Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

The Performance of Pretensioned Prestressed Concrete Beams Made With Lightweight Concrete

Caricato da

Khairul Salleh Baharudin0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

57 visualizzazioni10 pagineRC

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoRC

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

57 visualizzazioni10 pagineThe Performance of Pretensioned Prestressed Concrete Beams Made With Lightweight Concrete

Caricato da

Khairul Salleh BaharudinRC

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 10

THE PERFORMANCE OF PRETENSIONED

PRESTRESSED CONCRETE BEAMS MADE WITH

LIGHTWEIGHT CONCRETE

Wahid Omar, Ph.D

Roslli Noor Mohamed, MSc

Department of Structure & Material

Faculty of Civil Engineering

Universiti Teknologi Malaysia

81310 UTM Skudai

ABSTRACT

A study on the behaviour of prestressed concrete beams made from clinker

aggregate has been carried out at the Faculty of Civil Engineering, UTM. In this

paper, the performance of prestressed lightweight concrete beam under two point

load is discussed and comparisons are made with normal weight prestressed

concrete beam. The clinker is incorporated into the concrete as a direct

replacement for both fine and coarse aggregates at 100% replacement level. The

use of clinker lightweight concrete was found to save the amount of the total dead

load up to 18.8%. The test results show that lightweight concrete using clinker

exhibit an almost similar pattern in cracking behaviour and failure modes. The

test results show that the prestressed lightweight concrete beams can resist

loading up to 90% of the normal prestressed concrete beams. The study also

shows that clinker lightweight concrete exhibit good performance and is suitable

to be used in prestressed concrete beam.

Keywords: palm oil clinker lightweight concrete, lightweight aggregate,

prestressed concrete beam, mix design, cracking, failure

INTRODUCTION

Malaysia is one of the premier manufacturers of palm oil. Every palm oil mill

produces a waste by-product, known as clinker. Clinker was found to be suitable to

replace normal gravel aggregate in concrete mixture [1]. Concrete mixture

containing clinker as aggregates can be classified as lightweight aggregate concrete

J URNAL KEJ URUTERAAN AWAM (J OURNAL OF CIVIL ENGINEERING) Vol.14 No. 1 2002

due to its lower density. The British Standard, BS 8110 : Part 2 : 1985 classified

lightweight concrete as concrete having density of 2000 kg/m

3

or less [2].

According to RILEMs functional classification of lightweight concrete, structural

lightweight concrete is defined as having oven dry-density of less than 2000 kg/m

3

and compressive strength more than 15 N/mm

2

[3].

In the United States and Europe, lightweight aggregate concrete has been used as

construction material, replacing the normal dense aggregate since in the late

nineteenth century [4]. It has been used in structural concrete for many years and

in many cases purely due to economic considerations. The most obvious

characteristics of lightweight aggregate concrete is of course its density which is

always considerably less than normal concrete [4]. For the same crushing

strength, the density of concrete made with such lightweight aggregate can be as

much as one-third lower than that of normal concrete made with sand and gravel

or crushed rock aggregates [5].

Clinker has been used as an aggregate in concrete mixture, replacing the normal

dense aggregate in Britain for more than 90 years and it is still an important

aggregate in terms of quantity used. In the United States, clinker has also been used

for about as long as in Britain, and it is still widely employed in spite of the large

output and wide range of other alternative aggregates [4]. In Malaysia, the

development of using palm oil clinker as lightweight aggregate in construction

industry, especially in structural application started about 30 years ago [1].

Research on structural behaviour of reinforced concrete beams using palm oil

clinker as fine and coarse aggregate replacing the normal weight aggregate has

been carried out by Rezuwan [1]. In term of structural behavior, the researcher

found that the lightweight concrete beams show a comparable behaviour in

cracking, ultimate load and only a slight different in deflection. It was also found

that lightweight concrete using palm oil clinker satisfies the code provisions for

structural lightweight concrete. It was also deduced that the palm oil clinker does

not pose any adverse effect on the strength development of the lightweight

concrete.

