Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

VIt C

Caricato da

palkybd0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

30 visualizzazioni2 pagineVitamin C

Titolo originale

VIt c

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoVitamin C

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

30 visualizzazioni2 pagineVIt C

Caricato da

palkybdVitamin C

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Extraction of Ascorbic Acid

from Plant Tissues

WARD B. DAVIS

Agricultural Chemical Research Division,

Bureau of Agricultural Chemistry and Engineering,

U. S. Department of Agriculture,

Los Angeles, Calif.

HE extraction of ascorbic acid by a new procedure which

utilizes the Waring Blendor (2) is briefly described.

T This procedure will avoid the laborious grinding neces-

sary for plant tissue hard to triturate, as in the method of

Thornton (6) and others. Plant material was extracted by

covering the cutting knives of the Blendor with about 150

ml. of extractant, adding a sample of 10 to 20 grams, and

running the motor at high speed for 5 minutes. The Blendor

and reagents were kept in a room maintained near 5" C.

Sufficient Super-Cel filter aid was added to the finely divided

material suspended in the extractant to give quick filtration

by suction on a Biichner funnel. Convenient aliquots of

the clear, almost colorless filtrate which was made to a volume

of 150 ml. were titrated with 2,6-dichlorophenolindophenol.

The dye was standardized by the method of Menaker and

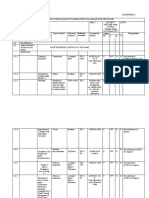

TABLE I. COMPARISON OF METHODS FOR EXTRACTION OF As-

CORBIC ACID (MQ. ASCORB~C ACID PER GRAM FRESH WEIQHT)

-Hand Method- -Blendor Method-

a b a b

Parsley

First extract 1.93 2.20 2.00 2.20

Second extract 0.07 0.06 0.03 0.03

Third extract 0.01 0.02 0.01 0.01

0.07 0.12 0.02 0.02 Residue

Total 2. 08 2. 40 2.06 2.26

First ext 7 of total 92.78 91.67 97.09 97.38

- - - -

Extract& &e, min. 24 20 10 10

Guerrant (4). Except where 2 per cent metaphosphoric

acid was used, the extractant was a mixture of 3 per cent

trichloroacetic acid and 2 per cent metaphosphoric acid.

After extraction, 8 per cent acetic acid was used for diluting

the mixture to volume. Ballentine's iodate method (1)

was used on some of the tissues. The end point is sharper

and results are higher than by the dye titration.

The Blendor method of extracting ascorbic acid was com-

pared with the usual method of grinding by hand. Five

grams of the plant tissue were ground 5 minutes with 25

ml. of extractant and 3 ml. of sand to a thin paste, which wm

poured into a 50-ml. conical centrifuge tube. Samples

ground in duplicate were centrifuged at the same time for

3 minutes. The fairly clear liquid was decanted, and then

10 ml. of fresh extractant, used to rinse the mortar, were

stirred with the residue in each tube. These were centrifuged

and decanted, and a final extraction was made with 5 ml.

The total liquid decanted was made to 50 ml. This was the

first extract. An aliquot of the first extract was made to

about 50 ml. and titrated. Two additional extractions were

made by grinding the residue in the mortar again for 2 min-

utes, each time with 25 ml. of extractant, and centrifuging.

The residue of tissue fragments and sand was diluted to 50

or 100 ml. and titrated. The end point, ordinarily obscured

by suspended particles, was clearly seen after centrifuging

a small quantity of the suspension in an angle centrifuge for

Cabbage 1 minute.

First extract 0.32 0.30 0.30 0.23 Twenty-gram samples of the same tissues extracted by the

0.00 0.00 0.01 0.01 hand grinding were reduced in the Blendor, in the manner

Residue 0.01 0.01

already described, for 5 minutes. Two additional extractions

Extraction time, min. 19 19 12 13 Only 5 grams of grapefruit peel and 10 grams of fresh peas

were used in the Blendor. The extractant for these two tis-

0.01 0.01 sues was 2 per cent metaphosphoric acid (3). Samples of the

Third extract 0 " : : ; ::ti fresh peas from the same l ot were weighed, frozen, and kept

Total 0.25 0.22 0.22 0.23 frozen until extracted to avoid loss of ascorbic acid on stand-

First ext %, of total 88.00 86.36 86.30 78.80 ing. Centrifuging the fresh pea tissue after extraction gave

Extractizn time, min. 18 18 10 11

the same results as filtration with acid-washed filter aid.

