Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Glulam Connection Details

Caricato da

Khairul Salleh BaharudinCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Glulam Connection Details

Caricato da

Khairul Salleh BaharudinCopyright:

Formati disponibili

T E C H N I C A L N O T E

G L U L A M

CONNECTION DETAILS

ENGINEERED WOOD SYSTEMS

2

2

0

0

2

E

N

G

I

N

E

E

R

E

D

W

O

O

D

S

Y

S

T

E

M

S

A

L

L

R

I

G

H

T

S

R

E

S

E

R

V

E

D

.

A

N

Y

C

O

P

Y

I

N

G

,

M

O

D

I

F

I

C

A

T

I

O

N

,

D

I

S

T

R

I

B

U

T

I

O

N

O

R

O

T

H

E

R

U

S

E

O

F

T

H

I

S

P

U

B

L

I

C

A

T

I

O

N

O

T

H

E

R

T

H

A

N

A

S

E

X

P

R

E

S

S

L

Y

A

U

T

H

O

R

I

Z

E

D

B

Y

E

W

S

I

S

P

R

O

H

I

B

I

T

E

D

B

Y

T

H

E

U

.

S

.

C

O

P

Y

R

I

G

H

T

L

A

W

S

.

GLULAM

CONNECTION

DETAILS

Introduction

Proper connection details are important

to the structural performance and ser-

viceability of any timber-framed structure.

While this is true for solid sawn as well

as glued laminated (glulam) timbers, the

larger sizes and longer spans made possi-

ble with glulam components make the

proper detailing of connections even

more critical. Careful consideration of

moisture-related expansion and contrac-

tion characteristics of wood is essential in

detailing glulam connections to prevent

inducing tension perpendicular-to-grain

stresses. Connections must be designed

to transfer design loads to and from the

structural glulam member without caus-

ing localized stress concentrations which

may initiate failure at the connection.

Its also important to design connections

to isolate all wood members from poten-

tial sources of excessive moisture. In

addition to accentuating any connection

problems related to expansion or con-

traction of the wood due to moisture

cycling, equilibrium moisture content in

excess of approximately 20 percent may

promote the growth of decay-causing

organisms in untreated wood.

Structural Effects of Shrinkage

and Improper Detailing

Wood expands and contracts as a result

of changes in its internal moisture con-

tent. While expansion in the direction

parallel to grain in a wood member is

minimal, dimensional change in the

direction perpendicular to grain can be

significant and must be considered in

connection design and detailing. A

24-inch-deep beam can decrease in

depth through shrinkage by approxi-

mately 1/8 inch as it changes from 12

to 8 percent in equilibrium moisture

content. In designing connections for

glulam members it is important to design

and detail the connection such that the

members shrinkage is not restrained. If

restrained, shrinkage of the beam can

cause tension perpendicular-to-grain

stresses to develop in the member at the

connection. If these stresses exceed the

capacity of the member, they may cause

the glulam to split parallel to the grain.

Once a tension-splitting failure has

occurred in a member, its shear and

bending capacity are greatly reduced.

In addition to the moisture-induced

tension perpendicular-to-grain failures

discussed above, similar failures can

result from a number of different

incorrect connection design details.

Improper beam notching, eccentric (out

of plane) loading of truss connections

and loading beams from the tension

side can induce internal moments and

tension perpendicular-to-grain stresses.

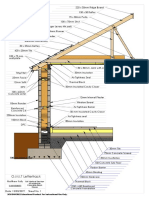

Effects of Moisture Accumulation

As most connections occur at the ends

of beams where the wood end-grain is

exposed, it is critical that these connec-

tions be designed to prevent moisture

accumulation. This can usually be

accomplished by detailing drain holes

or slots in box-type connectors and by

maintaining a gap of at least 1/2 inch

between the wood and concrete or

masonry construction. Because most

connections require the exposure of end

grain due to fastener penetration, even

those connections that occur away from

beam ends must be considered potential

decay locations. Field studies have

shown that any metal connectors or parts

of connectors that are placed in the cold

zone of the building (that area outside

of the building insulation envelope) can

become condensation points for ambient

moisture. This moisture has ready access

to the inside of the beam through

fasteners and exposed end grain. A few

examples of these kinds of fasteners are

saddle-type hangers, cantilever beam

hinges and beam-to-column connectors.

