Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Load Test On Scharge Motor

Caricato da

Ramakrishna Sagar0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

464 visualizzazioni4 paginelab manual for btech

Titolo originale

Load Test on Scharge Motor

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentolab manual for btech

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

464 visualizzazioni4 pagineLoad Test On Scharge Motor

Caricato da

Ramakrishna Sagarlab manual for btech

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING

ELECTRICAL MACHINES LAB II

Load Test On Scharge Motor Page 1 of 4

LOAD TEST ON SCHARGE MOTOR

1. AIM:

(a) To study speed variation vs brush separation.

(b) To perform load test on schrage motor at (i) subsynchronous speed and (ii) super synchronous

speed.

(c) To draw the following performance characteristics under the above conditions of operation

and compare them critically.

(i) Efficiency vs power output (ii) speed vs Torque. (iii) power factor vs Torque

2. APPARATUS:

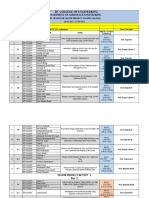

S. No. Name Type Range Quantity

1.

2.

3.

4.

Voltmeter

Ammeters

3 phase Variac

Lamp bank load

MI

MI

-

resistive

0-300/600V

0-20 A

400/0-400 V, 25 A

250 V, 3 Kw

1

5

1

2

3. THEORY:

The scharge motor is basically an invited three phase induction motor, in which 3-phase primary

winding is on the rotor, where as the 3 phase secondary winding is on the stator. The rotor of this machine

in addition to the main primary winding also carries a tertiary winding, housed in the same set of slots. The

tertiary winding is a closed commutator winding, the tappings of which are connected to the bars of the

commutator.

The terminals of secondary winding on the stator are connected to set of brushes placed on the

commutator, so that any desired voltage from the tertiary winding can be injected into the circuit of the

secondary winding. As a result, the speed of the scharge motor changes, depending upon the magnitude and

direction of the injected emf into the secondary winding, thus achieving variable speed control with shunt

characteristics.

This motor has an additional advantage that input power factor can also be controlled along with

control speed. Commercially, these motors are normally built with speed range from about 50 percent

below to about 50 percent above synchronous speed. Fig (2) shows the complete details of various

windings of scharge motor as per the above discussion.

Two brushes of each set connected to one phase of the secondary winding (i.e. a

1

, a

2

) can be moved

simultaneously and in opposite direction by gearing arrangement provided with the motor. Fig (1) a, b, and

c illustrate three possible modes of action of this motor. In Fig (1)a, two brushes of a set (a

1

, a

2

) are on the

same commutator bar, as such injected emf in the secondary is zero and the motor runs as an ordinary

induction motor at nearby synchronous speed, with secondary winding short-circuited through the

commutator bar. Fig (1)b, corresponds to operation of the motor in synchronous region, where as Fig (1)c

clearly illustrates that the motor will run at super synchronous speeds.

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING

ELECTRICAL MACHINES LAB II

Load Test On Scharge Motor Page 2 of 4

It may be observed that in all the above three diagram, the axis of the brush and the axis of secondary

winding remains the same. However, the phase angle of the injected voltage with respect to the secondary

induced voltage may be changed by shifting both the brushes a

1

, a

2

together in one direction as clearly

shown in Fig (1)d. This causes a shift between the axis of the secondary winding and the brush-axis, which

provides a control on the input power factor.

Fig 2 : Speed and power factor control in scharge motor

The efficiency and the power factor of this motor are higher, when being operated at higher speed,

compared to its operation at lower speed.

The main disadvantage of this motor is its limited power handling capacity and the operating voltage.

Thu supply voltage is limited to 600 volts for reliable operation, because primary winding on the rotor is

fed through sliprings. Power handling capacity is limited to 25 KW per pole-pair, because of commutation

problems.

4. CIRCUIT DIAGRAM:

Fig 2 : Load test on 3-phase scharge motor

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING

ELECTRICAL MACHINES LAB II

Load Test On Scharge Motor Page 3 of 4

5. PROCEDURE:

1. Connect the circuit diagram of Fig 2.

2. Ensure that the brushes are set to minimum speed position, with the brush-axis in the neutral

Position. Moreover, there should not be any mechanical load on the motor shaft at the time of starting.

3. Switch-on the 3-phase ac supply and start the motor, using the direct-on line starter.

4. Record the brush separation, preferable in terms of electrical degrees and motor speed, after the speed of

the motor has become steady.

5. Reduce the brush separation and record the speed of the motor as well as the brush separation in

electrical degrees.

