Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CarboTherm TB2 0213 R02

Caricato da

thulasi_krishnaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CarboTherm TB2 0213 R02

Caricato da

thulasi_krishnaCopyright:

Formati disponibili

e n a b l e

TechnicalBulletin

CarboThermBoronNitridefillersforthermoplasticpolymers

Novelsolutionswiththermallyconductive,electricallyinsulatingcompounds

Thermally conductive compounds are finding novel uses in

emerging markets, presenting new opportunities as well as

challenges for thermoplastic compounders. There is an

increasedfocusonusageofplasticincomponentassemblies

that need to dissipate heat while providing electrical

insulationbetweensystemcomponents.

Plastic is inherently electrically and thermally insulating.

Plastic processors have traditionally extendedplastics reach

bymodifyingitspropertiesusingvariousfillersandadditives.

A new generation of Boron Nitride fillers by SaintGobain is

now enabling novel applications in emerging markets for

engineeringplastic.

Whatisdrivingthistrend?

The renewed focus on thermally conductive and electrically

insulatingplasticcomponentsisdrivenbyavarietyoffactors

Megatrends such as fuel savings and electrical vehicles

are driving weight reduction initiatives. Plastic parts

allow40to50%weightreductionscomparedtometal.In

addition, each pound reduced in weight equates to

additionalfuelcostsavingsincomponenttransportation

intodaysglobalsupplychain.

Frequent design changes in system components in high

volume enduser applications demand faster design and

manufacturing cycles. This is easily achieved by widely

adopted netshape processes that enable custom

solutions

Electronicandelectricaldevicesarepackingmoreenergy

in smaller sizes, making traditional metal heat sinks

complicated and costly to diecast in small intricate

shapes.Plasticpresentsuniquesolutionswithitseaseof

processing. Furthermore, improved heat management

whilereducingcomponentweightinthenextgeneration

devices enables lower power ratings, a feature very

importantforelectricalequipment.

Besides the weight and easeofmanufacturing advantage,

thermoplastic also exhibit high strengthtoweight ratio,

excellentresistancetocorrosion,andrecyclingoptions.

Typical applications for thermallyconductive and

electricallyinsulatingplastics

Thermallyconductiveandelectricallyinsulatingplasticsopen

a broad range of new thermal management applications.

Molded parts may replace metals, ceramics, and non

conductiveplasticsinavarietyofapplications.

Most notably, the combination of thermal conductivity and

electrical insulation feature in a single component

combined with the ease of plastic molding expands

thermally conductive plastics use beyond just replacing

metalstoreplacinghybridcompositecomponents.

Typical applications for thermoplastic polymers include

custommolded heat sinks on circuit boards, tubing for heat

exchangers in appliances, insulation for highspeed rotating

machine components, heat sink enclosures for LED bulbs,

components for telecommunication devices,

parts/enclosures for underthehood and electronic

componentunitsinautomotive.

Roleofthefiller:CarboThermBoronNitride

Thermoplastic compounds must have the required thermal

conductivity to meet the needs of these applications.

Common lowcost mineral or glass fillers cannot be used as

the fillers thermal conductivity must be of a higher order of

magnitudethanthedesiredthermalconductivityofthefinal

product. Metal, carbon and graphite fillers are also

eliminated due to the electrical insulation requirement

leavingonlyceramicfillersaspotentialcandidates.

Among ceramic fillers that are thermally conductive and

electricallyinsulatingsuchashBN,AlN,Si3N4,SiC,Al2O3and

ZnO; hexagonal Boron Nitride (hBN) offers lowest density

and low coefficient of friction. Low density facilitates

maximum reduction in component weight, while lubricity

supportsreducedwearandimprovedequipmentlifecycle.