Some tissues foam in the Blendor, making the transfer to

First ext., % of total 75.54 79.83 the centrifuge tubes bothersome. A few drops of alcohol aid

Mustard greens in causing the foam to subside.

As shown in Table I, the new procedure appears not only

to be just as efficient but also to require less time and effort

Potato

First extract 0.09 0.07 on the part of the worker than the older, grinding method.

88.49 Even in cabbage tissue, which contains ascorbic acid oxidase,

First ext., of total

Grapefruit peela the new procedure seems satisfactory. The titration figures

Av. of 4 samples 1.75 1.92

for the tissue residues, although only approximate in nature,

indicates the completeness of the extractions.

Av. of 6 samples 0. 07 0.11

Av. of 6 samples, acid-washed

Higher results were obtained from samples in which acid-

Super-Cel ... 0.16

Av. of 6 samples, centrifuged ... 0.16 washed in comparison with unwashed Super-Cel was used.

a Extractant, 2% metaphosphoric acid. To test the recovery of added ascorbic acid, 20 mg. of pure

ascorbic acid were added to the titrated residues from 20

0.01 0.01 0.01 0.01

0.34 0.32 0.33 0.26

Second extract

Third extract

First ext., % of total

94.12 93.76 90.90 88.47 of 2 minutes each were made on each sample in duplicate,

Total

Frozen peas

0.22 0.19 First extract

Second extract

Residue

- - - -

Chard

First extract 0.40 0.42

First extract 1.11 1.07

First ext., 70 of total 90.16 85.88

86.79

Fresh peas5

217

218 I N D U S T R I A L A N D E N G I N E E R I N G C H E M I S T R Y Vol. 34, No. 2

grams of extracted tissues mixed with filter aid and fragments no plant tissue and the motor was run at high speed for

of filter paper. After the ascorbic acid was stirred into the 10 minutes.

residue, the extractant was added and the suspension was Much time and effort may be saved by this procedure, be-

placed in the Blendor. The procedure was then the same as cause a large number of workers have been making the

described for the extraction of fresh material. The degree ascorbic acid assay by the chemical method.

Literature Cited

of completeness of extraction of added ascorbic acid was

similar to that of the first extraction of naturally occurring

ascorbic acid.

90 to 101 per cent.

The total percentage recovered varied from

Boiled cabbage tissue residue gave about

(1) Ballentine, R.8 1x0. ENG. CHEM. 9 ANAL. ED., 13, 89 (1941).

(2) Davis, W. B., IND. ENG. CHEM., NEWS ED., 17, 752 (1939).

(3) King, C. G., IND. ENG. CHEX., ANAL. ED., 13, 228 (1941).

(4) Menaker, M. H., and Guerrant, N. B., Ibid., 10, 25 (1938).

( 5) Thornton, N. C., Contrib. Boyce Thompson Inst , 9, 273 (1938).

CovTRiBuTroN 37 from the Division of Agricultural Chomioal Research.

the same percentage recovery of added ascorbic acid as the

unboiled residue. A recovery of 99 per cent was made

when ascorbic acid was added to the extractant containing

Effect of Reinforcing Pigments

on Rubber Hydrocarbon

F. S. THORNHILL AND W. R. SMITH

Godfrey L. Cabot, Iiic., Boston, Mass.

The unsaturation values and amount of combined

sulfur at various states of vulcanization for a num-

ber of rubber compounds have been studied.

While the anticipated loss in unsaturation of the

rubber hydrocarbon was noted in stocks containing

nonreinforcing fillers, no such loss in unsaturation

could be detected in rubber compounds containing

reinforcing channel blacks. It is suggested that

this alteration in the mechanism of sulfur vul-

canization may be mostly responsible for the

physical characteristics of reinforced rubber stocks.

It has not been possible to detect any effect of

carbon black on the unsaturation value of natural

rubber. Calculation indicates that, while such an

effect would not be detected in the present case

with the analytical method employed, such an

effect, if present, should be detectable with carbon

blacks of greater surface area than those employed

in the present investigation.

