Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Stainless Steel 1.4501

Caricato da

Eduardo Paulini VillanuevaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Stainless Steel 1.4501

Caricato da

Eduardo Paulini VillanuevaCopyright:

Formati disponibili

Stainlesssteel1.

4501

Grade1.4501isausteniticferriticalsoreferredtoassuperduplexstainlesssteel,combinemanyofthebeneficialproperties

offerriticandausteniticsteels.Itoffersenhancedpittingandcrevicecorrosionresistanceinenvironments,wherestandard

stainless andduplexsteels areunsuitable.The duplexmicrostructure contributes higherstrength andresistance to stress

corrosioncracking,combinedwithgoodweldabilityfeatures.

Applications:

Componentsinoffshore

Wastewater

Seawaterdesalination

Chemical plants with aggressive chloridecontaining media: heat exchangers, separator parts, compressor and pump

components,turbineblades

Theinformationonourwebsiteisaccuratetothebestofourknowledgeandunderstanding.Althougheveryefforthasbeenmadetoensure

accuracy,thecompanycannotacceptanyresponsibilityforanydirectorindirectdamagesresultingfrompossibleerrorsorincorrect

applicationoftheinformationofthispublication.Wereservetherighttomakechanges.

Copyright2014RautaruukkiCorporation.Allrightsreserved.

Documentprintedon24.06.2014 www.ruukki.com

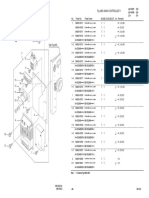

Dimensions

HotrolledEN1.4501(S32760)

Dimensionsmm Theor.weight

Thickness Width Length kg/m

2

kg/pc

6 1500 3000 49,50 223,0

8 1500 3000 66,00 297,0

10 1500 3000 82,50 371,0

12 1500 3000 99,00 446,0

15 1500 3000 124,00 557,0

20 1500 3000 165,00 743,0

25 1500 3000 206,25 928,0

Properties

Generalproperties

Hotformingtemperaturerangeis11501000C,aircooling

Solutionannealingtemperaturerangeis10401120C,airorwatercooling

Recommendedapplicationtemperaturerange10300C,becomesbrittleinhighertemperatures

PittingandcrevicecorrosionresistancesuperiortoEN1.4404

Theyieldstrengthisabouttwicethatofausteniticsteels,whichenablessavingsinmaterialweight

Coldworkingrequiressubstantiallyhigherforcesthanforausteniticsteels

Duetothehigherstrength,springbackeffectisalsohigherthanforauteniticgrades

Withahighspeedsteeltoolingmachiningisableatthesamefeedsandspeedsaswith1.4404

1.4501canbeweldedbyTIG,MIG,SMAW,SAW,FCWandPAW.Alsoapplicableforlaser,resistanceandhighfrequence

welding.

Thermalconductivityat20CW/(mK): 13

Specificthermalcapacityat20CJ/(kgK): 475

Electricalresistivityat20C(mm

2

)/m: 0.8

Magnetizable: Yes

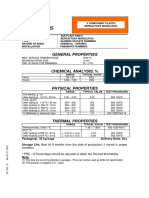

Chemicalproperties(%bymass)

C Si Mn P

max

S N Cr Cu Mo Nb Ni Others

acc.toEN100882

0.030

1.00

1.00

0.035

0.015

0.200.30 24.026.0 0.501.00 3.04.0 6.08.0 W

0.501.00

acc.toASTMA240/

A240M

0.030

1.00

1.00

0.030

0.010

0.200.30 24.026.0 0.501.00 3.04.0 6.08.0 W

0.501.00

Mechanicalproperties

Product Thickness

max/mm

Rp0.2

Mpa

Rm

Mpa

A80

<3mmTr

A

3mmTr

Impactenergy

ISOV(Long.)

