Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Reflector/Enclosure Assembly: Installation Instructions

Caricato da

José De Moya A.Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Reflector/Enclosure Assembly: Installation Instructions

Caricato da

José De Moya A.Copyright:

Formati disponibili

Bulletin 237107

Installation Instructions

Reflec tor/Enc losure

Assembly

for 3.7-Meter Earth Station Antennas

1.0 Introduction

1.1 The reflector/enclosure assembly includes a 204540

reflector assembly, a 208875 enclosure assembly, a

209170 feed system kit, a 203031-2 enclosure hardware

kit, a 205929 subreflector subassembly and a 203032 sub-

reflector strut kit.

1.2 The one-piece, precision-spun aluminum reflector

assembly enables ease of installation and ensures accu-

rate surface contour which provides exceptional operating

characteristics in the Ku receive/transmit frequency band.

1.3 The enclosure assembly attaches to the rear of the

reflector and provides weather protection for rf equipment

and can accommodate either a combining network or

redundant RFT package.

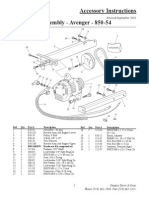

Figure 1

1.4 The feed system utilizes dual reflector Gregorian

optics which maximize gain and ensure exceptionally high

efficiency in both receive and transmit operating frequen-

cies.

Read the Instructions

Thoroughly Before Assembly

2.0 Antenna Kit Assembly

2.1 The following major assemblies are required to install

the 3.7-meter antenna kit. Check all assemblies before

beginning installation. Refer to parts list for detailed

description.

Type No. Description Qty.

204540 Reflector Assembly 1

208875 Enclosure Assembly 1

209170 Feed System Kit 1

203031-2 Enclosure Hardware Kit 1

205929 Subreflector Subassembly 1

203032 Subreflector Strut Kit 1

3.0 Enclosure Assembly

3.1 Refer to Figure 1. Carefully remove rear cover and

corresponding side panels from 208875 enclosure assem-

bly. Raise enclosure assembly and attach as shown

using 3/4 in by 3 in bolts, flat washers, convex wash-

ers, lock washers and nuts. Install supplied sealant

backing rod material around entire circumference of reflec-

tor/enclosure mating surfaces. Securely tighten enclosure

mounting hardware. Apply supplied RTV sealant around

outer perimeter of reflector mounting ring/enclosure

assembly junction to ensure a weatherproof seal.

Warning

Failure to properly install 1 in flat washers and convex

washers will result in reflector distortion.

2

Figure 2

4.0 Reflector to Mount Assembly

4.1 Refer to Figure 2. Route sling through upper holes in

reflector torsion box assembly and raise reflector/enclo-

sure assembly to vertical position as shown.

4.2 Attach rear of enclosure assembly to corresponding

elevation support angle assembly as shown using 3/4 in

by 2-1/4 in A-325 bolts, flat washers and nuts. Tighten

hardware per A-325 tensioning procedure. Note: Required

mounting hardware is supplied as part of 203031-2 hard-

ware kit.

Figure 3

4.3 Extend elevation jack and attach to top rear of enclo-

sure assembly as shown using 5/8 in bolts, flat washers

and nuts. Note: Required mounting hardware is supplied

as part of 203031-2 hardware kit.

4.4 Carefully raise reflector/enclosure assembly to zenith

(EL = 90) position.

5.0 Subreflector Assembly

5.1 Refer to Figure 3. Preassemble 202775 strut weld-

ments as shown using 202776 strut angles and 3/8 in by

2-1/4 in bolts, lock washers and nuts.

5.2 Type 205929 Subreflector Subassembly. Position

and attach subreflector mounting ring (part of 205929 sub-

reflector subassembly) to corresponding mounting holes in

strut support plates (part of 202775 strut weldment) using

3/8 in by 1 in bolts, oversized flat washers, lock washers

and nuts. Note: Ensure one subreflector adjustment stud

is located at 6 oclock position.

3

5.3 Refer to Figure 4. Attach 49187 angle clips around

reflector perimeter at indicated positions using 3/8 in by 1

in bolts, lock washers and nuts.

