Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

I. Company Background Profood International Corp

Caricato da

Julie Ann PiliDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

I. Company Background Profood International Corp

Caricato da

Julie Ann PiliCopyright:

Formati disponibili

I.

COMPANY BACKGROUND

PROFOOD INTERNATIONAL CORP.

Profood International Corporation is the largest Philippine based dried fruit producer and the standard

bearer of world class processed fruit products from the Philippine Islands.

From the small company that once catered only to the local market, Profood International Corporation

has grown to become the leading producer of various dried fruit, preserves, purees, concentrates, and

juices. Its products are available all over the Philippines and exported to many countries in Asia, the

Middle East, Europe, North, Central, and South America, the Caribbean, and Oceania.

An ISO 9001:2008, HACCP, KOSHER, HALAL, and NSF certified company, their main headquarters are

based in Cebu, Central Philippines. This makes it strategically accessible to source mangoes year round

from throughout the country. At present, the company has four manufacturing sites located in the

north, central, southern, and western parts of the Philippines to be close to the sources of various

regionally grown fruits.

With our sophisticated automated systems, fruit is processed efficiently in a highly sanitized

environment. In the aseptic process, the fruit puree is heated to sterilizing temperatures then

immediately cooled to room temperature within the system before it is packaged into sterile containers.

This technique allows retention of the fruit's natural flavor, color and aroma while prolonging shelf life.

Since its inception in 1980. Profood International Corporation has remained steadfast in its commitment

to product excellence. This strict adherence to superior quality has earned not only satisfaction from

discerning Filipino and foreign customers but also recognition from industry partners world wide.

Profood international corporation is committed to consequently provide high quality and a wide variety

of processed tropical fruit products while protecting the environment in which its product are grown

and processed. Its production practices are solidly built around environmental consciousness and eco-

friendly programs. It is astonished advocate of re-greening the barred Philippine hillsides by covering

them with mango trees. Its factories are even 80% independent of crude oil, using instead coconut

shells burning boilers for steam generation. Profood is aiming zero waste by its residues to value added

products such as feeds from peels, fuel from seeds to help preserve the environment.

Profoods dedication to quality is firmly bathed by quality stringed quality control measures, state of the

art production technologies and continuous improvement through research and innovation.

The company is also very aware to its social responsibility to the welfare of the farming communities

that it relies on with its dedication of helping the small farmer and fruit growing communities in the

country side. It lands a hand to small scaled fruit growers by buying straight from them, instead of using

larger operations for purchasing fresh mangoes and other Philippine fruits. Through the years it has

helped a lot of young students finishing schooling with its summer employment programs and its plants.

Profood International Corporation continues to maintain market leadership driven by the passion for

quality and professionalism that its global customers have come to rely on.

UNIVERSAL FEEDMILL CORPORATION

Universal Feed Mill Corporation is one of the leading feed miller in the Philippines that provides hog

feeds, poultry feeds and fighting cock (gamefowl) feeds at a very affordable and competitive price

nationwide.

Universal Feed Mill Corporation or Unifeeds is a company engaged in the manufacturing of hog and

poultry feeds. Its products include the famous Nutri-grow and Pit Fighter Sabong Feeds. These and other

labels are directly marketed and distributed by its sister company called JM Poultry and Livestock Supply

(Cebu), Inc.

Unifeeds establishment can be described as a spill-over effect of JMs success in the local agrivet scene.

Started in 1984 by Dr. Avelino and Elenita De Manuel ( a veterinarian and animal nutritionist couple), JM

was engaged into selling branded feeds and veterinary products, with customer base made up largely of

backyard raisers.

Vision:

The FEED OF CHOICE of all livestock raisers.

Mission Statements:

To provide hogs, poultry and aqua raisers excellent and complete line of quality feeds at very

affordable prices nationwide.

To serve as a catalyst in the Philippine livestock industrys endeavour to be globally competitive,

through technology transfer and continuous research and development.

To encourage Filipinos to engage in livestock raising as a viable industry to achieve financial

independence.

To adapt innovative and eco-friendly manufacturing practices for sustainable environment.

To provide employees stable and safe working environment with equal opportunity for learning

and personal growth.

GREENCOIL INDUSTRIES, INC.

Greencoil Industries, Inc. is the maker of Lion-Tiger Mosquito coils and Insect Sprays in the Philippines.

Greencoil Industries is the most trusted mosquito killer for more than 50, years.

Vision

To make this world a much better place to live. A nice resting place free from dreaded diseases.

Mission

To provide everyone quality products that will enhance a much better and healthier life

throughout generations.

