Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ah 14526

Caricato da

Lucio Valderrama PeredaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ah 14526

Caricato da

Lucio Valderrama PeredaCopyright:

Formati disponibili

COMPONENT CODE:

30

PARTS & SERVICE NEWS

REF NO.

DATE

AH14526

April 23, 2014

Page 1 of 4

AH14526

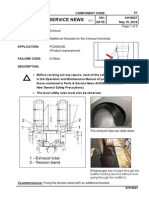

SUBJECT: Bolted Carbody

PURPOSE: Crack Inspection to Avoid Damages

APPLICATION: PC3000/6; PC4000/6; PC5500/6; PC8000/6

FAILURE CODE: 3020HA

DESCRIPTION:

:

Before carrying out any repairs, read all the safety instructions

in the Operation and Maintenance Manual of your shovel, and

those contained in Parts & Service News AH10509, (Release of

New General Safety Precautions).

The local safety rules must also be observed.

Excavator frames are of torsion-resisting design for a long service life.

Because of high dynamic stresses during operation, defects in material may occur.

That is why visual inspections have to be carried out at regular intervals, at least every half

year or every 3000 working hours.

When performed in time, these cracks can be mended and serious consequential damages

can be avoided.

1. Visual inspection of marked areas

2. Crack Inspection

3. Measures to be carried out when cracks are found

4. Drawing with the most stressed areas marked

(C)

Page 2 of 4

AH14526

For crack inspections, proceed as follows:

1. Visual inspection of marked areas

- Clean testing area to be grease-free.

- Carry out visual inspection for cracks very carefully.

2. Crack Inspection

In order to exactly determine cracks and their course, the test set,

Part No. 966 225, is available.

All testing means mentioned herein are contained in the above-mentioned test set.

Crack detection testing kit PN 966 225

No. PN Description

1 966 229 Permanent magnet

2 092 846 40 Magnetic powder

3 092 847 40 Cleaner, spray can, 500 ml

4 092 845 40 Contrasting agent

5 232 723 40 Universal box

Procedure:

- Remove paint in the area to be inspected, clean grease-free by means of cleaner.

- Spray on white contrast color so that surface is covered well, permit to dry.

- Apply permanent magnet in such a way that the presumed crack is between the

poles, check crosswise.

- Spray on magnetic-particle powder between the poles.

- Magnetize for at least 15 seconds, expect effect.

- Cracks become clearly visible as black lines.

The inspection along the crack should be repeated several

times, in order to avoid errors.

- Mark the cracks (trace).

Cracks in paint may indicate cracks in steel structure!

Page 3 of 4

AH14526

3. Measures to be carried out when cracks are found

(Refer also to the PSN AH08507a Repair welding procedure)

- If small cracks are detected, they can be removed by grinding to a depth of 2 mm.

Grind only as long as cracks do not go straight through.

Avoid notches from grinding.

- In case of deeper cracks, inform your local Komatsu Distributor and Komatsu

Field Service Manager for your region, in order to coordinate the further

procedure for welding repairs.

Info to your Komatsu Field Service Manager to include as much as possible:

- Illustration of corresponding attachment part showing course of crack

- Photos

- Copies of spare-parts catalogue sheets, with course of crack sketched in.

The more information about location and size of the crack, the better we can

detect the cause and the more efficiently the welding repair can be carried out

later on.

Page 4 of 4

AH14526

4. Drawing with the most stressed areas marked

We recommend carrying out the described crack inspection at these areas at regular

intervals, at least every half year or every 3000 working hours.

Potrebbero piacerti anche

- Parts & Service NewsDocumento4 pagineParts & Service NewsFernando Pérez SarriaNessuna valutazione finora

- AA00046C Partes & Servicios SM930E-4Documento9 pagineAA00046C Partes & Servicios SM930E-4Emmanuel Torres HerreraNessuna valutazione finora

- 3 - 05 Biela Motor L7044Documento13 pagine3 - 05 Biela Motor L7044Javier LeonidasNessuna valutazione finora

- AA01042A Fisura Horse CollarDocumento5 pagineAA01042A Fisura Horse CollarSebastiánRodrigoPérezHenríquezNessuna valutazione finora

- Bam 800 M800 RepairDocumento3 pagineBam 800 M800 Repairapi-3752216Nessuna valutazione finora

- NS-1-90. Dimensional InspectionDocumento9 pagineNS-1-90. Dimensional InspectionWHWENNessuna valutazione finora

- Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsDocumento4 pagineRepair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingskhuzafaNessuna valutazione finora