The aggregates produced from clinker are lightweight, porous and irregular in

shape, and consequently have low values of bulk density and specific gravity. The

pore structure of such aggregates is complex, and this together with their

absorption characteristics and relative density have been investigated and reported

by the authors [6]. Regarding to the point that lightweight concrete is very

economic especially for long span structure [7], investigation is carried out to study

the performance of clinker concrete mixture towards prestressed concrete beams.

This paper reports on the result of static load test on prestressed lightweight

concrete beams made from clinker as fine and coarse aggregate in the concrete

mix. The results are compared to the normal weight prestressed concrete beam

having similar section and under similar loading system.

J URNAL KEJ URUTERAAN AWAM (J OURNAL OF CIVIL ENGINEERING) Vol.14 No. 1 2002

EXPERIMENTAL WORKS

Details of Tests

A total of four prestressed concrete beam specimens were tested. Two beams were

casted using clinker lightweight concrete and another two beams using normal

weight concrete. The type of beam specimens are pretensioned prestressed

concrete beam. All beams were casted without the provision of web reinforcement.

Both types of concrete were designed to achieve target strength of 40N/mm

2

at

service and 30 N/mm

2

at transfer, which was the minimum required strength for

pre-tensioned prestressed structure [2]. Details of the beam specimens are shown in

Figure 1.

Figure 1: Details of beam specimens

Materials

Two concrete mixes, one is normal weight concrete (NWC) and the other is

lightweight concrete (LWC) were prepared. The normal weight concrete used sand

and gravel as fine and coarse aggregate while the lightweight concrete used

crushed clinker as fine and coarse aggregate. Both concrete mixes were

proportioned according to Building Research Establishment [8]. Since clinker is an

industrial waste, several tests have been carried out in order to obtain some basic

properties of these lightweight aggregates. The test results were then checked with

appropriate standards to ensure the suitability of clinker aggregate to be used in

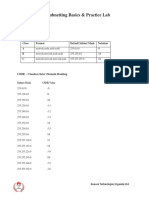

lightweight concrete mixture. Table 2 shows the basic properties of clinker

aggregate in the form of fine and coarse aggregate. The coarse clinker aggregates

had a maximum size of 10 mm and satisfied the BS 3797 grading limit.

Table 2: Basic Properties of Clinker Lightweight Aggregate

Properties of Clinker Aggregate Fine Aggregate Coarse Aggregate

Specific Gravity (Oven-dry) - 1.73

60

2-012.7mm

2500

P P

140

45

320

J URNAL KEJ URUTERAAN AWAM (J OURNAL OF CIVIL ENGINEERING) Vol.14 No. 1 2002

Bulk Density (kg/m

3

)

1080

827

Gradation (Sieve Analysis) Satisfied the

grading limit

BS 3797: 1990

Water absorption (%)

7.5 3.0

Loss-on-ignition (%)

0.45 -

The strands used in this study were from Grade 270 with nominal diameter of 12.7

mm and were manufactured to meet the standard requirement as prescribed in

ASTM 416 [9]. The characteristic strength of these strands (obtained from direct

tensile test) is 1860 N/mm

2

. Two numbers of strands were fixed in each beam, as

shown in Figure 1.

Lightweight Concrete Mix Design

The lightweight concrete mix using clinker as fine and coarse aggregate was

designed in accordance with the Building Research Establishment with some

considerations given to the variations in design necessity such as aggregate bulk

density and water absorption [8]. Casting, curing and testing the specimens were

carried out in accordance with the requirements of the British Standard. The

composition of the constituent materials and the saturated surface dry density for

both normal weight mix and lightweight mix were tabulated in Table 3.

Table 3: Constituent Material Composition for NWC and LWC

Type of mixes NWC LWC

Free-water / cement ratio 0.47 0.44

Free-water content (kg/m

3

) 188.33 205

Cement content (kg/m

3

) 401 512.5

Fine aggregate content (kg/m

3

) 778.7 487.2

Coarse aggregate content (kg/m

3

) 1032.3 645.8

Saturated surface dry density (kg/m

3

) 1.950 2.400

According to the design mix calculation, it was found that in order to produce a

design strength of 40 N/mm

2

for NWC and LWC, total cementitious materials

required were 401 and 512.5 kg/m

3

respectively. On the contrary, the saving in

total aggregate content in LWC mix design was quite significant, where, in this

research, it was found that about 37% of total aggregate content could be saved in

LWC.