6. Repeat step no. 5 for various values of brush separation, till the brushes of one set are on the same

commutator bar i.e. short circuiting the secondary winding. It may be observed that under this condition,

the motor should run at a speed slightly lower than the synchronous speed.

7. Increase the brush separation in a direction opposite to that in step 4, 5 and 6, so that the scharge motor

runs in the region of super-synchronous speed. Now repeat step no. 5 for different brush separation.

8. Adjust the speed of the scharge motor to the desired value, at which load test is to be performed i.e.

subsynchronous speed, preferably 2/3 of the synchronous speed.

9. With the motor running on no load, record, current drawn, applied voltage, wattmeter readings and the

speed.

10. Increase the load torque gradually and record the readings of all the meters included in the circuit as

well as the speed for various settings of the load, till the current drawn is of rated value.

11. Reduce the load on the motor gradually.

12. Adjust the speed of the motor in the super-synchronous region, preferably 4/3 of the synchronous

speed.

13. With the above brush setting, repeat step no. 9, 10 and 11.

14. Switch-off the ac supply to stop the motor.

6. TEST READINGS:

S.

No.

Applied

voltage

Input

current

Wattmeter readings Spring balance readings

W

1

W

2

T

1

T

2

Speed

DEPARTMENT OF ELECTRICAL AND ELECTRONICS ENGINEERING

ELECTRICAL MACHINES LAB II

Load Test On Scharge Motor Page 4 of 4

11. RESULTS:

Load test on schrage motor at (i) subsynchronous speed and (ii) super synchronous speed is

performed.

12. PRECAUTIONS:

1. Loose connections should be avoided.

2. Readings are taken without parallax error

13. VIVA QUESTIONS:

1. Why the primary winding of scharge motor is placed on the rotor?

2. What is the major function of the tertiary winding, provided in scharge motor?

3. Discuss various industrial applications of scharge motor.

4. Show by suitable diagram, how speed control can be achieved in subsynchronous and super synchronous

and super synchronous regions.

5. Discuss with suitable diagram, how power factor improvement is achieved in scharge motor.

6. Compare the efficiency of scharge motor at full load with the efficiency of 3-phase plain induction motor

of same rating and at full load.

Potrebbero piacerti anche

- Me2143-1 Motor CharacteristicsDocumento5 pagineMe2143-1 Motor CharacteristicsalibabawalaoaNessuna valutazione finora

- Chapter 1 Det50063 - IntroductionDocumento12 pagineChapter 1 Det50063 - IntroductionFara FaraNessuna valutazione finora

- Rajdhani Power Supply & Load DetailsDocumento32 pagineRajdhani Power Supply & Load DetailsDeepak GehlotNessuna valutazione finora

- Process Control System A Complete Guide - 2020 EditionDa EverandProcess Control System A Complete Guide - 2020 EditionNessuna valutazione finora

- Unit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptDocumento6 pagineUnit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptĐại học Bạc Liêu Truyền thông100% (1)

- UTP Student Industrial ReportDocumento50 pagineUTP Student Industrial ReportAnwar HalimNessuna valutazione finora

- PID Controllers and Tuning (Prof. Cesar Prada) PDFDocumento144 paginePID Controllers and Tuning (Prof. Cesar Prada) PDFYesika Alvarez OrtegaNessuna valutazione finora

- Exp. 3 - Load Test and Equivalent Circuit Determination On Three Phase Squirrel Cage Induction Motor andDocumento9 pagineExp. 3 - Load Test and Equivalent Circuit Determination On Three Phase Squirrel Cage Induction Motor andSanjay MeenaNessuna valutazione finora

- 11 AC Induction Motor TestingDocumento12 pagine11 AC Induction Motor TestingrajNessuna valutazione finora

- No Load Test: ObjectiveDocumento5 pagineNo Load Test: ObjectiveyashNessuna valutazione finora

- Statistical Procedures For Measurement Systems Verification and Validation ElsmarDocumento15 pagineStatistical Procedures For Measurement Systems Verification and Validation ElsmarEmeka ChieduNessuna valutazione finora

- Induction MotorDocumento20 pagineInduction MotorC V VIJAY KUMASRNessuna valutazione finora

- MCE321 - Friction Lecture NoteDocumento6 pagineMCE321 - Friction Lecture NoteBright OvieNessuna valutazione finora

- Electrical Hand BookDocumento142 pagineElectrical Hand Bookelias_el9002Nessuna valutazione finora