Not found in nature, hexagonal boron nitride is

manufacturedfromhightemperaturesynthesisofBoronand

Nitrogen precursors. hBN presents many benefits for

polymer processing, along with high thermal conductivity

andexcellentelectricalinsulation:

lubricious and nonabrading greatly reduces wear on

injectionmoldingandextrudingequipment

White particularly useful where white and clean

appearance is critical, such as plastic components in

food,medicalandarchitecturalsystems

Low density enables lowweight plastic compounds

comparedtootherthermallyconductivefillers

Low surface area helps achieve higher loading levels,

maximize thermal conductivity while maintaining

mechanicalintegrity

Availableinlargecrystalsizesallowsmaximumthermal

conductivity

Low coefficient of thermal expansion helps replace

metal or ceramic parts in dimensionally critical

applicationswhileenhancingelectricalisolationofplastic

compatiblewithavarietyofresinsystemsgivesplastic

compounders ease and flexibility to fit CarboTherm into

theirexistingresinmatrix

Available in highflow grades Supports highvolume

loadingforautomatedpolymerprocessingsystems

CarboTherm grades for thermoplastic polymer

processing

hBN from SaintGobain is available in more than 50 grades,

characterized by particle size distribution, tap density,

surfacearea,purityandawholehostofotherparameters.

ThepropertiesofagivenhBNgrade,whiledesirableinsome

applications, may lead to nonoptimal flow characteristics

and poor mixing in plastic processing. The requirements for

plasticcompoundingareveryunique.Optimumparticlesize,

surfacearea,tapdensity,flowproperties,andmechanical

properties of the filler all play an important role in mixing,

dispersion,aswellasendproductcharacteristics.

SaintGobains PCTF5, PCTP30D, PCTP40 and PCTH10MHF

presentarangeofsolutionasplasticfillers:

PCTF5fineplateletgradeforthinplasticapplications

PCTP30D freeflowing, loosely agglomerated powder

designed for costsensitive, highvolume applications.

Disperses uniformly by the high shear forces in the

thermoplastic melt, exhibits optimum thermal conductivity,

mechanicalperformance,andhighthroughput

PCTP40 our largest size platelet powder, most suitable for

applicationsrequiringsuperiorthermalconductivity

PCTH10MHF premium grade, highdensity agglomerated

powder, recommended for improved inplane (xy plane) as

wellasthroughplane(zplane)thermalconductivity

Grade PCTF5 PCTP30D PCTP40 PCTH10MHF

D50(Mean) Microns 7 180 45 140

D100(Max.) Microns 30 1500 250 200

TapDensity g/cc 0.3 0.6 0.5 0.8

SurfaceArea m2/g 7 1 1.1 2.5

ThermalConductivity,W/mK

Hexagonal

2.2

1.74

<0.3

34

30130

White

CarboThermThermalManagementFillersforthermoplastic

polymercompoundingtypicalproperties

Appearance

CrystalStructure

BulkDensity,g/cc

RefractiveIndex

CoefficientofFriction

DielectricConstant

SaintGobainhas50+yearsofexperienceinsynthesizingand

refining Boron Nitride powders to specific process

parameters.CarboThermBoronNitridepowdersenableeasy

processing, giving compounders the confidence to

consistentlyandreliablymeettheircustomersexpectations.

The information, recommendations and opinions set forth herein are offered solely for your consideration, inquiry and verification and are not, in part or total, to be

construed as constituting a warranty or representation for which we assume legal responsibility. Nothing contained herein is to be interpreted as authorization to

practiceapatentedinventionwithoutalicense.

SGBNCarboThermTB21013R02 www.bn.saintgobain.com 2013SaintGobainCeramicMaterials

CarboThermisatrademarkofSaintGobainCeramicMaterials.

SaintGobainBoronNitride

168CreeksideDrive

AmherstNY14228

T:18776912001(Tollfree)

T:17166912000

F:17166912090

E:BNSales@saintgobain.com

Potrebbero piacerti anche

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementDa EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNessuna valutazione finora

- TIMCAL Brochure Fuel CellsDocumento8 pagineTIMCAL Brochure Fuel Cellsjanakiram2010Nessuna valutazione finora

- CHEM - LEC - PolycarbonateDocumento5 pagineCHEM - LEC - PolycarbonateOri SeinNessuna valutazione finora

- The Background of Thermoforming The Advantages of ThermoformingDocumento7 pagineThe Background of Thermoforming The Advantages of ThermoformingA MahmoodNessuna valutazione finora

