Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 5

Caricato da

Francisco Zurisaddai Meneses0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

364 visualizzazioni154 pagineThis document outlines scheduled maintenance checks and inspection intervals for a Model 400/400A aircraft. It includes:

- Scheduled inspection core intervals that range from 200 flight hours to 12,200 flight hours or 1 to 12 years, depending on the inspection.

- Details of scheduled IFA-A inspections that examine different areas of the aircraft like the pilot's compartment, cabins, wings, landing gear, engines, etc.

- Tables listing various scheduled IFA-Special inspection intervals that range from 200 flight hours to 12,200 flight hours or 1 to 12 years.

In summary, the document provides maintenance personnel with schedules and procedures for regularly inspecting aircraft systems and structures to ensure continued air

Descrizione originale:

Titolo originale

Chapter_5

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document outlines scheduled maintenance checks and inspection intervals for a Model 400/400A aircraft. It includes:

- Scheduled inspection core intervals that range from 200 flight hours to 12,200 flight hours or 1 to 12 years, depending on the inspection.

- Details of scheduled IFA-A inspections that examine different areas of the aircraft like the pilot's compartment, cabins, wings, landing gear, engines, etc.

- Tables listing various scheduled IFA-Special inspection intervals that range from 200 flight hours to 12,200 flight hours or 1 to 12 years.

In summary, the document provides maintenance personnel with schedules and procedures for regularly inspecting aircraft systems and structures to ensure continued air

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

364 visualizzazioni154 pagineChapter 5

Caricato da

Francisco Zurisaddai MenesesThis document outlines scheduled maintenance checks and inspection intervals for a Model 400/400A aircraft. It includes:

- Scheduled inspection core intervals that range from 200 flight hours to 12,200 flight hours or 1 to 12 years, depending on the inspection.

- Details of scheduled IFA-A inspections that examine different areas of the aircraft like the pilot's compartment, cabins, wings, landing gear, engines, etc.

- Tables listing various scheduled IFA-Special inspection intervals that range from 200 flight hours to 12,200 flight hours or 1 to 12 years.

In summary, the document provides maintenance personnel with schedules and procedures for regularly inspecting aircraft systems and structures to ensure continued air

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 154

A2 Page 1

Jan 01/12 05-LOEP

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

List of Effective Pages

CH-SE-SU PAGE DATE

05-LOEP 1 Jan 01/12

05-CONTENTS 1 thru 3 Jan 01/12

05-20-00 601 thru 617 Jan 01/12

05-20-01 601 thru 610 Jan 01/12

05-20-02 601 thru 624 Jan 01/12

05-20-03 601 thru 635 Jan 01/12

05-20-04 601 thru 650 Jan 01/12

05-20-05 601 thru 614 Jan 30/09

Page 1

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

SUBJECT PAGE

CHAPTER 05 - TIME LIMITS/MAINTENANCE CHECKS

TABLE OF CONTENTS

Jan 01/12

A2

05-CONTENTS

05-20-00

Scheduled Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

Increased Flight Activity (IFA) Inspection Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

Scheduled Inspection Core Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .602

Recommended Inspection Program Transition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .604

Scheduled Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .604

Scheduled Special Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .605

Service Information Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .608

Inspection Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .609

Standard Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .610

Inspection Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .610

Additional Requirements Introduced By Revision Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .612

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .617

05-20-01

Scheduled IFA-Special Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

A. 200-Hour Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

B. 200-Flying Hours From The Airplane Build. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .602

C. 200-Flying Hours After Control Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .602

D. 600-Hour or 12-Months Initial and 200-Hour or 3-Month Subsequent . . . . . . . . . . . . . . . . . . . . . . . . . . . .603

E. One-Year Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .603

F. Two-Year Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .604

G. Four-Year Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .604

H. Five-Year Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .604

I. Six-Year Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .605

J. Eight-Year Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .605

K. Ten-Year Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .605

L. Ten-Year Initial and Five-Year Subsequent Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .605

M. Twelve-Year Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .605

N. 2,400-Hour Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .606

O. 3,000-Air Conditioning Operating Hours Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .606

P. 4,500-Hours/3,000-Landings Initial and 1,400-Hours/1,400-Landings Subsequent Intervals

(RK-1 thru RK-23 without Kit 128-8001 installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .606

Q. 7,000-Landings Initial and 200-Landings Subsequent Intervals (RK-1 thru RK-352). . . . . . . . . . . . . . . . . 606

R. 7,200-Hour Initial and 2,400-Hour Subsequent Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .607

S. 7,400-Hours/5,000-Landings Initial and 1,400-Hours/1,400-Landings Subsequent Intervals

(RK-1 thru RK-23 with Kit 128-8001 installed; RK-24 and After) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 607

T. 9,800-Hour Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .607

U. 12,200-Hour Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .608

V. 12,200-Hour Initial and 3,600-Hour Subsequent Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .608

Page 2

05-CONTENTS Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

SUBJECT PAGE

CHAPTER 05 - TIME LIMITS/MAINTENANCE CHECKS

TABLE OF CONTENTS (Continued)

W. Tire Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

05-20-02

Scheduled IFA-A Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

Pilot's Compartment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

Cabin Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 603

Forward Fuselage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604

Midfuselage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 606

Left-Hand Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 607

Right-Hand Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

Landing Gear and Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 609

Aft Fuselage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 611

Vertical Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612

Horizontal Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 613

Left-Hand Power Plant, Pylon and Nacelle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 614

Right-Hand Power Plant, Pylon and Nacelle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 616

Left-Hand Thrust Reverser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 618

Right-Hand Thrust Reverser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 620

Engine Ground Run and Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 622

05-20-03

Scheduled IFA-B Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

Pilot's Compartment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

Cabin Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 604

Forward Fuselage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 606

Midfuselage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 607

Left-Hand Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

Right-Hand Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 610

Landing Gear and Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 612

Aft Fuselage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 617

Vertical Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 620

Horizontal Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 622

Left-Hand Power Plant, Pylon and Nacelle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 623

Right-Hand Power Plant, Pylon and Nacelle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 624

Engine Ground Run and Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 625

Page 3

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

SUBJECT PAGE

CHAPTER 05 - TIME LIMITS/MAINTENANCE CHECKS

TABLE OF CONTENTS (Continued)

Jan 01/12 A2 05-CONTENTS

05-20-04

Scheduled IFA-C Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

Pilot's Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

Cabin Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .604

Forward Fuselage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .608

Midfuselage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .609

Left-Hand Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .611

Right-Hand Wing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .613

Landing Gear and Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .615

Aft Fuselage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .617

Vertical Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .622

Horizontal Stabilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .623

Engine Ground Run and Operational Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .624

05-20-05

Scheduled IFA-D Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

Page 601

A2 Jan 01/12 05-20-00

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

600600600

SCHEDULED MAINTENANCE CHECKS

GENERAL INFORMATION

Beginning January 2009, Hawker Beechcraft Corporation (HBC) introduced an Airplane Inspection Program for the

Model 400A tailored for Increased Flight Activity (IFA). This program is published as a supplement to the Model 400/

400A Maintenance Manual and was developed to support owner/operators who fly their airplane(s) 400 hours or

more annually. If the owner/operator meets or exceeds this flight hour utilization, they may continue to use the

existing 200 hour Recommended Inspection Program or they may elect to transition to the new IFA Inspection

Program. Owner/operators who fly 300+ hours or more annually may utilize this program but may not experience

the maximum operational benefits of the program. Once established on this program, owner/operators may

encounter reduced annual utilization due to airplane major modification, refurbishment or directed operational

reduction. Since this type of low flying activity is usually temporary, it is not necessary to remove the airplane from

the program.

The IFA Program supplement is compiled to assist the owner/operator and technician with inspecting the airplane

based on this increased activity. Additionally, information is provided to assist the owner/operator with transitioning

from the existing 200 hour Recommended Inspection Program to the new IFA Inspection Program.

Airplane maintenance records must be documented to identify the owner/operators current inspection program. For

additional guidance, refer to FAR 91.409(f).

Owner/operators who conduct flight operations under 14 CFR Part 91 should refer to Subpart E for additional

guidance and responsibilities regarding maintenance, preventive maintenance and alterations.