3

Connection Examples

The following pages contain figures that

illustrate various connection types. These

illustrations show correct connection

details along with examples of common

incorrect details and a discussion of the

failures that may occur due to the incor-

rect detailing. While the figures are not

all inclusive, they are provided as a tool

to illustrate the principles discussed in

the preceding section. Reviewing the

examples with these principles in mind

will enable the designer to more easily

detail proper connections.

While the details in this Technical Note

address serviceability concerns associated

with glulam connection detailing, it is

important to emphasize that all connec-

tion details must effectively transfer the

design loads imposed on the structure

and that all designs be in accordance

with accepted engineering practice.

There are a number of manufacturers of

pre-engineered metal connectors which

have been specifically designed for use in

glulam framing and it is recommended

that these connectors be used whenever

possible.

Summary

The details in this publication have been

provided to illustrate both the correct

and incorrect manner to make a connec-

tion involving glued laminated timbers.

These details emphasize seven basic

principles which, if followed, will lead to

efficient, durable and structurally sound

connections. These principles are:

1. Transfer loads in compression bearing

whenever possible.

2. Allow for dimensional changes in

the glulam due to potential in-service

moisture cycling.

3. Avoid the use of details which induce

tension perpendicular-to-grain stresses

in the member.

4. Avoid moisture entrapment at

connections.

5. Do not place the glulam in direct

contact with masonry or concrete.

6. Avoid eccentricity in joint details.

7. Minimize exposure of end grain.

2002 APA - The Engineered Wood Association

4

Similar to notching at beam ends. Splitting

may result from rapid drying due to exposed

end grain which may, in turn, induce tension

perpendicular-to-grain stresses and reduce

shear strength.

Similar to notching at beam ends. Can

cause splitting at inside corner due to shear

stress concentrations and induced tension

perpendicular-to-grain stresses.

Split

Split

Correct Incorrect Discussion

FIGURE 1

BEAM-TO-BEARING CONNECTIONS

2002 APA - The Engineered Wood Association

5

No bolt Bolt Split

1/2" minimum air

space shall be pro-

vided between wood

and masonry surface.

1/2" minimum air

space shall be

provided between

wood and

masonry surface.

Notching at ends of beam can cause splitting at

inside corner due to shear stress concentrations

and induced tension perpendicular-to-grain

stresses. A notch at the end of a glulam beam

should never exceed 1/10 of beam depth and

should be checked by the notched-beam formulas.

When beam is attached at the base as well as at

the lateral restraint clip at the top, shrinkage of the

beam can cause splitting at the top connection as

loads are transferred from the bearing seat to the

bolt. Splitting can also occur at this location if top

restraint doesnt allow the beam end to rotate as

the beam deflects under load.

No bolt Bolt Split

FIGURE 2

BEAM-TO-BEARING CONNECTIONS

Correct Incorrect Discussion

Split

2002 APA - The Engineered Wood Association

6

Clip angles

Clip angles with long rows of fasteners can cause

splits to form in both beam and girder shown

above due to tension perpendicular-to-grain

stresses induced at the bolts due to beam shrink-

age. Use a hanger with bearing seat as shown.

Hanger with

bearing seat

Hanger with

bearing seat

Splits

Splits

Side plates on saddle hanger with long rows

of fasteners can cause splits to form in beam

as shown due to beam shrinkage lifting beam

off of bearing plate and transferring the loads

to the bolts.

Correct

Incorrect Discussion

FIGURE 3

BEAM-TO-BEAM CONNECTION

2002 APA - The Engineered Wood Association

7

Bolts

Bolts

Nails

Nails

Split

Split

Shrinkage of supported beam causes bearing load

to transfer from beam saddle to bolts. This can

cause splitting of beam.

Shrinkage of supported beam causes bearing load

to transfer from beam saddle to nail group. This

can cause splitting of beam.

