Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Okkk

Caricato da

randykhardianTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Okkk

Caricato da

randykhardianCopyright:

Formati disponibili

Chowdary K P R et al.

/ Pharmacie Globale (IJCP) 2011, 7 (08)

Available online at www.pharmacie-globale.info ISSN 0976-8157

Research Article

PHARMACIE GLOBALE

INTERNATIONAL JOURNAL OF COMPREHENSIVE PHARMACY

FORMULATION DEVELOPMENT OF ACECLOFENAC TABLETS BY WET GRANULATION

AND DIRECT COMPRESSION METHODS EMPLOYING STARCH CITRATE

K P R Chowdary*, Veeraiah Enturi and Ch Achyuth Reddy

A U College of Pharmaceutical sciences, Andhra University, Visakhapatnam, Andhra Pradesh, India.

Received: 12 May 2011; Revised: 26 June 2011; Accepted: 30 June 2011; Available online: 5 July 2011

ABSTRACT

Aceclofenac, a widely prescribed anti inflammatory analgesic drug belongs to BCS class II and exhibit low and

variable oral bioavailability due to its poor solubility and dissolution rate. The objective of the present study is to

develop aceclofenac rapidly dissolving tablet formulations by wet granulation and direct compression methods

employing starch citrate, a new modified starch. As per FDA guidelines on biowaivers, drug products containing

weakly acidic BCS class II drugs with dissolution of >85% in 30 min are eligible for biowaiver. Hence dissolution

of >85% in 30 min is taken as target dissolution to achieve in the formulation development of aceclofenac

tablets. Starch citrate prepared by reacting potato starch with citric acid at elevated temperatures was insoluble

in water and has good swelling (1500%) property without pasting or gelling when heated in water. In the

micromeritic evaluation, the angle of repose and compressibility index values revealed the excellent flow

characteristic of starch citrate prepared. All the physical properties studied indicated that starch citrate is a

promising pharmaceutical excipient in tablets. Aceclofenac rapidly dissolving tablets with >85% dissolution in

30 min could be formulated employing starch citrate as directly compressible vehicle by direct compression

method (BF3) and also employing aceclofenac-starch citrate (1:2) solid dispersion by wet granulation method

(BF4). Formulations BF3 and BF4 respectively gave 87.57% and 94.80% dissolution in 30 min fulfilling the target

dissolution requirement for biowaiver.

Keywords: Aceclofenac Tablets, Starch citrate, Direct Compression, Solid Dispersion, Biowaiver.

INTRODUCTION

Aceclofenac, a widely prescribed anti inflammatory

analgesic drug belongs to BCS class II and exhibit low and

variable oral bioavailability due to its poor solubility and

dissolution rate. Achieving higher dissolution rate is a key

factor in its formulation development especially solid

dosage forms like tablets. Several techniques

1

such as

micronization, cyclodextrin complexation, use of

surfactants and solubilizers, solid dispersion in water

soluble and dispersible carriers, use of salts, prodrugs and

polymorphs which exhibit high solubility, microemulsions

and self emulsifying micro and nano disperse systems

have been used to enhance the solubility, dissolution rate

and bioavailability of poorly soluble drugs. Among the

various approaches, solid dispersions in water dispersible

excipient are a simple, industrially useful approach for

enhancing the solubility, dissolution rate and

bioavailability of poorly soluble drugs.

Wing

2

has reported reaction of starch with citric acid to

yield starch citrate, a biodegradable product possessing

high ion-exchange capacity. Wepner et al

3

have described

a process for the synthesis of citrate derivatives of starch.

Starch citrate is investigated as resistant starch in food

industry. Starch citrate, a new modified starch was

reported

4

as an efficient carrier in solid dispersions for

*Corresponding Author:

K P R Chowdary

A U College of Pharmaceutical sciences, Andhra University,

Visakhapatnam, Andhra Pradesh, India.