Fractional owners and fractional ownership program managers who conduct flight operations under 14 CFR Part 91

should refer to Subpart K for additional guidance and responsibilities regarding aircraft maintenance/inspection

programs.

Owner/operators who conduct flight operations under 14 CFR Part 135 should refer to Subpart J for additional

guidance and responsibilities regarding maintenance, preventive maintenance and alterations.

NOTE: For the purposes of maintenance and inspection tracking, flight hours are defined as the time the airplanes

wheels lift off of the runway until the time the airplanes wheels touch down on the runway.

INCREASED FLIGHT ACTIVITY (IFA) INSPECTION PROGRAM

The owner/operator is primarily responsible for maintaining the airplane in an airworthy condition, including

compliance with all applicable Airworthiness Directives as specified in 14 CFR 39. It is further the responsibility of

the owner/operator to ensure that the airplane is inspected in conformity with the requirements of 14 CFR Part 21,

Part 43 and Part 91.

HBC has prepared this inspection guide to assist the owner/operator in meeting the foregoing responsibilities. This

inspection guide is not intended to be all-inclusive, for no such guide can replace the good judgement of a

certificated airframe and power plant mechanic in the performance of his duties. As the one primarily responsible

for the airworthiness of the airplane, owner/operators should select only qualified personnel to inspect and maintain

the airplane.

While this guide may be used as an outline, detailed information on the many systems and components in the

airplane will be found in the various chapters of the maintenance manual and the pertinent supplier publications. It

is also necessary that reference be made the applicable maintenance manuals, HBC Service Bulletins, applicable

FAA regulations and publications, suppliers bulletins and other requirements. It is the responsibility of the airframe

and power plant mechanic inspecting or maintaining the airplane to have access to the previously noted documents

and this inspection guide.

05-20-00

Page 602

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

The time intervals for the recommended inspections and maintenance checks are based on usage under normal

environmental conditions. Airplanes operated in adverse environmental conditions (desert, tropical, coastal,

volcanic and etc.) may require inspection and/or maintenance at more frequent intervals. When operating in adverse

environmental conditions, accomplish the inspection and/or maintenance detailed within this chapter at intervals

based on contingencies of field experience by the owner/operators.

HBCs IFA Inspection Program consists of, but is not limited to, inspection items listed in this inspection guide,

applicable Airworthiness Directives (AD) issued against the airframe or any equipment installed therein, conformity

to the Type Certificate Data Sheet (TCDS) and all applicable Airworthiness Limitations listed in the Model 400/400A

Airworthiness Limitations Manual, Chapter 04-00-02.

The Model 400A IFA Inspection Program is divided into five separate ATA subchapters.

Chapter 05-20-01 - Scheduled Special Inspections

Chapter 05-20-02 - Scheduled IFA-A Inspections

Chapter 05-20-03 - Scheduled IFA-B Inspections

Chapter 05-20-04 - Scheduled IFA-C Inspections

Chapter 05-20-05 - Scheduled IFA-D Inspections

NOTE: There are maintenance and inspection tasks required by the Federal Aviation Administration (FAA). These

tasks are identified in the Model 400/400A Airworthiness Limitations Manual, Chapter 04-00-02, and should

be monitored in addition to the SCHEDULED INSPECTION. Review the Airworthiness Limitation Manual

tasks prior to commencing any SCHEDULED INSPECTION.

There are tasks which require more or less frequent inspection than those identified in the SCHEDULED

INSPECTION. These tasks are identified in Chapter 05-20-01 - as SCHEDULED SPECIAL INSPECTIONS

and should be monitored in addition to the SCHEDULED INSPECTION. Review SCHEDULED SPECIAL

INSPECTION tasks prior to commencing any SCHEDULED INSPECTION.

In addition to the inspections prescribed by this IFA Inspection Program, each static pressure system, each

altimeter instrument, and each automatic pressure altitude reporting system MUST be tested and inspected

at 24-month intervals in compliance with the requirements specified in 14 CFR 91.411 and 91.413 or the

applicable regulatory requirement.

SCHEDULED INSPECTION CORE INTERVALS

NOTE: The 12 month calendar interval is applicable to the IFA-A inspection only. The IFA-B, IFA-C and IFA-D

inspection requirements do not have calendar intervals.

IFA-A-Inspection should be completed at the first 400 flight hours or 12 months of service, whichever

occurs first and should be completed every 400 flight hours or 12 months thereafter.

IFA-B-Inspection should be completed at the first 800 flight hours of service and should be completed

every 800 flight hours thereafter.

IFA-C-Inspection will be completed at the first 1600 flight hours of service and should be completed

every 1600 flight hours thereafter.

IFA-D-Inspection will be completed at the first 6400 flight hours of service and should be completed

every 3200 flight hours thereafter.

Page 603

A2 Jan 01/12 05-20-00

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

SCHEDULED INSPECTION core intervals based on calendar time are due no later than the last day of the month

in which the inspection comes due. SCHEDULED INSPECTION core intervals based on flight hours may be

exceeded by no more than 40 flight hours. This exceedance is allowed to assist owner/operators with coordinating

operation and inspection schedules. In no instance should an airplane fly more than 440 flight hours between

SCHEDULED INSPECTIONS. Any flight hour exceedance used beyond the inspection core interval(s) must be

subtracted when computing the next repetitive inspection(s).

Example 1:

An owner/operators airplane is due an IFA-A, IFA-B inspection at 800 flight hours. The IFA-A inspection

has a calendar due date of 30 July 2008. The IFA-A, IFA-B inspection was accomplished at 840 flight

hours on 18 July 2008.

The next IFA-A inspection is due at 1200 flight hours (840 hours plus 400 hours, minus 40 hours

exceedance = 1200 hours) or 30 July 2009, whichever occurs first.

The next IFA-B inspection is due at 1600 flight hours (840 hours plus 800 hours, minus 40 hours

exceedance = 1600 hours).

Owner/operators who wish to perform an inspection earlier than the inspection core interval(s) may do so without

HBC concurrence. In such cases, compute the next repetitive inspection(s) due by adding the applicable core

inspection interval to the time the inspection(s) were accomplished.

Example 2:

An owner/operators airplane is due an IFA-A, IFA-B inspection at 800 flight hours. The IFA-A inspection

has a calendar due date of 30 July 2008. Due to mission scheduling, the owner/operators elects to

perform the IFA-A, IFA-B inspection on 15 May 2008 at 680 hours.

The next IFA-A inspection is due at 1080 flight hours (680 hours plus 400 hours = 1080 hours) or 30

May 2009, whichever occurs first.

The next IFA-B inspection is due at 1480 flight hours (680 hours plus 800 hours = 1480 hours).

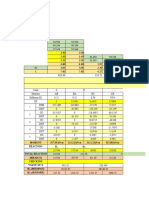

Chart 601 illustrates the SCHEDULED INSPECTION core intervals in a table format. This chart represents the IFA

Inspection Program based on a zero time airframe. Due to variations in operational and maintenance scheduling,

HBC understands that in service airplanes may have a SCHEDULED INSPECTION accomplished or due at times

other than those indicated in Chart 601. In these cases, it is important that the owner/operator remain within the

applicable core inspection intervals and limitations listed above.

05-20-00

Page 604

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

RECOMMENDED INSPECTION PROGRAM TRANSITION

Transition from the current 200 hour Recommended Inspection Program to the IFA Inspection Program is the

responsibility of the owner/operator of the airplane. The owner/operator and their elected maintenance facility

should carefully read and understand the requirements in the IFA Inspection Program before changing inspection

programs. A transition worksheet (Table 601) has been provided as part of the IFA Inspection Program to assist in

recalculating inspection targets.

SCHEDULED INSPECTIONS

a. Review the airplanes maintenance records and determine the last compliance date/time of each Scheduled

Inspection.

b. Record this information in the applicable blocks on the transition worksheet. See Example 3.

c. Using these figures, recalculate the next inspection(s) due using the inspection core intervals and limitations

listed in the IFA Inspection Program.

