Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fly Ash Pond Proposal 06-12-14 FINAL

Caricato da

JTEaston0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

112 visualizzazioni171 pagineProposal for method of environmental remediation of Coal Ash storage ponds in North Carolina via Calcium Polysulfide reaction. 10,000 sf Test area approved without permit per North Carolina rule.

Titolo originale

Fly Ash Pond Proposal 06-12-14 FINAL (1)

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoProposal for method of environmental remediation of Coal Ash storage ponds in North Carolina via Calcium Polysulfide reaction. 10,000 sf Test area approved without permit per North Carolina rule.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

112 visualizzazioni171 pagineFly Ash Pond Proposal 06-12-14 FINAL

Caricato da

JTEastonProposal for method of environmental remediation of Coal Ash storage ponds in North Carolina via Calcium Polysulfide reaction. 10,000 sf Test area approved without permit per North Carolina rule.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 171

PROPOSAL FOR FLY ASH POND

SOLIDIFICATION & REUSE

June 12, 2014

Prepared for:

Mr. Davis Leaphart

Duke Energy

526 S. Church Street

Charlotte, NC 28202

Mr. Tony Matthis

Duke Energy

526 S. Church Street

Charlotte, NC 28202

Prepared by:

The Concrete Sulfides Partnership (CSP)

Mark Hall - Vision Directional Drilling Prime Contractor

James Easton & James A. Papp Patent Holders

Michael G. Jones, PG, RSM : Pyramid Environmental - Consultant

Copies to :

John E. Skvarla III, DENR Secretary

Tom Reeder, Director of Div. of Water Resources

NC Senator Rick Gunn

Pyramid Environmental & Engineering, P.C.

503 Industrial Avenue

Greensboro, NC 27406

(336) 335-3174

Licensed Geology C-257 Licensed Engineering C1251

TABLE OF CONTENTS

1.0 STATEMENT OF PURPOSE ...................................................................... 1

1.1 DUKE ENERGY BUSINESS MEETING ( MAY 30, 2014 ) ....................................... 2

1.2 NC DENR APPROVALS ............................................................................................... 2

2.0 CALCIUM POLYSULFIDE (CPS) ............................................................. 3

3.0 HEALTH AND SAFETY OF CPS ............................................................... 4

4.0 CPS INJECTIONS / SOLIDIFICATION ................................................... 4

5.0 CONCRETE PRODUCTS ............................................................................ 5

6.0 DUKE ENERGY ASSISTANCE.................................................................. 6

7.0 OTHER CONSIDERATIONS ..................................................................... 6

8.0 CARBON DIOXIDE SEQUESTRATION .................................................. 7

9.0 CONCLUSIONS ............................................................................................ 8

FIGURES

Figure 1 : Proposed Method of By-Products Treatment

Figure 2 : Conceptual Illustration of Chemical Injections

Figure 3 : Conceptual Illustration of Injection Spacing

Figure 4 : Conceptual Illustration of Injection Pattern

APPENDICES

Appendix A : List of Duke Energy Coal Ash Ponds

Appendix B : DENR CPS Approval and 2010 Coal Ash Memorandum

Appendix C : In-Situ Remediation of Heavy Metals w/ Sulfur-Based Treatment Technologies

Appendix D : CPS Patent Documents

Appendix E : USEPA Coal Combustion Residual Beneficial Use Evaluation (Feb 2014)

Appendix F : USEPA Reregistration Eligibility Decision for Inorganic Polysulfides

Page I

Acronyms

CPS ................Calcium Polysulfide

CCR ................Coal Combustion Residuals

CCW ..............Coal Combustion Waste

CFR ................Code of Federal Regulations

CSM ...............Conceptual Site Model

COPC .............Constituents of Particular Concern

CPSC ..............Consumer Product Safety Commission

DENR .............Department of Environment and Natural Resources

EMP ...............Environmental Management Plan

FGD ................Flue Gas Desulferization (FGD) Material Calcium Sulfate

HASP .............Health & Safety Plan

HDPE .............High Density Polyethylene

IWEM ............Industrial Waste Evaluation Model

LTM ...............Long Term Monitoring

LURs ..............Land Use Restrictions

MCL ...............Maximum Contaminant Level (Drinking water)