- Ai Hempadur 17630 EnglishDocumento5 pagineAi Hempadur 17630 EnglishLukman ZakariyahNessuna valutazione finora

- BVM Corporation Maintenance Manual: Casing Slips "CMSXL"Documento5 pagineBVM Corporation Maintenance Manual: Casing Slips "CMSXL"Ali mohammadNessuna valutazione finora

- A70 Chassis Collision Repair Manual PDFDocumento79 pagineA70 Chassis Collision Repair Manual PDFstevencychenNessuna valutazione finora

- Repair Procedures: Connection Field Repair (Refacing)Documento5 pagineRepair Procedures: Connection Field Repair (Refacing)islam atif100% (1)

- ISS-059 Inspection Guidlines HP HosesDocumento7 pagineISS-059 Inspection Guidlines HP HosesforajistuNessuna valutazione finora

- Bandsaw BS 350 SHI Semiautomatic - Hydraulic Instructions For UseDocumento60 pagineBandsaw BS 350 SHI Semiautomatic - Hydraulic Instructions For UseMilenko KraišnikNessuna valutazione finora

- Kce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Documento5 pagineKce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Alexandru NicolaNessuna valutazione finora

- Durashield 110 61Documento6 pagineDurashield 110 61huicholeNessuna valutazione finora

- Cga TB 2.1980Documento6 pagineCga TB 2.1980gabriela troncosoNessuna valutazione finora

- MYKAnchor HF66Documento2 pagineMYKAnchor HF66cekicdjNessuna valutazione finora

- API - 650 Check List Tank InspectionDocumento5 pagineAPI - 650 Check List Tank InspectionMijanur RahmanNessuna valutazione finora

- Magnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Documento5 pagineMagnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Dinesh GuptaNessuna valutazione finora

- Clock Spring Installation ManualDocumento8 pagineClock Spring Installation ManualacornejomNessuna valutazione finora

- Pump Casing RepairDocumento3 paginePump Casing RepairDedi ThamrinNessuna valutazione finora

- Guidelines On Inspection of Drill String Components - September 1998Documento25 pagineGuidelines On Inspection of Drill String Components - September 1998Slim.B100% (1)

- Weld Spec 2Documento3 pagineWeld Spec 2spstainless316Nessuna valutazione finora

- Guideline For Reusable Parts and Salvage Operations: Inspection of Crankshafts For CracksDocumento42 pagineGuideline For Reusable Parts and Salvage Operations: Inspection of Crankshafts For CracksPaul GustavoNessuna valutazione finora

- 9853 1124 01 Overhauling Instructions COP2160-2560-2160EX-2560EX PDFDocumento68 pagine9853 1124 01 Overhauling Instructions COP2160-2560-2160EX-2560EX PDFcoelhoclaudios100% (2)

- 9g V 09 PaintingDocumento15 pagine9g V 09 Paintingdiuska13100% (1)

- Fluid Tech-Info enDocumento17 pagineFluid Tech-Info enadhityaNessuna valutazione finora

- API 653 - ASME Section V - NDE Practice Questions - 68 TermsDocumento7 pagineAPI 653 - ASME Section V - NDE Practice Questions - 68 TermsSERFORTEC CIA. LTDA.Nessuna valutazione finora

- Document Transmittal: SAW-CWCO-TR149 15 January 2013Documento8 pagineDocument Transmittal: SAW-CWCO-TR149 15 January 2013Budi IndraNessuna valutazione finora

- Road Marking SpecsDocumento6 pagineRoad Marking SpecsAbdullah AboodiNessuna valutazione finora

- Maintenance of Enhanced Drawgear - CMI9901Documento7 pagineMaintenance of Enhanced Drawgear - CMI9901Dwijamani SinghaNessuna valutazione finora

- Painting Procedure For Jembatan AMMMAN (INDOTRANS)Documento6 paginePainting Procedure For Jembatan AMMMAN (INDOTRANS)widiNessuna valutazione finora

- Liquid Turbine Flowmeter User ManualDocumento16 pagineLiquid Turbine Flowmeter User ManualJorge RamosNessuna valutazione finora

- Ship Equipment Repair Work ProceduresDocumento22 pagineShip Equipment Repair Work Proceduresalfian2801Nessuna valutazione finora

- Cosasco Two-Inch System: CORROSION COUPONS (Alloy Specimens) & Coupon Holder AssembliesDocumento17 pagineCosasco Two-Inch System: CORROSION COUPONS (Alloy Specimens) & Coupon Holder AssembliesArifinNessuna valutazione finora