Chart 601

Scheduled Inspections

HOUR INTERVAL IFA-A IFA-B IFA-C IFA-D HOUR INTERVAL IFA-A IFA-B IFA-C IFA-D

400 or 12 months X 6,800 X

800 X X 7,200 X X

1,200 X 7,600 X

1,600 X X X 8,000 X X X

2,000 X 8,400 X

2,400 X X 8,800 X X

2,800 X 9,200 X

3,200 X X X 9,600 X X X X

3,600 X 10,000 X

4,000 X X 10,400 X X

4,400 X 10,800 X

4,800 X X X 11,200 X X X

5,200 X 11,600 X

5,600 X X 12,000 X X

6,000 X 12,400 X

6,400 X X X X 12, 800 X X X X

Page 605

A2 Jan 01/12 05-20-00

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

Example 3:

RK-126 has 1820 hours Airframe Total Time. The owner/operator completed an A & B Inspection on

11/18/2008 at 1790 hours Airframe Total Time. The C Inspection was completed on 12/02/2007 at 1408

hours Airframe Total Time. The D Inspection interval has not yet been reached. Using this information

from the maintenance records, recalculate the next inspection(s) due using the inspection core intervals

in the IFA Inspection Program.

SCHEDULED SPECIAL INSPECTIONS

NOTE: New tasks have been added to the SCHEDULED SPECIAL INSPECTION. Additionally, some previous

inspections and inspection core intervals have been re-identified. Carefully review Chapter 05-20-01.

a. Review the airplanes maintenance records and determine the last compliance date/time of each Scheduled

Special Inspections.

b. Record this information in the applicable blocks on the transition worksheet. See Example 4.

c. Using these figures, recalculate the next inspection(s) due using the inspection core intervals and limitations

listed in the IFA Inspection Program, Chapter 05-20-01.

SCHEDULED SPECIAL INSPECTION core intervals based on calendar time are due no later than the last day of

the month in which the inspection comes due. SCHEDULED SPECIAL INSPECTION core intervals based on flight

hours may be exceeded by no more than 40 flight hours. Scheduled Special Inspection core intervals based on

landing /cycle count may be exceeded by no more than 30 landings/cycles. This exceedance is allowed to assist

owner/operators with coordinating operation and inspection schedules. Any flight hour exceedance used beyond the

inspection core interval(s) must be subtracted when computing the next repetitive inspection(s).

Example 3 Table

SCHEDULED INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

IFA-A Inspection 11/18/

2008

1790 400 Hours

or

12 months

11/30/

2009

2190

IFA-B Inspection 11/18/

2008

1790 800 Hours N/A 2590

IFA-C Inspection 12/02/

2007

1408 1600 Hours N/A 3008

IFA-D Inspection 6400 Hours

Initial/

3200 Hours

Subsequent

05-20-00

Page 606

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

Example 4:

For illustration purposes, use the same airplane status as identified in Example 3. Additionally, we consider the

airplane has not been modified with Kit 128-9008 (JT15D-5R Conversion). Also, we will calculate the new due date/

time for items replaced during the last inspection which include: Main Battery, Wing Flap Cables and Cabin Portable

Fire Bottle. During the last inspection, all one year inspection items were accomplished as well.

Example 4 Table

SCHEDULED SPECIAL INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

200 Hour Interval

Elevator Heater Horn Inspection 11/18/

2008

1790 200 Hours N/A 1990

Lubrication Schedule - Main Landing Gear

(MLG)

11/18/

2008

1790 200 Hours N/A 1990

Lubrication Schedule - Nose Landing Gear

(NLG)

11/18/

2008

1790 200 Hours N/A 1990

Lubrication Schedule - MLG & NLG Doors 11/18/

2008

1790 200 Hours N/A 1990

Thrust Reverser Lubrication 11/18/

2008

1790 200 Hours N/A 1990

Lubrication Schedule - Fuel Caps 11/18/

2008

1790 200 Hours N/A 1990

Lubrications Schedule - Flap Assembly 11/18/

2008

1790 200 Hours N/A 1990

Starter-Generator Inspection 11/18/

2008

1790 200 Hours N/A 1990

Entrance Door Steps Inspection 11/18/

2008

1790 200 Hours N/A 1990

Engine Igniter Plugs Inspection 11/18/

2008

1790 200 Hours N/A 1990

Nacelle Mounted Fuel Filter Element

Replacement (JT15D-5R Only)

N/A N/A N/A

Fuel Pump Overtemperature Indicator P/N

3071526 (JT15D-5/5R only)

N/A N/A N/A

Battery (NiCad) N/A N/A N/A

Page 607

A2 Jan 01/12 05-20-00

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

200 Flying Hours From The Airplane Build

LH & RH Flap Cables & Interconnect Cables

(Cable Tension Check)

08/15/

1996

202 One Time N/A N/A

LH & RH Spoiler Cables (Cable Tension Check) 08/15/

1996

202 One Time N/A N/A

200-Flying Hours After Control Cable

Replacement

LH & RH Flap Cables & Interconnect Cables

(Cable Tension Check)

11/18/

2008

1790 200 Hours N/A 1990

LH & RH Spoiler Cables (Cable Tension Check) N/A N/A N/A N/A

Rudder Control Cables (Cable Tension Check) N/A N/A N/A N/A

Elevator Control Cables (Cable Tension Check) N/A N/A N/A N/A

Elevator Servo Cables (Cable Tension Check) N/A N/A N/A N/A

Rudder Servo Cables (Cable Tension Check) N/A N/A N/A N/A

Spoiler Servo Cables (Cable Tension Check) N/A N/A N/A N/A

600- Hours or 12-Months Initial & 200 Hour or

3 Month Subsequent

Main Battery (Capacity Check) 11/18/

2008

1790 200 Hours 11/30/

2009

1990

One Year Intervals

Model GA-12 Individual Flotation Device

(Recertify)

11/18/

2008

1790 12 Month 11/30/

2009

Flight Data Recorder (Test) N/A N/A N/A N/A

Emergency Locator Transmitter (Inspection) 11/18/

2008

1790 12 Month 11/30/

2009

Cockpit Portable Fire Extinguisher (Weight

Check & Inspection)

11/18/

2008

1790 12 Month 11/30/

2009

Cabin Portable Fire Extinguisher (Weight Check

& Inspection)

11/18/

2008

1790 12 Month 11/30/

2009

N/A

Standby Power Supply Battery (Capacity Check) 11/18/

2008

1790 12 Month 11/30/

2009

Example 4 Table (Continued)

SCHEDULED SPECIAL INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

05-20-00

Page 608

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

SERVICE INFORMATION DOCUMENTS

HBC issues several types of service information documents for the benefit of owner/operators. These service

information documents may contain information regarding safety, operation, inspection, maintenance, modification

or general information. The service information documents used by Hawker Beechcraft Corporation, and their

intended purpose, are listed below:

SERVICE BULLETINS

A MANDATORY Service Bulletin (Red Border) contains information pertaining to inspections, repairs, procedures,

limitations, or modifications to specific airplanes, engines or appliances for which Hawker Beechcraft Corporation

considers compliance to be mandatory. Data contained in a MANDATORY Service Bulletin is FAA approved and

may change the airplanes Type Design.

A RECOMMENDED or OPTIONAL Service Bulletin (no border) contains information pertaining to changes,

modifications, improvements or inspections which may benefit the owner/operator. Hawker Beechcraft Corporation

strongly encourages compliance with RECOMMENDED Service Bulletins and owner/operators should give this

document a high degree of attention. An OPTIONAL Service Bulletin may be implemented at the owner/operators

discretion. Data contained in a RECOMMENDED and OPTIONAL Service Bulletin is FAA approved and may

change the airplanes Type Design.

COMMUNIQUE

A SAFETY COMMUNIQUE contains information on an unsafe condition (whether resulting from design,

manufacturing, maintenance or pilotage) which requires expeditious transmittal. A SAFETY COMMUNIQUE does

not authorize change of the airplanes Type Design.