g/L ................Microgram per Liter

mg/Kg ............Milligrams per Kilogram

MHSA ............Mine Health and Safety Administration

OSHA .............Occupational Safety and Health Administration

OSWER ..........Office of Solid Waste and Emergency Response

Pozzolan .........Pumice, Fly Ash, Pulverized Slag, Cinders

PSRGs ............Preliminary Soil Remediation Goals

RCRA .............Resource Conservation and Recovery Act

SAP ................Sampling & Analysis Plan

SMM ..............Sustainable Materials Management

TCLP ..............Toxicity Characteristic Leaching Procedure

US ACE .........United States Army Corps of Engineers

USEPA ...........United States Environmental Protection Agency

ZVI .................Zero-Valent Iron

Page II

DUKE ENERGY Coal Ash Pond Solidification and Reuse Proposal Page 1

The Concrete Sulfides Partnership 06/12/2014

PROPOSAL FOR FLY ASH POND

SOLIDIFICATION & BENEFICIAL REUSE

The Concrete Sulfides Partnership (CSP)

1.0 STATEMENT OF PURPOSE

Over the past century, Duke Energy has used coal combustion to produce energy for industrial and

private customers in North Carolina and the surrounding states. The production has generated

millions of cubic yards of coal ash, cinders, slag, and combustion by-products that have accumulated

mostly in ash ponds near the coal fired facilities. There are reportedly 36 ash ponds in North

Carolina that NC Department of Environment and Natural Resources (NC DENR) will require some

level of cleanup action. These ash ponds present inherent risk of contamination or failure which can

affect the public, nearby surface water, groundwater, and the environment.

After the pipe failure at the coal ash facility in Eden, the NC DENR mandated that Duke Energy

dewater, excavate, and transport the ash from three ash pond locations to lined landfill facilities.

Although the transfer of the material is feasible, it is not the most cost effective or beneficial use for

the ash material and only transfers the hazardous metals problem to a new location.

The purpose of this proposal from the Concrete Sulfides Partnership (CSP) is to provide a basic

framework for solidification, metals sequestration, and beneficial re-use of the material in the many

active and inactive ash ponds at the Duke Energy power generation facilities in North Carolina.

The public outcry in North Carolina for action in recent weeks and months has increased pressure

for action that not only reduces the risk of future ash spills into the waters of the State, but to provide

treatment and ultimate disposal for the hazards present in the coal ash. The NC DENR has mandated

cleanup at three of the coal ash ponds, and is requiring cleanup action at the remaining 33 coal ash

ponds. The list of the Duke Energy NC Coal Ash Ponds is presented in Appendix A.

Several bills are being considered in the NC legislature and further action on coal ash regulations is

pending at the US Environmental Protections Agency (USEPA).

DUKE ENERGY Coal Ash Pond Solidification and Reuse Proposal Page 2

The Concrete Sulfides Partnership 06/12/2014

1.1 Duke Energy Business Meeting ( May 30, 2014 )

In keeping with the discussions held on May 30, 2014 in the offices of Duke Energy, Concrete

Sulfides Partnership thanks Duke Energy for the initial meeting and the general guidance

provided in the meeting. The goals established in the meeting were to :

1. Provide an approvable method to sequester hazardous metal present in the coal ash &

other by-products in the ponds.

2. Provide a workable solution to solidify or cement the coal ash, cinders, and slag into a

product that can be removed from the ponds.

3. Remove the majority of the coal ash and other by products from the ponds for beneficial

reuse.

4. Meet the cradle-to-grave requirements of disposal of the ash to limit future liability for

Duke Energy and Concrete Sulfides Partnership.

5. Provide in-situ treatment for groundwater if needed to address concerns from the NC

DENR and the Public.

During the meeting Concrete Sulfides Partnership provided a rough framework detailing the

proposed remedy, proprietary technology, and proposed sequestration plan. Duke Energy asked

for evidence that the NC DENR has approval of the proposed chemical agent for injection, and

the answers are presented in the following sections, along with additional details.

1.2 NC DENR Approvals

Duke Energy asked if the proposed injectant (Calcium Polysulfide) was approved by the NC DENR.

Pyramid checked and found that the DENR has approved Calcium Polysulfide (CPS) for use in

North Carolina. The DENR approval letter dated J uly 10, 2001 is presented in Appendix B, along

with the list of approved chemical injectants.