Impactenergy

ISOV(Tr.)

acc.toEN100882 Plate 75 530 730930 25 25 100 60

acc.toASTMA240/A240M 530 750 25

Stainlesssteel1.4501

2

Resistanttointergranularcorrosionindeliverycondition: Yes

Resistanttointergranularcorrosioninsensitizedcondition: Yes

Minimum0.2%proofstrength,MPaattemperaturesC

100C 150C 200C 250C

450 420 400 380

MinimumRm,MPaatatemperature(inC)of

50C 100C 150C 200C 250C

acc.toEN100287 771 680 660 640 630

Physicalproperties

AccordingtoEN100881

Densitykg/dm

3

Modulusofelasticityat(GPA)

20C 100C 200C 300C 400C 500C

7.8 200 194 186 180

Meancoefficientofthermalexpansion

20C100C 100C200C 200C300C 300C400C 400C500C 500C600C

13.0 13.5 14.0

Thecontentofthisdocumenthasbeencreatedfromwebpagelastupdated25Apr2014

Oursalesandtechnicalsupportarehappytogiveyoumoreinformation.Visitwww.ruukki.com/contactus.

Stainlesssteel1.4501

3

Potrebbero piacerti anche

- SS 304Documento5 pagineSS 304Nirav PatelNessuna valutazione finora

- SS 6mo - 1.4547Documento1 paginaSS 6mo - 1.4547f_riseNessuna valutazione finora

- Technical Data 3CR12Documento15 pagineTechnical Data 3CR12rudiskw456Nessuna valutazione finora

- Austenitic Standard GradesDocumento6 pagineAustenitic Standard Gradesfierro44Nessuna valutazione finora

- Stainless Steel 304 Material Property Data SheetDocumento2 pagineStainless Steel 304 Material Property Data SheetRahul SrivastavaNessuna valutazione finora

- Macsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LDocumento4 pagineMacsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LNirav PatelNessuna valutazione finora

- Technical Brochure - Ferritics - MolyDocumento5 pagineTechnical Brochure - Ferritics - MolyJoshua WalkerNessuna valutazione finora

- EldaDocumento28 pagineEldaEldayadi Nefty Rizky ArismawanNessuna valutazione finora

- Atlas 304 - 304L: Colour Code: Lilac/TurquoiseDocumento3 pagineAtlas 304 - 304L: Colour Code: Lilac/TurquoiseOthoniel MunizNessuna valutazione finora

- CuAg0,1P PDFDocumento8 pagineCuAg0,1P PDFirajfarji2481Nessuna valutazione finora

- Cast Materials: Sulzer PumpsDocumento6 pagineCast Materials: Sulzer PumpsElmey Bin JulkeplyNessuna valutazione finora

- DIN WS 1.4003UNS S41003 Ferritic Stainless SteelDocumento2 pagineDIN WS 1.4003UNS S41003 Ferritic Stainless SteelIvanildo SilvaNessuna valutazione finora

- SS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Documento3 pagineSS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Harish AmpoluNessuna valutazione finora

- Materials Castings E00510 SulzerDocumento5 pagineMaterials Castings E00510 SulzerAmir SafdarNessuna valutazione finora

- Chemical Composition: Copper Alloy DataDocumento12 pagineChemical Composition: Copper Alloy DataErujNessuna valutazione finora

- Aalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97Documento3 pagineAalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97sgupta_192494Nessuna valutazione finora

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocumento2 pagine304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelTomy GeorgeNessuna valutazione finora

- Vishay Bccomponents: FeaturesDocumento16 pagineVishay Bccomponents: FeaturesPetrutStefanVartolomeiNessuna valutazione finora

- 1.4462 Duplex PropertiesDocumento2 pagine1.4462 Duplex PropertiesEROL30Nessuna valutazione finora

- ASTM 52100 Material Del Tornillo de PotenciaDocumento3 pagineASTM 52100 Material Del Tornillo de PotenciaEsteban CarrilloNessuna valutazione finora

- SINOXX 4435 Steel: Designation by StandardsDocumento2 pagineSINOXX 4435 Steel: Designation by StandardsMohammad MaroufkhaniNessuna valutazione finora

- 400 SeriesDocumento37 pagine400 SeriesShashank SaxenaNessuna valutazione finora

- Stabilized Ferritic Stainless Steel: General CharacteristicsDocumento37 pagineStabilized Ferritic Stainless Steel: General CharacteristicsBina Niaga MultiusahaNessuna valutazione finora

- Loadcell WiringDocumento2 pagineLoadcell WiringSreenath ReddiNessuna valutazione finora

- SX 316 / 316L Technical DataDocumento3 pagineSX 316 / 316L Technical DatavkmsNessuna valutazione finora