Correct Incorrect Discussion

FIGURE 4

BEAM-TO-BEAM CONNECTION

Correct Incorrect Discussion

FIGURE 5

BEAM-TO-BEAM CONNECTION

Application of load via fasteners below the neutral

axis can cause a tension-perpendicular-to-grain

failure in the beam. Location of majority of fasteners

above neutral axis or use of top-mounted hanger

will minimize the possibility of splitting of the beam.

Note that when face-mounted hangers are used,

oversized (in depth) hangers may be required to

place majority of fasteners above neutral axis.

Majority of fasteners

above neutral axis

of beam

Oversized (in depth) hanger

Majority of fasteners

below neutral axis

Splits

2002 APA - The Engineered Wood Association

8

Correct Incorrect Discussion

FIGURE 6

BEAM-TO-BEARING CONNECTION FIRE CUT

Deflection of square end-cut beams during a fire

can cause structural damage to bearing wall.

While such a failure is unlikely due to the excellent

performance of heavy timber construction during

fires, such detailing is prudent.

Concealed fish plate with long row of fasteners

can cause splits to form in both beam and girder

as shown above. Use a fish plate with bearing seat

as shown to the left.

Correct Incorrect Discussion

FIGURE 7

BEAM-TO-BEAM CONNECTIONS SEMI-CONCEALED USING FISH PLATES

2002 APA - The Engineered Wood Association

9

Correct Incorrect Discussion

FIGURE 8

HEAVY CONCENTRATED LOADS SUSPENDED FROM BEAM

Heavy concentrated loads such as heating and air

conditioning units, crane rails or main framing

members suspended from the bottom of beams

induce tension perpendicular-to-grain stresses and

may cause splits as shown.

This is not intended to apply to light loads such as

from 2x joists attached to the main beam with

light gauge nail-on metal hangers.

Splits

Shown with no slotted holes for use as a tension

tie. Design must insure no excessive rotation of

beams under load.

If used as a lateral support plate only, slotted

holes may be used with no further restrictions on

beam rotation required.

Splits

A notch in the top of a continuous beam over a

center support occurs in the tension zone of the

beam, greatly reducing its capacity. Design as two

simply supported beams if top notch is required.

Correct Incorrect Discussion

FIGURE 9

NOTCH IN BEAM OVER COLUMN

2002 APA - The Engineered Wood Association

10

OR

The relative vertical positioning of the side tabs

shown in this detail is very important to minimize

the possibility of splitting along the axis of these

tabs due to beam shrinkage.

Tension tie not

connected to

hanger

An integral tension-tie connection can cause

tension perpendicular-to-grain stress to develop

due to beam shrinkage. This can happen regard-

less of the location of the integral tension tie

connector. If a tension connection is required, a

separate connector may be used as shown in the

figure to the left. This tie is not welded to the beam

hanger.

Correct Incorrect Discussion

FIGURE 10

CANTILEVER BEAM CONNECTION INDEPENDENT TENSION TIE

Split

Split

An integral tension tie can be used if holes in tie

are vertically slotted and tie attachment bolts are

placed as shown to allow motion of bolt in slot due

to shrinkage of timber elements. If movement is

not allowed at this location, tension perpendicular-

to-grain stresses may develop in both members

and cause splitting.

Tension tie

welded to

connector

Note bolt position in

slot in welded

connection

Split

Correct Incorrect Discussion

FIGURE 11

CANTILEVER BEAM CONNECTION WELDED TIE TENSION

Split

2002 APA - The Engineered Wood Association

11

Deep splice plates applied to both sides can cause

splitting of both members if members shrink.

Sideplates resist this shrinkage and may induce

tension perpendicular-to-grain stresses which may

in turn cause splits.

Splits

Column

Column

Correct Incorrect Discussion

FIGURE 12

CANTILEVER BEAM CONNECTION NO TENSION TIE

With side tabs inverted, glulam beam shrinkage

shifts load from hanger seats to side tabs. This is

likely to induce tension perpendicular-to-grain

stresses which can lead to the development of

splits and beam failure.

Splits

Hanger seats

Side tabs

Correct Incorrect Discussion

FIGURE 13

CANTILEVER BEAM CONNECTION NO TENSION TIE

2002 APA - The Engineered Wood Association

12

Rotation of the beams under loading can cause

splitting at the tension tie plate unless slotted.