Greencoil industries Inc. produce two categories of products, which are Lion-Tiger mosquito coils and

Lion- Tiger Aerosol insect Spray.

Under Lion-Tiger mosquito Coils, the company produces the following:

Lion Tiger Lavender Scented Mosquito Coils, providing not only protection against mosquito

bites but also provide an aromatic lavender scent.

Lion Tiger Citrus Scented Mosquito Coils, giving out a refreshing citrus scent.

Flying Tiger Lavender Scented Mosquito Coil

Lion-Tiger Katol in regular, junior and king size

Lion Katol, is the most potent against dengue carrying mosquitoes.

Lion Katol Gold Premium, one of the best products in giving utmost protection against deadly

mosquitoes during rainy season.

Lion King

Tiger Katol, in a pitcher, and lunch box

Under Lion-Tiger Aerosol Insect Spray, the compay produces the Lion Tiger Insect Spray and Lion Tiger

Aerosol with mild scent.

Contact Information

Office Address:

Greencoil Industries, Inc.

Tingub cor Pagsabungan Road

Mandaue City, Cebu Philippines 6014

Telephone Numbers:

+63 32 4221413

+63 32 4221414

+63 32 4221422

Fax Numbers:

+63 32 4221424

Email Address: info@lion-tiger.com

II. OBSERVATIONS

PROFOOD INTERNATIONAL CORP.

A. General

Profood International Corp. is an ISO 9001:2008, HACCP, KOSHER, HALAL, and NSF certified company,

and their main headquarters and processing plant is strategically located in the central region of the

Philippines, specifically in A. S. Fortuna Street, Mandaue City, Cebu. The plant site is just a few

kilometers away from the sea and air ports in Cebu, giving way for a convenient access to a continuous

supply of premium, quality fruits from all over the country. Their environment is highly sanitized, making

sure that their products are processed efficiently. The company hires numerous amounts of male and

female employees who are highly and thoroughly trained to do specific tasks on which they are assigned

in the production process. Not only that, the company equips sophisticated, state-of-the-art-facilities

which proved the companys objective to achieve product excellence and superior quality.

B. Production/Process

Although the company produces various juices, purees, preserves, concentrates and dried fruit, what we

only saw was the production process of the dried mango and some juices. The production starts with

acquiring the fruit from the suppliers, and storing them in the warehouse. Practicing the FIFO method,

the mangoes are brought into the production area where they are manually peeled, cleansed, sliced to

different sizes, pasteurized, heated in the oven until they dry. They are then coated with sugar and

cooled to room temperature before they are packed into the sterile containers. The containers then are

weighed to ensure that each pack of dried mango has the desired weight and then distributed to the

different market. As to the production of the juices, the same process applies except that the fruits are

converted into their liquid form and they are mixed with water and other ingredients. They are then

heated to sterilizing temperatures then immediately cooled to room temperature within the system

before it is packaged into sterile containers. The whole process allows retention of the fruits natural

flavor, color, and aroma while prolonging their shelf life.

C. Inventory Management

The raw materials they acquire from the suppliers are stored in specific warehouses, e.g. a specific

warehouse for mangoes, another for coconut, etc. They apply the FIFO method in their inventory

especially with the fruits to avoid over ripeness. The same goes to the finished goods inventory. As to

both raw materials and finished goods, they are placed in containers that are labeled with numbers

which show the should-be amount of raw material/finished good in each container.

D. Property, Plant, and Equipment

The plant site is equipped with the following state-of-the-art facilities:

Four Dried Fruit Processing Plants

Canned Juice Plant

Aseptic Fruit Puree Plant

Stand-Up-Pouch (SUP) Line for Purees, Juices, Sauces and Preserves

Canned and Bottled Preserves Line

Pudding & Jelly Cups Line

Frozen Fruit Line

The aforementioned equipments are cleaned and checked daily to ensure the quality and sanitation of

their products. The equipments may be used for exactly 8 hours, or more or less than 8 hours depending

on the production demand.

UNIVERSAL FEEDMILL CORPORATION

A. General

Universal Feed Mill Corporation or Unifeeds is a company engaged in the manufacturing of hog and

poultry feeds. Its plant site is located in Don Suico St., Riverside, Canduman Mandaue City, Cebu. They

employ highly skilled staff and workers for their production, the plant site is fully automated and their

products are laboratory tested to bring the best in animal nutrition.

B. Production/Process

The company constantly purchases raw materials directly from suppliers. The raw materials are then

fortified with organic trace materials, prebiotics, probiotics, and natural feed supplements to ensure the

safety of the consumers and the environment. Various feeds are produced, namely hog feeds, poultry

feeds, and gamefowl feeds.