A MODEL SERIES COMMUNIQUE contains general information of interest to owner/operators and company

Authorized Service Centers (ASC) related to a specific product model series. Most often, this document is used to

share information related to general practices involving inspection, maintenance and/or operation of the specific

product. The MODEL SERIES COMMUNIQUE may announce upcoming or newly developed product improvements

or identify part number changes due to supersedure or obsolescence in advance of routine maintenance manual or

parts catalog revision. Information presented in MODEL SERIES COMMUNIQUES is considered company

acceptable. The MODEL SERIES COMMUNIQUE does not authorize change to the airplanes Type Design.

AHRS Power Supply Battery 11/18/

2008

1790 12 Month 11/30/

2009

Twelve Year Intervals

Cockpit Fire Extinguisher (Hydrostatic Inspect) 02/12/

2002

983 12 Year 02/28/

2014

N/A

Cabin Fire Extinguisher (Hydrostatic Inspect) 11/18/

2008

1790 12 Year 11/30/

2020

N/A

Example 4 Table (Continued)

SCHEDULED SPECIAL INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

Page 609

A2 Jan 01/12 05-20-00

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

FIELD SERVICE KIT

A FIELD SERVICE KIT contains approved Type Design data and/or parts assembled to support the previously

identified service information documents or it may act as a stand alone document. Data contained in a FIELD

SERVICE KITS is FAA approved and may change the airplanes Type Design. Each FIELD SERVICE KIT is

assigned a serial number which should be documented into the airplane maintenance records upon kit completion.

INSPECTION REQUIREMENTS

WARNING: When an airplane has experienced abnormal landing gear procedures of any type, as a safety

precaution, place the airplane on jacks prior to performing any inspection or maintenance.

Ensure that all three landing gears are down and locked prior to removing the airplane from

jacks.

CAUTION: Jacking of an airplane for the purpose of landing gear operation, inspection, servicing or maintenance

should be accomplished within an enclosed building or hangar. In the interest of safety, should it

become necessary to jack the airplane in the open, wind velocity in any direction and terrain variations

must be compensated for prior to jacking the airplane.

NOTE: For U.S. registered airplanes, standard airworthiness certificates remain valid as long as the aircraft meets

its approved type design, is in a condition for safe flight and maintenance, preventative maintenance, and

alterations are performed in accordance with 14 CFR Parts 21, 43, and 91. Refer to 14 CFR Part 21.181 for

more detail.

Information in this section provides specific instructions for the scheduled inspection of the airplane and/or

components, which should be accomplished according to the specified intervals in Chapter 05-20-01, 05-20-02, 05-

20-03, 05-20-04 and 05-20-05.

Airplane structure and/or components should be sufficiently clean to enable an effective inspection to be performed.

Inspections should make sure systems and/or components are free from any defects likely to affect airworthiness.

Inspections should be performed to a degree sufficient to make sure systems and/or components will remain

serviceable until the next applicable inspection is repeated.

Inspections should comply with the minimum standards identified in the STANDARD TERMS and INSPECTION

CRITERIA section below.

Ascertain that all placards and markings are in place and legible, especially those listed in the limitations sections

of the Airplane Flight Manual (AFM) and the Pilots Operating Manual (POM). Replace any placards that have been

inadvertently defaced or removed.

WARNING: When doing any of the inspections/checks contained in this maintenance schedule, obey all of

the warnings and cautions stated in the maintenance manual associated with the system or

component under inspection/check.

NOTE: Refer to Chapter 06-50-00 for the location of panels and doors needed to gain access to the inspection

areas.

Access requirements quoted are minimum requirements. Further dismantling of an item, group or assembly may be

considered necessary by a licensed airframe and power plant mechanic in order to assure airworthiness.

Due to different equipment fits between airplanes and in order to achieve satisfactory exposure of the area/item to

be inspected, it may be necessary to displace/remove other items, (e.g. electrical cables, tubes, ducts, fittings etc.)

which are not stated in the inspection schedule.

05-20-00

Page 610

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

STANDARD TERMS

WARNING: When doing any of the inspections/checks contained in this maintenance schedule, obey all of

the warnings and cautions stated in the maintenance manual for the system or component

under inspection/check.

A series of standard terms that are used throughout this inspection program are listed below to indicate the

inspection requirements. Their interpretations are as follows:

a. Area Inspection - A visual inspection of a specified item, assembly or installation in a noted area of the airplane

relating to an inspection interval and access quoted. Area inspections can be specified as general (Inspect) or

detailed.

b. Condition - The visual appearance of an item, assembly or installation which indicates proper installation,

presence of all fasteners and hardware (including safeties), security of electrical and bonding connections, as

applicable, and absence of leakage or material damage (i.e., cracks, loose fasteners, corrosion, dents, chaf,

distortion).

c. Inspect - A general visual inspection (using adequate lighting and viewed at no more than arms length away)

to survey the condition of an item, assembly or installation.

d. Detail Inspect - An intensive visual inspection (using adequate lighting and necessary inspections aids such as

inspection mirrors, magnification devices, borescopes, HBC approved NDT technique, etc...) to survey the

condition of an item, assembly or installation. Removal of the item, assembly or installation may not be

necessary if complete visual examination is possible using one or more inspection aids. Surface cleaning and

additional access procedures may be required.

e. Check - Make a comparison of a measurement of time, pressure, temperature, resistance, dimension or

quantity with a given value for that measurement.

f. Bench Check - This requires the component to be removed from the airplane and checked in accordance with

the data contained in the relevant HBC or Supplier Component Maintenance Manual.

g. Functional Test - Make sure, by use of test equipment if necessary, that a complete system functions correctly

in accordance with a published functional test procedure.

h. Operational Test - Make sure, without the use of test equipment, that a component within a system OR part of

a system operates correctly in accordance with a published functional test procedure.

INSPECTION CRITERIA

a. Metal parts: e.g. applicable to all metal parts, bodies or casings of units in systems and in electrical, instrument

and radio installations, metal pipes, ducting, tubes, rods, levers.

1. Inspect for: Cleanliness, external signs of damage, leaks, overheating or discharge. Fluid ingress.

Obstruction of drainage or vent holes or overflow pipe orifices. Correct seating and sealing of fairings and

serviceability of fasteners. Security of attachment, fasteners, connections, locking and bonding.

2. Freedom from: Distortion, dents, scores, chafing, pulled or missing fasteners, rivets, bolts, screws. Signs

of cracks and wear. Separation of bond. Failure of welds and spots welds. Deterioration of protective

treatment, and signs of corrosion.

b. Rubber, Fabric, Fiber Glass and Plastic Parts: e.g. coverings, ducting, flexible pipes, flexible mountings,

seals, insulation of electrical cables, heater muffs, windows etc.

Page 611

A2 Jan 01/12 05-20-00

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

1. Inspect for: Cleanliness, cracks, cuts, chafing, kinking, twisting, crushing, contraction - sufficient free

length, deterioration, crazing, loss of flexibility (other than fabric covered component), overheating and fluid

soakage. Security of attachment (supports, packing and electrical bonding correctly positioned, serviceable

and secure) connections and locking.

c. Electrical Wiring, wiring harness, connectors, clamps, backshell, and bonding straps:

1. Inspect for: Cuts or chafing in the wire insulation or conductor; Kinked, twisted, crushed or poorly routed

wire strands or wire harness assemblies; Loss of flexibility, overheating or fluid soakage. Security of

attachment (supports, clamps, electrical bonding correctly positioned, serviceable and secure connections).

d. Flight control system components (Primary and secondary control systems):

1. Inspect for: Correct alignment, freedom of movement, no interference - no fouling. Signs of bowing or

distortion, wear, chafing, scoring or gouging. Fraying. Kinking. Signs of wear. Flattening. Cracks. Loose

rivets. Deterioration of protective treatment and signs of corrosion. Electrical bonding straps correctly

positioned, undamaged and secure. Attachments, end connections and locking devices secure.

