Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Supplier Development Manual

Caricato da

Balavignesh Venugopal0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

101 visualizzazioni41 pagineThis document provides Pricol's supplier development manual. It outlines Pricol's quality and environmental policies and expectations for suppliers. It describes the supplier evaluation and selection process, including preliminary assessment and on-site audits. It also provides guidelines for suppliers on establishing quality and environmental management systems, statutory compliance, process control plans, handling non-conformances, performance reviews, and continual improvement. The aim is to develop suppliers to meet Pricol's objectives and customer satisfaction through a structured approach.

Descrizione originale:

QC

Titolo originale

supplierqualityassurancemanual_v1.0

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document provides Pricol's supplier development manual. It outlines Pricol's quality and environmental policies and expectations for suppliers. It describes the supplier evaluation and selection process, including preliminary assessment and on-site audits. It also provides guidelines for suppliers on establishing quality and environmental management systems, statutory compliance, process control plans, handling non-conformances, performance reviews, and continual improvement. The aim is to develop suppliers to meet Pricol's objectives and customer satisfaction through a structured approach.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

101 visualizzazioni41 pagineSupplier Development Manual

Caricato da

Balavignesh VenugopalThis document provides Pricol's supplier development manual. It outlines Pricol's quality and environmental policies and expectations for suppliers. It describes the supplier evaluation and selection process, including preliminary assessment and on-site audits. It also provides guidelines for suppliers on establishing quality and environmental management systems, statutory compliance, process control plans, handling non-conformances, performance reviews, and continual improvement. The aim is to develop suppliers to meet Pricol's objectives and customer satisfaction through a structured approach.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 41

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

SUPPLIER DEVELOPMENT MANUAL

1

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

1. FOREWORD

Pricol considers its suppliers as an integral part of Pricol Quality System. This Manual

explains the Quality System requirements of Pricol from its suppliers.

The main purpose of this Manual is to develop and monitor Supplier's performance in

meeting the Pricol requirements.

One of the key o!ective of an organi"ation is to provide products # services $hich

meet the requirements % expectations of the O&M # &nd customer. To ensure the

successful implementation of the company's o!ective( periodic assessments $ill e

performed at supplier's facility y Pricol )*T to develop the suppliers to meet the key

o!ective in a structured % cost effective manner.

+y $orking along $ith supply chain ,tier - ./ suppliers the products # services supplied

to Pricol are expected to e of consistent Quality. The same shall in turn help Pricol to

meet o!ectives of )0STOM&1 S2T3S*2)T3O4( of Original &quipment Manufacturers

,O&Ms/

Pricol also expect its suppliers to e a$are aout their responsiilities to$ards

maintaining clean and safe environment. This is required not only for us ut for our

future generation also.

2t Pricol( this is extremely important activity in our usiness operation. 5e think it is

the social responsiility of each individual to protect the environment % natural

resources.

M.Chanda!"#aan G.A. V"n#a$"!h N.S%a&a'(h)

S*A H"ad + SMS CMO

2

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

TA,LE OF CONTENTS

S-. N. T./01 Pa2" N.

1

*)a-0$& 3 En40.n'"n$ Mana2"'"n$ S&!$"' P.-01& 3

"5)0"'"n$! / "6/"1$a$0.n! 7.' S)//-0".

67

8.a Quality Policy

67

8. &nvironmental Policy 67

8.c Quality system requirement % expectation 67

8.d &nvironmental system requirement % guideline 69

8.e :uideline for supplier on environmental caring 69

2

E4a-)a$0.n and !"-"1$0.n /.1"!! .7 !)//-0" 7. 'a$"0a- 3

1.'/.n"n$

6;

8 N"% P.d)1$ / 1.'/.n"n$ d"4"-./'"n$. 6<

=.a 3nitial sample sumission 6<

=. Production Part approval process 86

=.c Situation $here customer notification not required 86

=.d PP2P 1un 88

9

S&!$"' $. (" 0'/-"'"n$"d ("7." !$a$0n2 Ma!!

P.d)1$0.n

8=

>.a &stalishment of Process )ontrol Plan # Standard 8=

>. &stalishment of operations standards % 5SS. 8>

>.c )ontent 8>

: S&!$"' $. (" 0'/-"'"n$"d a7$" !$a$0n2 'a!! /.d)1$0.n 87

7.a Quality 1equirement for regular suppliers 87

3

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

7. )ompliance to statutory # regulatory requirements 8;

7.c System for development of su supplier. 8;

7.d System for maintaining quality history of parts and its analysis. 8;

7.e :uideline for regular production deliveries. 8;

7.f 1evalidation # layout inspection? 8<

7.g Ongoing process capaility studies 8<

7.h Tool Management 8@

7.i *irst 3n *irst Out Practice? 8@

7.! )aliration of 3MT& ,3nspection measuring % test equipment/? 8@

7.k Maintenance of production equipment 8@

; P01.-+.n2.0n2*)a-0$&I'/.4"'"n$ 8@

9.a :uideline ? 1eporting on quality prolems. .6

9. Supplier Performance 1ating .8A.@

9.c Supplier 2uditsAQMS % Process audits =6A==

9.d Supplier Performance management ==

7 Chan2" Mana2"'"n$ =>

;.a &ngineering )hange management =>

;. >M )hange management. =>

< Ta0n0n2 3 C.n$0n).)! I'/.4"'"n$ =7

= S"-7+C"$0701a$0.n 10$"0a >DTS+DIRECT TO STORES? =;

10 A1#n.%-"d2"'"n$ 7.' =@

11 L0!$ .7 F.'a$ >6

4

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

1. *)a-0$& 3 En40.n'"n$ Mana2"'"n$ S&!$"' P.-01& 3 "5)0"'"n$! /

"6/"1$a$0.n! 7.' $h" S)//-0".

1.a? *UALIT@ POLIC@

Pricol $ill provide value and satisfaction to customers on products and services.

This $ill e achieved through

a/ Systematic training and motivation of employees.

/ )omplying $ith customer requirements and applicale statutory # 1egulatory

requirements.

c/ )ontinually improving the efficiency and effectiveness of the Quality

Management Systems.

1.(? ENVIRONMENTAL POLIC@ A

Pricol is committed in carrying out environmental friendly manufacturing and

management practices. This $ill e achieved through

&ncourage innovation to prevent environment pollution

)omply $ith environmental legislation( regulations( other requirements agreed

upon

Minimi"e $astes to preserve natural resources

)reate environment preservation a$areness amongst employees(suppliers and

the community.

)ontinually improve the efficiency and effectiveness of the environmental

Management System and OBS2S.

1ecycle and reuse to the extent possile

1.1? *UALIT@ S@STEM RE*UIREMENTS / EBPECTATIONSA

P01POS&?

This manual explains the quality requirements of Pricol's suppliers and various

activities employed y Pricol for the selection of Suppliers( Procurement of items( and

Performance 1ating for suppliers and the Cevelopment of Suppliers. The $ord

DSupplierE is all inclusive and includes SuAcontractors as $ell as Fo 5orkers

5

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

S)OP&?

This procedure is applicale to activities related to procurement of 1a$ Materials(

)omponents( 2ssemlies( Su 2ssemlies( Packing Materials( )onsumales and

)hemicals required for regular products and products under development( ut does not

apply to materials # items $hich do not affect the quality of the pricol products.

Pricol has adopted The TSA89@>@ Quality Management System in compliance $ith our

O&M customer requirements. Suppliers to pricol shall estalish a Quality System as per

3SO @668?.66< requirements $ith expectation to upgrade to level of TS 89@>@?.66@

as part of the continual improvement.

Pricol $ill carryout periodical assessments of Supplier Quality System to verify

conformance as per the Manual # customer specific requirements. The Supplier shall

take a timely corrective % preventive action on the discrepancies reported for

susequent verification y pricol.

1.d? ENVIRONMENTAL S@STEM RE*UIREMENTS / EBPECTATIONS

Though 3SO 8>668 certification is not a mandatory requirement ut pricol certainly

expect them to fulfill all legal ( environmental and safety regulations. This is applicale

to all products ( services % on site ha"ardous processes # operations . This requirement

shall e verified during periodical supplier audits y Pricol team.

Suppliers $ho are certified to TS89@>@( 3SO @668#3SO @66.( or 3SO8>668 are

expected to sumit a copy of the current and appropriate registration certificate to

Pricol. 2ny change in status ,loss( updated( ne$ standard( name change( location

change( scope change etc./ must e reported to Pricol immediately.