C. Inventory Management

There is only one warehouse for the raw materials and finished goods inventory. One side of the

warehouse is for the raw materials, while the other is the finished goods inventory. They constantly buy

raw materials from suppliers so there were many raw materials stored in the warehouse. Based on our

understanding, their production is not based on demand or a quota in their days produce. From what

we have seen, there were many sacks of feeds produced so production was temporarily stopped.

Property, Plant, and Equipment

The whole production is interrupted if one part of their PPE is damaged because all their PPEs are

connected with one another.

GREENCOIL INDUSTRIES, INC.

A. General

Greencoil Industries, Inc. office and processing plant is located in Tingub corner Pagsabungan Road,

Mandaue City, Cebu. The location is quite surprising because the plant site is not secluded by many

people. Nevertheless, the company is the maker of the well-known Lion-Tiger Mosquito Coils and Insect

Sprays, which protect us from the dreaded diseases like Dengue and Malaria. The company focuses its

workforce on manual labor, thus employing many men and women to perform their manufacturing

process. There is not much to focus on sanitation due to the nature and type of the raw materials used,

and the type of work done during the process.

B. Production/Process

The raw materials needed to make mosquito coils are coffee pulp, coco shells, dried ipil-ipil, mango and

mahogany leaves, sawdust, gum resin powder, and cassava starch. They are screened, chopped to fine

pieces, and put to a rotary dryer to reduce moisture content. They are the pulverized through a

pulverizing machine until they become a fine powder. All the material powder will then be poured into a

rotary mixing machine to mix them thoroughly. The mixed powder is transferred to the kneader.

Actives, cassava starch and coloring matter are also added in the kneader. The coils are formed through

a stamping machine. Wet coils are put on screen trays, and then placed in the push carts for drying.

These push carts are engaged in a chain pusher to go inside a tunnel dryer for 5 hours, and they are

harvested and will undergo the final quality control. Lastly, they are transferred to the packing machine

to be ready for shipment. Each coil guarantees 8.5 hours of continuous protection against mosquitoes.

C. Inventory Management

With regards to the inventory management of Greencoil Industries Inc., the ingredients (in sacks) are all

stacked and placed in a warehouse. Based on our understanding and observation, FIFO method is not

applied to their raw material inventory, but applied to finished goods inventory. During the stamping

and drying process there may be breakage of coils but it is not a problem since those that were broken

are brought back to the pulverizing machine to turn them again to fine powder and processed further

again. From the interview of our guide, they usually produce 9,000 or more coils each day but there

really is no quota with regards as to amount of finished goods done each day since amount of

production depends on the willingness of the employees as to the number of hours theyd work each

day. The finished goods are then placed in boxes, stored in the finished goods area awaiting shipment.

D. Property, Plant, and Equipment

The plant site is equipped with the pulverizing machine, rotary mixing machine, kneader, stamping

machine, and tunnel dryer. The machines they equip are already quite old, and there is much

maintenance needed.

III. INVENTORY

PRO FOOD INTERNATIONAL CORP.

WHAT COULD GO WRONG

ASSERTIONS

INTERNAL CONTROL

1. Employees may bring the fresh

fruits or finished products home

without management being able

to detect them.

Existence The company should invest in full body

scanners so that they could detect

employees engaging in theft of finished

products.

2. The quantities indicated in their

inventory listings do not

coincide with what the company

really has currently.

Completeness The company must continually review its

final inventory listing. Another employee

should check on the clerical accuracy of

the companys software regarding their

inventory listing.

3. Consigned products are included

as part of the companys

inventories.

Rights and Obligations Consigned products should be clearly

segregated from the companys actual

products. Aside from the labels which

allow employees to recognize which

products are consigned and which are not,

someone must also check the recording of

such inventories.

4. Spoiled items might have been

overlooked.

Valuation The companys accountant should always

be informed of the number of defective

and obsolete items so that he can

appropriately record its cost.

5. Billed products ready for

shipment have not yet been

excluded in the inventory.

Rights and Obligations Separate them from the rest of the group.

UNIVERSAL FEEDMILL CORP.

WHAT COULD GO WRONG

ASSERTIONS

INTERNAL CONTROL

1. Excessive Purchase of Raw Materials Existence Too many purchases can increase cost of

storage. Purchases should be regulated

by top management. They should

strengthen their cash disbursement cycle.

2. The spoiled feeds may not be

detected.

Valuation Final Review of Products before

packaging should be done.