The NC Division of Waste Management letter dated April 23, 2012 is also included to address

concerns arising from injections for pilot testing. This letter provides information that states that for

approved compounds injected in-situ, a small scale injection (<10,000 square feet in area) is

permitted by rule without further requirements. The permitted by rule pilot test is intended to

provide the responsible party the opportunity to test approved technology on a particular site prior to

seeking DENR approval for full-scale implementation. In addition,

In the meeting, Duke Energy characterized the typical ash pond as containing approximately

1,000,000 cubic yards of fly ash, cinders, and slag. The mixture of these solid combustion by-

products was randomly deposited over many years in the ash ponds. The Concrete Sulfide

Partnership proposes to complete testing and evaluation of the coal ash with respect to in situ

solidification and removal and mixing operations at the coal ash pond facilities. The pilot testing and

characterization of the ash deposits are critical steps to assure project success and should be

completed prior to full scale operations planning. The proposed calcium polysulfide (CPS)

sequestration of hazardous metals is detailed in the short article presented in Appendix C.

DUKE ENERGY Coal Ash Pond Solidification and Reuse Proposal Page 3

The Concrete Sulfides Partnership 06/12/2014

2.0 CALCIUM POLYSULFIDE (CPS)

As stated above, Pyramid checked with the Division of Waste Management (DWM) and found

that Calcium Polysulfide (CPS) is approved for metals sequestration at sites in North Carolina.

In the meeting with Duke Energy on May30, 2014, Concrete Sulfide Partnership presented a

copy of the Patent Declaration. The Patent Document (approved J une 6, 2014) for the proposed

use of CPS is presented in Appendix D.

The proposed use of CPS will provide three main benefits to Duke Energy.

1. Water soluble elemental heavy metals such as As, Ba, Cd, Cu, Cr, Hg, Mn, Mo, Se, U,

Zn, and cyanide are chemically reacted to create insoluble metal sulfide compounds.

2. Further toxic components chemically bind to Hydroxide polymer chains and are locked

into complex molecular structures within cementitious materials.

3. A high strength version of concrete denser than ordinary Portland cement is created

which solidifies the ash material.

There are several advantages to the use of Calcium Polysulfide (CPS) over the use of Ordinary

Portland Cement (OPC). These are:

The CO2 produced in the mining and manufacturing of OPC is 5 % of the total

Greenhouse gasses (GHGs) for the entire world. The production of one ton of Portland

cement leads to the production of one ton of GHGs. This relationship places OPC in a

category where any reduction in the production of OPC will help reduce GHGs.

CPS products are not GHG intensive and do not emit GHGs, but rather adsorb CO2. The

net benefit to the environment is that CO2 is removed from the atmosphere instead of the

process being a significant emitter.

Metals are chemically changed into insoluble metal sulfides that are no longer water

soluble and therefore are not dangerous to the environment.

The ash that was flowable is made solid (no longer flowable) which removes the

concerns of unanticipated or catastrophic release to surface water or groundwater.

Water present in the ash pond area is used to react with CPS and the ash materials which

will remove heavy metals from the water.

The USEPA studies found that the use of fly ash in concrete and wall board is no more a threat

than the raw materials they are replacing. The February 2014 USEPA study showing the

comparison between OPC concrete and Fly Ash Concrete is presented in Appendix E. This EPA

study presents data that supports the beneficial reuse of ash in concrete as proven and safe.

Limited testing of the concrete produced from the reaction of fly ash and pozzolanic materials

with CPS demonstrated that a durable concrete material can be produced. The rough percentages

of materials present in the test sample and material strengths are presented in the patent

documents. The material was tested at a compressive strength of over 4,000 pounds per square

inch (PSI) at 28 days. The mixture tested was 58% recycled waste material (ash & cinders).

DUKE ENERGY Coal Ash Pond Solidification and Reuse Proposal Page 4

The Concrete Sulfides Partnership 06/12/2014

3.0 HEALTH AND SAFETY OF CPS

The proposed ash pond solidification using calcium polysulfide (CPS) is ultimately safe.

Materials present in the CPS product have been approved by the NC DENR and by the USEPA.

Safety of CPS is addressed in The EPA Reregistration Eligibility Decision for Inorganic

Polysulfides publication (2005) which is presented in Attachment F. The use of solid calcium

polysulfides has been approved by US EPA for use as a fungicide and pesticide for agricultural

use. Colorado has approved CPS as one of the only substances for use in organic gardening and

organic food production. The calcium and sulfur that make up the primary ingredients are

considered ubiquitous and pose no threat to nature or biological organisms.

The plans to relocate the ash pond material to lined landfills will use hundreds of trucks to haul

hazardous ash material through populated areas producing dust, traffic, using more fossil fuel,

creating more CO2, and transferring the ash to another location without treatment. These are

significant community impacts.