- Specialty Plastics-Liquid Crystal PolymersDocumento28 pagineSpecialty Plastics-Liquid Crystal PolymersAshutosh SachanNessuna valutazione finora

- 30 38 Engl PDFDocumento18 pagine30 38 Engl PDFJavad AmnianNessuna valutazione finora

- Leading High Heat-Resistant PolymersDocumento12 pagineLeading High Heat-Resistant PolymerstilakmirleNessuna valutazione finora

- Sim900 - Https at Command Set - v1 00Documento11 pagineSim900 - Https at Command Set - v1 00ram sriNessuna valutazione finora

- Bipolar PlatesDocumento7 pagineBipolar PlatesNabilah SadaliNessuna valutazione finora

- Conventional Powdered Metal ComponentsDocumento15 pagineConventional Powdered Metal ComponentsPrabir Kumar PatiNessuna valutazione finora

- What Bergquist Materials For PCBDocumento33 pagineWhat Bergquist Materials For PCBjackNessuna valutazione finora

- Particulate Filled Polymer Composites 2nd Edition Chapter 8 Filled ThermoplasticsDocumento69 pagineParticulate Filled Polymer Composites 2nd Edition Chapter 8 Filled ThermoplasticsJose CastroNessuna valutazione finora

- UntitledDocumento64 pagineUntitledMeenakshi AnandNessuna valutazione finora

- 11-Almunaif Prr-Pipes and FittingsDocumento44 pagine11-Almunaif Prr-Pipes and FittingsmohammedNessuna valutazione finora

- R HPP Chemical Processing EN PDFDocumento36 pagineR HPP Chemical Processing EN PDFKumar SaravanaNessuna valutazione finora

- Aufsatz Franssen RFP 03-2012Documento6 pagineAufsatz Franssen RFP 03-2012Román M Martín del CNessuna valutazione finora

- Alubond TecnologíaDocumento15 pagineAlubond TecnologíaGabriel CamposNessuna valutazione finora

- Schunk Sealing RingsDocumento20 pagineSchunk Sealing Ringspeach5Nessuna valutazione finora

- Module 7 - RajagopalDocumento43 pagineModule 7 - Rajagopal10 AirNessuna valutazione finora

- BMC Auto ElectDocumento52 pagineBMC Auto ElectLâle Bulut100% (1)

- PPO SlideDocumento29 paginePPO SlideRadhashyam GiriNessuna valutazione finora

- KLEBSTOFFE - PUR ADHESIVES COMPETENCEDocumento10 pagineKLEBSTOFFE - PUR ADHESIVES COMPETENCEBoris KuseljNessuna valutazione finora

- PolyolyfinsDocumento40 paginePolyolyfinsManikiranSai100% (1)

- Turning Plastic Waste Into OilDocumento10 pagineTurning Plastic Waste Into OilSanjana SharmaNessuna valutazione finora

- MATS324A8 EnvImplDocumento21 pagineMATS324A8 EnvImplAlessandro CastagnaNessuna valutazione finora

- FRP Piping Technical Aspects - Joints Etc.Documento15 pagineFRP Piping Technical Aspects - Joints Etc.A_ValsamisNessuna valutazione finora

- Wear and Friction MaterialDocumento24 pagineWear and Friction MaterialPrem Sankar100% (2)

- Printed Circuit BoardDocumento13 paginePrinted Circuit BoardJimmy Makiling PamugasNessuna valutazione finora

- Carbon Fiber ThesisDocumento7 pagineCarbon Fiber ThesisWriterPaperCanada100% (2)

- Surface Engineering: Submitted byDocumento13 pagineSurface Engineering: Submitted byVarun Krishna PinnaNessuna valutazione finora

- AccessDocumento7 pagineAccessBranko FerenčakNessuna valutazione finora

- CRP 02 01Documento18 pagineCRP 02 01Sukses SejahteraNessuna valutazione finora

- Composites World Thermoformable Composite PanelsDocumento26 pagineComposites World Thermoformable Composite PanelsSunilBhandariNessuna valutazione finora