3. Items in their other site may be

excluded from inventory

Rights and Obligations Indicate in the inventory listing that there

are also items in the other site which are

not physically present but still are

includible in the companys inventory.

4. Raw Material Obsolescence Valuation Update Depreciation policies.

5. Excessive Production Existence Production Manager should set a limit

regarding their daily production.

GREEN COIL INDUSTRIES

WHAT COULD GO WRONG

ASSERTIONS

INTERNAL CONTROL

1. Unsuccessful drying of coils Existence Buy another tunnel dryer that could fit all

processed wet coils so as not to rely on the

weather

2. Not all coils might be included

in the count at year-end

Completeness Production Manager should also take note on

the number of coils they currently have

whether there are too much excess or not.

3. Upon shipment, the coils may

break and will not be salable

anymore

Existence Secure the coils by storing them in a truck

container that has stoppers that could

protect the coils from the roughness of the

road upon travel.

4. Powdered raw materials could

easily be blown away by the wind

or spilled

Existence When not in use, cover the sacks of the

powdered raw materials. Provide a secure tie

on the sacks.

5. Breaking coils upon packing Completeness Quality Control must be maintained even in

its last phase of production. Only allow the

expert employees pack the good coils so they

wont damage them.

IV. PPE

PROFOODS INC.

Audit Program

Audit Objective:

1. To determine whether the machinery, equipment and others under property, plant and

equipment was included in the books or in the balance sheet.

2. To determine whether the capitalizable costs were added to cost of the property plant and were

not expensed.

3. To determine whether the Profoods Inc. has the legal right or equivalent ownership rights to

that PPE included.

4. To determine whether the methods used in depreciating the property , plant and equipment are

consistent and was properly computed.

5. To determine whether the balances in the depreciation allowance accounts are reasonable,

considering the expected useful lives of the property units and estimated salvage value.

6. To determine whether the property, plant and equipment was properly valued.

Audit Procedures:

1. Prepare the summary of the Profoods summary of its property, plant and equipment and

analysis on Accumulated Depreciation for the year.

2. Determine whether a listing of all assets owned is maintained.

Obtain a copy

Review for completeness

Determine date of latest compilation

3. Obtain copies of the invoices which adequately document the purchase.

4. Check the records in the minutes of meeting of the Stockholders if there was the plan of

acquisition.

5. Conduct physical investigation on the current acquisition of PPE.

6. Investigate the machines and equipment if there were retirement or disposal.

7. Make inquiries to executives and supervisors regarding retired assets.

8. Check the evidence of the legal ownership of the company on PPEs.

9. Examine the Clients computation on depreciation through recomputation.

10. Investigate the status of the idle property, plant and equipment.

11. Determine whether there is appropriate security over mission assets. This includes

documenting previous history of theft.

UNIFEEDS INC.

Audit Program

Audit Objective:

1. To determine whether the property, plant and equipment was properly recorded in the books.

2. To determine whether the specific machines or equipment reflected in the books exists.

3. To determine whether the valuation of the property, plant and equipment is correct.

4. To determine whether the cost directly attributable to the property, plant and equipment was

capitalized and was not expensed.

5. To determine whether the company has legal rights on that PPE.

Audit Procedures:

1. Prepare the property, plant and equipment transactions and analysis of Accumulated

Depreciation during the year.

2. Have a physical inspection on the newly acquired property, plant and equipment.

3. Inquire of the owner/manager if there are any major additions (purchased or constructed by the

company or capitalizable leases).

4. Obtain copies of the invoices which adequately document the purchase.

5. Inquire of the owner/manager if there has been any change in depreciation lives or methods,

and if there are significant amounts of fully depreciated assets.

6. Recompute the depreciation of the machines or equipment.

7. Examine significant invoices for repairs and maintenance expenses. Document the items tested.

8. Analyze repairs and maintenance expense account.

9. Check if those machines recorded in the books was still working and can still give economic

benefit to company.

10. Investigate the PPEs that was retired or disposed.

GREENCOIL INC.

Audit Program

Audit Objective:

1. To determine whether the property, plant and equipment was properly recorded in the books.

2. To determine whether the specific machines or equipment reflected in the books exists.

3. To determine whether the valuation of the property, plant and equipment is correct.

4. To determine whether the cost directly attributable to the property, plant and equipment was

capitalized and was not expensed.

5. To determine whether the company has legal rights on that PPE.

Audit Procedures:

1. Prepare the property, plant and equipment transactions and analysis of Accumulated

Depreciation during the year.