- Blasting Coating ProcedureDocumento61 pagineBlasting Coating ProcedureZohair Aftab100% (1)

- Cementing Tools: General RequirementsDocumento4 pagineCementing Tools: General Requirementsislam atifNessuna valutazione finora

- sl2023 745Documento2 paginesl2023 745iodinecoil02Nessuna valutazione finora

- Fabrication Inspection ProcedureDocumento11 pagineFabrication Inspection Procedurewill_herry100% (6)

- Industrial Training Report Diesel Locomotive Works Varanasi: Mechanical Engineering DepartmentDocumento19 pagineIndustrial Training Report Diesel Locomotive Works Varanasi: Mechanical Engineering DepartmentVeer PatelNessuna valutazione finora

- 01 Body Rear End Panel ReplacementDocumento5 pagine01 Body Rear End Panel ReplacementNicolaescu GabrielNessuna valutazione finora

- Mpi Procedure PLR and StructuresDocumento17 pagineMpi Procedure PLR and StructuresfajardojonathannahumNessuna valutazione finora

- ASTM A456-Large Crankshaft ForgingsDocumento4 pagineASTM A456-Large Crankshaft ForgingsMarisol VivianoNessuna valutazione finora

- Preventive Maintenance - PFDocumento6 paginePreventive Maintenance - PFAnurag SrivastavaNessuna valutazione finora

- Product Catalogue 2015Documento203 pagineProduct Catalogue 2015Burghelea Ovidiu-GabrielNessuna valutazione finora

- Method Statement For GRP Pipe InstallationDocumento8 pagineMethod Statement For GRP Pipe Installationdj_holo100% (1)

- MS Tong MaintenanceDocumento7 pagineMS Tong MaintenanceBahman MatouriNessuna valutazione finora

- GMW15282 CorrosionUndercutting Scribe CreepbacDocumento7 pagineGMW15282 CorrosionUndercutting Scribe CreepbacRicardo F. SNessuna valutazione finora

- Sop Welding RevisiDocumento12 pagineSop Welding RevisifandyNessuna valutazione finora

- MN - Specs - 2356 - Chip - Seal 2007 - SP2005Documento5 pagineMN - Specs - 2356 - Chip - Seal 2007 - SP2005omkar navagireNessuna valutazione finora

- 53 004Documento16 pagine53 004Iain McCormackNessuna valutazione finora

- GMW - 4707-2002 Corrosion Protective Coating Zinc Plating OrganicDocumento3 pagineGMW - 4707-2002 Corrosion Protective Coating Zinc Plating Organichorse888Nessuna valutazione finora

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentDa EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentValutazione: 4.5 su 5 stelle4.5/5 (3)

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsDa EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Prompting Science and Engineering Students in Practical TrigonometryDa EverandPrompting Science and Engineering Students in Practical TrigonometryNessuna valutazione finora

- Fam PC4000 08205 PDFDocumento335 pagineFam PC4000 08205 PDFLucio Valderrama Pereda100% (1)

- Fampc4000 05Documento94 pagineFampc4000 05Lucio Valderrama PeredaNessuna valutazione finora

- Installation Manual: BT13019 Introduction & Models Page 1 of 2Documento5 pagineInstallation Manual: BT13019 Introduction & Models Page 1 of 2Lucio Valderrama PeredaNessuna valutazione finora

- Parts & Service News: Component Code: D5 Ref No. Date AH07513b March 19, 2014Documento13 pagineParts & Service News: Component Code: D5 Ref No. Date AH07513b March 19, 2014Lucio Valderrama PeredaNessuna valutazione finora

- Ah 14510Documento2 pagineAh 14510Lucio Valderrama PeredaNessuna valutazione finora

- Ah 14520Documento1 paginaAh 14520Lucio Valderrama PeredaNessuna valutazione finora

- Parts & Service News: Page 1 of 3 Exhaust Brackets For The Exhaust Manifolds PC4000/6D (Product Improvement)Documento3 pagineParts & Service News: Page 1 of 3 Exhaust Brackets For The Exhaust Manifolds PC4000/6D (Product Improvement)Lucio Valderrama PeredaNessuna valutazione finora

- AH10514CDocumento42 pagineAH10514CLucio Valderrama PeredaNessuna valutazione finora

- Ah 14529Documento2 pagineAh 14529Lucio Valderrama PeredaNessuna valutazione finora

- Ah 14514Documento4 pagineAh 14514Lucio Valderrama PeredaNessuna valutazione finora