1."? GUIDELINES FOR SUPPLIER ON ENVIRONMENT CARINGC

PRACTICES

8. 0se environment friendly ra$ material?

&ncourage the use of environment friendly materials in your organi"ation to the

extent possile.

.. 2void Gand )ontaminations?

2void land contamination y leakage and improper disposal of oil( $ater and

chemicals.

6

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

=. Safe $aste disposal?

&nsure environmentally safe disposal of $aste generated in process of any !o in

your organi"ation.

>. Optimum utili"ation of resources?

*ull effort required at every stage for optimum utili"ation of resources.

&ncourage reuse( reAcycling of material $henever#$hereever possile.

7. Gegal compliance?

&nsure compliance $ith the statutory environment requirement applicale to

your industry.

9. &nsure safety?

Safety procedure to e follo$ed every$here.

MSCS ,Material safety data sheet/ guidelines strictly e follo$ed for proper

storage % transportation of ha"ardous materials and others as applicale.

;. Cisplay of +oards?

0se display oards and highlights good practices and precautions to educate

employees on etter environmental management practices.

<. :ood $ork culture ,7S/?

Maintain neatness % cleanliness in $orking area and around.

+uild $ork culture on them of preserving nature#earth for the next generation.

Periodical 7S audit of your site as per checklist.

@. Training?

Provide training for the employees on the a$areness aout environment friendly

practices .

2. EVALUATION 3 SELECTION PROCESS FOR SUPPLIERS OF

MATERIALS / COMPONENTS

Supplier sourcing decisions require approval of BOSA SMS ased on evaluation of

Preliminary supplier assessment ,PS2688/ % susequent Supplier On Site 2ssessment

,SC#O2*#68/ y the Supplier Quality 2ssurance Team of Pricol.

7

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

SMS uyers $ill send the preliminary supplier assessment form ,PS2688/ to the

prospective supplier and the supplier shall duly fill and for$ard the same to Pricol for

evaluation $ithin ; $orking days.

The follo$ing $ill e used ut not limited to in the approval process.

SQ2 Memer $ill evaluate the potential supplier as per onsite assessment form

,SC#O2*#68/ $ith a minimum score of 97H and $ith each of the mandatory

questions satisfied.

&valuation of Supplier data related customer PPM( in house re!ection PPM(

re!ection handling system % corrective action.

:eneral details? financial staility( top management involvement % competent

facility.

Suppliers experience $ith customers of 2utomotive 3ndustry.

Technical capaility of facilities and processes to meet Pricol's requirement.

3SO @668?.66< # TS 89@>@?.66@ certifications for Manufacturers % 2uthori"ation

letter or certificate for distriutors( dealers % traders.

*or nonA3SO suppliers( a road map for System )ertification $ithin 8 year of

approval.

)ommercial Tax 1egistration.

2fter Supplier selection is done y Pricol( 1*Q( component specifications # dra$ing

have to e released( and if required Purchase contract to e released accordingly.

Purchase contract has to e agreed and signed y supplier.

R"+E4a-)a$0.n .7 !)//-0" A

The supplier shall inform Pricol $henever( there has een any change in location #

Management # scope of supply ( for reAevaluation and approval.

Pricol $ill reA evaluate the supplier once in every = years.

BOS-SMS and SQ2 Memer $ill evaluate # reAevaluate the oservations # details and

recommend for approval.

8. NEW PRODUCT / COMPONENT DEVEOPMENT PROCESS .

8.a INITIAL SAMPLE SU,MISSION

O!ectives of this phase are to revie$ and approved supplier deliverales to ensure

that product and process quality expectation are reached and to prepare product

launch.

8

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

The documents listed elo$ are to e prepared y the supplier and !ointly examined

and get approval $ith the )*T#4PC Team.

8. PreACelivery 3nspection 1eport.

.. Process *lo$ Ciagram.

=. 5ork instruction.

Once these documents have een examined and approved y Pricol( the supplier

undertakes to comply $ith them. 2ny proposal for modifying or improving the product

or process( including proposal related to transfer of production or move or relocation of

the production equipment( shall have to e approved y Pricol on the asis of the

documents modified y the Supplier.

Samples must e sumitted $ith required documentation as specified in the Pricol

requirements.

Minimum 86 no initial samples or as agreed must e sumitted to pricol for

verification.

3n the case of several processes at the supplier ,e.g.? several cavities inside a plastic

in!ection tool/ - the supplier is requested to sumit cavity $ise sample $ith report.

Supplier to preserve 7 4os initial samples per processes and have them properly

identified for the entire life of the component plus t$o years and must e accessile y

the supplier and Pricol at any time.

Supplier shall identify samples using an identification tag.

Supplier shall commence Pilot supply only after otaining the sample approval y Q&

pricol. Supplier to sumit( follo$ing documents along $ith Samples ?

8/ Supplier S31?

866 H Cimensional report is required for supplier tooling # Ceveloped components.

*or pricol supplied tooling( $here the S31 has een done % approved y pricol(

Supplier to sumit all critical dimensions as identified in Cra$ing( check sheet( control

plan.

./ 1a$ Material Test )ertificate ,2s 2pplicale/? Supplier to sumit ra$ material test

report( along $ith specimen.The test certificate to e mentioned $ith the atch#lot no

for easy traceaility.

=/ Cra$ing details availale at supplier? Supplier shall maintain the latest controlled

copy dra$ing( check sheet % S31 $ith revision status of component.

>/ 2ny Specific test or test given in the dra$ing?

4ote? *or Multiple )avity tool( cavity details are mandatory.

9

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

8.(? P.d)1$0.n Pa$ A//.4a- P.1"!!

P01POS&?

This guideline explains the various activities involved in the approval of production part

approval process ,PP2P/ for suppliers. The production part approval is required to

determine if all P13)OG's engineering design record and specification requirements are

properly understood and the process at supplier end has the potential to meet the

product requirements consistently during actual production run at the quoted

production rate.

S)OP&?

8. This procedure is applicale for all components supplier supplying $ith their o$n

Material # Pricol supplied material.

.. This procedure is not applicale to 1a$ Materials( )onsumales( Proprietary parts(

Packing materials( as they are not supplying components# part specific to P13)OG

design. *or standard parts# components Pricol has prepared its dra$ing ased on the

standard on the supplier specification # dra$ings.

Part 2pproval Process sumission is required for all suppliers making parts as per pricol

specification % to e used for incorporation into finished products prior to first supply of

parts to pricol efore the regular production.

Part 2pproval shall e otained from pricol $hen any of the follo$ing conditions occur(

prior to dispatch of ulk production.

8. *or a ne$ part

.. *or a product design change # &)4

=. *or a process # 1a$ material # Machine# Production location changes

at supplier end.

>. &xisting part $ith ne$ mould # tool.

7. Ma!or mould # tool # die correction affecting significant %

critical characteristic.

9. 2ny other O&M customer specific requirements

;. )hange of sucontractor for parts( processes ,e.g. heat treating( plating/

8.1? SITUATIONS WHERE CUSTOMER NOTIFICATION IS NOT

RE*UIREDA

10

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

4OT&? )ustomer notification is not required $here the changes do not affect

customer fit( form( function( duraility and performance.

8. )hanges to component level dra$ings( manufactured at supplier end internally or y

their sucontractors that do not impact the part supplied to Pricol.

.. Tool movement $ith in the same plane ,used in equivalent equipment $ith no

changes in Process flo$( no disassemly of the tool/ or equipment movement $ithin

the same plant ,same equipment( no change in process flo$/.

&g A +ased on the lean manufacturing initiatives( some equipment is designed for

Moility(i.e. on $heels $ith quick disconnects. )ell configurations or location $ithin a

department may e changed $ithout affecting process flo$.

4o change made to Process flo$ or )ontrol Plan.

=. )hange in equipment ,same process flo$ $ith same asic technology or

methodology/

&g A 4e$ equipment( additional equipment( replacement( or change in

&quipment si"e.

>. 3dentical gage replacement.

&g A :ages replaced as a part of gage maintenance or caliration system.

7. 1ealance of operator in !o content $ith no change in process flo$.

&g A Gean manufacturing allo$s for realancing( !o content to eliminate ottleneck

3ssues.