2. Determine whether a listing of all assets owned is maintained.

Obtain a copy

Review for completeness

Determine date of latest compilation

3. Test the cost by examining supporting documents such as purchase orders, paid checks,

vendors invoices, purchase contracts, receiving reports, etc.

4. Trace the original cost and acquisition date of the asset to prior period property records.

5. Determine that the disposition was properly authorized.

6. Consideration of depreciation methods and lives and reasonableness of accumulated

depreciation.

7. Recompute depreciation expense on selected assets.

8. Inquire of the owner/manager if there has been any change in depreciation lives or methods,

and if there are significant amounts of fully depreciated assets.

9. Inquire of the owner/manager if there are any major retirements, sales of property,

abandonments, or damages to property not reflected in the books.

10. Consider the independently testing the physical existence of and, if appropriate, the title to

property, plant and equipment.

V. DOCUMENTATION

PROFOODS INC.

UNIVERSAL FEEDMILL CORPORATION

Potrebbero piacerti anche

- Survey Questionnaire FinalDocumento1 paginaSurvey Questionnaire FinalKaren Rosali F. Diaz100% (1)

- Sales Reviewer PDFDocumento25 pagineSales Reviewer PDFShaireen Prisco Rojas100% (2)

- Terminal Report - BirDocumento92 pagineTerminal Report - BirBen Ritche LayosNessuna valutazione finora

- FeasibDocumento138 pagineFeasibMarinella LosaNessuna valutazione finora

- Camelback Cost Management AnalysisDocumento23 pagineCamelback Cost Management AnalysisVidya Sagar Ch100% (2)

- Introduction of Jollibee Food CorporationDocumento1 paginaIntroduction of Jollibee Food CorporationJames Ryan Egido CaiNessuna valutazione finora

- Company Name: Profood International Inc. Company ProfileDocumento6 pagineCompany Name: Profood International Inc. Company ProfileJeric Israel0% (1)

- Nego Case Digest 1 PDFDocumento70 pagineNego Case Digest 1 PDFJulie Ann PiliNessuna valutazione finora

- Thesis 1-25Documento13 pagineThesis 1-25Harry PeterNessuna valutazione finora

- RecipesDocumento9 pagineRecipesJulie Ann PiliNessuna valutazione finora

- Philippine Spring Water ResourcesDocumento2 paginePhilippine Spring Water ResourcesJenica AngelesNessuna valutazione finora

- Narrative Report DoneDocumento53 pagineNarrative Report DoneElaine BanezNessuna valutazione finora

- Asignment-Paolo Jollibee 2Documento3 pagineAsignment-Paolo Jollibee 2Felizardo Tapleras Demayuga Jr.Nessuna valutazione finora

- Document Purpose: Implementation Plan ChecklistDocumento2 pagineDocument Purpose: Implementation Plan ChecklistJulie Ann PiliNessuna valutazione finora

- 2013 New Pre-Mid Dept ExamDocumento6 pagine2013 New Pre-Mid Dept ExamJulie Ann PiliNessuna valutazione finora

- Pro FoodsDocumento6 paginePro FoodsJeric Israel0% (1)

- Almost DoneDocumento195 pagineAlmost DoneaileenNessuna valutazione finora

- SWOT Analysis-CDO - FoodsphereDocumento7 pagineSWOT Analysis-CDO - FoodsphereJeswel RebatoNessuna valutazione finora

- CDM PortfolioDocumento8 pagineCDM PortfolioMae100% (1)

- Payments User Guide - English (2006)Documento39 paginePayments User Guide - English (2006)Gláucia CarvalhoNessuna valutazione finora

- Case BME 13Documento5 pagineCase BME 13oo ngaNessuna valutazione finora

- Profood International Himoan NagDocumento19 pagineProfood International Himoan NagRyan TogononNessuna valutazione finora

- C Ebu Institute of Technology University: Plant VisitDocumento5 pagineC Ebu Institute of Technology University: Plant VisitAdonis Cabingas ArponNessuna valutazione finora

- Union Galva Steel FinalDocumento11 pagineUnion Galva Steel FinalAnonymous 0zrCNQNessuna valutazione finora

- Cebu Educational Plant Tour Reflection PaperDocumento2 pagineCebu Educational Plant Tour Reflection PaperVenz Lacre100% (1)

- ME502-P01 Magic Melt Food Inc.: Plant VisitDocumento4 pagineME502-P01 Magic Melt Food Inc.: Plant VisitAdonis Cabingas ArponNessuna valutazione finora

- Company History FinalDocumento10 pagineCompany History FinalElla Andrea Montilla PototNessuna valutazione finora