- So Many Heat Exchangers, So Little TimeDocumento3 pagineSo Many Heat Exchangers, So Little Timefawmer61Nessuna valutazione finora

- Unit VDocumento11 pagineUnit VBHOWIN KNessuna valutazione finora

- PE100 TechHandbook PDFDocumento64 paginePE100 TechHandbook PDFIvan CastroNessuna valutazione finora

- Adhesion Promoter Makes Hybrid Components Even Lighter and More RigidDocumento6 pagineAdhesion Promoter Makes Hybrid Components Even Lighter and More RigidSebastian AndreoliNessuna valutazione finora

- 9 Tasnee Final Plastic Compounding Tasnee GpcaDocumento33 pagine9 Tasnee Final Plastic Compounding Tasnee GpcaParas PatelNessuna valutazione finora

- Consumer Goods - Low Cost and Easy Processability Make HDPE A Material of Choice inDocumento5 pagineConsumer Goods - Low Cost and Easy Processability Make HDPE A Material of Choice inDwi YuliantoNessuna valutazione finora

- Plastics Processing Techniques TrainingDocumento76 paginePlastics Processing Techniques Trainingsadananda_pvcNessuna valutazione finora

- Plastic Technology (Uyumluluk Modu)Documento72 paginePlastic Technology (Uyumluluk Modu)Suchetha RajuNessuna valutazione finora

- Research ArticleDocumento9 pagineResearch ArticleGufran AhmadNessuna valutazione finora

- Manufacturing Process and Material Properties of Carbon and Graphite MaterialsDocumento12 pagineManufacturing Process and Material Properties of Carbon and Graphite Materialsdtkraeut100% (1)

- CALCE Best Practices Controlling Moisture PCBDocumento10 pagineCALCE Best Practices Controlling Moisture PCBBeta TesterNessuna valutazione finora

- Application of Polymer For TransportationDocumento25 pagineApplication of Polymer For TransportationKunashiny Ramash100% (1)

- Evaluation of High Pressure Water Atomized Powders For Large Scale PIM Production Using Different Binder FormulationsDocumento10 pagineEvaluation of High Pressure Water Atomized Powders For Large Scale PIM Production Using Different Binder FormulationsfebriyansyahNessuna valutazione finora

- How To Choose The Best PCB Substrate For BoardDocumento12 pagineHow To Choose The Best PCB Substrate For BoardjackNessuna valutazione finora

- Development of Low Cost Carbon Fibre in Automotive ApplicationDocumento15 pagineDevelopment of Low Cost Carbon Fibre in Automotive ApplicationMuthu BalajiNessuna valutazione finora

- Debinding and Sintering Solutions For Metals and CeramicsDocumento8 pagineDebinding and Sintering Solutions For Metals and CeramicsdtkraeutNessuna valutazione finora

- ResinDocumento7 pagineResinMohammad Doost MohammadiNessuna valutazione finora

- Polymers in Automobiles: Applications and PropertiesDocumento24 paginePolymers in Automobiles: Applications and PropertiesAkash SainiNessuna valutazione finora

- Demand For NonDocumento7 pagineDemand For NongganageNessuna valutazione finora

- A1120897415 23418 4 2018 PolymersDocumento43 pagineA1120897415 23418 4 2018 PolymersKushNessuna valutazione finora

- Study and Characterization of The Dielectric Behavior of Low Linear Density Polyethylene Composites MixeDocumento20 pagineStudy and Characterization of The Dielectric Behavior of Low Linear Density Polyethylene Composites MixeCRISTIAN FABIAN PACHERRES SANCHEZNessuna valutazione finora

- Business Oppurtunities in Plastics Processing & Allied IndustriesDocumento100 pagineBusiness Oppurtunities in Plastics Processing & Allied IndustriesNitin GuptaNessuna valutazione finora

- Biodegradable Nanocomposites With Improved Physical Properties Created Via SolidDocumento3 pagineBiodegradable Nanocomposites With Improved Physical Properties Created Via SolidSuchismita SahooNessuna valutazione finora