9. )hanges resulting in reducing 1P4 on P*M&2 ,$ith no change to process flo$/

&g A &xamples include added controls( increased sample si"e and error Aproofing

3nstallation.

8.d? PPAP R)n

Product # Process )hange 4otification *ormat to e used in case of product # process

change than the previous agreed specs.

Minimum =66 nos # =66 shots or one set of shift production or as agreed shall e taken

for PP2P run

The purpose of this stage is to ensure that the process developed y supplier is

capale to produce the defined components in compliance $ith Pricol requirements(

and targets defined for the one shift and consequently to demonstrate?

1un at rate and Pricol reserved capacity

)apaility of the process.

11

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

+uild correct product in accordance $ith Pricol approved $ork instructions and

control plan.

The duration of run must e sufficient to assess the staility of the process

,minimum = hours of production and =66 components # shots/ - Bo$ever

depending on the nature of the component pricol reserve the right to require the

supplier to run longer and more components than here referred.

Supplier to identify training needs of all concern production % quality

engineering personnel( training record to e maintained % shall e made

availale for verification on demand.

*ollo$ing the production run( the follo$ing reports must e issued to Pricol

*ull run production report? conditions( quantities produced and re!ected(

analysis of defects( speed of the production line( Total Gine 1e!ect to e

calculated $ith decision accepted or refused.

Process audit report including capailities )p( )pk study for )ritical#key

characteristics as per drg#identified. Minimum )pk required is not less than

8.== or as agreed. )apaility study to e performed on at least 76

components.

R"5)0"d S)('0!!0.n .7 d.1)'"n$!A

0nless other $ise specified( the follo$ing documents and parts to e sumitted for

Production Part 2pproval Process?

8. Cesign records.

.. &ngineering )hange Cocuments ,3f any/.

=. Pricol &ngineering 2pproval ,5here required/.

>. Cesign *M&2.

7. Process *lo$ Ciagrams.

9. Process *M&2.

;. Cimensional 1esults.

<. Material( Performance Test 1esults.

@. 3nitial Process Study.

86.

Measurement System 2nalysis.

88.

Qualified Gaoratory Cocuments.

8..

)ontrol Plan.

8=.

2ppearance 2pproval 1eport.

8>.

+ulk Material 1equirements )heck Gist.

12

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

87.

Sample Product.

89.

Master Sample.

8;.

)hecking 2ids.

8<.

Part Sumission 5arrant.

8@.

1ecords of )ompliance $ith pricol specific requirements ,if any/.

The supplier shall sumit to the uyer and retain a copy of the 1ecords #

Cocumentation at appropriate location of manufacturing( along $ith approved master

sample from Pricol % make it readily availale to the Pricol representative upon

request.

9.S&!$"'! $. (" 0'/-"'"n$"d ("7." !$a$0n2 'a!! /.d)1$0.n

9.a? E!$a(-0!h'"n$ .7 P.1"!! C.n$.- P-an / S$andad

5hy is Process control standard necessaryI

Quality can never e achieved only through inspection of finished parts. 3t has to e

uilt into the process. *or uilding quality in the processes ( it must e carefully

planned % controlled. This could e done y estalishing a standard for controlling the

process in all the manufacturing stages starting from the receipt of ra$ materials to

shipment of part. 2 properly planned % effectively implemented process control

standard $ill help to?

a. 2chieve stale quality y controlling variations.

. Jno$ if stale quality is eing maintained or not.

c. Jno$ if defects are eing detected quickly or not

d. Jno$ if further processing # dispatch of defective product is to e stopped or not

after detection.

Keral instructions to $orkers( making !udgement y intuition % $orking $ith only

common sense are some of the asic reasons for generation of defects. The method to

avoid defects is to make a process control plan #standard % implement it thoroughly.

Preparation of Process control plan # standard shall e started efore sample # pilot

production. Since it is difficult to meet all conditions during sample production( the

13

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

process capaility shall e studied % carefully examined. The process control plan

standard must e modified suitaly on the asis of sample # pilot production results.

)heck sheets should e carefully designed to record data of various checks on the

asis of the process control plan # standard. The check sheets should contain check

items( specification( measuring instrument # equipment used etc. so that they provide

handy data $hich can e used for investigation in case of defects % also for up

gradation of process. Supplier to use pricol defined )B&)J SB&&T % S2MPG34: PG24

for PC3 verification( supplier to ensure availaility of latest dra$ing # check sheet as

per specification.

9.(? E!$a(-0!h'"n$ .7 O/"a$0.n S$d! / WSS

The primary purpose of making operation stds. is to provide correct $ork instruction to

operators( thus preventing generation of defects due to ignorance of $orkers. 2lso an

operation std(. helps in maintaining the same level of quality even if operator of a

process station is changed. The ne$ operator can e easily trained using the operation

std. Thus avoiding personAtoAperson variation reducing the chance of human error.

Operation stds. are also necessary for control purpose ,i.e check if $orkers are doing

the !o as per the instructions/.

S1./"A 3n principle( operation standards must e made for all the process stations %

fundamentally speaking shall e made for such operations $here their asence $ould

adversely affect product quality.

Bo$ever( please ,indicate safety # critical char. in the title column as per the dra$ing #

flo$ chart provided y pricol if the operation has a earing on item of a part/. 2n

operation standard format shall have( among other things( the columns for enactment

date( revision records( and control no.( place of usage % copy distriution. 2 control

register should e made for operation standards % original operation standards should

e kept in safe custody.

91. C.n$"n$!A

Operation Method?

5rite the operation condition( operation procedures % descrie the correct $ay of

performing an operation in a simple manner preferaly through sketches # visual aids .

)aution Points?

&xplain in an easily understandale $ay using pictures( sketches etc. the caution

points % don'ts regarding the operation.

14

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

Process # Machine parameters?

5rite the control parameters of the process # machine % their control specifications for

that station. The control parameters given in your std. shall conform to process control

standard.

Quality )heck Points?

5rite the quality check points ( !udgment criteria( % check frequency etc. for that

station

2normality Bandling?

5rite instructions for the operator( as to $hat he should do in case of anormalities

, e.g inform the supervisor ( 866H inspection etc. /

Cefect Bistory?

5rite details % causes of occurrence of critical quality prolems( $hich have occurred

at the station or at similar stations( so as to prevent recurrence of these prolems.

3mplementation of operation standards?

The supervisors of your company should continually check if the operators follo$ the

standards or not. 3n case $orkers don't follo$ the operation standards( the supervisors

must educate them. They must also revie$ the standards % revise them to eliminate

any shortcomings. Operators should e encouraged to give their suggestions for

upgrading the standards. 3t is the responsiility of Production supervisor # 3ncharge to

ensure that 5SS ,5ork Standard Sheet/ are follo$ed at all stations.

1evie$ of Operation standards?

5henever there is a quality anormality or a feed ack aout quality prolem( it shall

e thoroughly investigated % during this time all related operation standards must e

critically revie$ed. +ased on investigation results( not only the directly relevant

operation stds( ut also the ones related to similar operations must e revised %

upgraded . 1ememer the dictum Dif a std. is not upgraded periodically( it gradually

ecomes uselessL. 3n case of any anormality reported in the process output the same

is deployed hori"ontally at all the similar stations.

Fo set up instructions?

15

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

The instructions ,set up % verification of set up/ for all ma!or !o changes ,die change(

ma!or tool change( and model change/( affecting critical quality characteristics etc.

shall e recorded.

:.S@STEMS TO ,E IMPLEMENTED AFTER STARTING MASS PRODUCTION.

:.a? *)a-0$& R"5)0"'"n$ 7. "2)-a !)//-0"!

Pricol $ill accept only purchased material( components( or processes $hich meet

the Pricol's dra$ings # specifications. The supplier shall estalish and 1eA

maintain a system to assure that only the latest applicale

dra$ings#specifications are used.

The supplier is expected to perform the inspections # tests required to

sustantiate conformance to the applicale dra$ing specifications. &ach lot

supplied to Pricol should e attached $ith the PC31( 5here ever defined(

supplier to use Pricol defined check sheet for PC31

0nless other$ise specified( supplier to maintain the ra$ material verification

report#Mill test report for each atch of ra$ material procured. % shall e

sumitted to Pricol upon request.

The supplier shall send the test specimen for the la check purpose

a. Test pad % utton for ruer parts during ne$ atch production.