- Crest Tube - Product LiteratureDocumento16 pagineCrest Tube - Product LiteratureVu Thieu TuanNessuna valutazione finora

- SS 304Documento4 pagineSS 304Imtinan Mohsin100% (1)

- Royal 6010Documento1 paginaRoyal 6010Santosh SharmaNessuna valutazione finora

- Steel UserguideDocumento50 pagineSteel UserguideBhanu Pratap ChoudhuryNessuna valutazione finora

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Documento3 pagineAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102HoangNessuna valutazione finora

- Durehete 950Documento5 pagineDurehete 950ellisforheroes100% (1)

- PPT-Q A For Steel and ConcreteDocumento146 paginePPT-Q A For Steel and ConcreteDr.SRINIVAS RAO PASUPULETI50% (2)

- 2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeDocumento13 pagine2304 Tubing ASTM A789 / ASME SA789 S32304 1.4362 Duplex Steel TubeGonzalo MazaNessuna valutazione finora

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFDocumento57 pagineAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaNessuna valutazione finora

- Grades of Stainless Steel - Grade 316: SX 316 / 316L Technical DataDocumento3 pagineGrades of Stainless Steel - Grade 316: SX 316 / 316L Technical Data03sri03Nessuna valutazione finora

- 25CR20NIDocumento2 pagine25CR20NIShariq KhanNessuna valutazione finora

- Uns s32760Documento3 pagineUns s32760NitinNessuna valutazione finora

- 1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,LrregularDocumento3 pagine1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,Lrregularroberto_perraciniNessuna valutazione finora

- Stainless SteelDocumento6 pagineStainless SteelNiko NištićNessuna valutazione finora

- S31803Documento2 pagineS31803Elliott RussellNessuna valutazione finora

- Alloy 625 Wire & Rod: U.S. Alloy CoDocumento1 paginaAlloy 625 Wire & Rod: U.S. Alloy CowinstonsequeiraNessuna valutazione finora

- Born From Fire, Made To Endure: Stainless SteelDocumento12 pagineBorn From Fire, Made To Endure: Stainless Steelqnetomid55Nessuna valutazione finora

- Kiran - Steel Data SheetDocumento57 pagineKiran - Steel Data SheetkirankumargattyNessuna valutazione finora

- Material SpecificationDocumento50 pagineMaterial SpecificationSangyt Karna0% (2)

- Aluminium AW 6101A T6 Busbar FlatDocumento3 pagineAluminium AW 6101A T6 Busbar Flatdoshi78Nessuna valutazione finora

- Anti-Surge Thick Film Chip Re Sis Tors 0603, 0805, 1206, 1210 ERJ P03, P06, P08, P14Documento5 pagineAnti-Surge Thick Film Chip Re Sis Tors 0603, 0805, 1206, 1210 ERJ P03, P06, P08, P14Francisco Lopez MoyaNessuna valutazione finora

- Userguide For SSDocumento26 pagineUserguide For SSehsan4uNessuna valutazione finora

- BoltsDocumento6 pagineBoltsJuragan IwalNessuna valutazione finora

- Nitronic60 MainDocumento28 pagineNitronic60 MainAnonymous IpqcBBNessuna valutazione finora

- Hardox 450 Uk Data SheetDocumento2 pagineHardox 450 Uk Data SheetNenad BozicNessuna valutazione finora

- 430 SSDocumento2 pagine430 SStranngocthuan200Nessuna valutazione finora

- Rwprorox SL 960Documento2 pagineRwprorox SL 960wassim nasriNessuna valutazione finora

- 2021 CatalogueDocumento27 pagine2021 CatalogueGMAR ComercializadoraNessuna valutazione finora

- Crom Plated BarsDocumento24 pagineCrom Plated BarschonubobbyNessuna valutazione finora

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesDa EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesValutazione: 4.5 su 5 stelle4.5/5 (5)

- Corrosion and its Consequences for Reinforced Concrete StructuresDa EverandCorrosion and its Consequences for Reinforced Concrete StructuresNessuna valutazione finora

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionDa EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNessuna valutazione finora

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesDa EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNessuna valutazione finora

- N2 Brochure - Praxair PDFDocumento12 pagineN2 Brochure - Praxair PDFEduardo Paulini VillanuevaNessuna valutazione finora

- Pipeline DesignDocumento60 paginePipeline DesignEduardo Paulini Villanueva0% (1)