- DC Motor Calculations - National InstrumentsDocumento22 pagineDC Motor Calculations - National InstrumentsJosé PerezNessuna valutazione finora

- Modelling of The Three-Phase Induction Motor Using PDFDocumento11 pagineModelling of The Three-Phase Induction Motor Using PDFShreya SonwaniNessuna valutazione finora

- AC Variable Frequency Drive With Static SteplessDocumento0 pagineAC Variable Frequency Drive With Static Steplessswapneel_kulkarniNessuna valutazione finora

- Measurement of Three Phase PowerDocumento4 pagineMeasurement of Three Phase PowerPriya JakoonNessuna valutazione finora

- 3882 1 RG3CatalogueDocumento12 pagine3882 1 RG3CatalogueJose Domingo Castro100% (1)

- TMR Vs QMR TMR Vs QMR TMR vs. QMR TMR vs. QMRDocumento15 pagineTMR Vs QMR TMR Vs QMR TMR vs. QMR TMR vs. QMRdijoz85Nessuna valutazione finora

- Induction Motor (Asynchronous Motor) : Electrical MachinesDocumento41 pagineInduction Motor (Asynchronous Motor) : Electrical MachinesNAITIKNessuna valutazione finora

- Speed Control of DC MotorDocumento19 pagineSpeed Control of DC MotorVijaya LakshmiNessuna valutazione finora

- DC MotorsDocumento216 pagineDC Motorsdin_thorpe3248Nessuna valutazione finora

- Calculation of Power Losses in The Damper Winding Winding of Large Hidrogenerators at Open-Circuit and Load ConditionsDocumento8 pagineCalculation of Power Losses in The Damper Winding Winding of Large Hidrogenerators at Open-Circuit and Load ConditionsWalter SantiNessuna valutazione finora

- AC Electric Machines Lab ManulDocumento98 pagineAC Electric Machines Lab Manulmuhammad_sarwar_27Nessuna valutazione finora

- UNIT I - SCR Triggering and CommutationDocumento14 pagineUNIT I - SCR Triggering and CommutationmalathynarayaniNessuna valutazione finora

- Parallel Operation of Synchronous Generators-V3Documento70 pagineParallel Operation of Synchronous Generators-V3John Patrick CeldaNessuna valutazione finora

- Saturated and Unsaturated Synchronous Reactance in Synchronous GeneratorDocumento2 pagineSaturated and Unsaturated Synchronous Reactance in Synchronous Generatoryeprem82Nessuna valutazione finora

- Analysis of Chopper Fed D.C. Drive With PWM & Hysteresis Current Control SchemeDocumento8 pagineAnalysis of Chopper Fed D.C. Drive With PWM & Hysteresis Current Control SchemeS Bharadwaj ReddyNessuna valutazione finora

- LAB-VOLT 3-Phase Induction (Squirrel-Cage) MachinesDocumento11 pagineLAB-VOLT 3-Phase Induction (Squirrel-Cage) Machinesanyr2Nessuna valutazione finora

- Commissioning Generator AVR, PSS and Model Validation: Wenyan Gu, Member, IEEEDocumento5 pagineCommissioning Generator AVR, PSS and Model Validation: Wenyan Gu, Member, IEEEProject MentorNessuna valutazione finora

- Industrial Drives and ControlDocumento42 pagineIndustrial Drives and Controlsreeragks1989100% (1)

- Electrical Power SystremDocumento8 pagineElectrical Power SystremSagar ThotaNessuna valutazione finora

- Medical Application of BLDCDocumento5 pagineMedical Application of BLDCAbd Al HAmidNessuna valutazione finora

- BLDCDocumento4 pagineBLDCsathishNessuna valutazione finora

- Rotor Flux Based MRASDocumento6 pagineRotor Flux Based MRASMastan ReddyNessuna valutazione finora

- Practical ExamDocumento2 paginePractical ExamIrfan AliNessuna valutazione finora

- Process Control Lab ManualDocumento30 pagineProcess Control Lab ManualAkash Sundar50% (2)

- Control Structures of Power Electronics For DPGSDocumento23 pagineControl Structures of Power Electronics For DPGSAnna Maria BanicaNessuna valutazione finora

- Hydraulic and Pneumatic Systems by Batch1 17M101,102,107,108,109,110Documento49 pagineHydraulic and Pneumatic Systems by Batch1 17M101,102,107,108,109,110Agash ChellappaNessuna valutazione finora

- Power Systems Lab PDFDocumento54 paginePower Systems Lab PDFBhanu BkvNessuna valutazione finora