Contact no: +91-9866283578; Email: prof.kprchowdary@rediffmail.com

enhancing the dissolution rate of poorly soluble drugs.

Direct compression is the preferred method for the

preparation of tablets.

5

It offers several advantages.

6,7

Notable among them are:

i) It is economical compared to wet granulation since it

requires fewer unit operations.

ii) More suitable for moisture and heat sensitive APIs

since it eliminates wetting and drying steps.

iii) Changes in dissolution profiles are less likely to occur

in tablets made by direct compression method on

storage than in those made from granulations.

8

This is

extremely important because the official compendium

now requires dissolution specifications in most solid

dosage forms.

9

Disintegration or dissolution is the rate limiting step in

absorption in the case of tablets of poorly soluble API

prepared by wet granulation. The tablets prepared by

direct compression disintegrate into API particles instead

of granules that directly come into contact with

dissolution fluid and exhibits comparatively faster

dissolution. Starch citrate, a new modified starch, was also

reported

10

to be a promising directly compressible vehicle

for the preparation of tablets by direct compression

method.

The objective of the present study is to develop

aceclofenac rapidly dissolving tablet formulations by wet

granulation and direct compression methods employing

starch citrate, a new modified starch. As per FDA

1 Pharmacie Globale

(IJCP), Vol. 02, Issue 07

Chowdary K P R et al. / Pharmacie Globale (IJCP) 2011, 7 (08)

guidelines

11

on biowaivers, drug products containing

weakly acidic BCS class II drugs with dissolution of > 85%

in 30 min in phosphate buffer pH 6.8 are eligible for

biowaiver. Hence a dissolution of >85% in 30 min is taken

as target dissolution to achieve in the formulation

development of aceclofenac tablets. In the present study

starch citrate was prepared, characterized and used in the

formulation development of aceclofenac tablets with

>85% dissolution in 30 min.

MATERIALS AND METHODS

Aceclofenac was gift sample from M/s Hetero Drugs Pvt.

Ltd, Hyderabad., Starch citrate was prepared in the

laboratory, Citric acid (Qualigens), Dichloromethane

(Qualigens), potato starch (S.D Fine Chemicals), Methanol

(S.D Fine Chemicals), crospovidone lactose, talc,

magnesium stearate and acacia were procured from

commercial sources.

Preparation of Starch Citrate

Starch citrate was prepared based on the method of

Klaushfer et al

12

with some modifications. Citric acid (20g)

was dissolved in 20 ml of water, the pH of the solution was

adjusted to 3.5 with 10 M sodium hydroxide and finally

the volume was made upto 50 ml by adding water. The

citric acid solution (50 ml) was mixed with 50g of potato

starch in a stainless steel tray and conditioned for 16 h at

room temperature (28C). The tray was then placed in

forced air oven and dried at 60C for 6 h. The mixture

obtained was ground and further dried in a forced air oven

at 130C for 2 h. The dry mixture was repeatedly washed

with water to remove unreacted citric acid. The washed

starch citrate was further dried at 50C to remove the

water/moisture completely. The product obtained was

ground and sized.

Characterization of Starch Citrate

The starch citrate prepared was evaluated for the

following:

Solubility: Solubility of starch citrate was tested in water,

aqueous buffers of pH 1.2, 4.5, and 7.4 and organic

solvents such as alcohol, dichloromethane, chloroform,

acetone and petroleum ether.

pH: The pH of a 1% w/v slurry was measured.

Melting Point: Melting point was determined by using

melting point apparatus.

Viscosity: Viscosity of 1% dispersion in water was

measured using Ostwald Viscometer.

Swelling Index: Starch citrate (200 mg) was added to 10

ml of water and light liquid paraffin taken in two different

graduated test tubes and mixed. The dispersion in the

tubes was allowed to stand for 12 h. The volumes of the

sediment in the tubes were recorded. The swelling index of

the material was calculated as follows.

displacement method using benzene as liquid.