NOTE: Free movement should be established at extreme ranges of travel with full trim applied.

Full travel of the rudder circuit should be confirmed with the pedals at the full forward and full aft

adjustment positions.

e. Electrical Motors, Alternators, Generators and Actuators:

1. Inspect for: Cleanliness, obvious damage, signs of overheating, corrosion and security of attachments and

connections. If protective covers are required to be removed: cleanliness, scoring, pitting, brush wear and

freedom of movement in the brush holders, correct brush seating and armature condition, adequate spring

tension. Overheating or arching. Fluid ingress.

f. Relays, Solenoids and Contactors:

1. Inspect for: Cleanliness, obvious damage, signs of overheating or

2. arching, corrosion and security of attachments and connections. If protective covers are required to be

removed: cleanliness, pitting or burning of contacts, signs of overheating or arching and security of contacts

exposed.

g. Markings, notices, frequency charts, compass corrector cards, warning and caution labels, placards:

1. Inspect for: Proper placard information, legibility and security of attachment.

NOTE: Any other inspection or work requirement not covered by the above standards is specifically written

into the attachment.

h. Structural Inspection - e.g. lap joints, butt straps, stringers, frames, bulkheads, ribs, longerons and skins.

1. Inspect for:

a) Lack of adhesion of the paint or sealant. (This could indicate the presence of surface corrosion under

the paint film or sealant).

b) Bubbles or eruption of the paint film or sealant. (This condition could indicate local pockets of corrosion

and it is important to ascertain, beyond reasonable doubt, that any bubble or eruption found is a build

up of paint or sealant and not a build up of corrosion product. If any doubt exists the bubble or eruption

should be broken, the area cleaned up and, if satisfactory, the treatment restored).

05-20-00

Page 612

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

c) Signs of corrosion on the edge of any member where it joins the skin. (If corrosion is found, the suspect

are of the joint must be cleaned of all paint. If corrosion is confirmed and it penetrates between the

faying surfaces of the joint, the affected area must be visually examined by removing bolts or rivets to

check the extent of corrosion and to assist in repair).

d) Any areas exhibiting signs of possible cracking or corrosion should be stripped of paint and inspected

further using fluorescent penetrant.

ADDITIONAL REQUIREMENTS INTRODUCED BY REVISION ACTION

Unless otherwise directed by applicable civil aviation regulatory notification or HBC Service Bulletin, additional

inspection requirement(s) introduced into the IFA Inspection Program by publication revision action should be

accomplished at the next SCHEDULED INSPECTION.

For example, if the IFA Inspection Program were revised and the revision introduced new SCHEDULED

INSPECTION requirement(s) to the IFA-B inspection, then the new requirement(s) would need to be accomplished

at the first IFA-B inspection following release of the revision.

Additional SCHEDULED SPECIAL INSPECTION requirements introduced into the IFA Inspection Program by

publication revision action should be accomplished at the calendar/flight hour interval specified in the revision. If the

airplane has already exceeded the specified calendar/flight hour interval prior to the release of the revision, the

additional inspection requirement(s) should be accomplished at the next SCHEDULED INSPECTION.

For example, if the IFA Inspection Program SCHEDULED SPECIAL INSPECTION was revised and introduced new

landing gear inspection requirement(s) at 7000 landings, then the new inspection requirement(s) would need to be

accomplished when the airplane reached 7000 landing. If an airplane has more than 7000 landings at the time of

the release of the revision, then the new 7000 landing requirement(s) would need to be accomplished at the next

SCHEDULED INSPECTION.

Page 613

A2 Jan 01/12 05-20-00

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

Table 601

Transition Conversion

SCHEDULED INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

IFA-A Inspection 400 Hours

or

12 months

IFA-B Inspection 800 Hours

IFA-C Inspection 1600 Hours

IFA-D Inspection 6400 Hours

Initial/

3200 Hours

Subsequent

SCHEDULED SPECIAL INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

200 Hour Interval

Elevator Heater Horn Inspection

Lubrication Schedule - Main Landing Gear

(MLG)

Lubrication Schedule - Nose Landing Gear

(NLG)

Lubrication Schedule - MLG & NLG Doors

Thrust Reverser Lubrication

Lubrication Schedule - Fuel Caps

Lubrications Schedule - Flap Assembly

Starter-Generator Inspection

Entrance Door Steps Inspection

Engine Igniter Plugs Inspection

Nacelle Mounted Fuel Filter Element

Replacement (JT15D-5R Only)

Fuel Pump Overtemperature Indicator P/N

3071526 (JT15D-5/5R only)

Battery (NiCad)

05-20-00

Page 614

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

200 Flying Hours From The Airplane Build

LH & RH Flap Cables & Interconnect Cables

(Cable Tension Check)

LH & RH Spoiler Cables (Cable Tension Check)

200-Flying Hours After Control Cable

Replacement

LH & RH Flap Cables & Interconnect Cables

(Cable Tension Check)

LH & RH Spoiler Cables (Cable Tension Check)

Rudder Control Cables (Cable Tension Check)

Elevator Control Cables (Cable Tension Check)

Elevator Servo Cables (Cable Tension Check)

Rudder Servo Cables (Cable Tension Check)

Spoiler Servo Cables (Cable Tension Check)

600- Hours or 12-Months Initial & 200 Hour or

3 Month Subsequent

Main Battery (Capacity Check)

One Year Intervals

Model GA-12 Individual Flotation Device

(Recertify)

Flight Data Recorder (Test)

Emergency Locator Transmitter (Inspection)

Cockpit Portable Fire Extinguisher (Weight

Check & Inspection)

Cabin Portable Fire Extinguisher (Weight Check

& Inspection)

Standby Power Supply Battery (Capacity Check)

AHRS Power Supply Battery

Table 601

Transition Conversion (Continued)

SCHEDULED INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

Page 615

A2 Jan 01/12 05-20-00

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

Two Year Intervals

Altimeter, ATC Transponder & Air Data

Computer (Recertify)

Mach Overspeed Warning System (Functional

Test)

Cockpit Voice Recorder Underwater Locator

Beacon (RK-36 and After) (Functional Test)

Air Data System Inspection (RVSM Airplanes

Only)

Flight Data Recorder Underwater Locator

Beacon (RK-36 and After) (Functional Test)

Four Year Intervals

Oxygen Valve - Passenger Oxygen Control

Valve (O-Ring Replacement & Lube)

Five Year Intervals

Model XF-35 Life Preservers (P/N P01074-113)

Six Year Intervals

Underwater Locator Beacon (RK-36 and After)

(Battery Replacement)

Crew Oxygen Mask BE Aerospace Sweep-On

2000 (Overhaul)

Eight Year Intervals

Passenger Oxygen Mask BE Aerospace P/N

174080 (Overhaul/Replace)

Ten Year Intervals

SCV-37 Flotation Vest (P/N HS3701C)

(Recertify)

Model XF-35 Life Preserver (P/N P01074-201)

Table 601

Transition Conversion (Continued)

SCHEDULED INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

05-20-00

Page 616

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

Protective Breathing Equipment (PBE) AVOX

Systems P/N 802300-14 (Replace)

Ten Year Initial & Five Year Subsequent

Wing-to-Fuselage Attach Bolt (Inspection)

Twelve Year Intervals

Cockpit Fire Extinguisher (Hydrostatic Inspect)

Cabin Fire Extinguisher (Hydrostatic Inspect)

3,000-Air Conditioner Operating Hours

Drive Motor (Overhaul)

7,000-Landings Initial & 200-Landings

Subsequent Intervals (RK-1 thru RK-352)

Main Landing Gear Fitting Assembly & Mid

Fuselage Main Landing Gear Uplock Fitting

(Inspection)

9800-Hour Intervals

Airborne Flight Information System (AFIS)

Wiring (Inspection)

12,200-Hour Intervals

Collins Servo Mount Slip Clutch (Test)

12,200 Hour Initial & 3,600 Hour Subsequent

Airborne Flight Information System (AFIS)

Antenna Feed-Through (Inspection)

Table 601

Transition Conversion (Continued)

SCHEDULED INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

Page 617

A2 Jan 01/12 05-20-00

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

REPLACEMENT PARTS

Use only parts obtained from sources approved by Hawker Beechcraft Corporation, in connection with the

maintenance and repair of Hawker Beechcraft Corporation airplanes.