- Study On Co-Extrusion Process Using Die of Multi - Orifice For Plastic Optic Fiber ProductionDocumento7 pagineStudy On Co-Extrusion Process Using Die of Multi - Orifice For Plastic Optic Fiber ProductionParag NambiarNessuna valutazione finora

- Modelica Thermal ModelingDocumento4 pagineModelica Thermal Modelingthulasi_krishnaNessuna valutazione finora

- Gearmotor size estimator spreadsheetDocumento2 pagineGearmotor size estimator spreadsheetS C GaurNessuna valutazione finora

- Feedback Control Performance MeasuresDocumento37 pagineFeedback Control Performance MeasuresmrkmatNessuna valutazione finora

- Simulation CellierDocumento65 pagineSimulation Cellierthulasi_krishnaNessuna valutazione finora

- LaminateDocumento3 pagineLaminatethulasi_krishnaNessuna valutazione finora

- Mil DTL 38999 Series IIIDocumento10 pagineMil DTL 38999 Series IIIthulasi_krishnaNessuna valutazione finora

- Chinese Baby Gender Chart - Lunar Month of ConceptionDocumento6 pagineChinese Baby Gender Chart - Lunar Month of Conceptionthulasi_krishnaNessuna valutazione finora

- Model Based Systems Engineering For Aircraft Systems - How DoesDocumento9 pagineModel Based Systems Engineering For Aircraft Systems - How DoesAlmas QasimNessuna valutazione finora

- Expense Tracker: Date Purpose Payment Method Transaction # Payee Expense Category Notes Amount Total ExpensesDocumento9 pagineExpense Tracker: Date Purpose Payment Method Transaction # Payee Expense Category Notes Amount Total Expensesthulasi_krishnaNessuna valutazione finora

- Valve Sizing CalculationsDocumento20 pagineValve Sizing Calculationsask_friend100% (3)

- FastenersDocumento178 pagineFastenersthulasi_krishna100% (6)

- Technical Manual - O-Ring Gland Design InformationDocumento31 pagineTechnical Manual - O-Ring Gland Design InformationplaunieNessuna valutazione finora

- Economic and Product Design Considerations in Machiningchapter 24Documento38 pagineEconomic and Product Design Considerations in Machiningchapter 24احمد عمر حديدNessuna valutazione finora

- Seals and Gaskets: 3.0 Table of ContentsDocumento40 pagineSeals and Gaskets: 3.0 Table of Contentsthulasi_krishnaNessuna valutazione finora

- Seal Design Considerations Using Kalrez PartsDocumento4 pagineSeal Design Considerations Using Kalrez Partsthulasi_krishnaNessuna valutazione finora

- Project Status Dashboard Xl2007Documento22 pagineProject Status Dashboard Xl2007Jkjiwani AccaNessuna valutazione finora

- Lecture3 - Three Phase Power Converter Control Strategies For Three Machine TypesDocumento26 pagineLecture3 - Three Phase Power Converter Control Strategies For Three Machine Typesthulasi_krishnaNessuna valutazione finora

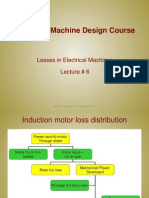

- Lecture6 - Losses in Electric MachinesDocumento24 pagineLecture6 - Losses in Electric Machinesthulasi_krishnaNessuna valutazione finora

- Electromagnetic Design of DC MotorsDocumento24 pagineElectromagnetic Design of DC Motorsthulasi_krishna100% (1)

- Lecture2 - Basic Electric Motor & Generator TheoryDocumento21 pagineLecture2 - Basic Electric Motor & Generator Theorythulasi_krishnaNessuna valutazione finora

- F 4Documento9 pagineF 4thulasi_krishnaNessuna valutazione finora

- Brushless DC Motor Phase Poles Lot ConfigurationsDocumento17 pagineBrushless DC Motor Phase Poles Lot Configurationsthulasi_krishnaNessuna valutazione finora

- Lecture1 - History & IntroductionDocumento20 pagineLecture1 - History & Introductionramaswamykama786100% (1)

- Projectto Dolist1Documento2 pagineProjectto Dolist1Vikas PhatakNessuna valutazione finora