. &nd its of rod % sheet during fresh procurement of ra$ material

+atch declaration letter to e enclosed $ith the PC31 until the next atch of ra$

material is produced # procured.

Supplier to ensure every lot to e identified $ith T2: $ith detail as defined.

Supplier to follo$( defined standard packing method( quantity for each lot( any

change in method of packing should get prior approval from SQ2.

The supplier is expected to respond $ith )orrective 2ctions 1eport for all nonA

conforming product or material received y Pricol and for high re!ection

materials the process needs to e revie$ed and relevant PP2P documents need

to e modified.

The supplier is expected to maintain @6H on time delivery performance( $hich

$ill e communicated periodically.

3n order to minimi"e the amount of inventory at Pricol( suppliers are expected to

meet delivery requirements( reduce lead times and react effectively to schedule

changes.

The supplier is expected to analy"e and take appropriate corrective actions for

delayed supplies.

4OT&?3f the supplier is unale to meet Pricol's Celivery requirements and the

production Schedules indicate that the product must e expedited using

alternate transportation

16

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

*ollo$ing rules#instructions to e strictly adhered during process as part of

system?

8. Gast shot samples shall accompany the tool#mould#die( $henever( there is a reak

do$n or tool#mould#die is offAloaded.

.. 3mmediate information to Pricol( $henever a suspect shipment has een made

ased on the later on findings in your process#records.

=. Cie#Mould#Tool preventive maintenance schedule must include the )heck of 3nserts(

pins( segments health#any crack#$ear out etc.

>. &xtra -precaution in 4ight Shift $orking i.e. added supervisor#Quality 3nspector can

e one of the $ays. ,5ith a Proper Gog +OOJ#communication System for day shift/.

7. 2ny correction # modification in the Cie#Mould#Tool shall e carried out at the

supplier end after the concurrence from pricol.

:.(? C.'/-0an1" $. !$a$)$.& / "2)-a$.& "5)0"'"n$!

2ll suppliers of materials( components( processes shall have a process to assure

that governmental and safety constraints on restricted( toxic and ha"ardous

sustances are complied $ith relative to purchased products and the manufacturing

process. 3n order for Pricol to develop products $hich are compliant to current

1egulated # 1estricted Sustances policies of oth governmental agencies and our

)ustomers( the supplier shall sumit at the time of supply of initial lots( the relevant

MSCS# Pollution )ontrol oard certificate and confirm that they comply $ith the

regulatory requirements.

:.1? S@STEM FOR DEV. OF SU,+SUPPLIERSA

Supplier shall prioriti"e % estalish a documented system for ensuring quality

management system at their critical su Asuppliers on similar grounds. The supplier

has the responsiility of ensuring that its suAcontractors have een approved and are

under a controlled system of evaluation and revie$.

:.d? S@STEM FOR MAINTAINING *UALIT@ HISTOR@ OF PARTS 3 ITS

ANAL@SISA

17

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

The supplier shall estalish a documented system for maintaining quality history

of each part. *or each part( trends shall e maintained month $ise for each type

of re!ection. On a monthly asis analysis of all these re!ections shall e carried

out to see the effectiveness of corrective actions initiated % )ontinuous

improvement $ith reference to Pricol set o!ectives. 3t is recommended to

maintain the quality records sheet of prolems reported ,Q*1 # $arranty in

Pricol/ along $ith the corrective # preventive action initiated.

:."? GUIDELINESA REGULAR PRODUCTION DELIVERIES

MO43TO134: C&G3K&1M P&1*O1M24)& :03C&G34&S?

O4 G34& S)B&C0G34: SMST&M ,+.+/

O!ective? 2ll the approved suppliers shall operate through O4 G34& S)B&C0G34:

SMST&M( there y reducing the follo$ up and communication cost.

8. 2 unique supplier code shall e allocated to each supplier( $hose schedules are

displayed on his respective +.+ $e site.

The suppliers can access their +.+ $e site y logging on to our materials site

$hich is as follo$s

h$$/A//%%%./01.-.1..0n/'a$"0a-!/

.. The initial 0ser login % Pass$ord $ill e their respective code( $hich can e

changed as and $hen required to maintain the privacy.

=. The supplier shall al$ays have a valid &AM23G 3C( $hich shall e used y pricol

and the respective supplier for communication $ith their uyers.

>. The supplier shall ensure the frequent visiting to their respective +.+ sites(

$hich automatically get updated $ith the revision of our production plan ,at

least t$ice in day/ to have updated kno$ledge of their schedules and status of

previous deliveries.

Supplier shall monitor the performance of the supply vs schedule % shall initiate

immediate corrective % preventive actions against shortfall of 866H ontime delivery.

:.7? REVALIDATION / LA@OUT INSPECTIONA

1evalidation is a detailed verification of appearance( performance( endurance items

including the PC31 items $hich comprises items for regular check. Supplier shall carry

out revalidation of parts ,for all functional parts % for those frequency to e decided

ased on the usage( general parts asked y Pricol % revalidation of ra$ material at

least once a year. 2ction plan for layout on yearly asis can e taken.

Minimum five parts shall e checked for revalidation. 3ncase of multiple line # moulds(

minimum one sample per line#mould shall e taken for revalidation. &ach year

revalidation plan shall e made % if asked y pricol ( reports shall e sumitted for

18

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

verification. The similar activity can e extended to critical su suppliers to ensure the

consistency in pricol quality requirement.

:.2?.ONGOING PROCESS CAPA,ILIT@ STUDIES

Curing the mass production for items of part % for those characteristics as decided

along $ith pricol or as per control plan . On going process capaility studies shall e

carried out $hich includes the control charts to e maintained for special

characteristics. *or these characteristics control limits shall e calculated % e used for

their control charts. 3n case of any nonAcontrol of the process is oserved immediate

corrective action shall e taken.

*or calculating the control limits( data should e taken for the enough period so that all

possile variations are included ,e.g. variation of man # machine # method #

measurement # environment( material etc./

The control limit calculated shall e verified on monthly asis % shall e changed in

case of any process change.

)apaility index ,)p % )pk/ for all the fit characteristics shall e calculated every

month. )apaility index for all these characteristics shall e 8.== % aove. 3n case it is

less than 8.== improvements in the process shall e taken up $ith parallel 866H

inspection till )pk 8.== is achieved. 3f reports of the capaility study is asked y pricol

same shall e sumitted to pricol.

:.h? T..- Mana2"'"n$

)ompany shall have the proper facilities for maintenance( repair of tools % their

storage. 2 recording#monitoring system shall e implemented.

A To record the details of tool ( change of tool ( repair of tools % tool life .

A To change the tools as per the specified frequency.

A 4e$ tool # mould monitoring $ith respect to timely completion shall e as per

Tool Progress 1eport % sumitted to Pricol.

:.0? F0!$ In F0!$ O)$ Pa1$01"A

*3*O shall e practiced as part of the system in component % *inished parts stores.

2ny simple( user friendly % effective D*3*OE methodology shall e adapted as per your

company processes # layout .

:.D? Ca-0(a$0.n .7 IMTE >In!/"1$0.n '"a!)0n2 3 T"!$0n2 E 5)0/'"n$?A

Suppliers shall implement an effective caliration control system for all types of 3MT&.

,3nspection measuring % testing equipment/ used in inspection % processes.

19

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

:.#? Ma0n$"nan1" .7 /.d)1$0.n "5)0/'"n$

2 documented system shall e implemented for proper control % maintenance of

production equipments.

System shall include follo$ing?

5ork start up checks? ,2utonomous maintenance/

Periodic checks? ,Preventive maintenance/.

These are the checks of important dimensions of machine tools( dies( mould etc. to

kno$ the extent of $ear % also for caliration of measuring devices fixed on machines.

; .PRICOL + CONTINUOUS *UALIT@ IMPROVEMENT

2 )ontinuous Quality 3mprovement plan is required from suppliers to achieve the level

of PPM ,Parts per Million/ that the automotive industry requires. This plan $ill focus

on?

Preventive quality

&radication of prolem root causes.

Gearning from mistakes $ith lessons learned cards

This is to e initiated y the supplier during start of serial production % Pricol revie$s it

periodically.

Pricol intiates in terms of Quality )ost Celiveries % performance measurale. This Q)C

enefits is designed in such a $ay to help Pricol Pricol and the suppliers to

continuously improve product quality (competitiveness and the logistics chain

The development of ne$ usiness et$een Pricol and its suppliers depends on the

achievement of the " E". D"7"1$ " performance level.