Genuine Hawker Beechcraft Corporation parts are produced and inspected under rigorous procedures to insure

airworthiness and suitability for use in Hawker Beechcraft Corporation airplane applications. Parts purchased from

sources other than those approved by Hawker Beechcraft Corporation, even though outwardly identical in

appearance, may not have the required tests and inspections performed, may be different in fabrication techniques

and materials, and may be dangerous when installed in an airplane.

Salvaged airplanes parts, reworked parts obtained from sources not approved by the HAwker Beechcraft

Corporation or parts, components or structural assemblies, the service history of which is unknown or cannot be

authenticated, may have been subjected to unacceptable stresses or temperatures or have other hidden damage,

not discernible through routine visual or usual nondestructive testing techniques. This may render the part,

component or structural assembly, even though originally manufactured by the Hawker Beechcraft Corporation,

unsuitable and unsafe for airplane use.

Hawker Beechcraft Corporation expressly disclaims any responsibility for malfunctions, failures, damage or injury

caused by use of parts not approved by the Hawker Beechcraft Corporation.

Any maintenance requiring the disconnection and reconnection of flight control cables, plumbing, electrical

connectors or wiring requires identification of each side of the component being disconnected to facilitate correct

reassembly. At or prior to disassembly, components should be color coded, tagged or properly identified in a away

that will be obvious how to correctly reconnect the components. After reconnection of any component, remove all

identification tags. Check all associated systems for correct function prior to returning the airplane to service.

Tire Change

Nose Wheel (Inspection/Lube)

Main Wheels (Inspection/Lube)

Table 601

Transition Conversion (Continued)

SCHEDULED INSPECTIONS

DATE

C/W

HOURS

C/W INTERVAL

NEXT

DUE

DATE

NEXT

DUE

HOURS

Page 601

A2 Jan 01/12 05-20-01

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

600600600

05-20-01

SCHEDULED IFA-SPECIAL INSPECTIONS

SCHEDULED IFA-SPECIAL INSPECTIONS

TASK

CODE DATE MECH INSP

A. 200-HOUR INTERVALS

H300011

H300012

1. Perform ELEVATOR HORN INSPECTION/CHECK (Ref.

Chapter 30-12-00).

H120035

H120036

2. Perform LUBRICATION SCHEDULE - MAIN LANDING

GEAR (Ref. Chapter 12-20-00).

H120041 3. Perform LUBRICATION SCHEDULE - NOSE LANDING

GEAR (Ref. Chapter 12-20-00).

H120042 4. Perform LUBRICATION SCHEDULE - MAIN LANDING

GEAR AND NOSE LANDING GEAR DOORS (Ref. Chapter

12-20-00).

H120037

H120038

5. Perform THRUST REVERSER LUBRICATION - Guide rod

cleaning and lubrication (Ref. Chapter 78-30-00).

H120043

H120044

6. Perform LUBRICATION SCHEDULE - FUEL CAPS (Ref.

Chapter 12-20-00).

H120039

H120040

7. Perform LUBRICATION SCHEDULE - FLAP ASSEMBLY

(Ref. Chapter 12-20-00).

H240019

H240020

8. STARTER-GENERATOR (Generator removal is not

necessary.) (Ref. Chapter 80-10-00).

a. Inspect for security and visible damage.

b. Inspect brushes for wear.

c. Inspect electrical connections for security, wear,

deterioration and damage.

H520019 9. ENTRANCE DOOR STEPS

a. Visually inspect for cracks, loose or missing fasteners,

any indication of structural damage and proper operation.

b. Visually inspect step cable for condition.

H740003

H740004

10. ENGINE IGNITOR PLUGS - Inspect for wear and condition.

Refer to Pratt & Whitney JT15D-5/-5R Maintenance Manual,

Chapter 74-20-02.

05-20-01

Page 602

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

A. 200-HOUR INTERVALS (Continued)

H730001

H730002

11. NACELLE MOUNTED FUEL FILTER ASSEMBLY, P/N

307618 (JT15D-5R Only) - Check filter for foreign matter.

Replace filter if necessary. Refer to Pratt & Whitney JT15D-5/

-5R Maintenance Manual, Chapter 73-10-13.

H730003

H730004

12. FUEL PUMP OUTLET FILTER, P/N 3059778 (JT15D-5 and

JT15D-5R) - Check for foreign matter and/or distortion. Install

new filter at each inspection. Refer to Pratt & Whitney JT15D-

5/-5R Maintenance Manual, Chapter 73-10-02.

H730007

H730008

13. FUEL PUMP OVERTEMPERATURE INDICATOR, P/N

3071526 (JT15D-5R Only) - Inspect position of indicator. If

extended, refer to Pratt & Whitney JT15D-5/-5R Maintenance

Manual, Chapter 74-00-00.

H240021 14. BATTERY (Ni-Cad only) - Check electrolyte level and charge

(deep cycle if necessary). Refer to Chapter 24 in the

Component Maintenance Manual, P/N 128-590001-81 or

subsequent.

B. 200-FLYING HOURS FROM THE AIRPLANE BUILD

H270057

H270058

1. LH and RH FLAP CABLES AND INTERCONNECT CABLES

- Check cable tensions (Ref. Chapter 27-50-00).

H270059

H270060

2. LH and RH SPOILER CABLES - Check cable tension (Ref.

Chapter 27-60-00).

C. 200-FLYING HOURS AFTER CONTROL CABLE

REPLACEMENT

H270048

H270049

1. LH and RH FLAP CABLES AND INTERCONNECT CABLES

- Check cable tensions (Ref. Chapter 27-50-00).

H270050

H270051

2. LH and RH SPOILER CABLES - Check cable tension (Ref.

Chapter 27-60-00).

H270052 3. RUDDER CONTROL CABLES - Check cable tensions (Ref.

Chapter 27-20-00).

H270054 4. ELEVATOR CONTROL CABLES - Check cable tensions

(Ref. Chapter 27-30-00).

H270055 5. ELEVATOR SERVO CABLES - Check cable tensions (Ref.

Chapter 22-13-00).

H270053 6. RUDDER SERVO CABLES - Check cable tensions (Ref.

Chapter 22-13-00).

SCHEDULED IFA-SPECIAL INSPECTIONS (Continued)

TASK

CODE DATE MECH INSP

Page 603

A2 Jan 01/12 05-20-01

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

C. 200-FLYING HOURS AFTER CONTROL CABLE

REPLACEMENT (Continued)

H270056 7. SPOILER SERVO CABLES - Check cable tension (Ref.

Chapter 22-13-00).

D. 600-HOUR OR 12-MONTHS INITIAL AND 200-HOUR OR 3-

MONTH SUBSEQUENT

H243026 1. MAIN BATTERY - Perform the EMERGENCY CAPACITY

TEST in accordance with battery manufacturers

maintenance recommendations.

E. ONE-YEAR INTERVALS

H256030

thru

H256040

1. INDIVIDUAL FLOATATION DEVICE (Model Number GA-12)

- Recertify device once a year after being placed in service.

H313005 2. FLIGHT DATA RECORDER (if applicable) - Perform the

FLIGHT DATA RECORDER (FDR) INSPECTION CHECK

(Ref. Chapter 31-30-00).

H250018 3. EMERGENCY LOCATOR TRANSMITTER (If installed) -

Inspect the ELT as required by 14 CFR 91.207 (d) for:

a. Proper installation.

b. Battery corrosion.

c. Operation of controls and crash sensor.

d. The presence of sufficient signal radiated from its

antenna.

Refer to the Artex Maintenance Manual, Document Numbers 570-

1015 or 570-5000 or subsequent, for the appropriate ELT model

number.