All concrete batches were designed for cohesive and workable mix. The fresh unit

weight of LWC is 1950 kg/m

3

compared to NWC which is 2370 kg/

3

, which the

difference is about 18 %. This result was in good agreement with that obtained by

Bender (1980), who found that 20% - 30% of the total dead load could be reduced

by replacing the normal weight concrete with lightweight concrete [7]. The

J URNAL KEJ URUTERAAN AWAM (J OURNAL OF CIVIL ENGINEERING) Vol.14 No. 1 2002

hardened concrete properties of all specimens were made and tested using standard

mould based on British Standard.

Casting of Beams and Testing

All beam specimens were casted in formworks that were located in a prestressing

bed with force capacity of 1000 kN. Prior to casting, the strands were first fixed

and tensioned by using TITAN 20 hydraulic jack. The LWC and NWC specimens

were cast separately. Compaction was carried out using a poker vibrator. The

beams were covered with polythene sheeting and were left for two days before

removing the formworks. All beam specimens were cured using wet hessian in the

laboratory. All beams were detensioned after achieving the transfer strength at age

of 7 days.

Altogether, four numbers of prestressed concrete beams were casted. All

prestressed concrete beams were tested after a curing period of 28 days. Two-point

load tests were carried out on normal weight and lightweight specimens. The full

set-up for the two point loading test of both types of prestressed concrete beams is

shown in Figure 2. The load was applied using ENERPAC hydraulic jack with

load capacity of 200 tons. The loads were applied at an interval of 5 kN. During the

test, data on mid-span deflection and strains in concrete were automatically

measured at every load stages using Kyowa data acquisition system, together with

the control software, UCS-25AS.

Figure 2: Two Point Load Test on Prestressed Lightweight Concrete Beam

EXPERIMENTAL RESULTS AND DISCUSSIONS

Basic Properties of Lightweight Concrete

The results of LWC and NWC properties in term of cube compressive strength,

flexural tensile strength, indirect tensile strength and static modulus of elasticity

were tabulated in Table 4. The mean cube strength for LWC is 44.1 N/mm

2

compared to 46.1 N/mm

2

of the NWC. It was found that the strength of lightweight

J URNAL KEJ URUTERAAN AWAM (J OURNAL OF CIVIL ENGINEERING) Vol.14 No. 1 2002

concrete is only slightly lower than the strength attained by the normal weight

concrete.

For flexural and splitting tensile strength, the tests were performed in accordance

to BS 1881: Part 116 and 117. The mean moduli of rupture obtained for LWC and

NWC are 6.1 N/mm

2

and 6.4 N/mm

2

respectively. The splitting tensile strengths

obtained for LWC and NWC are 3.17 N/mm

2

and 3.31 N/mm

2

respectively. Based

on these results, it shows that the tensile strength of lightweight concrete is slightly

lower than the tensile strength of normal weight concrete.

The mean secant moduli for LWC and NWC are 22 kN/mm

2

and 30 kN/mm

2

respectively. The value of the LWC was about 0.73 times of the normal weight,

concrete. This value is in close agreement with the research result obtained by the

Cement and Concrete Association [10] on lightweight aggregate, in which case, the

elastic modulus of LWC is approximately 0.5 to 0.75 times the value for NWC.

Table 4: Basic Material Properties of NWC and LWC

NWC LWC

Weight (kg) Strength Weight (kg) Strength

Compressive Cube

Strength (N/mm2) 2.39 46.1 1.98 44.4

(100 x 100 x 100 mm)

Flexural Tensile

Strength (N/mm2) 11.8 6.43 10.9 6.09

(100 x 100 x 500 mm)

Splitting Tensile

Strength (N/mm2) 12.2 3.31 11.1 3.17

(150 dia. X 300 mm)

Elastic Modulus

(kN/mm2) 12.2 30 11 22

(150 dia. X 300 mm)

Cracking Behaviour

During testing, it is found that, in all beam specimens, cracks tend to appear earlier

in lightweight beam specimens. This indicates that the lightweight beams have a

lower cracking load compared to the normal weight beams. This phenomenon may

be explained by the lower tensile strength properties of lightweight concrete, as

indicated in the investigation of basic material properties.