5.4 Raise and attach preassembled subreflector strut

assemblies between corresponding angle clips using 3/8

in by 2-1/4 in bolts, lock washers and nuts. Note: Ensure

one subreflector adjustment stud is located at 6 oclock

position.

5.5 Attach 202790 ring and corresponding 49965 hub

mounting ring to each side of reflector vetex opening as

shown using 1/4-20 by 1-1/2 in bolts, flat washers, lock

washers and nuts.

6.0 Subreflector Setting

6.1 Refer to Figure 5. Temporarily tape twine tautly across

bottom of subreflector rim at 90intervals beginning at 12

oclock (top) position as shown. Note: Twine defines the

subreflector aperture.

4

Figure 4

6.2 Position supplied 203896 setting bar on flat of 202790

ring at 12 oclock (top) position and outside bolt circle.

Sweep bar across corresponding subreflector aperture

area and note relative position between previously

installed twine and setting bar. Repeat procedure at 6

oclock (bottom) position. Use noted positions to indicate

required directional movement of top portion of subreflec-

tor aperture relative to aperture bottom using subreflector

stud adjustment hardware (3 places). Repeat above pro-

cedure at 3 and 9 oclock positions to indicate proper

aperture side adjustment. Repeat entire procedure until all

four noted positions indicate that subreflector aperture is

set parallel to 202790 ring and securely tighten adjustment

hardware. Note: Setting bar is supplied as part of 203032

subreflector strut kit.

6.3 Measure and note the distance between either outer-

most angle clip bolt head and the subreflector rim as

shown. Obtain corresponding measurements from remain-

ing subreflector struts and adjust subreflector mounting

hardware (4 places) to achieve a maximum differential of

1/16 in. Securely tighten adjustment hardware.

5

Figure 5

6.4 Repeat adjustment procedure performed in paragraph

6.2, remove twine from subreflector aperture and lower

reflector assembly to operating position.

6

Figure 6

7.0 Feed System Assembly

7.1 Refer to Figure 6. Apply supplied stick wax or silicone

grease to contact surface of feed hub assembly to aid

feed rotation. Install preassembled feed system assembly

through reflector vertex opening and attach as shown

using three 1/4-20 by 3/4 in socket head capscrews, flat

washers, lock washers and 202878 clamps in alternate

mounting holes. Loosely install three 1/4-20 by 3/4 in

bolts, flat washers, lock washers and 202789 clamps in

remaining mounting holes. Properly position feed system

and securely tighten 202789 clamps.

Warning

Do not use combiner to rotate feed assembly.

7.2 Attach customer-supplied waveguide assemblies to

corresponding combiner assembly ports using supplied

45598-75 hardware kits.

7.3 Carefully reinstall previously removed enclosure rear

cover and corresponding enclosure side panels.

Andrew Corporation

10500 West 153rd Street

Orland Park, IL U.S.A. 60462

Telephone: 708/349-3300

FAX (U.S.A.): 1-800-349-5444

Internet: http://www.andrew.com

Customer Service, 24 hours: U.S.A. Canada Mexico: 1-800/255-1479

U.K.: 0800 250055 Republic of Ireland: 1 800 535358

Other Europe: +44 1592 782612

Printed in U.S.A. 11/88

Copyright 1998 by Andrew Corporation

Tensioning Procedure

A-325 Hardware

A-325 hardware must be properly tensioned to avoid slip-

page between bolted surfaces under high loads. Slippage

can cause the corresponding assembly to move slightly

and cause antenna misalignment. Make sure all bolts are

tensioned per procedure below and replace any bolts that

break. Note: Bolts that are tensioned are for final connec-

tions only and should not be loosened for reuse.

Proper Tensioning:

1. Lubricate bolt threads with stick wax to reduce friction.

2. Insert bolt and add flat washer, if required. Do not allow

wax under flat washer.

3. Add nut and finger tighten.

4. After connections are completed, tighten bolts until sur-

faces are joined and nuts are snug. Do not proceed with

steps 5 and 6 below unless the connection is final and is

not intended to be loosened again.

5. Mark nuts and ends of bolts with straight line. See A.

6. Tighten nuts further with extra long wrench or power

wrench until nuts are moved 1/3 turn (12030). See B.