This $ill e monitored through

1eporting on quality issues.

Supplier performance 1eports.

Supplier audits.

>M change management.

Supplier development % follo$ up.

;.a? GUDIELINESA REPORTING ON *UALIT@ PRO,LEMS

3n case of Quality prolem oserved at line or end of line (customer complaints(

,during line usage # $arranty failures/ $hich requires corrective action from supplier(

Pricol $ill intimate the Quality *ailure to the supplier. 2 corrective action shall e taken

y the supplier in order to prevent the reoccurrence of the same % any other similar

processes.

20

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

Supplier can adopt <C or Jai"en methodology for reporting corrective action.

2s soon as( the intimation received either through mail or veral communication(

supplier to update customer concern log sheet and quality responsile person to note

the defect( and initiate correction as elo$.

Supplier to estalish )*T $ith all concern area( along $ith team leader( define

the prolem as reported and actual concern # discrepancy oserved >D1 3 D2?.

3nterim action to e initiated to contain defective shipment to pricol. 2ll pipe line

stock#quantity to e identified and arrange for segregation of parts( all in house(

transit % stock availale at pricol to e reverified 866H efore dispatching to

pricol >D8?.

>D9? 3dentify the root cause? supplier to define all the event( that produce the

defect part( use fish one chart( related to >M condition#5hy $hy analysis as

defined in 2pex report to e sumitted to pricol $ithin ; days

>D:? Permanent )orrective 2ction? 3dentify and implement permanent

corrective actions that $ill eliminate the prolem. 1ememer that permanent

means forever. The prolem should never e ale to occur again.

>D;? Kerifies &ffectiveness of 2ction? Kerification takes place in these four

areas? 1oot )ause( 3nterim 2ctions( Permanent 2ctions( Prevention. Kerify the

implemented action does eliminate the prolem ,short term( long term and

other similar processes/ and does not cause any other prolems.

>D7? Prevent 1ecurrence? Preventing recurrence means preventing changes to

the part( process or system that allo$ a prolem to occur. Prevention covers all

similar and related processes( designs( systems( etc update all concern

documents as defined in 2pex.

>D<? )ongratulate Mour Team 1ecogni"e the contriutions of all the team

memers as a group and individually.

Supplier to close the all aove <C $ithin 87 days( supplier to monitor( next three

lots( for corrective action effectiveness.

N.n+C.n7.'0n2 S)//-0"! >D"40a$0.n A//.4a-?

5hen a supplier identifies a deviation from specification( Q& Cepartment at Pricol must

e informed of the details. The nonconforming products must not e dispatched to

Pricol till clearance from Q& Cepartment.

;.(? SUPPLIER PERFORMANCE RATINGA

21

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

Kendor 1ating - Overvie$

Kendor rating for Pricol $ill have four parameters( covering the quality and

transactional aspects of supply. These parameters are?

a. Celivery A Transactional 2spect

. Quality A Transactional 2spect

c. )ooperativeness ,1ush Orders/ A Transactional 2spect

The aove factors A Celivery( Quality and )ooperativeness shall e considered for

phase 8 of implementation.

)orrective 2ctions in +.+ shall e considered for phase . of implementation

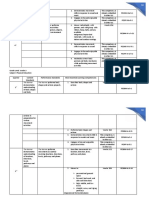

8. Schedule lines - 1ating )alculation

The matrix elo$ indicates the distriution of $eightage for each scenario mentioned

Tale 8? 5eightage Matrix for each schedule line

S.4.

Scenario Celivery Quality )ooperativeness

8

1ush

Schedules

4ot

2pplicale

6.7 6.7

.

Standard

Schedules

6.7 6.7 4ot 2pplicale

.. Schedule lines - Celivery 1ating )alculation

)orrect master records are preArequisite for effective rating. Celivery 1ating $ill e

computed as follo$s?

Tale .? Celivery 1ating Matrix

Cay Schedule

Sl. 4o Celivery Kariation against Schedule

date

CK *actor

8 up to N8 Cay , Gate y one day/ 8

. +et$een N. Cays to N9 days 6.@

= +et$een N; day and N87 Cays 6.7

> Others 6

5eek Schedule

22

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

Sl. 4o Celivery Kariation against Schedule

date

CK *actor

8 upto N; Cay , Gate y seven days/ 8

. +et$een N< Cays to 8. days 6.<6

= Others 6

Month Schedule

Sl. 4o Celivery Kariation against Schedule

date

CK *actor

8 upto N=8 Cay 8

. Others 6

The overall rating for a standard schedule line is illustrated elo$

3n case of the delivery rating for the supply date $ill come from the 86= entry( $hile

the Quantity details $ill come from the 867 entry at the respective stores. *or a P.O

$ith . schedule lines( Material accounting is to e carried out on *irstAin asis for each

schedule line

Tale = ?Sample )alculation

Tale =.8 1eceipt Cetails

1eceipt Got 3tem

1eceived

QTM

)umulative

1eceived QTM

1eceived Cate

Sch

Gine

3t

e

m

Typ

e of

Sch

Schedul

e

1elease

date

Sch

Gine

Qty

2

1equire

d

Celivery

Cate

1eceive

d Qty

+

1eceiv

ed

Cate

Qty

1atio

)

CK

*actor

C

Overall

1atingOQty

1atoP CK

*actor

Schedule

Gine

3tem Standard

Gead Time

1equired

Gead Time

Type of

Schedule

Schedule

1elease date

Schedule

Gine Qty

1equired

Celivery Cate

8 Q 86 days 7 Cays 1ush .< *e .686 766 67 Mar .686

. Q 86 days 86 Cays Standard .< *e .686 .66 86 Mar .686

23

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

8 Q 876 876 67 Mar .686

. Q .76 >66 6< Mar .686

= Q 8;7 7;7 6@ Mar .686

> Q 8.7 ;66 86 Mar .686

24

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

Tale =.. ?

Material

1eceipt

accounting

against

schedule

lines and

calculation

of Kendor

delivery#

service

level rating

Sch

Gine

3t

e

m

Typ

e

of

Sch

Sche

dule1

eleas

e

date

Sch

Gine

Qty

1equi

red

Celiv

ery

Cate

1ecei

ved

Qty

1ecei

ved

Cate

Qty

1ati

o

CK

*act

or

)oA

operati

veness

*actor

)oper

ativen

ess

Score

Overall

)oopera

tiveness

Score

,on

scale of

866/

8 Q 1u

sh

.<

*e

.686

766 67

Mar

.686

876 67

Mar

86

O,8

76#

766

/

O6.

=6

4ot

2ppli

cale

8

,Suppli

ed

$ithin

reqd.

date/

O8P6.

=

O6.=

O2vg

,6.=(6(6

/P866

O6.86P8

66

O86

8 Q 1u

sh

.<

*e

.686

.76 6<

Mar

86

.76

#76

6

O6.

7

6 O6.7P

6

O6

8 Q 1u

sh

.<

*e

.686

866 6@

Mar

86

866

#76

6 O

6..

6 O6..P

6

O6

25

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

Sch

Gine

3tem Type

of

Sch

Schedul

e

1elease

Cate

Sch

Gin

e

Qty

1equire

d

Celivery

Cate

1eceiv

ed Qty

1eceiv

ed

Cate

Qty

1atio

CK

*act

or

1atin

g

,On

scale

of

866/

Servic

e

1atin

g

Over

all

Celiv

ery

1atin

g

, on

Scale

of

866/

. Q

Stan

dard

.< *e

.686

.6

6

86 Mar

.686

;7

86

Mar

.686

O;7#.

66

O6.=;

7

8 O6.=;

7P8P8

66

O=;.7

4ot

2pplic

ale

for

Stand

ard

Sched

ules

Osu

m,.=

;.7(=

=.;7/

O98.

.7

. Q

Stan

dard

.< *e

.686

8.7

.6

Mar

.686

O8.7#

.66

O6.9;

7

6.7

O6.9;

7P6.7

P866

O==.;

7

8. S1h"d)-" -0n"! F *)a-0$& Ra$0n2 Ca-1)-a$0.n

Quality 1ating $ill e computed taking into consideration re!ection and re$ork of

components. The computation logic $ill e as follo$s?