- Sts AnswersDocumento11 pagineSts AnswersIvo NNessuna valutazione finora

- Coconut JamDocumento2 pagineCoconut JamPenny LowNessuna valutazione finora

- IPIDocumento4 pagineIPIJeric IsraelNessuna valutazione finora

- Narrative Report 1-3Documento4 pagineNarrative Report 1-3James Daniel SwintonNessuna valutazione finora

- Final MorDocumento22 pagineFinal MorJeff BugsNessuna valutazione finora

- Project Proposal: Business ProfileDocumento5 pagineProject Proposal: Business ProfileJohn Kenneth Escober BentirNessuna valutazione finora

- Philippines Country ReportDocumento18 paginePhilippines Country ReportNichael UyNessuna valutazione finora

- Lesson 1 - AH 112Documento7 pagineLesson 1 - AH 112April Rose Cercado100% (2)

- Perceived Advantage of Social Networking Sites in Selected Restaurants in Lucena City Chapter 3Documento5 paginePerceived Advantage of Social Networking Sites in Selected Restaurants in Lucena City Chapter 3hannapott0% (1)

- The Laws and Agencies Relating To Food Safety and SanitationDocumento32 pagineThe Laws and Agencies Relating To Food Safety and Sanitationpatricia versozaNessuna valutazione finora

- Statistics and ProbabilityDocumento14 pagineStatistics and ProbabilityLyn Jeni100% (1)

- Case Analysis 4 Expired GravyDocumento5 pagineCase Analysis 4 Expired GravyJP Ramos DatinguinooNessuna valutazione finora

- Development of Village-Type Cacao Pod Breaker With Bean SeparatorDocumento58 pagineDevelopment of Village-Type Cacao Pod Breaker With Bean SeparatorJayson Sagsagat100% (1)

- How Does It Affect The Economies in The Philippines WORD REFERENCES PPT ContentDocumento3 pagineHow Does It Affect The Economies in The Philippines WORD REFERENCES PPT ContentGianJoshuaDayritNessuna valutazione finora

- I Have Here Two Different Headlines From Different Time and Year. 2018 Manila Times News Headline. Focus/Main Point (Bong Revilla Is "NOT GUILTY")Documento3 pagineI Have Here Two Different Headlines From Different Time and Year. 2018 Manila Times News Headline. Focus/Main Point (Bong Revilla Is "NOT GUILTY")Hannah Grace EboñaNessuna valutazione finora

- A Proposed Study On How To Automate The Peeling of Chicken and Quail Egg 1 1Documento21 pagineA Proposed Study On How To Automate The Peeling of Chicken and Quail Egg 1 1Rhadel GantuangcoNessuna valutazione finora

- Unit IDocumento32 pagineUnit Ithebrahyz0% (1)

- Group 5 Espasol Con YemaDocumento109 pagineGroup 5 Espasol Con YemaSkye IsleNessuna valutazione finora

- LongaDocumento3 pagineLongaMosses Emmanuel A. Miranda100% (1)

- Superfinal DQDocumento40 pagineSuperfinal DQJoyce AquinoNessuna valutazione finora

- Alternative Courses of ActionDocumento15 pagineAlternative Courses of ActionLorna BacligNessuna valutazione finora

- Chapter I II III IV V Group 4 For DefenseDocumento41 pagineChapter I II III IV V Group 4 For DefenseMa Sylvia ShoreNessuna valutazione finora

- Product and Services of JollibeeDocumento1 paginaProduct and Services of JollibeeJESTINE MARY OGAYRENessuna valutazione finora

- Jollibee Temporarily Shuts Down Branch in Fried Towel' MessDocumento3 pagineJollibee Temporarily Shuts Down Branch in Fried Towel' MessYumeko JyabamiNessuna valutazione finora

- Sensory Analysis of Fiber Enriched Baked Tupig Using Chico C1Documento23 pagineSensory Analysis of Fiber Enriched Baked Tupig Using Chico C1Denyssa Jhae Lumanas100% (1)

- Skinless TilapiaDocumento33 pagineSkinless TilapiaLeonel VidalNessuna valutazione finora

- Aggregate PlanningDocumento5 pagineAggregate PlanningJenny PinedaNessuna valutazione finora

- Management and Personnel RequirementsDocumento7 pagineManagement and Personnel RequirementsqwwwwwwwNessuna valutazione finora

- Reflection On The Exporting, Importing and Counter Trade By: Sophia P. MagdayaoDocumento1 paginaReflection On The Exporting, Importing and Counter Trade By: Sophia P. MagdayaoHella Mae RambunayNessuna valutazione finora