Reflector/Enclosure Assembly

Parts List

Type No. Description Qty.

204540 Reflector Assembly 1

208875 Enclosure Assembly 1

203031-2 Enclosure Hardware Kit consists of:

47597 RTV Sealant 1

9963-717 3/4 x 3 Bolt 4*

9997-232 1 Flat Washer 7*

9974-10 3/4 Look Washer 4*

9999-121 3/4 Hex Nut 5*

205936 Convex Washer 6

205937 Sealant Backing Rod 13.5 ft

45980-25 3/4 x 2-1/4 Bolt and Nut Assembly 3

9997-202 3/4 Flat Washer 4

45980-31 5/8 x 4 Bolt and Nut Assembly 3

9997-227 5/8 Flat Washer 3

205929 Subreflector Subassembly 1

203032 Subreflector Strut Kit consists of:

202775 Strut Weldment 4

49187 Angle CAip 8

202776 Strut Angle 4

9963-127 3/8 x 2-1/4 Bolt 14*

9963-115 3/8 x 1 Bolt 21*

9974-63 3/8 Lock Washer 35*

9999-60 3/8 Nut 35*

203039 3/8 Flat Washer (oversized) 5*

203896 Setting Bar 1

209170 Food System Kit consists of:

- - - - - - Feed System Assembly 1

9963-75 1/4-20 x 3/4 Bolt 4*

9963-120 1/4-20 x 1-1/2 Bolt 13*

9974-15 1/4 Lock Washer 20*

999742 1/4 Flat Washer 20*

9999-57 1/4 Nut 13*

9972-6 1/4-20 x 3/4 Sockethead Screw 4*

202789 Clamp 3

202878 Clamp 3

202790 Ring 1

49965 Hub Mounting Ring 1

12225 Silicone Grease 2

205867 Alignment Clamp 1

*Includes spare(s).

Notice

The installation, maintenance, or removal of antenna sys-

tems requires qualified, experienced personnel. Andrew

installation instructions have been written for such person-

nel. Antenna systems should be inspected once a year by

qualified personnel to verify proper installation, mainte-

nance and condition of equipment.

Andrew disclaims any liability or responsibility for the

results of improper or unsafe installation practices.

Potrebbero piacerti anche

- Antena Andrew 3.7m PDFDocumento7 pagineAntena Andrew 3.7m PDFMemoPalacioNessuna valutazione finora

- Manual Prodelin 4096-433Documento15 pagineManual Prodelin 4096-433Claudio EspositoNessuna valutazione finora

- Ceiling Fan Lucci WhitehavenDocumento13 pagineCeiling Fan Lucci Whitehaven2201Nessuna valutazione finora

- Antenna Systems: 2.4m Navigator Offset Antenna Receive Only and Transmit-ReceiveDocumento13 pagineAntenna Systems: 2.4m Navigator Offset Antenna Receive Only and Transmit-ReceiveBenjamin HuaylliriNessuna valutazione finora

- Ss AFFECTED PRODUCT 3508BDocumento13 pagineSs AFFECTED PRODUCT 3508Bjoalca31Nessuna valutazione finora

- Svs Rotor Installation 110vDocumento11 pagineSvs Rotor Installation 110vJavier I. ConchaNessuna valutazione finora

- Colby 52 Quick-Install Ceiling Fan Owner's ManualDocumento16 pagineColby 52 Quick-Install Ceiling Fan Owner's Manualorodz1Nessuna valutazione finora

- Fireball Ignition PDFDocumento14 pagineFireball Ignition PDFLucian LeonteNessuna valutazione finora

- SERVICE BULLETIN No. 012-2009 21-12-2009Documento13 pagineSERVICE BULLETIN No. 012-2009 21-12-2009Bert SmitNessuna valutazione finora

- Instructions Installation of Back-Channel Cooling Kit For Frames D3, D4 & E2Documento23 pagineInstructions Installation of Back-Channel Cooling Kit For Frames D3, D4 & E2Oton SilvaNessuna valutazione finora