- Power System Control and OperationDocumento3 paginePower System Control and OperationSantosh ThapaNessuna valutazione finora

- IEC 61850 OverviewDocumento12 pagineIEC 61850 Overviewnk1224Nessuna valutazione finora

- Solenoid Lab ManualDocumento17 pagineSolenoid Lab Manualbrandon999Nessuna valutazione finora

- Psoc ObjectiveDocumento6 paginePsoc ObjectiveswarnaNessuna valutazione finora

- Transformer FaultsDocumento11 pagineTransformer FaultsMusembiNessuna valutazione finora

- Conductor Size, General: Table C-2 NEC References For Conductor SizingDocumento4 pagineConductor Size, General: Table C-2 NEC References For Conductor SizingYashwanth NNessuna valutazione finora

- Speed Control of Vsi Based Induction Motor Using AnnDocumento38 pagineSpeed Control of Vsi Based Induction Motor Using AnnPAVAN CHAVALINessuna valutazione finora

- International Refereed Journal of Engineering and Science (IRJES)Documento8 pagineInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comNessuna valutazione finora

- Artificial Loading of Induction MotorsDocumento6 pagineArtificial Loading of Induction Motorsamkeew100% (1)

- BrakingDocumento19 pagineBrakingMohammad Umar RehmanNessuna valutazione finora

- Steady-State Stability Limit Studies Using Matlab SimulationDocumento12 pagineSteady-State Stability Limit Studies Using Matlab SimulationPius OdabaNessuna valutazione finora

- Effect of Source Inductance On The Performance of AC To DC ConvertersDocumento11 pagineEffect of Source Inductance On The Performance of AC To DC Convertersmohammed aliNessuna valutazione finora

- Chapter Twelve: DC Chopper DrivesDocumento24 pagineChapter Twelve: DC Chopper Drivesfor lifeNessuna valutazione finora

- Electric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, UttarakhandDocumento15 pagineElectric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, Uttarakhandjaya mishraNessuna valutazione finora

- EE6601 QBDocumento8 pagineEE6601 QBTamizh arasanNessuna valutazione finora

- EE6601 QB PDFDocumento8 pagineEE6601 QB PDFMr PerfectNessuna valutazione finora

- DownloadELECTRICAL MACHINES-II - Unit 2Documento42 pagineDownloadELECTRICAL MACHINES-II - Unit 2Khadar KhanNessuna valutazione finora

- Eem507 Electrical Technology: Unit - 1 D.C.MotorDocumento7 pagineEem507 Electrical Technology: Unit - 1 D.C.MotorShubham SharmaNessuna valutazione finora

- Electrical Machines: Lecture Notes for Electrical Machines CourseDa EverandElectrical Machines: Lecture Notes for Electrical Machines CourseNessuna valutazione finora

- Power Electronics: Lecture Notes of Power Electronics CourseDa EverandPower Electronics: Lecture Notes of Power Electronics CourseNessuna valutazione finora

- Identifying The Water Level in The Overhead TankDocumento9 pagineIdentifying The Water Level in The Overhead TankRamakrishna SagarNessuna valutazione finora

- 3.1 Conceptualization of Smart Urban Transportation SystemsDocumento10 pagine3.1 Conceptualization of Smart Urban Transportation SystemsRamakrishna SagarNessuna valutazione finora

- Session 1: Conceptualization of Smart Urban Energy SystemsDocumento12 pagineSession 1: Conceptualization of Smart Urban Energy SystemsRamakrishna SagarNessuna valutazione finora

- Cities As Complex Socio-Technical SystemsDocumento7 pagineCities As Complex Socio-Technical SystemsRamakrishna SagarNessuna valutazione finora

- Coursera VYVHHPE4UJSY PDFDocumento1 paginaCoursera VYVHHPE4UJSY PDFRamakrishna SagarNessuna valutazione finora

- Presented By-Pardeep Dahiya 13001504023 M.Tech. MechanicalDocumento20 paginePresented By-Pardeep Dahiya 13001504023 M.Tech. MechanicalRamakrishna SagarNessuna valutazione finora

- Piezoelectrictransducer 141128011014 Conversion Gate01 PDFDocumento60 paginePiezoelectrictransducer 141128011014 Conversion Gate01 PDFRamakrishna SagarNessuna valutazione finora

- Environmental EnggDocumento72 pagineEnvironmental EnggRamakrishna SagarNessuna valutazione finora