Bulk density

13

: Bulk density (g/cc) was determined by

three tap method in a graduated cylinder.

Angle of repose

14

: Angle of repose was measured by fixed

funnel method.

Compressibility index

15

: Compressibility index (CI) was

determined by measuring the initial volume (Vo) and final

volume (V) after hundred tapings of a sample of starch

citrate in a measuring cylinder. CI was calculated using

equation:

Estimation of Aceclofenac

A UV spectrophotometric method based on the

measurement of absorbance at 275 nm in phosphate

buffer pH 6.8 was used for estimation of aceclofenac. The

method obeyed Beer- Lamberts law in the concentration

range of 1-10 m/mL. When the standard drug solution

was assayed repeatedly (n=6), the relative error

(accuracy) and coefficient of variation (precision) were

found to be 0.75% and 1.5% respectively. No interference

from excipients used was observed.

Formulation of Aceclofenac Tablets

Four different batches of tablets each containing 50 mg of

aceclofenac were formulated and evaluated. The formulae

of tablets prepared are given in Table 1. In batch BF1 the

tablets were formulated employing aceclofenac alone and

Dicalcium Phosphate (DCP) as diluent and prepared by

wet granulation method using water as granulating fluid.

In batch BF2 the tablets were formulated employing

aceclofenac alone and lactose as diluent and prepared by

wet granulation method using water as granulating fluid.

In batch BF3 the tablets were formulated employing

starch citrate as directly compressible vehicle and

prepared by direct compression method. In batch BF4 the

tablets were formulated employing aceclofenac-starch

citrate (1:2) solid dispersion and the tablets were

prepared by wet granulation method employing water as

granulating fluid. In all the batches acacia (2%) as binder,

crospovidone (5%) as disintegrant, talc (2%) and

magnesium stearate (2%) as lubricants were used. In each

batch 100 tablets were prepared.

Table 1. Formulae of Aceclofenac tablets formulated

employing starch citrate by wet granulation and direct

compression methods

Ingredient Formulation

mg/Tablet BF1 BF2 BF3 BF4

Aceclofenac 50 50 50 -

Starch Citrate - - 140 -

Aceclofenac-starch Citrate (1:2) - - - 150

solid dispersion

DCP 145.8 - - 45.8

Lactose - 145.8 5.8 -

Crospovidone 11 11 11 11

Acacia 4.4 4.4 4.4 4.4

Talc 4.4 4.4 4.4 4.4

Test for gelling property: The gelling property

(gelatinization) of the starch and starch citrate prepared

was evaluated by heating a 7% w/v dispersion of each in

water at 100C for 30 min.

Moisture absorption: The hygroscopic nature of starch

citrate was evaluated by moisture absorption studies in a

closed desiccator at 84% relative humidity and room

temperature.

Particle size: Particle size analysis was done by sieving

using standard sieves.

Density: Density (g/cc) was determined by liquid

Magnesium stearate 4.4 4.4 4.4 4.4

Total weight of Tablet (mg) 220 220 220 220

BF1: tablets formulated employing aceclofenac alone and using DCP as

diluent; BF2: tablets formulated employing aceclofenac alone and using

lactose as diluent; BF3: tablets formulated by direct compression

employing starch citrate as DCV. BF4: tablets formulated employing

aceclofenac-starch citrate (1:2) solid dispersion

Preparation of solid dispersions of aceclofenac in

starch citrate

Solid dispersions of aceclofenac and starch citrate were

prepared in 1:2 ratio of drug: carrier by solvent

evaporation method. Aceclofenac (1 g) was dissolved in

2 Pharmacie Globale

(IJCP), Vol. 02, Issue 07

Chowdary K P R et al. / Pharmacie Globale (IJCP) 2011, 7 (08)

dichloromethane (10 ml) in a dry mortar to get a clear

solution. Starch citrate (2 g) was then added and mixed.