- Installation Instructions for Hustler 4-BTV and 5-BTV Trap Vertical AntennasDocumento14 pagineInstallation Instructions for Hustler 4-BTV and 5-BTV Trap Vertical AntennasAl SmithermanNessuna valutazione finora

- Installation Instructions Hustler 4-Btv, 5-Btv Trap VerticalDocumento14 pagineInstallation Instructions Hustler 4-Btv, 5-Btv Trap VerticalpartgioNessuna valutazione finora

- EU3512-3X Environmental Enclosure and Light Duty Wall Mount: InstallationDocumento12 pagineEU3512-3X Environmental Enclosure and Light Duty Wall Mount: InstallationByron RieraNessuna valutazione finora

- QTXEN Series Ceiling Fan Light Installation and Operation GuideDocumento8 pagineQTXEN Series Ceiling Fan Light Installation and Operation GuideMark CanfieldNessuna valutazione finora

- Eaw KF750Documento9 pagineEaw KF750stam5028Nessuna valutazione finora

- CCL Extrusion Guy65yard InstallationDocumento14 pagineCCL Extrusion Guy65yard InstallationJuan Pablo Vélez DuqueNessuna valutazione finora

- Alternator Installation Instructions for Avenger 850-54Documento6 pagineAlternator Installation Instructions for Avenger 850-54cristi_stoiciucNessuna valutazione finora

- KTE 300 HousingDocumento18 pagineKTE 300 HousingVarun GargNessuna valutazione finora

- Respironics Everflo Filter Replacement Manual - NewDocumento6 pagineRespironics Everflo Filter Replacement Manual - NewJose EstradaNessuna valutazione finora

- 1.8M Antenna Assembly ManualDocumento24 pagine1.8M Antenna Assembly Manualmanuel_897Nessuna valutazione finora

- Sehs9065 Deutsch CeDocumento11 pagineSehs9065 Deutsch CeAlvaro arceNessuna valutazione finora

- Eaton CM-52 Remote Racking IL02400003EDocumento16 pagineEaton CM-52 Remote Racking IL02400003EadvancedmotorNessuna valutazione finora

- Acson AHU O&M ManualDocumento13 pagineAcson AHU O&M ManualKamran AhmedNessuna valutazione finora

- 518 Centrifuge IOM Manual Rev.CDocumento120 pagine518 Centrifuge IOM Manual Rev.CGiorgiana RosuNessuna valutazione finora

- Coupling InstallDocumento7 pagineCoupling InstallNimNessuna valutazione finora

- Cherry Burrell Processor ManualDocumento48 pagineCherry Burrell Processor ManualMadan YadavNessuna valutazione finora

- Instalación y Mantenimiento de Válvulas RotativasDocumento4 pagineInstalación y Mantenimiento de Válvulas RotativasGustavo León CarreraNessuna valutazione finora

- 4096 406Documento5 pagine4096 406Pranalanka WarunawansaNessuna valutazione finora

- Altus Hugger InstructionsDocumento3 pagineAltus Hugger InstructionstylerdurdaneNessuna valutazione finora

- Tc920 ManualDocumento3 pagineTc920 ManualJuliao MatosNessuna valutazione finora

- Ceiling Fan Service ManualDocumento19 pagineCeiling Fan Service ManualOrly Inosa100% (1)

- 18 GJ04D1 6Documento40 pagine18 GJ04D1 6sil_muahdibNessuna valutazione finora

- HFCC D Iom 03Documento16 pagineHFCC D Iom 03geovany_villagraNessuna valutazione finora

- D-2 Power Vent ManualDocumento24 pagineD-2 Power Vent ManualJon BondNessuna valutazione finora

- Biodiesel Pump - 115V - 20 GPMDocumento4 pagineBiodiesel Pump - 115V - 20 GPMOrganic MechanicNessuna valutazione finora

- Harbor Breeze Ceiling Fan Manual Model BDB52WW5PDocumento10 pagineHarbor Breeze Ceiling Fan Manual Model BDB52WW5PobfuscatefrogNessuna valutazione finora

- Introducing The Airbrake: Moore Fans Anti Windmilling DeviceDocumento5 pagineIntroducing The Airbrake: Moore Fans Anti Windmilling DevicedfmolinaNessuna valutazione finora