R"D"1$0.n PPM Quantity re!ected# Total Quantity Supplied P 8666666

R"%.# PPM Quantity re$orked#Total Quantity Supplied P 8666666

Sa-4a2" PPM Quantity Salvaged# Total Quantity Supplied P8666666

*//' 1e!ection PPM N 1e$ork PPM

Therefore

5here QT O The target in ppm that Pricol has set for a commodity class

QppmO 2ctual ppm level for the vendor for a particular component in that

commodity class

1e!ection and re$ork ppm $ill e considered for computing Qppm and $ill form part of

the vendor rating $hile salvage ppm $ill e computed separately and $ill e only for

reference for Pricol.

*)a-0$& Ra$0n2A *R G *//'/*T

26

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

The logic of keeping salvage ppm separate is that one of the reasons for salvage is also

our design specification issues and other for manufacturaility issues( for $hich the

vendor should not e penali"ed.

The rating and for vendors shall e as per the tale elo$?

Tale >? Quality 1ating Matrix

Parameter 1ating

Q1RO8 866

Q1S8 24C RO8.7 <6

Q1S8.7 24C RO. 96

Q1S. 24C RO..7 >6

Q1S..7 .6

The Quality Target ,QT/ shall e as per the elo$ matrix ?

Tale >.8

Material :roup 4o. Material :roup 4ame Quality Target ppm ,QT/

866 1a$ Material 3mports 876

868 1a$ Material Comestics 876

888 Packing Materials =66

88. )onsumales A Production =66

88= )onsumales - Tools =66

88@ &lectronics .66

8.6 3mport .66

8.. )onsumales - Others =66

.66 Pressed 8766

.68 Machined >666

.6. Moulded .666

.6= Proprietary 8766

.6> Su 2ssemly A 3nhouse ;76

.67 Moulded )omp,3/ 1uer 8766

.69 Su A 2ssemly APlastic .666

.6; Su A 2ssemly APressed 8766

.6<

Su A 2ssemly

AMachined

>666

.6@

Su A 2ssemly A5ire

2ssy

8766

=68 Cie )asting >666

=6. *errous >666

)B&M3)2GS )hemicals =66

M2134& M2134& 8766

others Others 8766

27

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

*or the given example

1ec

eipt Got

3tem

1eceived

QTM

)umulative

1eceived

QTM

1eceive

d Cate

2ccept

ed Qty

1e!ected Qty

8 Q 876 876

67 Mar

.686

8>@ 8

. Q .76 >66

6< Mar

.686

.76 6

= Q 8;7 7;7

6@ Mar

.686

8;> 8

> Q 8.7 ;66

86 Mar

.686

8.7 6

PPM

OT,8N6N8N6/#,;66/UP8666666

O.<7<

2ssuming component as the Molded component

Target PPM for Molded component , from Tale >.8/ .666

Q1

O.<7<#.666

O8.>.@

Quality 1ating ,*1OM T2+G& >/ O<6

9. S1h"d)-" -0n"! F C../"a$04"n"!! Ra$0n2 Ca-1)-a$0.n

)ooperativeness and compliance to +.+ for corrective action are the t$o areas s

measured for service. )ompliance to +.+ is planned for inclusion in Phase of vendor

rating ,planned to e released y Sep .686/

System $ill check the Gead Time given to vendors for supply of components and the

Gead time that has een entered in master dataase in the system. 3n case the lead

time given to vendors is greater than lead time entered in the master dataase( then

such a supply $ill e considered as regular schedule. Only regular schedules are

considered for Celivery 1ating

Bo$ever( in case the lead time given to vendors for supply is less than the lead time

entered in the master dataase( then such schedules are considered as rush schedules

and the same $ill e highlighted in +.+ $ith a flag reading as V10SB'. Only rush

schedules are considered for Service 1ating.

*or rating this part of the service rating( )ooperativeness $ill e measured as follo$s?

28

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

Tale 7..? Sample )ooperativeness Score

)ooperativeness parameter O ,Qty supplied against Schedule# Total 1ush Schedule

QTM/P866

*or delivery quantities against rush schedules( actual delivery date extending up to

7H and or 8 day $hichever is higher eyond required delivery date is a$arded

866H delivery rating.

3f the vendor has got no rush Schedules for the month( then cooperativeness rating

$ill not e applicale.

:.S1h"d)-" L0n" + O4"a-- Ra$0n2

Tale 9..? )orrective 2ctions in +.+A 1ating Matrix

S.4.

Scenario

Celivery

,1d/

Quality

,1q/

)ooperative

ness ,1c/

)orrective

2ctions in

+.+ ,1/

Overall 1ating

8

1ush

Schedules

4ot

2pplica

le

6.7 6.7

4ot

2pplicale

O

,1qP6.7N1cP6.7/#866

.

Standard

Schedules

6.7 6.7

4ot

2pplicale

4ot

2pplicale

O,1qP6.7N1qP6.78/#

866

*or the aove example ? , KendorAMaterialAPOASchedule $ise/

S.4.

)omp

onent

Schedule Type

Celivery

Score ,1d/

Quality

Score

)ooperativeness

Score

Overall 1ating

8 Q

1ush

Schedules

42 <6 =6

O

,<6P6.7N=6P6.7

/

O77

. Q

Standard

Schedules

98..7 <6 42

O,98..7P6.7N<6

P6.7/#866

O;6.9.7

Sch

Gine

3tem Type of

Sch

P.O

1elease

date

Sch

Gine

Qty

1equir

ed

Celiver

y Cate

1ece

ived

Qty

1eceiv

ed

Cate

Qty

1atio

CK

*acto

r

)oA

operativ

eness

*actor

)oA

opera

tiven

ess

Score

8 Q 1ush

.< *e

.686

766

67 Mar

.686

876

67 Mar

86

O,876#

766/

O6.=6 4ot

2ppli

cale

8

,Supplie

d $ithin

reqd

date/

Osum

,=6H

N6H

N6H/

O=6

H

8 Q 1ush

.< *e

.686

.76

6< Mar

86

.76#76

6 O6.7

6

8 Q 1ush .< *e

.686

866 6@ Mar

86

866#76

6 O 6..

6

29

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

;.C.'/.n"n$ L"4"- F Ra$0n2 Ca-1)-a$0.n

9.=?)omponent Gevel 1ating Tale

Month

)om

p

Standard Schedules 1ush Schedules Overall 1ating for

)omponent

, H/

O,2N+/#,MN4/ H

Total

1ating

Scored

,2/

Total

Possile

score

,M/

Total 1ating

Scored

,+/

Total

Possile

score

,4/

2pr

.686

Q 42 42 77 866

OT,77N;6.9.7/#.6

6UP866

OT8.7.9.7#.66UP8

66

O9..<8H

2pr

.686

Q ;6.9.7 866 42 42

7. C.n!.-0da$"d V"nd. Ra$0n2

Kendor )omp

Overall 1ating for )omponent

,average of rating of all components/

86 Q 9..<8H

86 M =6H

2pr .686 Overall O 2verage ,9..<8H(=6H/ O>9.>8H

P2ssumption that rating for component M is =6H ,calculated on the same methodology

as that illustrated for component Q/

<. P"7.'an1" D"+a$0n2A

D"-a&! 1a)!0n2 D"+a$0n2

8. Premium freight 8H

.. Pricol line stoppage .H

=. )ustomer line stoppage <H

<.1 P"'0)' F"02h$A

30

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

The supplier ahsll maintain records of premium freight paid y them ,$hether payale

y themselves or payale y pricol/ along $ith date( amount involved % reasons

thereof. They shall send monthly statements of such premium freight to pricol

Materials Management.

Pha!" 2 R"5)0"'"n$!

:. C-.!)" .7 1."1$04" a1$0.n! >$h.)2h ,2,? Ra$0n2 Ca-1)-a$0.n

2ny nonAconformity raised in +.+ is evaluated for closure and rated as per the

matrix elo$

Tale 9.8? )orrective 2ctions in +.+A 1ating Matrix

Parameter 1ating

)orrective

action $ithin

; days 866

)orrective

action $ithin

87 days 76

)orrective

action given

after 87 days 86

2t default the )losure of corrective action should e at 866. This $ill e the case if the

vendor has no re!ection at all.

PS ? )losure of corrective actions ,through +.+/ is planned for inclusion in the overall

rating y Sep .686 after necessary system readiness and training of vendors.