- Calendar 2014: January February MarchDocumento4 pagineCalendar 2014: January February Marchthulasi_krishnaNessuna valutazione finora

- Bolt DesignDocumento18 pagineBolt Designthulasi_krishnaNessuna valutazione finora

- Random Vibration - An Overview - BarryControlsDocumento15 pagineRandom Vibration - An Overview - BarryControlsGuru75Nessuna valutazione finora

- Lecture1 - History & IntroductionDocumento20 pagineLecture1 - History & Introductionramaswamykama786100% (1)

- Lecture2 - Basic Electric Motor & Generator TheoryDocumento21 pagineLecture2 - Basic Electric Motor & Generator Theorythulasi_krishnaNessuna valutazione finora

- MIT8 02SC Notes16to18Documento30 pagineMIT8 02SC Notes16to18GeorgeChangNessuna valutazione finora

- Ei2303 Ii Ii 4&5Documento23 pagineEi2303 Ii Ii 4&5Ramanathan SunderNessuna valutazione finora

- Outline For PhotosynthesisDocumento6 pagineOutline For Photosynthesiswitzy11Nessuna valutazione finora

- RIR Values for Amorphous Phases Analyzed by MSL's CheMinDocumento2 pagineRIR Values for Amorphous Phases Analyzed by MSL's CheMinxavi lifeNessuna valutazione finora

- User Manual of Laser Engraving Machine PDFDocumento36 pagineUser Manual of Laser Engraving Machine PDFRobby SubhansyahNessuna valutazione finora

- Thiabendazole RedDocumento103 pagineThiabendazole RedFandhi Adi100% (1)

- LM Product BrochureDocumento20 pagineLM Product BrochurekashishNessuna valutazione finora

- Book Print Gunastar Final - 1528261270Documento103 pagineBook Print Gunastar Final - 1528261270santoshNessuna valutazione finora

- Solvent RecoveryDocumento22 pagineSolvent RecoveryNikul Rathod100% (1)

- Lowara LSN Low Res LDocumento12 pagineLowara LSN Low Res LDodi SuhendraNessuna valutazione finora

- Research Programmes: EligibilityDocumento14 pagineResearch Programmes: Eligibilitysatyakrishna1234Nessuna valutazione finora

- Calculation Cover Sheet: ClientDocumento8 pagineCalculation Cover Sheet: Clientanamaria ursuNessuna valutazione finora

- April 2010 One FileDocumento296 pagineApril 2010 One FileSaad MotawéaNessuna valutazione finora

- Incompatibilities in Prescription 4e (1917)Documento334 pagineIncompatibilities in Prescription 4e (1917)Benjel AndayaNessuna valutazione finora

- Lec34 Soil P and KDocumento24 pagineLec34 Soil P and KDIBINessuna valutazione finora

- Energy Engineering SyllabusDocumento49 pagineEnergy Engineering SyllabusKarthiik88Nessuna valutazione finora

- HF Scientific Online Chlorine Monitors and Reagents - CLXDocumento3 pagineHF Scientific Online Chlorine Monitors and Reagents - CLXMCE ProcessNessuna valutazione finora

- Quality and Testing of Packaging Materials & PackagesDocumento41 pagineQuality and Testing of Packaging Materials & PackagesChamara MadugalleNessuna valutazione finora

- Material Science QuestionsDocumento40 pagineMaterial Science QuestionsLucky KapoorNessuna valutazione finora

- 100-800 HP Boiler Control System PLC HMI Safety FunctionsDocumento4 pagine100-800 HP Boiler Control System PLC HMI Safety FunctionssebaversaNessuna valutazione finora

- Valvoline Lithium Ep2 GreaseDocumento1 paginaValvoline Lithium Ep2 GreaseDicky PratamaNessuna valutazione finora

- Manufacturing of Light Weight Composite Parts For Automotive ApplicationsDocumento84 pagineManufacturing of Light Weight Composite Parts For Automotive ApplicationsvkrishnarajNessuna valutazione finora