Comparing the pattern of crack line between the normal weight and lightweight

specimens, it shows that for lightweight specimens, the crack line propagated

smoothly and almost linear during the load increment. This is due to the softer and

weaker properties of lightweight aggregate. On contrast, for normal weight

specimens which have stronger aggregate, the crack lines always propagated in a

J URNAL KEJ URUTERAAN AWAM (J OURNAL OF CIVIL ENGINEERING) Vol.14 No. 1 2002

form of jagged line and take an appreciable time to develop. In normal practice,

tension failure generally occurs due to the breakdown of the bond between the

surface of aggregate and the matrix [4].

Load-Deflection

The typical load-deflection curves for lightweight and normal weight prestressed

concrete beam specimens (after averaged) are shown in Figure 3. The maximum

load achieved for both LWC and NWC specimens are 110 kN and 103 kN with

maximum deflection about 6.1 mm and 4.6 mm respectively. Based on these

results it is found that the ultimate load for LWC beams is almost similar to those

of NWC beams. The different in load carrying capacity for LWC beams is only

6.4%. It was also found that LWC beams tend to have higher deflection at lower

failure load compared to the NWC specimens about 32%. This phenomenon is well

agreed with the fact that material with lower elasticity modulus would deform

more than the stiffer material [11].

Load-Deflection

0

20

40

60

80

100

120

0 2 4 6 8

Deflection (mm)

L

o

a

d

(

k

N

)

LWC

NWC

Figure 3: Load-Deflection for NWC and LWC beams

Failure Mode

All beam specimens were failed in shear mode, with almost similar value of

maximum strength. The LWC specimens exhibit a very similar pattern of failure

mode with the NWC specimens. The combination of several web-shear cracks,

which formed with only small increase in load, have developed a larger crack

width and thus effectively crushed the web part and the bottom flange of both

J URNAL KEJ URUTERAAN AWAM (J OURNAL OF CIVIL ENGINEERING) Vol.14 No. 1 2002

specimens. For both specimens, the inclination of the failure cracks is about 20 to

30.

This type of failure is known as web compression failure or web-distress failure,

which usually occurred at the region of combined stresses. According to

Khachaturian [12], failures in this region (combined stresses region) are brittle and

often violent. He also said that this type failure behaviour is peculiar to prestressed

concrete beams with thin web and with higher prestress. The propagation of these

inclined cracks is accompanied by an increase in the inclined tensile stresses,

which is not effectively taken by the prestressing strands because for straight

tendon, the prestressing strands is not placed in a way that perpendicular to the

inclined cracks, as in the case of pure flexure.

Variation of Strain on Concrete

Variation of strain on concrete surface over the depth for normal weight and

lightweight beam specimens are shown in Figure 4. Generally, for both beams, the

strain reading at each location tends to increase with the increment of load. In all

cases, the strain readings above the neutral axis represent strain in compression

while those below represent strain in tension.

From Figure 4 (a) and 4 (b), they show that the maximum strains measured at the

top of NWC-OR and LWC-OR specimens are 1241 and 1435 respectively

while at bottom fibre, the maximum strain gained are about 1004 and 1088 .

Comparing these values, it is noted that strain values for lightweight specimen

always greater than the normal weight specimen. This observation is well

demonstrated the point that material with lower elasticity modulus deforms more

and thus produced higher strain value.

NWC

0

50

100

150

200

250

300

350

-1500 -1000 -500 0 500 1000 1500

Strain in microstrain

D

e

p

t

h

o

f

b

e

a

m

(

m

m

)

109kN

100kN

80kN

60kN

40kN

20kN

0kN

Figure 4(a): Variation of Strain on Concrete on NWC beams

J URNAL KEJ URUTERAAN AWAM (J OURNAL OF CIVIL ENGINEERING) Vol.14 No. 1 2002

LWC

0

50

100

150

200

250

300

350

-2500 -1500 -500 500 1500

Strain in Microstrain (Thousands)

D

e

p

t

h

o

f

t

h

e

b

e

a

m

(

m

m

)

100kN

90kN

80kN

60kN

40kN

20kN

0kN

Figure 4(b): Variation of Strain on Concrete on LWC beams

CONCLUSIONS

Based on the experiment results, the following conclusions may be drawn:

1) Clinker lightweight aggregate, in a form of fine and coarse, could produce

workable and cohesive lightweight concrete mix with a density of 1950

kg/m

3

, thus saving about 18.8 % of the total dead weight.