The thick slurry was kneaded for 15 min for complete

evaporation of dichloromethane and then dried at 55C

until dry. The dried mass was pulverized and sieved

through mesh no. 100.

Preparation of Aceclofenac Tablets by Wet

Granulation Method

Compressed tablets each containing 50 mg of aceclofenac

were prepared by wet granulation method employing

aceclofenac alone(BF1 and BF2) and its solid dispersions

in starch citrate (BF4). The required quantities of

aceclofenac or aceclofenac-starch citrate (1:2) solid

dispersion, diluent (DCP or lactose) and acacia were mixed

thoroughly in mortar by following geometric dilution

technique. The granulating fluid, water was added and

mixed thoroughly to form dough mass. The mass was

passed through mesh No 12 to obtain wet granules. The

wet granules were dried at 60C for 2h. The dried granules

were passed through mesh No 16 to break the aggregates.

Crospovidone and the lubricants (talc and magnesium

stearate) were passed through mesh No 100 on to dry

granules and blended in a closed polyethylene bag. The

each test. A temperature 37+1C was maintained

throughout. Samples of dissolution medium (5 ml) were

withdrawn through a filter (0.45) at different time

intervals and assayed for aceclofenac at 275 nm. For

comparison, dissolution of aceclofenac from one

commercial brand was also studied. All the dissolution

experiments were conducted in triplicate (n=3).

RESULTS AND DISCUSSION

Starch citrate was prepared by reacting starch with citric

acid at elevated temperatures. When citric acid is heated,

it will dehydrate to yield an anhydride. The citric

anhydride can then react with starch to from starch

citrate. The reactions involved are shown in Figure 1.

Starch citrate prepared was found to be white, crystalline,

non hygroscopic powder and can easily be ground to

different sizes. Powder that passes through mesh no.80

and retained on mesh no.120 was collected. This powder

has an average particle size of 152 m. The starch citrate

prepared was characterised by determining various

physical properties. The properties of starch citrate are

summarised in Table 2.

Table 2. Physical Properties of the Starch Citrate

Prepared

tablet granules were compressed into tablets on a

Property Result

Cadmach 16-station rotary tablet punching machine (M/s

Solubility Insoluble in all aqueous and organic

Cadmach Engineering Co. Pvt. Ltd., Mumbai) to a hardness solvents tested

of 6 kg/cm

2

using 9 mm concave punches.

PH (1% w/v aqueous 7.72

dispersion)

Preparation of Tablets by Direct Compression Method Melting Point Charred at 210C

Compressed tablets each containing 50 mg of aceclofenac Viscosity (1% w/v aqueous 1.01 cps

were prepared by direct compression method (BF3)

dispersion)

employing starch concave punches as directly

compressible vehicle. All the materials required as per the

formulae were blended in a closed polyethylene bag. The

blends were compressed into tablets on a Cadmach 16-

station rotary tablet punching machine (M/s Cadmach

Machinery Co. Pvt. Ltd) to a hardness of 6 kg/cm

2

using 9

mm concave punches. In each case 100 tablets were

compressed.

Evaluation of Tablets

All the tablets prepared were evaluated for content of

active ingredients, hardness, friability, disintegration time

and dissolution rate as per official (IP) methods. Hardness

of tablets was tested using Monsanto Hardness tester.

Friability of the tablets was determined in a Roche

friabilator. Disintegration time was determined in a

Labindia tablet disintegration test machine (Model: DT

1000) using water as test fluid.

Estimation of Drug Content in the Tablets

From each batch of tablets prepared 20 tablets were

accurately weighed and powdered. Tablet powder

equivalent to 50 mg of drug was taken for assay into a 100

ml conical flask and extracted with 3x20 ml quantities of

methanol. The methanolic extracts were filtered and

collected into a 100 ml volumetric flask and the volume

was made upto 100 ml with methanol. The solution was

then suitably diluted with phosphate buffer of pH 6.8. The

absorbance of the solution was measured at 275 nm. Drug

content of the tablets was calculated using the standard

calibration curve.