EVERAL investigators (20) have established that sulfur

vulcanization of rubber involves chemical combination

S of sulfur and rubber hydrocarbon. A definite decrease

in unsaturation of the rubber hydrocarbon as vulcanization

progresses has been generally noted (S, 10, 18).

While it has often been concluded that a double bond is

saturated for each atomic equivalent of combined sulfur (10,

18), recent work by Brown and Hauser (3, 7 ) demonstrates

that this conclusion cannot be applied in all cases. I n certain

compounds they found the loss in unsaturation with extent

of vulcanization to be considerably less than anticipated on

the above basis. Their results indicated that stocks reaching

optimum cure with the least loss of unsaturation possessed

the greatest tensile strength.

Although a considerable amount of work has been done on

this problem, wehave not found a published account of simi-

lar investigations performed on stocks containing significant

loadings of reinforcing fillers. Since, as pointed out below,

the nature of the bonding between such fillers and the rubber

molecule has not been clearly defined, one is not justified in

applying previous results obtained on stocks containing no re-

inforcing fillers to those bearing appreciable loadings of such

substances. Accordingly one portion of the present investi-

gation was concerned with determining the effect of various.

fillers on the course of sulfur vulcanization, as judged from

combined sulfur and unsaturatioii values.

Aapointed out by Gehman and Field (S), it is undoubtedly

true that the black particle in a carbon-black-reinforced

rubber stock is firmly attached to the rubber molecule. The

nature of the bonding between the black and rubber has not

been clearly defined. Some investigators (4, 8, 14, 17) main-

tain that the association is physical and involves dcfinitc

forces of adhesion or adsorption; othcrs ( I S ) have suggested

formation of primary valence linkages with the rubber hydro-

carbon. The opinion of the present autho& is that if such

linkages are formed, the ethylenic bonds of the rubber mole-

cule would probably beinvolved. If this latter view is correct,

then a specific loss in unsaturation of the rubber hydrocarbon,

due to the reinforcing filler, should occur. Thus the second

objective of the present study was to determine whether it

was possible by chemical means to detect such a linkage. If

measurable, this effect, together with the surface area deter-

minations reported previously (15), would be particularly

valuable in estimating the reinforcing value of various fillers.

Experimental Procedure

The unsaturation of the rubber stocks was determined by

addition of iodine chloride. The procedure followed was es-

sentially Kemps technique (9, 11) as modified by Blake and

Bruce ( 9) :

A 0.1-gramsample of stock was dissolved in boiling p-dichloro-

benzene. Solution be-

camemore difficult with well cured compounds. This was over -

This usually required from 2 to 3 hours.

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- DSFDSFDocumento2 pagineDSFDSFpalkybdNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- BTR5 Quick Start Guide ENDocumento1 paginaBTR5 Quick Start Guide ENpalkybdNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- GT Bicycle OwnersManualDocumento108 pagineGT Bicycle OwnersManualHNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Breast Cancer TempDocumento1 paginaBreast Cancer TemppalkybdNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- 2018 02 08 6MonthsBuggyIM MS14971 Online PDFDocumento37 pagine2018 02 08 6MonthsBuggyIM MS14971 Online PDFpalkybdNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Non Linear Kinetics PracticeDocumento2 pagineNon Linear Kinetics PracticepalkybdNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Sanet - ST - Formulation Science and Technology Vol 3Documento364 pagineSanet - ST - Formulation Science and Technology Vol 3palkybd100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Clustering BasicDocumento8 pagineClustering BasicpalkybdNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- AvayaDocumento24 pagineAvayatheturbolemmingNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Maxtor M3 Portable - User Manual-EN - E01 - 19 05 2016 PDFDocumento22 pagineMaxtor M3 Portable - User Manual-EN - E01 - 19 05 2016 PDFAhmad ElsheemyNessuna valutazione finora

- Vmware Vcenter6 Performance White PaperDocumento19 pagineVmware Vcenter6 Performance White PaperpalkybdNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- PDF Spring 2017 Sat SD State Provided SSD Coordinator ManualDocumento96 paginePDF Spring 2017 Sat SD State Provided SSD Coordinator ManualpalkybdNessuna valutazione finora