If beam shrinks, bearing load may be transferred

to bolts. This can cause splitting of beam. This

detail also restrains beam rotation due to deflec-

tion under loading which can also cause splitting.

Lateral support plate slot holes to prevent positive

moment from forming over supports

Splits

Splits

Correct Incorrect Discussion

FIGURE 14

BEAM TO COLUMN U-BRACKET WOOD OR PIPE COLUMN

2002 APA - The Engineered Wood Association

13

Shrinkage or beam rotation under loading can cause

splitting of the glulam members and/or buckling

of T-bracket

Splits

Optional lateral support plate slot holes to prevent

positive moment from forming over support.

Correct Incorrect Discussion

FIGURE 15

BEAM TO COLUMN T-BRACKET

Splitting may occur due to beam rotation as beam

deflects under load.

Splits

Holes

slotted

Correct Incorrect Discussion

FIGURE 16

BEAM TO COLUMN WITH TOP LATERAL SUPPORT PLATE

Steel bearing plate Untreated wood in contact with concrete is subject

to decay.

Correct Incorrect Discussion

FIGURE 17

WOOD COLUMN TO CONCRETE BASE

2002 APA - The Engineered Wood Association

14

Corners rounded on beam

Square corners on beam

Corners of beams resting in bent metal hangers

should be eased to provide full bearing. If not

eased, corners of beam may crush, reducing

bearing capacity of beam and possibly causing

beam settlement.

Crushing

Correct Incorrect Discussion

FIGURE 18

BEAM IN BENT HANGER

Steel arch shoe must be provided with drain slot to

minimize moisture buildup which could result in

decay. Interior bolts must be kept close together to

prevent splitting if shrinkage occurs.

Steel shoe

Drain slot full width

of shoe

Decay

Splitting

Steel shoe No drain slot

Correct Incorrect Discussion

FIGURE 19

GLULAM ARCH TO FOUNDATION

2002 APA - The Engineered Wood Association

15

Correct Incorrect Discussion

FIGURE 20

TRUSS CONNECTORS

Fixed-angle gusset plate does not let members

rotate under load. This may induce moments in

ends of members which can cause splitting of webs

at bolt locations.

Longitudinal axes of all three members do not

intersect. This can induce shear, moment and

tension perpendicular-to-grain stresses. A combi-

nation of the above stresses may induce a failure

at the joint.

Split

Split

2002 APA - The Engineered Wood Association

ENGINEERED WOOD SYSTEMS

We have field representatives in

most major U.S. cities and in Canada who

can help answer questions involving APA

and APA EWS trademarked products. For

additional assistance in specifying engineered

wood products or systems, contact us:

APA THE ENGINEERED

WOOD ASSOCIATION

HEADQUARTERS

7011 So. 19th St.

I

P.O. Box 11700

Tacoma, Washington 98411-0700

(253) 565-6600

I

Fax: (253) 565-7265

(International Offices:

Bournemouth, United Kingdom;

Mexico City, Mexico; Tokyo, Japan.)

PRODUCT SUPPORT HELP DESK

(253) 620-7400

E-mail Address: help@apawood.org

The product use recommendations in this

publication are based on the continuing pro-

grams of l aboratory testi ng, product

research, and comprehensive field experi-

ence of Engineered Wood Systems. However,

because EWS has no control over quality of

workmanship or the conditions under which

engineered wood products are used, it can-

not accept responsibility for product perfor-

mance or designs as actually constructed.

Because engineered wood product perfor-

mance requirements vary geographically,

consult your local architect, engineer or

design professional to assure compliance

with code, construction, and performance

requirements.