- Advanced Inspection by Acoustic Emission (AE) On-Line or Off-LineDocumento23 pagineAdvanced Inspection by Acoustic Emission (AE) On-Line or Off-LineRamakrishna SagarNessuna valutazione finora

- Service ConditionsDocumento19 pagineService ConditionsRamakrishna SagarNessuna valutazione finora

- Irc 70-1977Documento18 pagineIrc 70-1977pradeepgollapudiNessuna valutazione finora

- Mixed Up MonstersDocumento33 pagineMixed Up MonstersjaneNessuna valutazione finora

- Career Essay 1Documento2 pagineCareer Essay 1api-572592063Nessuna valutazione finora

- CT SizingDocumento62 pagineCT SizingMohamed TalebNessuna valutazione finora

- AIA1800 Operator ManualDocumento184 pagineAIA1800 Operator ManualZain Sa'adehNessuna valutazione finora

- Lecture 4 ENGR 243 DynamicsDocumento45 pagineLecture 4 ENGR 243 DynamicsRobby RebolledoNessuna valutazione finora

- An Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesDocumento7 pagineAn Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesleecubongNessuna valutazione finora

- Task 3 - LPDocumento21 pagineTask 3 - LPTan S YeeNessuna valutazione finora

- The Person Environment Occupation (PEO) Model of Occupational TherapyDocumento15 pagineThe Person Environment Occupation (PEO) Model of Occupational TherapyAlice GiffordNessuna valutazione finora

- Module 1: Overview of Applied Behaviour Analysis (ABA)Documento37 pagineModule 1: Overview of Applied Behaviour Analysis (ABA)PriyaNessuna valutazione finora

- Damodaram Sanjivayya National Law University Visakhapatnam, A.P., IndiaDocumento25 pagineDamodaram Sanjivayya National Law University Visakhapatnam, A.P., IndiaSumanth RoxtaNessuna valutazione finora

- Gods Omnipresence in The World On Possible MeaninDocumento20 pagineGods Omnipresence in The World On Possible MeaninJoan Amanci Casas MuñozNessuna valutazione finora

- LEIA Home Lifts Guide FNLDocumento5 pagineLEIA Home Lifts Guide FNLTejinder SinghNessuna valutazione finora

- Chapter 2 ProblemsDocumento6 pagineChapter 2 ProblemsYour MaterialsNessuna valutazione finora

- Lesson PlanDocumento2 pagineLesson Plannicole rigonNessuna valutazione finora

- GPS Spoofing (2002-2003)Documento8 pagineGPS Spoofing (2002-2003)Roger JohnstonNessuna valutazione finora

- Jesus Prayer-JoinerDocumento13 pagineJesus Prayer-Joinersleepknot_maggotNessuna valutazione finora

- Solved Simplex Problems PDFDocumento5 pagineSolved Simplex Problems PDFTejasa MishraNessuna valutazione finora

- Project Scheduling and TrackingDocumento47 pagineProject Scheduling and TrackingArun VinodhNessuna valutazione finora

- Benevisión N15 Mindray Service ManualDocumento123 pagineBenevisión N15 Mindray Service ManualSulay Avila LlanosNessuna valutazione finora

- Chapter3 Elasticity and ForecastingDocumento25 pagineChapter3 Elasticity and ForecastingGee JoeNessuna valutazione finora

- Heterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Documento5 pagineHeterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Gabriel RoblesNessuna valutazione finora

- Technical Bulletin LXL: No. Subject Release DateDocumento8 pagineTechnical Bulletin LXL: No. Subject Release DateTrunggana AbdulNessuna valutazione finora

- .Urp 203 Note 2022 - 1642405559000Documento6 pagine.Urp 203 Note 2022 - 1642405559000Farouk SalehNessuna valutazione finora

- Time-Sensitive Networking - An IntroductionDocumento5 pagineTime-Sensitive Networking - An Introductionsmyethdrath24Nessuna valutazione finora

- Quantitative Methods For Economics and Business Lecture N. 5Documento20 pagineQuantitative Methods For Economics and Business Lecture N. 5ghassen msakenNessuna valutazione finora

- Financial Accounting 2 SummaryDocumento10 pagineFinancial Accounting 2 SummaryChoong Xin WeiNessuna valutazione finora

- Assessment of Students' Oral Communication in English ClassDocumento10 pagineAssessment of Students' Oral Communication in English ClassKeebeek S ArbasNessuna valutazione finora

- Review1 ScheduleDocumento3 pagineReview1 Schedulejayasuryam.ae18Nessuna valutazione finora