- 469 Maldives Lightweight Stroller ManualDocumento5 pagine469 Maldives Lightweight Stroller ManualpalkybdNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- G2 Portable HDD - User's ManualDocumento35 pagineG2 Portable HDD - User's ManualChinakohlNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Backup and Restore Logical Volume Using LVM SnapshotDocumento25 pagineBackup and Restore Logical Volume Using LVM SnapshotpalkybdNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Maxtor M3 Portable - User Manual-EN - E01 - 19 05 2016 PDFDocumento22 pagineMaxtor M3 Portable - User Manual-EN - E01 - 19 05 2016 PDFAhmad ElsheemyNessuna valutazione finora

- Bob Revolution Owner S Manual: Assembly InstructionsDocumento2 pagineBob Revolution Owner S Manual: Assembly InstructionspalkybdNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Psutil 5.0.1Documento8 paginePsutil 5.0.1palkybdNessuna valutazione finora

- Rocker Base: 2-13 English 14-24 Français 25-31 DEUTSCH 32-39 ESPAÑOL 40-47 Português 48-57 한국어Documento56 pagineRocker Base: 2-13 English 14-24 Français 25-31 DEUTSCH 32-39 ESPAÑOL 40-47 Português 48-57 한국어palkybdNessuna valutazione finora

- Seagate Dashboard en USDocumento17 pagineSeagate Dashboard en USpalkybdNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Sns Instructions After02Documento36 pagineSns Instructions After02palkybdNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Snake Arm Lamp Instruction ManualDocumento2 pagineSnake Arm Lamp Instruction ManualpalkybdNessuna valutazione finora

- Manual NV356EDocumento20 pagineManual NV356EpalkybdNessuna valutazione finora

- G3 ICS and Base Manual For WebDocumento49 pagineG3 ICS and Base Manual For WebpalkybdNessuna valutazione finora

- NunaDocumento59 pagineNunapalkybdNessuna valutazione finora

- Autologin UbuntuDocumento3 pagineAutologin UbuntupalkybdNessuna valutazione finora

- Baby TrendDocumento6 pagineBaby TrendpalkybdNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- O2 Stroller Base Illustrated Folder Text Booklet WarrantyDocumento26 pagineO2 Stroller Base Illustrated Folder Text Booklet WarrantypalkybdNessuna valutazione finora

- Cortina Magic 10 2016Documento46 pagineCortina Magic 10 2016palkybdNessuna valutazione finora

- Docker For Virtualization Admin EbookDocumento12 pagineDocker For Virtualization Admin EbookAdam MazozNessuna valutazione finora

- Salt AnalysisDocumento9 pagineSalt AnalysisAnanyaNessuna valutazione finora

- Report For Experiment #21 Radioactive Decay: Monique DesrochersDocumento9 pagineReport For Experiment #21 Radioactive Decay: Monique DesrochersMonique DesrochersNessuna valutazione finora

- Physics II Problems PDFDocumento1 paginaPhysics II Problems PDFBOSS BOSSNessuna valutazione finora

- How To Build An Alpha Particle Spark DetectorDocumento6 pagineHow To Build An Alpha Particle Spark Detectorjuan9gonzalez_9100% (1)

- GRG - Spec Data-1 Rev 4-7-11Documento1 paginaGRG - Spec Data-1 Rev 4-7-11Chandru MohanNessuna valutazione finora

- Separators SizingDocumento16 pagineSeparators SizingRonald GeorgeNessuna valutazione finora

- CHEM 135 Exam 2 F15 KeyDocumento7 pagineCHEM 135 Exam 2 F15 KeyMikeNessuna valutazione finora

- MP Lecture NotesDocumento125 pagineMP Lecture NotesTatenda SibandaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- APPLIED CHEMISTRY Lab ManualDocumento50 pagineAPPLIED CHEMISTRY Lab ManualHarshit RajNessuna valutazione finora

- CEN 12566-3 European Standard enDocumento45 pagineCEN 12566-3 European Standard enDebreteni Florin100% (1)