Dissolution Rate Study

Dissolution rate of aceclofenac from the tablets prepared

was studied in phosphate buffer pH 6.8 (900 ml)

employing USP 8 station Dissolution Rate Test Apparatus

(M/s Labindia Disso 8000) with a paddle stirrer at 50 rpm.

One tablet containing 50 mg of aceclofenac was used in

Swelling Index 1500

Gelling Property No gelling and the swollen particles

of starch citrate separated from

water. Whereas in the case of

starch, it was gelatinized and

formed gel.

Moisture Absorption 4.5 %

Particle Size 152 m (80/120 mesh)

Density 0.645 g/cc

Bulk Density 0.834 g/cc

Angle of Repose 21.04

0

Compressibility Index 8.81 %

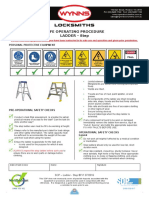

Figure 1. Starch-Citric Acid Reaction

When tested for m.p., it was charred at 220C. Starch

citrate prepared was insoluble in water, aqueous fluids of

acidic and alkaline pH and several organic solvents tested.

In water it exhibited good swelling (1500%). No

gelling/pasting was observed with starch citrate when its

aqueous dispersion was heated at 100C for 30 min, where

as potato starch formed a paste/gel during the above heat

treatment. In the micromeritic evaluation, the angle of

repose and compressibility index values revealed the

excellent flow characteristic of starch citrate prepared. All

3 Pharmacie Globale

(IJCP), Vol. 02, Issue 07

Chowdary K P R et al. / Pharmacie Globale (IJCP) 2011, 7 (08)

the physical properties studied indicated that starch

citrate is a promising pharmaceutical excipient in tablets.

Starch citrate has earlier reported

4,10

as an efficient

carrier

4

for solid dispersions to enhance dissolution rate of

poorly soluble drugs and also as a promising directly

compressible vehicle.

10

Four different batches of aceclofenac tablets were

formulated and prepared by wet granulation and direct

compression methods as per the formulae given in Table

1. The physical properties of the prepared tablets are

summarized in Table 3. All the aceclofenac tablets

prepared were found to contain the aceclofenac with in

1002% of the labeled claim. Hardness of the tablets was

in the range 7-8 Kg/cm

2

. Percentage weight loss in the

friability test was less than 0.56% in all the cases. Tablets

formulated employing starch citrate (BF3 & BF4)

disintegrated rapidly within 40 sec. Tablets formulated

employing aceclofenac alone (BF1 & BF2) disintegrated

within 2-3 min. All the four batches of tablets prepared

fulfilled the official (IP) specification for weight variation.

As such all the aceclofenac tablets prepared were of good

quality with regard to drug content, friability, hardness

and disintegration time and fulfilled the official (IP)

specifications of uncoated tablets.

Table 3. Drug content, hardness, friability, disintegration time and weight variation of aceclofenac tablets

formulated employing starch citrate by wet granulation and direct compression methods

Formulation Drug Content

(mg/tab)

Hardness

(Kg/cm2)

Friability

(% weight loss)

Disintegration Time

(min-sec)

Weight Variation

(maximum % deviation)