;.1? S)//-0" A)d0$! .

5e shall explain in this chapter regarding the audit of quality system( $hich is

conducted y Pricol on its suppliers. The o!ective of audits is to maintain % improve

quality of product through effective implementation % improvement of quality system.

Preparation for the audit ?

3t is useful to prepare the checklist to carry out the audit. )hecklist should include all

the areas to e audited.

2udit records?

31

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

2udit results % improvement action plans identified during supplier audits are

circulated through mail#minute( after the audit. *ollo$ up audit may e planned ased

on the criticality( score % susequent supply status.

Quality Management System 2udit ,QMS 2udit/?

5e shall explain in this chapter regarding the quality management system audit

,SQM686/( $hich is conducted y pricol on your company. These audits are

undertaken as a preventive measure to get the confidence that the quality

management system eing follo$ed y your company on the follo$ing requirements(

8. Management 1esponsiility

.. 3nternal 2udit

=. 3ncoming material % su supplier control

>. 3nAprocess control

7. 3nspection Measuring % Testing &quipment ,3MT&/ control

9. Machine tool die maintenance

;. )ontrol of non confirming products

<. 2nalysis of customer complaints

@. 4e$ product development

86. )ustomer supplied products

88. Cocument change data control

8.. Storage( packing % preservation

8=. Bouse keeping

8>. B1 % Training

87. Statutory # 1egulatory requirements

QMS 1ating criteria?

Supplier overall performance $ill e monitored as per the elo$ criteria(

Ra$0n2 C0$"0a

G""n

>V"& G..d?

@"--.%

>A4"a2"?

R"d

>,"-.% A4"a2"?

QMS 2udit Score <8H A 866H 98H A <6H +elo$ 96H

2ctions 1equired

&nsure sustenance

% focus on

continuous

improvements

)ounter measure

report to e

sumitted to

achieve :reen

ststus

)ounter measure

report to e

sumitted to

achieve :reen

status

Process 2udits?

32

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

5e shall explain in this chapter regarding the process audit ,SMP2)A68/( $hich is

conducted y pricol on your company % $hich can e conducted y you $ithin your

company. These audits are undertaken as a preventive measure to get the confidence

that the processes eing follo$ed y your company shall continue to produce defect

free parts .

These are the detailed audit of your processes. These audits are conducted as per the

documented control plan % other standards referred in the drg. The purpose of the

audit is

to identify areas $here improvements are required for correcting specific quality

prolem faced

to highlight areas $here improvements can e made in the process for effecting

general improvement in the quality % productivity of parts produced.

2ction plan?

2fter an audit y pricol( supplier $ill e asked to sumit an improvement action plan

giving specific dates for implementation of improvement actions against each point

mentioned during audit.

Preparation for process audit?

&stalish the purpose of the audit i.e. preventive measure or to solve the specific

quality prolem .

)ollect all relevant std. # documents

3nvestigate the previous quality performance of the part % collect the relevant data

, re!. PPM Or complaint from the customer ( line prolems previously reported./

)ollect the previous audit % countermeasure report.

Prepare a checklist of the critical areas you $ould like to check to ensure that the allA

critical areas are covered.

)hecklist may include the follo$ing areas?

8. Cocumented $ork instructions # process control parameters

.. )heck for !o# machine set up efore regular production

=. Machine !igs # fixture control

>. Cie # mould # tool control

7. Process control

9. 3ncoming # in process # final inspection

;. Storage # Bandling

<. Traceaility

@. )aliration of inspection # measuring instruments

86. )orrective % preventive actions

88. )ontrol % monitoring of special processes

8.. Plant Gayout for smooth material flo$ % 7S

33

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

8=. Statistical process control

;.d? S)//-0" P"7.'an1" Mana2"'"n$

+ased on the last = months Quality performance Pricol $ill identify the Poor Performing

Suppliers( $hich $ill e follo$ed on a monthly asis(

Pricol $ill launch a Supplier performance improvement Program,SP3P/y notifying the

poor performing supplier mainly focused on follo$ing methodology?

Top Management meeting ,division # ranch # group level/? Pricol $ill notify Top

Supplier Management ,:roup senior management( )hief Operating Officer( or

Plant :eneral Manager/ y sending an official letter.

Supplier top management to present( detail analysis % provide action plan to

improve quality performance

:&4+2 2ctivity ,shop floor activity/? Pricol $ill check the implementation and

the efficiency of corrective actions presented during the monthly meeting y

visiting the supplier's facility $ithin the month. 2t the same time( Pricol $ill

propose to support the supplier y deploying the Pricol supplier performance

improvement program.

The exit of the supplier from Supplier Performance 3mprovement Program

,SP3P/$ill e decided y the Pricol SQ2#SMS BOS upon satisfactory achievement

of the targets agreed in the SP3P charter ut $ill take along at least =

consecutive months in order to measure accurate improvement.

3n case of no improvement during = consecutive months follo$ing action $ill e

decided y Pricol $ith the follo$ing consequences?

4o 1*Q process for any ne$ usiness

4o ne$ +usiness a$ard from any Pricol plant for the duration of the 4e$

+usiness on Bold status

2 monthly follo$Aup y the BOS SMS in order to evaluate the relevance of the

Supplier action plans.

5hen the supplier achieves the target given y pricol( quality performance status for a

period of three months to confirm the results.

Phase O0T?

34

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

3f the supplier is not improved after applying the quality activities through Supplier

Performance 3mprovement Program,SP3P/( Pricol $ill decide to phase out the

reluctant supplier $ith a clear deadline and identified resources to manage the

transfers.

7. CHANGE MANAGEMENTA

7. a? En20n""0n2 Chan2" Mana2"'"n$A

Supplier $ill receive notification for engineering change $ith relevant ne$

specifications # Cra$ings from memer material( supplier $ill study the requirements

and revie$ the changes required in tooling # material # process and implement the

same $ithin the expected date and get sample inspection approval efore pilot lot

production.

The suppliers have to communicate and get decision from the SMS uyer on the

disposal of materials availale at their unit.

The osolete dra$ing shall e scrapped or sent to Pricol or marked as Vosolete' and

can e used for later reference.

The supplier shall follo$ the production part approval process as in the chapter =(

efore taking production lot.

7. (? 9M 1han2" 'ana2"'"n$A

The supplier has the oligation to communicate any product or process changes to

Pricol in $riting and to otain approval prior implementing the expected changes.

Supplier to inform in $ritten( respective uyer( % shall get approval from Pricol Q&(

efore starting mass production.

Pl refer elo$ tale( to understand >M )hange conditions(

35

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

>M Cefinition &xamples of >M changes

Material

)hanges to e made to $hat

is used in the components or

ra$ materials or to the

component or ra$ material

source

Material change from Polyamide to

polypropylene or equivalent(

Packaging material from = ply cardoard to .

plies

)hange in packing # quantity method.

)hange ra$ material supplier or suAsupplier

Method

)hanges to e made in ho$

$e produce or test or control

components

Packaging # 3nspection # 1e$ork operation

addition or deletion# location shift.

2utomatic process to manual process(

Single component processing to atch

processing

Temperature in heat treatment furnace(

)ontrol frequency change from 866H to 7 at

start of production( or vice versa

Machine

)hanges to e made in the

machines( gauges or tools

used to produce or test or

control components

)hange layout of production line( ut no change

in equipment.

)hange in supply site( one unit to another or

sister unit.

2ddition of ne$ machine in order to increase

capacity.

1enovation of old mould #tool(

Ma!or re$ork #1epair of tool.

Purchase ne$ test equipment(

Man

)hanges to e made in the

organi"ational of the

$orkforce involved in the

manufacturing of the goods

Boshin activity of Gine realance from >

operators to = operators

Go$er skill set of the operators to reduce direct

laor costs

4e$ shift has to e constituted at the supplier to

extend capacity

4on respect of the >M y the supplier( $hich $ill lead to pricol line stoppage( customer

line quality failure in field # usage( customer dissatisfaction( Pricol management $ill

decide appropriate action.

<. TRAINING 3 CONTINUOUS IMPROVEMENTA

Ha0I"n

To provide value for money to the customer to remain competitive % to maintain

gro$th of the organi"ation( path of kai"en or continuous improvement shall e

follo$ed. Jai"en signifies small improvements as a result of continuous efforts

involving employees at all levels from all areas.