- Final Case StoryDocumento30 pagineFinal Case StoryMarilyn Claudine N. BambillaNessuna valutazione finora

- Quality ControlDocumento3 pagineQuality ControlAnkit0% (2)

- Basic Objective of The On The Job TrainingDocumento4 pagineBasic Objective of The On The Job TrainingSai DiazNessuna valutazione finora

- Bayron - 2018 - Individual Case - Salad TomatoDocumento1 paginaBayron - 2018 - Individual Case - Salad TomatoJames Español NavasquezNessuna valutazione finora

- Draft 1Documento6 pagineDraft 1Maverick BeeNessuna valutazione finora

- Julies Case StudyDocumento4 pagineJulies Case StudyKristel Anne AquinoNessuna valutazione finora

- Rediscovery of The PhilippinesDocumento3 pagineRediscovery of The PhilippinesMikashi Lang50% (4)

- The Man Behind The Famous Bee (Jollibee)Documento2 pagineThe Man Behind The Famous Bee (Jollibee)Jake MundoNessuna valutazione finora

- PRODUCTION OF DRIED MANGOES-jomsDocumento4 paginePRODUCTION OF DRIED MANGOES-jomsJomhel CalluengNessuna valutazione finora

- Problem and Its Background: TH THDocumento9 pagineProblem and Its Background: TH THAngela mae PanganibanNessuna valutazione finora

- Lao Farm Eco TourismDocumento12 pagineLao Farm Eco TourismAise TrigoNessuna valutazione finora

- Chapter 15Documento19 pagineChapter 15Julie Ann Pili100% (1)

- CSR in Global ContextDocumento8 pagineCSR in Global ContextJulie Ann PiliNessuna valutazione finora

- Ben Reeds Case StudyDocumento2 pagineBen Reeds Case StudyJulie Ann PiliNessuna valutazione finora

- St. James Clothiers:: Evaluation of Manual & IT-Based Sales Accounting System RisksDocumento7 pagineSt. James Clothiers:: Evaluation of Manual & IT-Based Sales Accounting System RisksJulie Ann Pili0% (1)

- Julie Ann G. Pili, Bsa-4 ACCTG19 (MWF6:00-7:00PM) Venus Tek-Ing, Bsa-4 Illustrative Small Business Systems Flowchart Sales and Collections CycleDocumento1 paginaJulie Ann G. Pili, Bsa-4 ACCTG19 (MWF6:00-7:00PM) Venus Tek-Ing, Bsa-4 Illustrative Small Business Systems Flowchart Sales and Collections CycleJulie Ann PiliNessuna valutazione finora

- Comprehensive Audit Problem (Julie&Angelo)Documento8 pagineComprehensive Audit Problem (Julie&Angelo)Julie Ann Pili100% (3)

- Capital Budgeting - Phase 2Documento39 pagineCapital Budgeting - Phase 2Julie Ann PiliNessuna valutazione finora

- Paleontology: The Study of Ancient Life!Documento23 paginePaleontology: The Study of Ancient Life!Julie Ann PiliNessuna valutazione finora

- Eco-Friendly Handmade Paper Making: Shri AMM Murugappa Chettiar Research CentreDocumento0 pagineEco-Friendly Handmade Paper Making: Shri AMM Murugappa Chettiar Research CentreAnand RasNessuna valutazione finora

- Case 18Documento6 pagineCase 18Julie Ann PiliNessuna valutazione finora

- LANDSCAPEDocumento2 pagineLANDSCAPEJulie Ann PiliNessuna valutazione finora

- IT Education StandardsDocumento98 pagineIT Education StandardsJulie Ann PiliNessuna valutazione finora

- Tax Infomercial Final ProjectDocumento1 paginaTax Infomercial Final ProjectJulie Ann PiliNessuna valutazione finora

- Industrialization On Social ChangeDocumento2 pagineIndustrialization On Social ChangeJulie Ann PiliNessuna valutazione finora

- Rizal ReferencesDocumento6 pagineRizal ReferencesJulie Ann PiliNessuna valutazione finora

- United India Insurance Company Limited: M/S Neeraj KumarDocumento3 pagineUnited India Insurance Company Limited: M/S Neeraj KumarB&R HSE BALCO SEP SiteNessuna valutazione finora

- Chapter 3Documento100 pagineChapter 3HayamnotNessuna valutazione finora

- A COMPARATIVE STUDY OF OLA AND UBER CUSTOMERS IN DELHI After COVID-19Documento9 pagineA COMPARATIVE STUDY OF OLA AND UBER CUSTOMERS IN DELHI After COVID-19trivikram SahuNessuna valutazione finora