- Weld StudsDocumento24 pagineWeld StudsDGWNessuna valutazione finora

- Aspl 2011 PDFDocumento29 pagineAspl 2011 PDFRajkumar ANessuna valutazione finora

- Material BalancesDocumento15 pagineMaterial BalancesHalil İbrahim ÖzdemirNessuna valutazione finora

- Quiz Oil & Gas EngineeringDocumento110 pagineQuiz Oil & Gas EngineeringLisa Malone100% (1)

- Ferodo - Brake Pads Data Sheets enDocumento7 pagineFerodo - Brake Pads Data Sheets enfranziskaner79Nessuna valutazione finora

- Confined Space EntryDocumento15 pagineConfined Space EntryEnginnering Section100% (1)

- Aerodynamic Characteristics of NACA 4412 AirfoilDocumento19 pagineAerodynamic Characteristics of NACA 4412 AirfoilMuhammad HattaNessuna valutazione finora

- Corrosion Behavior of Stainless Steel in Hydrochloric Acid and Nitric Acid SolutionsDocumento5 pagineCorrosion Behavior of Stainless Steel in Hydrochloric Acid and Nitric Acid SolutionsantonytechnoNessuna valutazione finora

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesDa EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesValutazione: 5 su 5 stelle5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationDa EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationValutazione: 4 su 5 stelle4/5 (18)

- Guidelines for the Management of Change for Process SafetyDa EverandGuidelines for the Management of Change for Process SafetyNessuna valutazione finora

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksDa EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksValutazione: 5 su 5 stelle5/5 (1)

- Inherently Safer Chemical Processes: A Life Cycle ApproachDa EverandInherently Safer Chemical Processes: A Life Cycle ApproachValutazione: 5 su 5 stelle5/5 (1)

- Introduction to Petroleum Process SafetyDa EverandIntroduction to Petroleum Process SafetyValutazione: 3 su 5 stelle3/5 (2)

- Guidelines for Implementing Process Safety ManagementDa EverandGuidelines for Implementing Process Safety ManagementNessuna valutazione finora

- Incidents That Define Process SafetyDa EverandIncidents That Define Process SafetyNessuna valutazione finora

- Guidelines for Siting and Layout of FacilitiesDa EverandGuidelines for Siting and Layout of FacilitiesNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Chemical Process Safety: Learning from Case HistoriesDa EverandChemical Process Safety: Learning from Case HistoriesValutazione: 4 su 5 stelle4/5 (14)

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisDa EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNessuna valutazione finora

- Operational Excellence: Journey to Creating Sustainable ValueDa EverandOperational Excellence: Journey to Creating Sustainable ValueNessuna valutazione finora

- Safety Fundamentals and Best Practices in Construction IndustryDa EverandSafety Fundamentals and Best Practices in Construction IndustryNessuna valutazione finora

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDa EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNessuna valutazione finora

- Rules of Thumb for Maintenance and Reliability EngineersDa EverandRules of Thumb for Maintenance and Reliability EngineersValutazione: 4.5 su 5 stelle4.5/5 (12)

- Guidelines for Developing Quantitative Safety Risk CriteriaDa EverandGuidelines for Developing Quantitative Safety Risk CriteriaNessuna valutazione finora

- Perfume Engineering: Design, Performance and ClassificationDa EverandPerfume Engineering: Design, Performance and ClassificationValutazione: 4 su 5 stelle4/5 (5)

- LNG Risk Based Safety: Modeling and Consequence AnalysisDa EverandLNG Risk Based Safety: Modeling and Consequence AnalysisNessuna valutazione finora

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Guidelines for Engineering Design for Process SafetyDa EverandGuidelines for Engineering Design for Process SafetyNessuna valutazione finora

- Process Plant Equipment: Operation, Control, and ReliabilityDa EverandProcess Plant Equipment: Operation, Control, and ReliabilityValutazione: 5 su 5 stelle5/5 (1)

- A Complete Guide to Safety Officer Interview Questions and AnswersDa EverandA Complete Guide to Safety Officer Interview Questions and AnswersValutazione: 4 su 5 stelle4/5 (1)