36

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

*or implementing kai"en in your company( employees should e motivated to give

suggestions ,e.g. y giving re$ards( recognition etc./ % an environment in your

company should e created $hich gives confidence to the employees that their

suggestions $ill e listened % if appropriate $ill e implemented.

2ll the improvements done may e converted into the $orth of money Saved e.g

- Man hour saved

- Space saved

- Material saved

This $ill help your company in analy"ing the quality # effectiveness of suggestions and

the enefits your company is getting from this activity.

Quality # productivity # cost # customer satisfaction performance measurement %

improvement

Mour company shall $ork to improve the quality % productivity continuously.

Performance indicators shall e identified y you to improve quality % productivity .The

progress in these areas shall e monitored y the management at regular intervals.

*ollo$ing are the examples of performance indicators

Performance indicators

- machine do$n time

- machine set up ( tool die change % machine change over time

- cycle time for each product

Some of the suggested techniques used for improving the productivity

- machine reakdo$n analysis

- time % motion study of each process

3mproving the quality of the product Performance indicators

- 3n house re!ection# re$ork trend.

- )apaility indices , )p % )pk / H of processes having )pk 8.== % aove

- Measurement System 2nalysis , H 1 % 1 /

- S1K re!ection # line re!ection at pricol

- H $arranty

S.'" .7 $h" $"1hn05)"! $ha$ 1an (" )!"d 7. 5)a-0$& 0'/.4"'"n$! a"

SP)

*M&2

)ause % &ffect diagram

Bistogram

MS2

Pareto analysis

Cesign of experiments

*ault tree analysis

37

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

TPM

Six Sigma

Quality )ircle

5hy 5hy analysis

C.!$ "d)1$0.nA

Some of the performance indicators are

- Kalue added per employee

- )ost of quality

- Product produced per employee,Per Man# Cay production monitoring system/

- 1eduction in material movement inside the company

- Man hour saved

- Saving of shop floor space

- )ost of carrying inventory

S.'" .7 $h" $"1hn05)"! )!"d 7. 1.!$ "d)1$0.n

- ench marking

- standardi"ation

- measure of cost of quality

- value analysis

2ny changes done in the process( material( method( design( susupplier location shall

e done in consultation $ith pricol( if necessary $ith prior approval of pricol.

I'/.4"'"n$ 0n 1)!$.'" !a$0!7a1$0.n

The supplier shall $ork continuously to improve the customer satisfaction i.e. pricol ..

Performance indicators

- Quality system audit # process audit rating # Supplier Performance rating

- 4o. Of complaints ,veral complaints( other feedack/

- 4o. 5arranty claims # Hage of PPM

- Celivery performance , H on time delivery /

- )ost control # K2 # K&

- Quick response to Pricol needs # )ycle time.

- H Of components supplied in reusale packing

The performance level on the customer satisfaction shall e a part of your

Management revie$.

=. SELF+CERTIFICATION CRITERIA >D TS A DIRECT TO STORES ?A

Self )ertification of suppliers $ill e ased on successful implementation of quality

assurance requirement as per the SQ2 % the CTS agreement et$een supplier and

pricol.

38

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

O!ective % scope?

To eliminate non value adding activity in supply chain and shall e applicale for all the

in$ard components from suppliers.

)omponent identification ased on ?

4o re!ection#1e$ork PPM for the past one year

Gots supplied is 7 % aove.

QMS Score more than 96H

Supplier $illingness

CTS 1equirements

CTS Tag $ith details

CTS seal stamped invoice

Pre delivery inspection report

Gay out inspection report

*or any deviation on CTS supply( the supplier should immediately arrange for the

segregation and support pricol line assemly $ithout affecting the production

schedules.

2nalyse the exact root cause and sumit the corrective action to SQ2 $ith proper

evidences. SQ2 $ill monitor the consistency of the corrective action and once the

corrective action found to e ineffective( lot $ill e in$arded through normal

inspection.

39

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

SUPPLIER ACHNOWLEDGEMENT/ACCEPTANCE FORM

5e have received the Pricol Supplier development manual and agree to aide $ith the

expectation(terms and conditions as stated in the manual. 5e promise to make ourself

a$are of the related activities that are considered to pose a significant impact on the

activities of pricol in its !ourney to$ard quality.

5e extent our support to the o!ectives and efforts taken y pricol for an occupational

health( safety and environmental friendly manufacturing and management practices.

Supplier details?

Supplier name ?

Supplier )ode ?

2ddress ?

,$ith email id/

)ontact 4umer ?

)&O# Plant head ?

Signature ?

Cate?

*Please return a copy of the acknowledgement form duly accepted and signed by

the CEO/Plant head of the organization within 15 days of receipt

Supplier Quality 2ssurance Team

Pricol Gimited( Plant 3

Periyanaickenpalayam(

Ooty Main 1oad(

)oimatore 9>8 6.6

Tamil4adu(3ndia.

40

REVISION 00

"GROW TOGETHER" DATE 10/07/2012

SUPPLIER DEVELOPMENT MANUAL

Sa'/-" F.'a$! 7. R"7""n1"

Supplier Assessment

Form1.doc

PPAP Formats - IV

Edition.xls

8 D Report.xls

dts tag size.xls !S Audit "#ec$

s#eet.xls

PR%"ESS A&DI'

"(E") S(EE'.xls

41

PSA form

DTS -Tag

QMS Checksheet

Process audit Check sheet

PPAP Format IV edition

8 D Reort

Potrebbero piacerti anche

- General Overview of Integrated Management SystemDocumento38 pagineGeneral Overview of Integrated Management Systemperlan1234Nessuna valutazione finora

- Integrated Approach To Product Design-1Documento4 pagineIntegrated Approach To Product Design-1vivek.namsNessuna valutazione finora

- Performance ApprisalDocumento87 paginePerformance Apprisalignatiius0% (1)

- PMP 8 Project Quality Management FLDocumento27 paginePMP 8 Project Quality Management FLMoeshfieq WilliamsNessuna valutazione finora

- ASQ Six SigmaDocumento536 pagineASQ Six Sigmarvelavelan100% (1)

- TQM & Product Development 18 06 2013Documento154 pagineTQM & Product Development 18 06 2013Mustapha RosyaNessuna valutazione finora

- GMP Audit Report - QCSDocumento16 pagineGMP Audit Report - QCSALOKE GANGULY100% (2)

- Process Industry Practices Working in Harmony Improving Capital and Maintenance EfficiencyDocumento40 pagineProcess Industry Practices Working in Harmony Improving Capital and Maintenance Efficiencysunilas218408Nessuna valutazione finora

- ISO 9001 ClausesDocumento6 pagineISO 9001 ClausesJazib SoofiNessuna valutazione finora

- TQM SlidesDocumento30 pagineTQM SlidesN.VivekananthamoorthyNessuna valutazione finora

- Lesson Plan On Advanced Topics in MASDocumento9 pagineLesson Plan On Advanced Topics in MASVictor RamirezNessuna valutazione finora

- Bestseller Environmental RequirementsDocumento14 pagineBestseller Environmental RequirementsRabiul IslamNessuna valutazione finora

- Seemonraja: 12 Years Petrochemical PlantsDocumento6 pagineSeemonraja: 12 Years Petrochemical PlantsSiva KumarNessuna valutazione finora

- What Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItDocumento4 pagineWhat Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItfaidbNessuna valutazione finora

- Title Develop A Maintenance Schedule in The Hospitality Industry Level 5 Credits 5Documento3 pagineTitle Develop A Maintenance Schedule in The Hospitality Industry Level 5 Credits 5plaestineNessuna valutazione finora

- R. Praveen: Email@Documento3 pagineR. Praveen: Email@Harini DossNessuna valutazione finora

- Quality Management Plan TemplateDocumento9 pagineQuality Management Plan TemplateMelford Bernard100% (2)

- Method Statment of Installation and Testing of STPDocumento12 pagineMethod Statment of Installation and Testing of STPmuhannadsaqer89hotmail.comNessuna valutazione finora

- QAQC GuidelinesDocumento20 pagineQAQC GuidelinesFurqanam196100% (2)

- Analyzer 3 Process Industry PracticeDocumento16 pagineAnalyzer 3 Process Industry PracticearindammannaNessuna valutazione finora

- Solid Surface ManualDocumento58 pagineSolid Surface ManualBala Praveen0% (1)