- Wa1200-6 Eess019800 1010Documento16 pagineWa1200-6 Eess019800 1010Benjamin Valenzuela PolancoNessuna valutazione finora

- 1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Documento2 pagine1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Mario FloresNessuna valutazione finora

- Raksha Mantralaya Ministry of DefenceDocumento16 pagineRaksha Mantralaya Ministry of Defencesubhasmita sahuNessuna valutazione finora

- Adaptive Leadership: Leadership: Theory and PracticeDocumento14 pagineAdaptive Leadership: Leadership: Theory and PracticeJose Daniel Quintero100% (1)

- Paul Spicker - The Welfare State A General TheoryDocumento162 paginePaul Spicker - The Welfare State A General TheoryTista ArumNessuna valutazione finora

- IMDSI22Documento82 pagineIMDSI22Dang JinlongNessuna valutazione finora

- BSH 7005-15Documento129 pagineBSH 7005-15Mark InnesNessuna valutazione finora

- Brahms Symphony No 4Documento2 pagineBrahms Symphony No 4KlausNessuna valutazione finora

- Microfinance Ass 1Documento15 pagineMicrofinance Ass 1Willard MusengeyiNessuna valutazione finora

- Week - 2 Lab - 1 - Part I Lab Aim: Basic Programming Concepts, Python InstallationDocumento13 pagineWeek - 2 Lab - 1 - Part I Lab Aim: Basic Programming Concepts, Python InstallationSahil Shah100% (1)

- DS Important QuestionsDocumento15 pagineDS Important QuestionsLavanya JNessuna valutazione finora

- Nescom Test For AM (Electrical) ImpDocumento5 pagineNescom Test For AM (Electrical) Impشاہد یونسNessuna valutazione finora

- The Comma Rules Conversion 15 SlidesDocumento15 pagineThe Comma Rules Conversion 15 SlidesToh Choon HongNessuna valutazione finora

- Presenters: Horace M. Estrella Jay Mart A. Lazana Princess Camille R. HipolitoDocumento23 paginePresenters: Horace M. Estrella Jay Mart A. Lazana Princess Camille R. HipolitoHorace EstrellaNessuna valutazione finora

- Twin PregnancyDocumento73 pagineTwin Pregnancykrishna mandalNessuna valutazione finora

- All India Civil Services Coaching Centre, Chennai - 28Documento4 pagineAll India Civil Services Coaching Centre, Chennai - 28prakashNessuna valutazione finora

- Jpedal ManualDocumento20 pagineJpedal ManualDamián DávilaNessuna valutazione finora

- Benefits and Limitations of BEPDocumento2 pagineBenefits and Limitations of BEPAnishaAppuNessuna valutazione finora

- ST3 ManualDocumento48 pagineST3 ManualRon FosterNessuna valutazione finora

- MDI - Good Fellas - ScriptDocumento20 pagineMDI - Good Fellas - ScriptRahulSamaddarNessuna valutazione finora

- A Literary Nightmare, by Mark Twain (1876)Documento5 pagineA Literary Nightmare, by Mark Twain (1876)skanzeniNessuna valutazione finora

- Albert Roussel, Paul LandormyDocumento18 pagineAlbert Roussel, Paul Landormymmarriuss7Nessuna valutazione finora

- Analytics Designer - Comment Deletion - SAP CommunityDocumento6 pagineAnalytics Designer - Comment Deletion - SAP CommunityARPITA BISWASNessuna valutazione finora

- Days Papers 2001Documento341 pagineDays Papers 2001jorgefeitoza_hotmailNessuna valutazione finora

- Final Self Hypnosis Paperback For PrintDocumento150 pagineFinal Self Hypnosis Paperback For PrintRic Painter100% (12)

- Concrete Specification (BS8500)Documento3 pagineConcrete Specification (BS8500)teh100% (1)

- Etextbook PDF For Pharmacology Connections To Nursing Practice 3rd EditionDocumento61 pagineEtextbook PDF For Pharmacology Connections To Nursing Practice 3rd Editionkarla.woodruff22798% (45)

- 9881 enDocumento345 pagine9881 enSaid BenNessuna valutazione finora

- Sheltered 2 Item Recycle ListDocumento5 pagineSheltered 2 Item Recycle ListRachel GNessuna valutazione finora

- Green Dot ExtractDocumento25 pagineGreen Dot ExtractAllen & UnwinNessuna valutazione finora

- Drager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementDocumento24 pagineDrager Narkomed 6400 Field Service Procedure Software Version 4.02 EnhancementAmirNessuna valutazione finora