- Panasonic FV11VHL2 Ventilating Fan InstructionsDocumento12 paginePanasonic FV11VHL2 Ventilating Fan Instructionssharklaser69Nessuna valutazione finora

- Antenna Feeder System InstallationDocumento24 pagineAntenna Feeder System InstallationAbdul RahimNessuna valutazione finora

- Butterfly Valve User ManualDocumento10 pagineButterfly Valve User ManualEduardoAscencioNessuna valutazione finora

- DACRON HighlanderManualChapter4Documento18 pagineDACRON HighlanderManualChapter4wordpower777Nessuna valutazione finora

- Manual Evaporador RotatorioDocumento28 pagineManual Evaporador Rotatorioratt10Nessuna valutazione finora

- Isq IomDocumento19 pagineIsq IomJericho EstrellaNessuna valutazione finora

- EAW KF750 Loudspeaker Truss InstructionsDocumento3 pagineEAW KF750 Loudspeaker Truss InstructionsEduin Quintero RamirezNessuna valutazione finora

- Technical Bulletin: CopierDocumento22 pagineTechnical Bulletin: CopiernickypanzeNessuna valutazione finora

- Cook INSTALLATION, OPERATION, AND MAINTENANCE MANUALDocumento12 pagineCook INSTALLATION, OPERATION, AND MAINTENANCE MANUALtylerdurdaneNessuna valutazione finora

- 39CQ Iom 06302014Documento20 pagine39CQ Iom 06302014Non Etabas GadnatamNessuna valutazione finora

- 7650 EdDocumento8 pagine7650 EdHJNessuna valutazione finora

- 7000 Series Field Operations Manual PDFDocumento45 pagine7000 Series Field Operations Manual PDFmanzanaNessuna valutazione finora

- Catalog HRC Jaw CouplingsDocumento8 pagineCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- Bonh 1Documento38 pagineBonh 1Maria DazaNessuna valutazione finora

- Tri-band HF Beam Antenna ManualDocumento11 pagineTri-band HF Beam Antenna ManualOscar NavaNessuna valutazione finora

- Section Ii: InstallationDocumento10 pagineSection Ii: InstallationGLOZOYA25Nessuna valutazione finora

- Installation Manual: Universal Top-of-Pole Mount UNI-TP/08LLDocumento11 pagineInstallation Manual: Universal Top-of-Pole Mount UNI-TP/08LLlexdanteNessuna valutazione finora

- RBS 6201 PDFDocumento25 pagineRBS 6201 PDFYasir ChestiNessuna valutazione finora

- Si 1185Documento6 pagineSi 1185user10002Nessuna valutazione finora

- Installation InstructionsDocumento4 pagineInstallation InstructionsFreddy MartinezNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDa EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNessuna valutazione finora

- A Design Review of A 350WDocumento36 pagineA Design Review of A 350WJosé De Moya A.Nessuna valutazione finora

- Ds Cku 4.6 TXRXDocumento13 pagineDs Cku 4.6 TXRXJosé De Moya A.Nessuna valutazione finora

- 900watts SMPSDocumento1 pagina900watts SMPSJosé De Moya A.Nessuna valutazione finora

- Mplab IDE Com Mplab Editor e Mplab SimulatorDocumento360 pagineMplab IDE Com Mplab Editor e Mplab SimulatorNando100% (1)

- Behringer 1602aDocumento4 pagineBehringer 1602aJosé De Moya A.Nessuna valutazione finora

- Archie Dobsons WarDocumento19 pagineArchie Dobsons Warapi-306902851Nessuna valutazione finora

- 3GDocumento10 pagine3GAkhtar KhanNessuna valutazione finora

- Ad9854 BDocumento44 pagineAd9854 Bkama_raj19758808Nessuna valutazione finora

- Personal Recollections and Experiences Concerning The Battle of Stone River by Hascall, Milo S., 1829-1904Documento18 paginePersonal Recollections and Experiences Concerning The Battle of Stone River by Hascall, Milo S., 1829-1904Gutenberg.orgNessuna valutazione finora

- IX Physics project explores soundDocumento28 pagineIX Physics project explores soundshusa harshaNessuna valutazione finora