BF1

49.1 7.0 0.38 2-30 3.5

BF2

48.9 8.0 0.55 3-00 2.5

BF3

49.3 7.0 0.28 0-40 1.0

BF4

50.2 8.0 0.56 0-30 2.5

Commercial 100.4 6.0 0.68 5-00 --

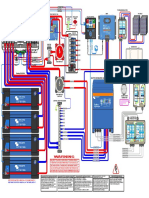

Dissolution rate of aceclofenac tablets prepared and one

commercial brand was studied in phosphate buffer of pH

6.8. The dissolution profiles of the tablets prepared are

shown in Figure 2. The dissolution parameters of the

prepared tablets are given in Table 4. Dissolution of

aceclofenac from all the tablets prepared followed first

order kinetics with correlation coefficient R values >

0.938. Dissolution Efficiency (DE30) values were calculated

as described by Khan et al

16

. All the dissolution

parameters (PD30, T50, DE30, K1) indicated rapid and higher

dissolution of aceclofenac from tablets formulated

employing starch citrate as directly compressible vehicle

(BF3) and aceclofenac-starch citrate (1:2) solid dispersion

(BF4) when compared to tablets formulated employing

aceclofenac alone (BF1 & BF2) and commercial brand

tested. Tablets formulated employing lactose as diluent

(BF2) gave relatively higher dissolution rate and DE30

values when compared to those formulated employing DCP

as diluent (BF1).

Tablets formulated employing starch citrate as directly

compressible vehicle (BF3) and aceclofenac-starch citrate

(1:2) solid dispersion (BF4) gave much higher dissolution

rates and DE30 values when compared to formulation BF1

(control). A 16.45 and 21.13 fold increase in the

dissolution rate (K1) was observed with formulations BF3

and BF4 respectively when compared to formulation BF1.

A 4.5 and 5.8 fold increase in the dissolution rate (K1) was

observed with these formulations when compared to

commercial formulation. Formulations BF3 and BF4

respectively gave 87.57% and 94.80% dissolution in 30

min fulfilling the target dissolution requirement for

biowaiver. Formulations BF1, BF2 and commercial brand

could not fulfill the target dissolution requirement.

Table 4. Dissolution parameters of aceclofenac tablets formulated employing starch citrate by wet granulation

and direct compression methods

Formulation PD30

(%)

T50

(min)

DE30

(%)

Increase in DE30

(No of Folds)

K1

(min

-1

)

Increase in K1

(No of Folds)

BF1 20.03 > 60 11.22 - 0.0069 -

BF2 40.56 45.0 24.30 2.17 0.0143 2.07

BF3 87.57

17.0 44.83 3.99 0.1130 16.45

BF4 94.80

12.0 56.98 5.08 0.1450 21.13

Commercial 54.52

24.0 31.42 2.80 0.0250 3.63

PD30 : percent dissolved in 30 min; T50: time for 50 % dissolution; DE30: dissolution efficiency upto 30 min; K1: first order dissolution rate.

Figure 2 Dissolution Profiles of Aceclofenac Tablets

Formulated Employing Starch Citrate by Wet

Granulation and Direct Compression Methods

CONCLUSION

Starch citrate prepared by reacting potato starch with

citric acid at elevated temperatures was insoluble in water

and has good swelling (1500%) property without pasting

or gelling when heated in water. In the micromeritic

evaluation, the angle of repose and compressibility index

values revealed the excellent flow characteristic of starch

citrate prepared. All the physical properties studied

indicated that starch citrate is a promising pharmaceutical

excipient in tablets. Aceclofenac rapidly dissolving tablets

with >85% dissolution in 30 min could be formulated

employing starch citrate as directly compressible vehicle

by direct compression method (BF3) and also employing

aceclofenac-starch citrate (1:2) solid dispersion by wet

granulation method (BF4). Formulations BF3 and BF4

respectively gave 87.57% and 94.80% dissolution in 30

min fulfilling target dissolution requirement for biowaiver.

ACKNOWLEDGMENT

Authors are thankful to University Grants Commission,

New Delhi for providing financial assistance in the form of

UGC JRF to Veeraiah Enturi.

4 Pharmacie Globale

(IJCP), Vol. 02, Issue 07

Chowdary K P R et al. / Pharmacie Globale (IJCP) 2011, 7 (08)

REFERENCES

1. Chowdary K P R and Madhavi B L R; Novel Drug

Delivery Technologies for Insoluble Drugs. Indian

Drugs 2005; 42(9): 557-562.