- Binance - Ftmusd, 30Documento53 pagineBinance - Ftmusd, 30Eduardo Paulini VillanuevaNessuna valutazione finora

- HorariosDocumento2 pagineHorariosEduardo Paulini VillanuevaNessuna valutazione finora

- Chrinos ReportDocumento13 pagineChrinos ReportEduardo Paulini VillanuevaNessuna valutazione finora

- DataDocumento3 pagineDataEduardo Paulini VillanuevaNessuna valutazione finora

- Market OverviewDocumento8 pagineMarket OverviewEduardo Paulini VillanuevaNessuna valutazione finora

- 02 - Testing & Drilling IntroDocumento39 pagine02 - Testing & Drilling IntroEduardo Paulini VillanuevaNessuna valutazione finora

- 3 Point ProblemDocumento8 pagine3 Point ProblemDhana Strata NNessuna valutazione finora

- Caso de EstudioDocumento97 pagineCaso de EstudioEduardo Paulini VillanuevaNessuna valutazione finora

- ESP Installation ProcedureDocumento5 pagineESP Installation ProcedureEduardo Paulini VillanuevaNessuna valutazione finora

- Yellow PDFDocumento2 pagineYellow PDFEduardo Fernandes ArandasNessuna valutazione finora

- Measurements of Dissolved Substances in Water Injection LinesDocumento6 pagineMeasurements of Dissolved Substances in Water Injection LinesEduardo Paulini VillanuevaNessuna valutazione finora

- Exporting A Trend From The Memory ModuleDocumento1 paginaExporting A Trend From The Memory ModuleEduardo Paulini VillanuevaNessuna valutazione finora

- Hora RiosDocumento2 pagineHora RiosEduardo Paulini VillanuevaNessuna valutazione finora

- Sabiduria CentenariaDocumento1 paginaSabiduria CentenariaEduardo Paulini VillanuevaNessuna valutazione finora

- Cover Letter LipesaDocumento1 paginaCover Letter LipesaEduardo Paulini VillanuevaNessuna valutazione finora

- 02 - Testing & Drilling IntroDocumento39 pagine02 - Testing & Drilling IntroEduardo Paulini VillanuevaNessuna valutazione finora

- Report Tips Marking SchemeDocumento3 pagineReport Tips Marking SchemeEduardo Paulini VillanuevaNessuna valutazione finora

- Cover Letter LipesaDocumento1 paginaCover Letter LipesaEduardo Paulini VillanuevaNessuna valutazione finora

- BLLDGSF SDF SDF SDF S DF S DF SDF SD Fs DF SD FS DF SD FDocumento1 paginaBLLDGSF SDF SDF SDF S DF S DF SDF SD Fs DF SD FS DF SD FEduardo Paulini VillanuevaNessuna valutazione finora

- 01 - SlbwellactivitiesDocumento17 pagine01 - SlbwellactivitiesEduardo Paulini VillanuevaNessuna valutazione finora

- 02 - Testing & Drilling IntroDocumento39 pagine02 - Testing & Drilling IntroEduardo Paulini VillanuevaNessuna valutazione finora

- SimbaDocumento1 paginaSimbaEduardo Paulini VillanuevaNessuna valutazione finora

- Heat Exchanger DesignDocumento8 pagineHeat Exchanger DesignEduardo Paulini VillanuevaNessuna valutazione finora

- Compressible Cake Constant RateDocumento3 pagineCompressible Cake Constant RateEduardo Paulini VillanuevaNessuna valutazione finora

- Upon Your Arrival at ParisDocumento1 paginaUpon Your Arrival at ParisEduardo Paulini VillanuevaNessuna valutazione finora

- Coup Reform-Resistance v.82 PDFDocumento6 pagineCoup Reform-Resistance v.82 PDFEduardo Paulini VillanuevaNessuna valutazione finora

- Baker - Hughes - BHI Bits Uni Aberdeen SlidesDocumento9 pagineBaker - Hughes - BHI Bits Uni Aberdeen SlidesEduardo Paulini VillanuevaNessuna valutazione finora

- Castrol Alphasyn T-320Documento2 pagineCastrol Alphasyn T-320perroutalNessuna valutazione finora