2) In comparing the constituent materials of NWC and LWC, it was found

that LWC requires 14% more total cementitious contents than the

corresponding NWC. On the contrary, lightweight mixture provides

economic used of aggregate where about 37% of total aggregate content

were saved for the same strength of LWC and NWC.

3) The results from basic material properties of LWC show that the

compressive and tensile strength of LWC is lower than the NWC, but the

different is small, which is around 3.6% to 4.6%.

4) The value of elastic modulus of clinker lightweight concrete can be

accepted as specified by Cement and Concrete Association.

5) The static load test shows that the ultimate load capacity for prestressed

lightweight concrete beam specimens is only 6.4% lower than the normal

weight specimens.

6) The deflection of prestressed lightweight concrete beams was slightly

greater than the normal specimens. This was as expected due to the lower

elasticity modulus value.

7) The cracking behaviour of LWC beam specimens show an almost similar

pattern with those of NWC specimens, except at slightly lower load

capacity.

8) The failure mode of both LWC and NWC beams show a very similar

result, where all beam specimens failed in shear manner.

J URNAL KEJ URUTERAAN AWAM (J OURNAL OF CIVIL ENGINEERING) Vol.14 No. 1 2002

9) The strain readings on lightweight concrete specimens always give a

higher value compared to the strain readings in normal weight specimens,

due to the fact that lower elasticity modulus deforms more and thus

produced higher strain.

REFERENCES

Kamaruddin, R., Application of Bamboo and Oil Palm Clinker in Lightweight

Reinforced Concrete Beams, M.Sc. Thesis, Universiti Putra Malaysia.

(1991).

British Standard Institution, Structural Use of Concrete, Part 1.Code of Practice

for Design and Construction. (1985).

Comite Euro-International de la Precontrainte (FIP), Lightweight Aggregate

Concrete, CEB/FIP Manual of Design and Technology, The Construction

Press, Lancaster. (1977).

Short, A. and Kinniburgh, W., Lightweight Concrete, Applied Science Publishers

Ltd., London. (1978).

Federation Internationale de la Precontrainte (FIP), FIP manual of Lightweight

Aggregate Concrete, University of Surrey, Glasgow. (1983).

Omar, W. and Mohamed, R.N., Properties of Lightweight Concrete Using Palm

Oil Clinker in Prestressed Concrete Beam, Conference on Concrete

Engineering and Technology(CONCET), Shah Alam, June. (2001).

Bender, B., The Economics and Use of Lightweight Concrete in Civil Engineering

Structure, Proceedings of the Second International Congress on

Lightweight Concrete, United Kingdom, April 1980.

Teychenne, D.C., Franklin, R.E. and Erntroy, H.C., Design of Normal Concrete

Mixes, Department of the Environment, Building Research Establishment,

London, 1988.

American Society for Testing and Materials. Standard Specification for Steel

Strand, Uncoated Seven-Wire for Prestressed Concrete. Philadelphia, PA:

(ASTM A416) (1996).

Spratt, B.H., The Structural Use of Lightweight Aggregate Concrete, Cement and

Concrete Assiociation, United Kingdom, (1974).

Shuaib H. Ahmad and Barker, R. Flexural Behaviour of Reinforced High-Strength

Lightweight Concrete Beams. Technical Paper, ACI Structural Journal.

USA: Title No. 88-S9: 69-77 (1991).