2. Wing R E; Starch citrate: preparation and ion exchange

properties. Starch 1996; 48:275- 279.

3. Wepner B, Berghofer E, Miesenberger E, Tiefenbacher

K, Ng PNK; Citrate starch: application as resistant

starch in different food systems. Starch. 1999; 5:354-

361.

4. Chowdary K P R and Veeraiah Enturi; Factorial Studies

on The Enhancement of Dissolution Rate of Nimesulide

Tablets Employing Starch Citrate - A New Modified

Starch, PEG 4000 And PVP K-30. Int J Pharm Res Dev.

2011; 3(1):224-230.

5. Shangraw R F; Direct Compression Tableting,

Encyclopedia of Pharmaceutical Technology. Vol(4),

2nd ed. Newyork: Marcel Dekker, USA. 1988; 85.

6. Armstrong N A; Selection of excipients for direct

compression tablet formulation. Pharm Technol Eur.

1989; 9:24-30.

7. Jivraj M Martini L G and Thomson C M; An Overview of

the Different Excipients Useful for the Direct

Compression of Tablets, PSTT. 2000; 3:58-63.

8. Rubinstein M H; Tablets Pharmaceutics: The Science of

Dosage of Form, 1st ed, Churchill, UK. 1998; 304.

9. Banker U V; Role of Ingredients and Excipients in

Developing Pharmaceuticals. Manuf Chem. 1994; 65:32-

34.

10.Chowdary K P R, Veeraiah Enturi and Sujatha S;

Preparation and Evaluation of Starch Citrate: A New

Modified Starch as Directly Compressible Vehicle in

Tablet Formulations. Int J Chem Sci. 2011; 9(1):177-

187.

11.Waiver of In-vivo Bioavailability and Bioequivalence

Studies for Immediate-Release Solid Oral Dosage Forms

Based on a Biopharmaceutics Classification System.

Available from: FDA/CEDR resources page. Food and

Drug Administration Web site. http://www.fda.gov/

downloads/Drugs/GuidanceComplianceRegulatoryInfo

rmation/Guidances/ucm070246.pdf.

12.Klaushofer H, Berghofer E, Steyrer W; Starch Citrates-

Production and Technical Application Properties.

Starch. 1978; 30(2):47-51.

13.Martin A; Micromeritics. In: Martin A, ed. Physical

Pharmacy. Baltimore, MD: Lippincott. Williams &

Wilkins. 2001; 423.

14.Cooper J and Gunn C; Tutorial Pharmacy: Powder flow

and compaction; In: Carter SJ. Eds, New Delhi, India:

CBS Publications. 1986; 211.

15.Aulton M E, Wells T I; Pharmaceutics: The Science of

dosage form design. 2nd ed. London, England: Churchill

Livingstone. 1988; 89.

16.Khan K A; The Concept of Dissolution Efficiency. J

Pharma Pharmacol. 1975; 27:48-49.

5 Pharmacie Globale

(IJCP), Vol. 02, Issue 07

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- BCM21331Documento2 pagineBCM21331pavlodeNessuna valutazione finora

- Altuglass ManualDocumento36 pagineAltuglass Manualpislaruionut9394Nessuna valutazione finora

- Adwise 4.5 REST API DocumentationDocumento127 pagineAdwise 4.5 REST API Documentationcocy_imyutNessuna valutazione finora

- Le Jeu D'instruction Du 6809Documento7 pagineLe Jeu D'instruction Du 6809ZH HamzaNessuna valutazione finora

- AHRI Standard 1230 - 2010 PDFDocumento184 pagineAHRI Standard 1230 - 2010 PDFDaud Simon ANessuna valutazione finora

- Wynns SOP Ladder StepDocumento5 pagineWynns SOP Ladder StepAlketa ZakaNessuna valutazione finora

- Chemistry Project Report On Finding EMF of Electrochemical CellDocumento15 pagineChemistry Project Report On Finding EMF of Electrochemical CellAnant Chaturvedi80% (51)