H262001 4. COCKPIT PORTABLE FIRE EXTINGUISHER - Inspect

weight, operating pressure and condition.

H262002 5. CABIN PORTABLE FIRE EXTINGUISHER - Inspect weight,

operating pressure and condition.

H240012 6. STANDBY POWER SUPPLY BATTERY (JET Model PS835)

- Perform battery capacitance test (Ref. Chapter 24-30-02 in

the Component Maintenance Manual, 128-590001-81 or

subsequent.

SCHEDULED IFA-SPECIAL INSPECTIONS (Continued)

TASK

CODE DATE MECH INSP

05-20-01

Page 604

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

E. ONE-YEAR INTERVALS (Continued)

H240013 7. AHRS POWER SUPPLY BATTERY (JET Model PS835) -

Perform battery capacitance test (Ref. Chapter 24-30-02 in

the Component Maintenance Manual, 128-590001-81 or

subsequent.

F. TWO-YEAR INTERVALS

H340012

H340013

H340014

1. ALTIMETER, ATC TRANSPONDER AND AIR DATA

COMPUTER - Check per current CFR's.

H340006 2. MACH OVERSPEED WARNING SYSTEM - Perform

functional test by use of pitot/static tester (Ref. AIR-SPEED

AND MACH WARNING TEST, Chapter 34-12-00).

H230005 3. COCKPIT VOICE RECORDER UNDERWATER LOCATOR

BEACON (RK-36 and After) - Functional test. Refer to the

Dukane (Seacom Division) Technical Manual in Chapter 23 of

the Component Maintenance Manual, P/N 128-590001-81 or

subsequent for test procedures.

H340007 4. AIR DATA SYSTEM (RVSM Only) (RK-1 thru RK-299 that

have complied with Service Bulletin No. 34-3431; RK-300 and

After) - Measure step height of the Static port. Check air data

system for RVSM accuracy (Ref. Chapter 34-10-01).

H313011 5. FLIGHT DATA RECORDER UNDERWATER LOCATOR

BEACON (RK-36 and After) - Functional test. Refer to the

Dukane (Seacom Division) Technical Manual in Chapter 23 of

the Component Maintenance Manual, P/N 128-590001-81 or

subsequent for test procedures.

G. FOUR-YEAR INTERVALS

H350003 1. OXYGEN VALVE - Refer to PASSENGER OXYGEN

CONTROL VALVE O-RING REPLACEMENT (Ref. Chapter

35-21-00).

H. FIVE-YEAR INTERVALS

H256030.1

thru

H250040.1

1. LIFE PRESERVER (Model XF-35 - P/N P01074-113) -

Recertify preserver every five years after being placed in

service.

SCHEDULED IFA-SPECIAL INSPECTIONS (Continued)

TASK

CODE DATE MECH INSP

Page 605

A2 Jan 01/12 05-20-01

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

I. SIX-YEAR INTERVALS

H312020 1. UNDERWATER LOCATOR BEACON (RK-36 and After) -

Replace battery. Refer to the Dukane (Seacom Division)

Technical Manual in Chapter 23 of the Component

Maintenance Manual, P/N 128-590001-81 or subsequent for

test procedures.

H350010 2. CREW OXYGEN MASK (BE AEROSPACE, SWEEP-ON

2000) - Perform overhaul six years from date of manufacture

or last overhaul.

H350013 3. OXYGEN CYLINDER REGULATOR (P/N 172400) - Overhaul

during oxygen cylinder hydrostatic inspection, but no later

than six years from date of manufacturer or last overhaul.

J. EIGHT-YEAR INTERVALS

H350011 1. PASSENGER OXYGEN MASK (BE AEROSPACE, P/N

174080 and 174095) - Overhaul or replace.

K. TEN-YEAR INTERVALS

H256030.2

thru

H256040.2

1. SCV-37 FLOATATION VEST (P/N HS3701C) - Recertify vest

every ten years after being placed in service.

H256030.3

thru

H256040.3

2. LIFE PRESERVER (Model XF-35 - P/N P01074-201) -

Recertify preserver every ten years after being placed in

service.

H350012 3. PROTECTIVE BREATHING EQUIPMENT (PBE) AVOX

SYSTEMS (P/N 802300-14) - Replace every ten years from

date of manufacture.

L. TEN-YEAR INITIAL AND FIVE-YEAR SUBSEQUENT

INTERVALS

H570008 1. WING-TO-FUSELAGE ATTACH BOLTS - Detail inspect for

corrosion, wear and any evidence of damage. Magnetic

particle inspect for cracks (Ref. Chapter 57-40-00).

M. TWELVE-YEAR INTERVALS

H262005 1. COCKPIT FIRE EXTINGUISHER - Hydrostatically test

cylinder.

H262006 2. CABIN FIRE EXTINGUISHER - Hydrostatically test cylinder.

SCHEDULED IFA-SPECIAL INSPECTIONS (Continued)

TASK

CODE DATE MECH INSP

05-20-01

Page 606

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

N. 2,400-HOUR INTERVALS

H550016 1. HORIZONTAL STABILIZER INTERNAL STRUCTURE

(Airplanes modified by Kit 128-6200) - Detail inspect for

cracks, corrosion, missing fasteners and evidence of

structural damage using either the radiographic (X-Ray) or

borescope inspection procedure (Ref. Chapter 55-10-00).

O. 3,000-AIR CONDITIONING OPERATING HOURS INTERVALS

H210037 1. DRIVE MOTOR - Perform overhaul of the drive motor per the

Chapter 21-00-12, Section 7.1.2 in the Component

Maintenance Manual, 128-590001-81 or subsequent.

P. 4,500-HOURS/3,000-LANDINGS INITIAL AND 1,400-HOURS/

1,400-LANDINGS SUBSEQUENT INTERVALS (RK-1 THRU

RK-23 WITHOUT KIT 128-8001 INSTALLED)

H322113

H322213

1. MAIN LANDING GEAR RETRACTION CYLINDER (P/N

45AS38515) - Perform Eddy current inspection of the

retraction cylinder mounting lug for evidence of cracks in

accordance with Chapter 20-80-03. Removal of the spherical

bearing is not required. Refer to Figure 601.

H322013 2. NOSE LANDING GEAR RETRACTION CYLINDER (P/N

45AS39503) - Perform Eddy current inspection of the

retraction cylinder mounting lug for evidence of cracks in

accordance with Chapter 20-80-03. Removal of the spherical

bearing is not required. Refer to Figure 602.

Q. 7,000-LANDINGS INTERVAL AND 200-LANDINGS

SUBSEQUENT INTERVALS (RK-1 THRU RK-352)

H531095 1. MAIN LANDING GEAR FITTING ASSEMBLY (P/N

45A33506) INSPECTION (RK-1 THRU RK-352) - Perform a

detail visual inspection and a borescope inspection. Refer to

the MAIN LANDING GEAR FITTINGS - INSPECTION/

CHECK, Chapter 53-40-00.

NOTE

Replacement of NAS1203 and NAS1204 bolts with HL21PB Hi-Lok

bolts in the Main Landing Gear Fitting Assembly is terminating action

for the 200 hour subsequent interval. Refer to Chapter 53-40-00,

Figure 601, Detail C, Bolts A and B.

SCHEDULED IFA-SPECIAL INSPECTIONS (Continued)

TASK

CODE DATE MECH INSP

Page 607

A2 Jan 01/12 05-20-01

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

Q. 7,000-LANDINGS INTERVAL AND 200-LANDINGS

SUBSEQUENT INTERVALS (RK-1 THRU RK-352)

(Continued)

H531096 2. MID FUSELAGE MAIN LANDING GEAR UPLOCK FITTING

(P/N 45A33480) INSPECTION (RK-1 THRU RK-604) -

Perform a detail visual inspection and a borescope inspection.

Refer to the MAIN LANDING GEAR FITTINGS -

INSPECTION/CHECK, Chapter 53-40-00.

NOTE

Replacement of the Mid Fusealge Main Landing Gear Uplock Fitting

P/N 45A33480 with P/N 128-430003 is terminating action for the 200

hour subsequent interval.