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Concrete-Making MaterialsDocumento661 pagineConcrete-Making Materialsabiy390% (21)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- LRFD - Manual For Engineered Wood ConstructionDocumento100 pagineLRFD - Manual For Engineered Wood ConstructionDedy Kristianto100% (2)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Finite Element Project Abaqus TutorialDocumento46 pagineFinite Element Project Abaqus TutorialhasibNessuna valutazione finora

- Glulam Connection DetailsDocumento0 pagineGlulam Connection DetailsMichael SheininNessuna valutazione finora

- Data Structures and AlgorithmsDocumento45 pagineData Structures and AlgorithmsKeith Tanaka MagakaNessuna valutazione finora

- Oracle Data Integration - An Overview With Emphasis in DW AppDocumento34 pagineOracle Data Integration - An Overview With Emphasis in DW Appkinan_kazuki104Nessuna valutazione finora

- Steps For Charm ConfigurationDocumento7 pagineSteps For Charm ConfigurationpoornasapNessuna valutazione finora

- Ets Design Guide 2010Documento49 pagineEts Design Guide 2010Khairul Salleh BaharudinNessuna valutazione finora

- Structural Lightweight Aggregate ConcreteDocumento161 pagineStructural Lightweight Aggregate ConcreteServie41100% (2)

- Bellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechDocumento15 pagineBellin, E. H. (1984) - The Psychoanalytic Narrative On The Transformational Axis Between Writing and SpeechofanimenochNessuna valutazione finora

- AutoCAD 2013Documento264 pagineAutoCAD 2013panosscribd100% (1)

- Innovation in Cement IndustryDocumento92 pagineInnovation in Cement IndustryKhairul Salleh Baharudin100% (1)

- Flat Slab DesignDocumento76 pagineFlat Slab Designyunuswsa97% (36)

- Technical DrawingDocumento58 pagineTechnical Drawingamacarras95% (21)

- Glulam SupplementDocumento24 pagineGlulam SupplementLee Ager100% (1)

- Fundamentals of Neural Networks by Laurene FausettDocumento476 pagineFundamentals of Neural Networks by Laurene Fausettsivakumar89% (18)

- 000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Documento22 pagine000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Raul Bautista100% (1)

- Operational Guidelines For VlsfoDocumento2 pagineOperational Guidelines For VlsfoИгорьNessuna valutazione finora

- SM Sample ExamDocumento4 pagineSM Sample ExamKhairul Salleh BaharudinNessuna valutazione finora

- 3 Master Reversal Candle PatternDocumento6 pagine3 Master Reversal Candle PatternHashirama SenjuNessuna valutazione finora

- Knowledge BaseDocumento75 pagineKnowledge BaseKhairul Salleh BaharudinNessuna valutazione finora

- Dynamics: Vector Mechanics For EngineersDocumento20 pagineDynamics: Vector Mechanics For EngineersRamilvalmeoNessuna valutazione finora

- RC Slab-Yield Line Theory-SalamDocumento7 pagineRC Slab-Yield Line Theory-SalamKhairul Salleh BaharudinNessuna valutazione finora

- Learn Abaqus script in one hourDocumento12 pagineLearn Abaqus script in one hourbaspopNessuna valutazione finora

- Xsteel - Lesson 6Documento24 pagineXsteel - Lesson 6saisssms9116100% (3)

- Flat SlabDocumento18 pagineFlat SlabKhairul Salleh BaharudinNessuna valutazione finora

- Factor Affecting Ultimate Strenght of Solid and Glulam Timber BeamsDocumento10 pagineFactor Affecting Ultimate Strenght of Solid and Glulam Timber BeamsKhairul Salleh BaharudinNessuna valutazione finora

- Experimental Behaviour of Threaded Steel Rods Glued Into High-Density HardwoodDocumento9 pagineExperimental Behaviour of Threaded Steel Rods Glued Into High-Density HardwoodKhairul Salleh BaharudinNessuna valutazione finora

- Experiments On Dowel-Type Timber ConnectionsDocumento14 pagineExperiments On Dowel-Type Timber ConnectionsKhairul Salleh BaharudinNessuna valutazione finora

- GN Roof&TrussDocumento4 pagineGN Roof&TrussKhairul Salleh BaharudinNessuna valutazione finora

- MTIB Malaysian WoodDocumento3 pagineMTIB Malaysian WoodKhairul Salleh BaharudinNessuna valutazione finora

- Flexural Behaviour of Glue-Laminated Fibre Composite Sandwich BeamsDocumento9 pagineFlexural Behaviour of Glue-Laminated Fibre Composite Sandwich BeamsKhairul Salleh BaharudinNessuna valutazione finora

- Finite Element Modelling of Anisotropic Elasto-Plastic Timber Composite Beams With OpeningsDocumento10 pagineFinite Element Modelling of Anisotropic Elasto-Plastic Timber Composite Beams With OpeningsKhairul Salleh BaharudinNessuna valutazione finora

