessuna valutazione finora

- Basicline BL 21t9stDocumento28 pagineBasicline BL 21t9stgabriel6276Nessuna valutazione finora

- Daily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFDocumento6 pagineDaily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFAEO Begowala100% (2)

- LR Phono PreampsDocumento44 pagineLR Phono PreampsMartin FernandezNessuna valutazione finora

- Hughes Brothers PDFDocumento52 pagineHughes Brothers PDFJavier MaldonadoNessuna valutazione finora

- GRC Fiori End User Guide Final - V2Documento75 pagineGRC Fiori End User Guide Final - V2Subhash BharmappaNessuna valutazione finora

- KernelDocumento326 pagineKernelSkyezine Via Kit FoxNessuna valutazione finora

- Safety Training Evaluation Form: Instructor RatingDocumento1 paginaSafety Training Evaluation Form: Instructor RatingNate JamesNessuna valutazione finora

- Smart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsDocumento5 pagineSmart Lighting Market Analysis and Forecast 2025 by Global Marketing InsightsEko Hadi Susanto100% (1)