Form No. EWS T300E

Revised November 2002/0100

www.apawood.org

@

W

e

b

Addre

s

s

:

2002 APA - The Engineered Wood Association

Potrebbero piacerti anche

- Detailing StairsDocumento7 pagineDetailing StairsSelbi CeylanNessuna valutazione finora

- Structural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteDa EverandStructural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteNessuna valutazione finora

- Glu Lam Span TablesDocumento42 pagineGlu Lam Span TablesTuroyNessuna valutazione finora

- Abbreviation in ArchitectureDocumento2 pagineAbbreviation in ArchitectureThai NguyenNessuna valutazione finora

- Structural Joints in GlulamDocumento8 pagineStructural Joints in Glulamziggo88100% (1)

- American Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsDocumento32 pagineAmerican Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsMohammad Humayun KabirNessuna valutazione finora

- Tension Structure Connection Details Fabric ArchitectureDocumento10 pagineTension Structure Connection Details Fabric ArchitecturesofiakamranNessuna valutazione finora

- Construction Details Kalzip Roof SystemsDocumento87 pagineConstruction Details Kalzip Roof SystemsSudhakar KrishnamurthyNessuna valutazione finora

- 1 Residential - Construction - DetailsDocumento308 pagine1 Residential - Construction - DetailssamaaNessuna valutazione finora

- Construction DetailsDocumento56 pagineConstruction Detailsasingh400Nessuna valutazione finora

- Splices and Other Connections in BridgesDocumento10 pagineSplices and Other Connections in BridgesPankaj_Taneja_9684Nessuna valutazione finora

- Walnut Creek DrawingsDocumento11 pagineWalnut Creek DrawingsariNessuna valutazione finora

- Tehnologia Posi StrutDocumento35 pagineTehnologia Posi Strutdanut_docNessuna valutazione finora

- Truss ManualDocumento10 pagineTruss ManualRiyaz SiddiqueNessuna valutazione finora

- Timber Frame Junction DetailsDocumento28 pagineTimber Frame Junction DetailshemendraengNessuna valutazione finora

- Steel StaircaseDocumento24 pagineSteel StaircaseKanak Yadav100% (1)

- Screws Design Guide VU 1.1 PDFDocumento52 pagineScrews Design Guide VU 1.1 PDFLoma100% (1)

- A4-20 - Roof DetailsDocumento1 paginaA4-20 - Roof DetailsBleriNessuna valutazione finora

- En Downloads Brochures TexlonHSP ETFE Brochure enDocumento4 pagineEn Downloads Brochures TexlonHSP ETFE Brochure ennubis_zionNessuna valutazione finora

- Glulam Construction and Connection DetailsDocumento7 pagineGlulam Construction and Connection DetailsNiceman NatiqiNessuna valutazione finora

- Portal Frames Final - 2Documento19 paginePortal Frames Final - 2Ar Vivek KareliaNessuna valutazione finora

- Glulam Wood BeamsDocumento37 pagineGlulam Wood Beamsu16sr6Nessuna valutazione finora

- Truss Solutions For Curved RoofsDocumento3 pagineTruss Solutions For Curved RoofszamaxxNessuna valutazione finora

- Construction Document Sheet Numbers and Sheet OrderDocumento4 pagineConstruction Document Sheet Numbers and Sheet OrderAnnisa SyahraniNessuna valutazione finora

- Wall Details PDFDocumento3 pagineWall Details PDFBharathVenkatachalam0% (1)

- Reporters: Clemente, John Andrei de Pedro, John Paul Fajardo, Xandra Ale Soriano, AlgernonDocumento19 pagineReporters: Clemente, John Andrei de Pedro, John Paul Fajardo, Xandra Ale Soriano, AlgernonJogz de PedroNessuna valutazione finora

- Glulam Handbook 02Documento111 pagineGlulam Handbook 02Mirela Enache100% (1)

- EnerSIP Construction ManualDocumento53 pagineEnerSIP Construction ManualIvan Klyuchka100% (2)

- Glulam Connection Detail PDFDocumento19 pagineGlulam Connection Detail PDFAbdurrahman CinarNessuna valutazione finora

- Diaphragm Action and Design - SpringerDocumento3 pagineDiaphragm Action and Design - SpringerGuillermo Agustín Yáñez QuezadaNessuna valutazione finora

- TBA 09 Detailing of Clay MasonryDocumento42 pagineTBA 09 Detailing of Clay MasonryHenderson CheungNessuna valutazione finora