- Non-Destructive Tests of Modulus of Elasticity For The Glued Laminated Timber BeamsDocumento4 pagineNon-Destructive Tests of Modulus of Elasticity For The Glued Laminated Timber BeamsKhairul Salleh BaharudinNessuna valutazione finora

- MTC Natural Oil CoatingDocumento22 pagineMTC Natural Oil CoatingKhairul Salleh BaharudinNessuna valutazione finora

- Omar El Mukhtar M Fka 2008Documento74 pagineOmar El Mukhtar M Fka 2008Khairul Salleh BaharudinNessuna valutazione finora

- IMChap 014 SDocumento14 pagineIMChap 014 STroy WingerNessuna valutazione finora

- USB GPW CB03 MT02 - EngDocumento21 pagineUSB GPW CB03 MT02 - EngRafael BispoNessuna valutazione finora

- h6541 Drive Sparing Symmetrix Vmax WPDocumento19 pagineh6541 Drive Sparing Symmetrix Vmax WPsantoshNessuna valutazione finora

- Syllabi M.Tech. WRDMDocumento114 pagineSyllabi M.Tech. WRDMMadhab KoiralaNessuna valutazione finora

- Toyo ML210 thread cutting gear assembly drawingsDocumento12 pagineToyo ML210 thread cutting gear assembly drawingsiril anwarNessuna valutazione finora

- Alc10 DatasheetDocumento7 pagineAlc10 Datasheetd4l170Nessuna valutazione finora

- SubNetting Practice LabDocumento3 pagineSubNetting Practice LabOdoch HerbertNessuna valutazione finora

- Ain 2016 Pilot Report m600Documento4 pagineAin 2016 Pilot Report m600Antonio Cesar de Sa LeitaoNessuna valutazione finora

- Camshaft Test SheetDocumento4 pagineCamshaft Test SheetsughieantoNessuna valutazione finora

- Eltek PSR 327Documento2 pagineEltek PSR 327fan liuNessuna valutazione finora

- Database Classification TypesDocumento10 pagineDatabase Classification TypesBhiea Mische MatilacNessuna valutazione finora

- Simultaneous EquationsDocumento11 pagineSimultaneous EquationsSaleena AurangzaibNessuna valutazione finora

- 997-3 CIP Safety Adapter: Single Point Lesson (SPL) - Configure CIP Safety Adapter and A-B PLCDocumento18 pagine997-3 CIP Safety Adapter: Single Point Lesson (SPL) - Configure CIP Safety Adapter and A-B PLCTensaigaNessuna valutazione finora

- F (X, Y) Sin (Xy) + X LN (Y) Find F at (0, )Documento9 pagineF (X, Y) Sin (Xy) + X LN (Y) Find F at (0, )muhammad abrarNessuna valutazione finora

- Massive MIMO For Communications With Drone SwarmsDocumento26 pagineMassive MIMO For Communications With Drone SwarmsAsher Suranjith JayakumarNessuna valutazione finora

- Python Programming Lecture#2 - Functions, Lists, Packages & Formatting I/ODocumento69 paginePython Programming Lecture#2 - Functions, Lists, Packages & Formatting I/OHamsa VeniNessuna valutazione finora

- 8086 Instruction SetDocumento66 pagine8086 Instruction SetRaj KumarNessuna valutazione finora

- Enzyme Inhibition and ToxicityDocumento12 pagineEnzyme Inhibition and ToxicityDaniel OmolewaNessuna valutazione finora

- 13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilDocumento9 pagine13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilJenifer TejadaNessuna valutazione finora

- FDocumento1 paginaFDiego PorrasNessuna valutazione finora

- The Machining of Brake DiscsDocumento8 pagineThe Machining of Brake DiscsBusu Cyp100% (1)

- Module 4 - What Is The Required Rate of ReturnDocumento2 pagineModule 4 - What Is The Required Rate of ReturnEthics BAENessuna valutazione finora

- Excel 2007 Lesson 7 QuizDocumento5 pagineExcel 2007 Lesson 7 Quizdeep72Nessuna valutazione finora