- 28 - Scaffolding ProceduresDocumento17 pagine28 - Scaffolding ProceduresLalit Tomar100% (1)

- Toaz - Info Exhibitor List Till 17 Dec 2009 PRDocumento311 pagineToaz - Info Exhibitor List Till 17 Dec 2009 PRAman DubeyNessuna valutazione finora

- Rubber Insulating Sleeves: Standard Specification ForDocumento10 pagineRubber Insulating Sleeves: Standard Specification ForPavan KumarNessuna valutazione finora

- 4th Quarter Sector Performance Report FinalDocumento27 pagine4th Quarter Sector Performance Report FinalPulsmade MalawiNessuna valutazione finora

- Tabela de Equivalência Entre Durezas Astm E 140: SiteDocumento3 pagineTabela de Equivalência Entre Durezas Astm E 140: SitejoaopedrosousaNessuna valutazione finora

- Midi Mainten GBDocumento47 pagineMidi Mainten GBdan antonNessuna valutazione finora

- Soal Prototype Design Lks 2014Documento12 pagineSoal Prototype Design Lks 2014Ichal Jelmis JheNessuna valutazione finora

- 2704 - Diplocks RZ3 N Demand AnalysisDocumento399 pagine2704 - Diplocks RZ3 N Demand AnalysisMrityunjay MallikNessuna valutazione finora

- (Airliner Tech 08) L-1011-TristarDocumento107 pagine(Airliner Tech 08) L-1011-Tristarmunjalshah94100% (3)

- AIS Relational DatabasesDocumento79 pagineAIS Relational DatabasesKhairi Airi0% (1)

- Tower WeightsDocumento4 pagineTower WeightsASR REDDYNessuna valutazione finora

- Thermodyancs Chapter 9 Solution ManuelDocumento36 pagineThermodyancs Chapter 9 Solution ManuelFarhad MojaverNessuna valutazione finora

- SE370LC英文Documento2 pagineSE370LC英文Karl KarlNessuna valutazione finora

- 3-D Reconstruction in Radiology: by Reuven Shreiber, M.D. Applications For Post Processing: MIP, MPRDocumento4 pagine3-D Reconstruction in Radiology: by Reuven Shreiber, M.D. Applications For Post Processing: MIP, MPRSoban DaudNessuna valutazione finora

- Topaz Master 85t Ahtsv Vessel Spec Feb2018lrDocumento6 pagineTopaz Master 85t Ahtsv Vessel Spec Feb2018lrJym GensonNessuna valutazione finora

- 574 Plano HidraulicoDocumento2 pagine574 Plano HidraulicoCarlos IrabedraNessuna valutazione finora

- Chapter 3-Radial Flow Into WellboreDocumento53 pagineChapter 3-Radial Flow Into WellboreArif MokhtarNessuna valutazione finora

- Lynx Ion BMS Example With Quattro 8KW 24V 230VDocumento1 paginaLynx Ion BMS Example With Quattro 8KW 24V 230VAlba Car MarNessuna valutazione finora

- ZF 8098 Steering Gear ManualDocumento2 pagineZF 8098 Steering Gear ManualMher33% (3)

- Non-Metallic Expansion Joints: Standard Specification ForDocumento3 pagineNon-Metallic Expansion Joints: Standard Specification ForIlkuNessuna valutazione finora

- Common Pain Points in A System Using A Classic DatabaseDocumento8 pagineCommon Pain Points in A System Using A Classic Databasevimal_mali662Nessuna valutazione finora

- QC Procedure - Bored Pile Work: Project: ....................... Client: ........................Documento5 pagineQC Procedure - Bored Pile Work: Project: ....................... Client: ........................Budoy SmithNessuna valutazione finora

- Slide Gate AC SD 1006Documento2 pagineSlide Gate AC SD 1006thrayambakNessuna valutazione finora