- Mepco Online BillDocumento2 pagineMepco Online BillMuhammad Shehar Yar UE MULTAM CAMPUSNessuna valutazione finora

- EJ Dosi 1997 OpportunitiesPatternsTechChange 2957752Documento19 pagineEJ Dosi 1997 OpportunitiesPatternsTechChange 2957752DanielNessuna valutazione finora

- SIM WS2022-23 Lec8Documento16 pagineSIM WS2022-23 Lec8CarolinaNessuna valutazione finora

- Analisis Strategi Pemasaran Pada Usaha Kecil Menengah (Ukm) Makanan Ringan (Studi Penelitian UKM Snack Barokah Di Solo)Documento13 pagineAnalisis Strategi Pemasaran Pada Usaha Kecil Menengah (Ukm) Makanan Ringan (Studi Penelitian UKM Snack Barokah Di Solo)Anisa PutriNessuna valutazione finora

- QSM EXTRUDER 2019 09 - WebDocumento6 pagineQSM EXTRUDER 2019 09 - WebNgọc Trần MinhNessuna valutazione finora

- Bai Tap Ias36Documento25 pagineBai Tap Ias36Thiện PhátNessuna valutazione finora

- Direct TAX: & International TaxationDocumento531 pagineDirect TAX: & International Taxationavinashkives21Nessuna valutazione finora

- Financial Times Europe - 6.10.2022Documento24 pagineFinancial Times Europe - 6.10.2022Tihomir RajčićNessuna valutazione finora

- Adjustment of Goodwill-Admission PDFDocumento2 pagineAdjustment of Goodwill-Admission PDFarnav trivediNessuna valutazione finora

- What Factors Affect The Fraud Detection? The Role of Red Flags and Auditor ExperienceDocumento11 pagineWhat Factors Affect The Fraud Detection? The Role of Red Flags and Auditor ExperienceNadela ZahraNessuna valutazione finora

- Overhead Sub Transmission Construction Manual Earthing Overhead Sub TransmissionDocumento10 pagineOverhead Sub Transmission Construction Manual Earthing Overhead Sub TransmissionTerex14253Nessuna valutazione finora

- Business Letters: 05/23/2022 1 Dr. Priyanka MokshmarDocumento63 pagineBusiness Letters: 05/23/2022 1 Dr. Priyanka Mokshmarniyati dixitNessuna valutazione finora

- Forest Regulations 2004Documento86 pagineForest Regulations 2004DENIS NGUVUNessuna valutazione finora

- PICC Profile - fINALDocumento11 paginePICC Profile - fINALAbhay JainNessuna valutazione finora

- Solved The Demand For Good X Is Given by QDX 1200Documento1 paginaSolved The Demand For Good X Is Given by QDX 1200M Bilal SaleemNessuna valutazione finora

- DB aabgegghcfhd0x0DCDDocumento5 pagineDB aabgegghcfhd0x0DCDIsmael DialloNessuna valutazione finora

- Sequences A LevelDocumento8 pagineSequences A LevelSemaNessuna valutazione finora

- Managing in A Global Economy Demystifying International Macroeconomics 2nd Edition Marthinsen 128505542X Solution ManualDocumento8 pagineManaging in A Global Economy Demystifying International Macroeconomics 2nd Edition Marthinsen 128505542X Solution Manualleigh100% (29)

- Journal, Ledger and Trial Balance: Dr. Sharon Sophia, Vellore Institute of TechnologyDocumento11 pagineJournal, Ledger and Trial Balance: Dr. Sharon Sophia, Vellore Institute of Technologyermias100% (1)

- Best Memorial (Respondent) - GIMC 2019Documento36 pagineBest Memorial (Respondent) - GIMC 2019raj bhoirNessuna valutazione finora

- Data Analysis 5aDocumento4 pagineData Analysis 5aAndemariamNessuna valutazione finora

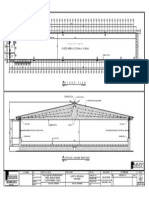

- Floor Plan and Cross SectionDocumento1 paginaFloor Plan and Cross SectiondeanNessuna valutazione finora

- A Design of Bio-Mask Extracting MachineDocumento34 pagineA Design of Bio-Mask Extracting MachineAsh Mico0% (1)

- Assignment/ TugasanDocumento11 pagineAssignment/ TugasanhemaNessuna valutazione finora

- 100518-Concrete Roof Installation Manual 0515Documento26 pagine100518-Concrete Roof Installation Manual 0515Moe Oo HtunNessuna valutazione finora