R. 7,200-HOUR INITIAL AND 2,400-HOURS SUBSEQUENT

INTERVALS

H550015 1. HORIZONTAL STABILIZER RIB INSPECTION (P/N

45A21112-5, 45A21113-5, 45A21101-11, 45A21116-5,

45A21117-5) - Perform radiographic (X-Ray) inspection of the

horizontal stabilizer rib assemblies in accordance with

Chapter 55-10-00. As an alternate means of inspection, a

borescope inspection may be performed in accordance with

Chapter 55-10-00.

S. 7,400-HOURS/5,000-LANDINGS INITIAL AND 1,400-HOURS/

1,400-LANDINGS SUBSEQUENT INTERVALS (RK-1 THRU

RK-23 WITH KIT 128-8001 INSTALLED; RK-24 AND AFTER)

H322114

H322214

1. MAIN LANDING GEAR RETRACTION CYLINDER (P/N

45AS38515) - Perform Eddy current inspection of the

retraction cylinder mounting lug for evidence of cracks in

accordance with Chapter 20-80-03. Removal of the spherical

bearing is not required. Refer to Figure 601.

H322014 2. NOSE LANDING GEAR RETRACTION CYLINDER (P/N

45AS39503) - Perform Eddy current inspection of the

retraction cylinder mounting lug for evidence of cracks in

accordance with Chapter 20-80-03. Removal of the spherical

bearing is not required. Refer to Figure 602.

T. 9,800-HOUR INTERVALS

H341176 1. AIRBORNE FLIGHT INFORMATION SYSTEM (AFIS)

WIRING (RK-483 and After - Optional) - Visually inspect for

signs of chafing, security and corrosion.

SCHEDULED IFA-SPECIAL INSPECTIONS (Continued)

TASK

CODE DATE MECH INSP

05-20-01

Page 608

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

U. 12,200-HOUR INTERVALS

H220001 1. COLLINS SERVO MOUNT SLIP CLUTCH - Test the Collins

servo mount slip clutches in the elevator, rudder and spoiler

servo mounts per the Rockwell-Collins Beechjet Avionics

System Manual (P/N 523-0775807) Section 5.2.2 SVO-85 ( )

Servo/SMT-85 ( )/-87 ( ) Servo Mount.

V. 12,200-HOUR INITIAL AND 3,600-HOUR SUBSEQUENT

INTERVALS

H341177 1. AIRBORNE FLIGHT INFORMATION SYSTEM (AFIS)

ANTENNA FUSELAGE FEED-THROUGH (FS 378.54 - lower

fuselage (RK-483 and After - Optional) - Detail inspect for

corrosion and wear. Using Eddy current method (with a

surface probe) inspect for cracks and any indication of

structural damage. Antenna removal is required (Ref. Chapter

34-59-00).

W. TIRE CHANGE- Accomplish at every tire change. Refer to the

Model MU-300/400/400A Component Maintenance Manual.

H3200NO 1. NOSE WHEEL

a. Inspect wheel for cracks and damage in accordance with

Chapter 32-46-12 in the Component Maintenance

Manual, 128-590001-81 or subsequent.

b. Clean and inspect wheel bearings and cones, lubricate

wheel bearings (Ref. Chapter 12-20-00).

c. Inspect axle, caps and spacers for corrosion and

condition.

H3200LH

H3200RH

2. MAIN WHEELS

a. Inspect wheel for cracks and damage in accordance with

Chapter 32-40-54 or 32-40-99 in the Component

Maintenance Manual, 128-590001-81 or subsequent.

b. Clean and inspect wheel bearings and cones, lubricate

wheel bearings (Ref. Chapter 12-20-00).

c. Check wheel brake disc drive keys for loose and missing

hardware.

d. Inspect axle, nut and spacers for corrosion and condition.

e. Perform HUBCAP INSPECTION (Ref. Chapter 32-40-

00).

SCHEDULED IFA-SPECIAL INSPECTIONS (Continued)

TASK

CODE DATE MECH INSP

Page 609

A2 Jan 01/12 05-20-01

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

MLG Retraction Actuator (P/N 45AS38515)

(RK-1 and After)

Figure 601

05-20-01

Page 610

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

NLG Retraction Actuator (P/N 45AS39503)

(RK-1 and After)

Figure 602

Page 601

A2 Jan 01/12 05-20-02

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

600600600

05-20-0

SCHEDULED IFA-A INSPECTIONS

PILOT'S COMPARTMENT

SCHEDULED IFA-A INSPECTIONS

TASK

CODE DATE MECH INSP

A. PILOT'S COMPARTMENT

H350005 1. PILOT'S AND COPILOT'S OXYGEN SYSTEM - Perform

FLIGHT CREW MASK - INSPECTION/CHECK (Ref. Chapter

35-11-00)

H350006 2. PROTECTIVE BREATHING EQUIPMENT (PBE) P/N 802300-

XX (If Installed) - Inspect in accordance with AVOX SYSTEMS

Instruction 89253.01 (Ref. Chapter 35 in the Component

Maintenance Manual, P/N 128-590001-81 or subsequent).

H270006 3. CONTROL COLUMN (Above Floor Panels)

a. Inspect for condition and freedom of movement.

b. Inspect wire harness on forward side of the control column

for damage and security.

H270047 4. CONTROL YOKE - Inspect for condition and freedom of

movement.

H270001 5. RUDDER PEDALS (Above Floor Panels) - Inspect for condition

and freedom of movement.

H250001 6. PILOT'S AND COPILOT'S SEATS

a. Inspect upholstery, safety belts and shoulder harness for

condition and proper operation of shoulder harness inertial

reels.

b. Inspect seat adjusting mechanisms for proper locking.

H250002 7. SMOKE GOGGLES - Inspect goggles and storage box for

condition.

H530004 8. CENTER PEDESTAL

a. Inspect thrust levers and thrust reversers for condition and

freedom of movement.

b. Inspect pedestal switches and components for condition.

H330006 9. COCKPIT ADVISORY, CAUTION AND WARNING LIGHTS -

Inspect all for condition and operation.

05-20-02

Page 602

Jan 01/12 A2

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

A. PILOT'S COMPARTMENT (Continued)

H340005 10. FLIGHT INFORMATION DISPLAYS AND INSTRUMENTS

a. Inspect all for condition.

b. Check oxygen and nitrogen operating pressures.

H120001 11. Lubricate items as specified in Chapter 12.

SCHEDULED IFA-A INSPECTIONS (Continued)

TASK

CODE DATE MECH INSP

Page 603

A2 Jan 01/12 05-20-02

MODEL 400/400A MAINTENANCE MANUAL SUPPLEMENT

CABIN SECTION

SCHEDULED IFA-A INSPECTIONS

TASK

CODE DATE MECH INSP

A. CABIN SECTION

H330001 1. CABIN INTERIOR LIGHTS - Inspect all for condition and

operation.

2. EMERGENCY LIGHTING SYSTEM

H330007 a. (RK-1 thru RK-109, except RK-98) - Move the EMER LT

switch to the TEST/ON position and ensure emergency

lighting illuminates. Return EMER LT switch to the OFF

position.

H330003 b. (RK-98, RK-110 and After) - Perform EMERGENCY

LIGHTING SYSTEM OPERATIONAL INSPECTION (Ref.

Chapter 33-51-00).

H350007 3. PORTABLE OXYGEN & MASK (If Installed) - Inspect for

condition and operating pressure.

H250004 4. PASSENGER AND TOILET SEAT

a. Inspect upholstery, safety belts and shoulder harness for

condition and proper operation of shoulder harness inertia

reels.

b. Inspect seat adjusting mechanisms for proper locking (toilet

seat exempt).

c. Inspect shoulder harness attachment post for worn or

missing grommet and proper engagement with seat belt.

d. Check toilet servicing.

H120002 5. Lubricate items as specified in Chapter 12.

05-20-02

Page 604

Jan 01/12 A2