- Ba 10aDocumento4 pagineBa 10aFrancis LoboNessuna valutazione finora

- Introduction To The Chemostat H.T. Banks and Marie DavidianDocumento27 pagineIntroduction To The Chemostat H.T. Banks and Marie DavidianCristina CroitoruNessuna valutazione finora

- Asian PaintsDocumento13 pagineAsian PaintsGurnoor SinghNessuna valutazione finora

- The EURO Currency Coins: Research atDocumento37 pagineThe EURO Currency Coins: Research atSherif EltoukhiNessuna valutazione finora

- TB-0017-02 BITZER Oil Draining Guidelines For CSH ScrewsDocumento7 pagineTB-0017-02 BITZER Oil Draining Guidelines For CSH ScrewsVaibhav SaxenaNessuna valutazione finora

- Jahangirabad Instiute of Technology Barabanki Department of Mechanical EngineeringDocumento23 pagineJahangirabad Instiute of Technology Barabanki Department of Mechanical EngineeringMuhammad ImranNessuna valutazione finora

- Methodology of Drought Stress Research: Experimental Setup and Physiological CharacterizationDocumento25 pagineMethodology of Drought Stress Research: Experimental Setup and Physiological CharacterizationPriya Vijay kumaarNessuna valutazione finora

- Commissioning and Decommissioning of Installations For Dry Chlorine Gas and LiquidDocumento18 pagineCommissioning and Decommissioning of Installations For Dry Chlorine Gas and LiquidKimberly ConleyNessuna valutazione finora

- Dissertation Rohaizreen Irdayu BT Mohd Radzi 12436Documento77 pagineDissertation Rohaizreen Irdayu BT Mohd Radzi 12436a.hasan670Nessuna valutazione finora

- Chapter 1 - Matter in Our SurroundingsDocumento22 pagineChapter 1 - Matter in Our SurroundingsTara SinghNessuna valutazione finora

- Model QAP For Plates1Documento3 pagineModel QAP For Plates1tarun kaushalNessuna valutazione finora

- CSEC Chemistry January 2009 P032Documento7 pagineCSEC Chemistry January 2009 P032AshleyNessuna valutazione finora

- AFT Arrow 5 Data Sheet PDFDocumento2 pagineAFT Arrow 5 Data Sheet PDFerjainrachitNessuna valutazione finora

- Unit III: Alkanes and Cycloalkanes: E. D. Gloria Ust - Faculty of Pharmacy Chem200 - Organic ChemistryDocumento19 pagineUnit III: Alkanes and Cycloalkanes: E. D. Gloria Ust - Faculty of Pharmacy Chem200 - Organic ChemistryLyra LasangreNessuna valutazione finora

- Silfoam - Wackers PDFDocumento60 pagineSilfoam - Wackers PDFsrushtiNessuna valutazione finora

- Things Your Screw Designer Never-FinalDocumento6 pagineThings Your Screw Designer Never-FinalRajesh Kumar100% (2)

- AS Physics: Number of Pixels X Bits Per Pixel and 1 Byte 8 BitsDocumento2 pagineAS Physics: Number of Pixels X Bits Per Pixel and 1 Byte 8 BitsAnanYasinNessuna valutazione finora

- Rheological PropertiesDocumento12 pagineRheological Propertiesdarshan0160% (1)

- Chapter 21 22 - Chemical Reactions Balancing Chemical EquationsDocumento34 pagineChapter 21 22 - Chemical Reactions Balancing Chemical EquationsAlwielland BelloNessuna valutazione finora

- 14.THERMAL ENGG (RAJPUT) - Performance of Steam GeneratorDocumento17 pagine14.THERMAL ENGG (RAJPUT) - Performance of Steam GeneratorFasil MesfinNessuna valutazione finora

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactDa EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactValutazione: 5 su 5 stelle5/5 (5)

- Process Plant Equipment: Operation, Control, and ReliabilityDa EverandProcess Plant Equipment: Operation, Control, and ReliabilityValutazione: 5 su 5 stelle5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDa EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNessuna valutazione finora

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDa EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincValutazione: 3.5 su 5 stelle3.5/5 (137)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDa EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeValutazione: 5 su 5 stelle5/5 (4)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDa EverandChemistry for Breakfast: The Amazing Science of Everyday LifeValutazione: 4.5 su 5 stelle4.5/5 (90)