- Method Statement For Stone Finish GRC Fabrication and ErectionDocumento5 pagineMethod Statement For Stone Finish GRC Fabrication and ErectionAnjo MolinaNessuna valutazione finora

- STUD ADHESIVE BONDED M10x50mm PDFDocumento61 pagineSTUD ADHESIVE BONDED M10x50mm PDFEd2sverissimoNessuna valutazione finora

- Chilled Water Systems Rev2 PDFDocumento31 pagineChilled Water Systems Rev2 PDF123john123100% (1)

- Catalogue - SRS Flex Industries PDFDocumento21 pagineCatalogue - SRS Flex Industries PDFSandeep RapakaNessuna valutazione finora

- Samyang PDFDocumento186 pagineSamyang PDFDidin BaeNessuna valutazione finora

- Astm A53-A53m 2018Documento23 pagineAstm A53-A53m 2018Lewis M. Nixon100% (4)

- Fridge BoschDocumento3 pagineFridge BoschAyman AlhalfawyNessuna valutazione finora

- A. What Is Soil Nailing GroutingDocumento7 pagineA. What Is Soil Nailing GroutingBENJAMIN III BIDANGNessuna valutazione finora

- Presentation 123Documento13 paginePresentation 123Harishitha ManivannanNessuna valutazione finora

- RAB Penawaran ROOFTOP TerbaruDocumento6 pagineRAB Penawaran ROOFTOP Terbarujual granit lokal murahNessuna valutazione finora

- Goulds Pumps Coupling GuardDocumento36 pagineGoulds Pumps Coupling GuardmishraenggNessuna valutazione finora

- Model Number Nomenclature: 5 0 T C - A 0 4 A 1 A 5 - 0 A 0 A 0Documento1 paginaModel Number Nomenclature: 5 0 T C - A 0 4 A 1 A 5 - 0 A 0 A 0Maria Elena JineteNessuna valutazione finora

- Limit State Design of Steel Members To AS4100Documento20 pagineLimit State Design of Steel Members To AS4100Sam ThomasNessuna valutazione finora

- Nitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesDocumento2 pagineNitoproof 600PF: Hydrocarbon Free, Liquid Applied Elastomeric One Coat Waterproofing Membrane UsesKishore Nayak kNessuna valutazione finora

- ME307 Solved SecondM T111Documento10 pagineME307 Solved SecondM T111Wolf MoonNessuna valutazione finora

- Fire Fighting in BuildingsDocumento20 pagineFire Fighting in BuildingsAishwarya Naidu100% (1)

- Ace Plast Ram C Revised July 2016Documento1 paginaAce Plast Ram C Revised July 2016pulakjaiswal85Nessuna valutazione finora

- Alucobest Aluminum Composite Panel For Architectural & BuildingDocumento12 pagineAlucobest Aluminum Composite Panel For Architectural & BuildingAli ZhangNessuna valutazione finora

- Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricDocumento14 pagineElectrodeposited Coatings On Mechanical Fasteners, Inch and MetricKamal El ShawadfyNessuna valutazione finora

- En 13398Documento9 pagineEn 13398jovzareNessuna valutazione finora

- Cryogenic MaterialsDocumento7 pagineCryogenic Materialsstudent1Nessuna valutazione finora

- Pvelite Seminar NotesDocumento314 paginePvelite Seminar NotesRafael_Yevgeny100% (3)

- 3CC System Performance SpecificationDocumento1 pagina3CC System Performance SpecificationAnonymous qTP5oq7gNessuna valutazione finora

- Bain Marie: User ManualDocumento6 pagineBain Marie: User ManualToni TursićNessuna valutazione finora

- Hahn Plastics Hanit Ultra Fencing Specifications Specification GuideDocumento9 pagineHahn Plastics Hanit Ultra Fencing Specifications Specification GuideMohammad AlizadehNessuna valutazione finora

- Fig.4400 Main Controller 1Documento2 pagineFig.4400 Main Controller 1ДмитрийNessuna valutazione finora

- Mcset DMLDocumento1 paginaMcset DMLلؤي المهندسNessuna valutazione finora

- Crushing Strain of Concrete - Google SearchDocumento3 pagineCrushing Strain of Concrete - Google SearchUtkarsh YadavNessuna valutazione finora

- ESAB Welding HandbookDocumento31 pagineESAB Welding Handbookhooky1100% (4)