- High-power 4-channel amplifierDocumento2 pagineHigh-power 4-channel amplifierjoseluisblanco69Nessuna valutazione finora

- Consumer Buying Behavior for Colour TelevisionsDocumento48 pagineConsumer Buying Behavior for Colour Televisionssarvesh.bhartiNessuna valutazione finora

- G6122 EtcDocumento4 pagineG6122 Etcapi-3697437Nessuna valutazione finora

- NYSTABAKK, Solmund, Franco Donatoni - Algo-Due Pezzi Per Chitarra - An Analysis, 2009 PDFDocumento18 pagineNYSTABAKK, Solmund, Franco Donatoni - Algo-Due Pezzi Per Chitarra - An Analysis, 2009 PDFGian Franco Carrera I.Nessuna valutazione finora

- GGSN Monitoring & First Layer HandlingDocumento24 pagineGGSN Monitoring & First Layer Handlingkimlookman100% (2)

- MinimalismDocumento2 pagineMinimalismapi-298795829Nessuna valutazione finora

- Hit Dada Sali (2015)Documento1 paginaHit Dada Sali (2015)ostrc100% (1)

- Recomendacion ETIS TS 102 250 PDFDocumento252 pagineRecomendacion ETIS TS 102 250 PDFjtafurpNessuna valutazione finora

- LUTOSLAWSKI - 20 Polish Christmas Carols - Lacrimosa - 5 SongsDocumento2 pagineLUTOSLAWSKI - 20 Polish Christmas Carols - Lacrimosa - 5 SongsPaulo ArrudaNessuna valutazione finora

- TP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓Documento11 pagineTP-62 TP-42 TP-50 TP-70 TP-72: Pedal Timpani Timbale À Pédale Timbal De Pedal 踏板定音鼓lucasloudNessuna valutazione finora

- The Nightingale Class4Documento3 pagineThe Nightingale Class4vikrant choureNessuna valutazione finora

- Manual CS 300-04 - 06 - English PDFDocumento20 pagineManual CS 300-04 - 06 - English PDFVladimir StefanovicNessuna valutazione finora

- Badiou - The False Movements of CinemaDocumento6 pagineBadiou - The False Movements of Cinemab_gookNessuna valutazione finora

- New Song Book For Dzire PLUS & DzireDocumento17 pagineNew Song Book For Dzire PLUS & DzireMukund SidhayeNessuna valutazione finora

- AcrossTheUniverse TheBeatlesDocumento1 paginaAcrossTheUniverse TheBeatlesarthurcleeNessuna valutazione finora

- Repicame El Timbal-Tenor SaxDocumento2 pagineRepicame El Timbal-Tenor SaxBalam FabrizzioNessuna valutazione finora

- Castañeda, Marimar A. (Film Review)Documento3 pagineCastañeda, Marimar A. (Film Review)Mikesy EslavaNessuna valutazione finora

- Column Systems: TC4300 TC4018ADocumento2 pagineColumn Systems: TC4300 TC4018ApanapapakNessuna valutazione finora

- Black Water: Transcribed by Danny Begelman Words and Music by Patrick SimmonsDocumento8 pagineBlack Water: Transcribed by Danny Begelman Words and Music by Patrick SimmonsnguyenqtNessuna valutazione finora

- The Weekender 11-07-2012Documento72 pagineThe Weekender 11-07-2012The Times LeaderNessuna valutazione finora

- KORG Volca FM AlgorithmsDocumento3 pagineKORG Volca FM AlgorithmsonzemillevergesNessuna valutazione finora

- Shabooh Shoobah - WikipediaDocumento13 pagineShabooh Shoobah - WikipediabNessuna valutazione finora

- Yamaha EMX 5016 CF Owner's ManualDocumento40 pagineYamaha EMX 5016 CF Owner's ManualCamilo FerrúaNessuna valutazione finora

- Time PeriodDocumento8 pagineTime PeriodSahadev ShresthaNessuna valutazione finora

- Grade 1 to 12 School Daily Lesson LogDocumento4 pagineGrade 1 to 12 School Daily Lesson LogAiza ChulipaWakit TabaresNessuna valutazione finora