- Typical Timber Construction DetailsDocumento13 pagineTypical Timber Construction DetailsPanagiotis AnagnostopoulosNessuna valutazione finora

- ARCH 1301 - Design Sectional DetailsDocumento1 paginaARCH 1301 - Design Sectional DetailsKainaaz F. VariavaNessuna valutazione finora

- Facade ConstructionDocumento16 pagineFacade ConstructionJaskirat100% (1)

- Structural Glued-Laminated Timber (40pag)Documento40 pagineStructural Glued-Laminated Timber (40pag)pawkom100% (1)

- Uk Truss BrochureDocumento104 pagineUk Truss BrochureJFAFPNessuna valutazione finora

- Integrated Buildings: The Systems Basis of ArchitectureDa EverandIntegrated Buildings: The Systems Basis of ArchitectureValutazione: 5 su 5 stelle5/5 (1)

- Flat Roof 1Documento10 pagineFlat Roof 1agent206Nessuna valutazione finora

- Balcony Railing DetailDocumento1 paginaBalcony Railing DetailItika AtriNessuna valutazione finora

- Floor and Roof Connections To Masonry WallsDocumento4 pagineFloor and Roof Connections To Masonry WallsChris FindlayNessuna valutazione finora

- WoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 2 PDFDocumento4 pagineWoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 2 PDFtdegrobertNessuna valutazione finora

- Timber FloorsDocumento30 pagineTimber FloorsGlistering DharNessuna valutazione finora

- Typical Connections For HollowSectionsDocumento11 pagineTypical Connections For HollowSectionsMihai MoldovanNessuna valutazione finora

- Layers of A Floor - Anatomy, and Parts (Illustrated)Documento8 pagineLayers of A Floor - Anatomy, and Parts (Illustrated)Melaine A. FranciscoNessuna valutazione finora

- Engineered TimberDocumento14 pagineEngineered TimberNaar Muhendislik100% (1)

- Rheinzink Roof Covering SystemsDocumento16 pagineRheinzink Roof Covering Systemspablo_658Nessuna valutazione finora

- Glulam - Service Class 1Documento3 pagineGlulam - Service Class 1ikanyu79Nessuna valutazione finora

- Evolution of EtfeDocumento4 pagineEvolution of EtfeMonika SadhaNessuna valutazione finora

- Appendix EDocumento7 pagineAppendix EfahimehrezvaniNessuna valutazione finora

- Passive Block Foundation DrawingDocumento1 paginaPassive Block Foundation Drawingapi-426990805100% (1)

- WoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFDocumento4 pagineWoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFtdegrobertNessuna valutazione finora

- Conecciones Madera Laminada Apa Feb 2007 Conexiones Madera Laminada BibliotecaDocumento21 pagineConecciones Madera Laminada Apa Feb 2007 Conexiones Madera Laminada BibliotecaamondacaNessuna valutazione finora

- 11.1.1 Connections in BuildingsDocumento12 pagine11.1.1 Connections in BuildingsNicoreac Monica PaulaNessuna valutazione finora

- Or Less: How To Determine The Best Connections For Steel Joists and Metal DeckDocumento4 pagineOr Less: How To Determine The Best Connections For Steel Joists and Metal DeckMinh Tâm TrầnNessuna valutazione finora

- Reinforcement Detailing in Concrete StructuresDocumento6 pagineReinforcement Detailing in Concrete StructurescherogonyaNessuna valutazione finora

- ConnectionsDocumento17 pagineConnectionsAlexandru OlaruNessuna valutazione finora

- Tech Sheet: Root Causes and Guidelines To Promote Optimized Fastener PerformanceDocumento9 pagineTech Sheet: Root Causes and Guidelines To Promote Optimized Fastener PerformanceFarzadNessuna valutazione finora

- The Constructable Structure in Steel: F. Maatje, ICCS BV, The Netherlands H.G.A. Evers, ICCS BV, The NetherlandsDocumento10 pagineThe Constructable Structure in Steel: F. Maatje, ICCS BV, The Netherlands H.G.A. Evers, ICCS BV, The NetherlandsTsiry Tsilavo RajaonaryNessuna valutazione finora