In contrast, in-situ cementation of the ash ponds using CPS will have very positive impacts on

the surrounding community. The process will be completed on site, within the pond footprint,

and the CPS injections will solidify the ash immediately. The toxic metals that everyone is

concerned about will be sequestered and a usable concrete product will be created. The concrete

can later be mined and transported by rail to an approved end user. The sequestered material will

be non-hazardous and will reduce transportation costs for beneficial re-use as gravel. The impact

to the surrounding community will be minimal.

4.0 CPS INJECTIONS / SOLIDIFICATION

Concrete Sulfide Partnership proposes to solidify the ash pond material using CPS to sequester toxic

metals and provide a solid material where a flowable material exists now. After solidification, a

strategy for beneficial reuse will be arranged. The primary idea at this point in time is to break up

and remove the material from the ponds and crush the material for gravel in road bed construction.

Other appropriate uses may include, road base, parking areas, shoulders, embankments, aggregate

for inclusion in some cement and or other products, blocks, rip-rap, seawalls, breakwaters, etc

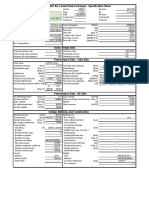

A description of the CPS injections/solidification process is presented on the attached figures.

Figure 1 shows a typical coal ash pond (the Dan River Steam Station) as an example, and shows the

general dimensions of the impoundment. Figure 2 shows the process of CPS injection using a

reamer drill head injecting the mixture and blending it as the reamer moves through the ash. The

proposed horizontal drilling method can easily span the short or long axis of most ash ponds. The

CPS mixture could also be injected into horizontal injection wells placed at regular intervals if this

proves to be a more effective method. The injection pressures will be established by completing a

pilot test, and may vary with depth and the consistency of the material. Figure 3 shows the proposed

staggered pattern of injections with anticipated overlap of solidification, and Figure 4 shows a larger

view of the injection pattern. The bottom injections can be performed early in the process to address

concerns about lining the ash ponds if needed.

DUKE ENERGY Coal Ash Pond Solidification and Reuse Proposal Page 5

The Concrete Sulfides Partnership 06/12/2014

5.0 CONCRETE PRODUCTS

The use of fly ash in concrete products is well documented and safe. Pozzolanic concrete was used

by the Romans over 2,000 years ago and much of the material is still with us today. The advantage

that CPS provides is that potential toxic metals are converted to metals sulfides and rendered

insoluble. Concrete products produced from the cementation process can be used for many purposes,

and a wide range of concrete products can be considered. The NC DENR and USEPA recommend

and encourage reuse of the ash material in concrete products. The most obvious use would be to

mine the concrete from the ponds, crush and size the material, and use it for road bed aggregate.

Duke Energy will propose the most suitable uses for the material and work to satisfy government

and public concerns.

As requested by Duke Energy, Concrete Sulfide Partnership (CSP) has pursued letters of interest

from end users of the treated and solidified ash material / concrete. There is interest in procuring

relatively low cost pozzolanic concrete material for road base and other uses throughout the State.

Contractors east of Interstate I-95 have been paying a premium for gravel for roadbed, parking, and

other projects. Providing lower cost suitable gravel for State and private construction is an ideal use

for the concrete.

The contractors who have been contacted so far are interested in using this aggregate and would

appreciate the anticipated lower cost concrete gravel or other concrete materials. It is expected that

and the production and distribution of the pozzolanic concrete can meet the needs of potential

contractors and government agencies. The coastal plain is hungry for high quality aggregate for

many uses and could be the largest market for the gravel and other concrete products.

Concrete Sulfide Partnership has solicited letters of interest from several contractors and the

NCDOT. The NCDOT will soon be starting on a 7 year project to re-build roads and bridges on the

outer banks near Cape Hatteras. This work would require large quantities of gravel and other

concrete products that could be specified and made from these ash materials. The Concrete Sulfide

Partnership is currently seeking Letters of Interest from the NC DOT and contractors throughout the

State. These letters have not been received yet, and will be provided to Duke Energy under separate

cover.

In addition, the production of pozzolanic concrete carries a much smaller Greenhouse Gas (GHG)

emissions footprint than Ordinary Portland Cement (OPC). The use of CPS and the contracts for rail

distribution of the material would cut the use of fossil fuels consumed in the process and reduce

GHGs.

DUKE ENERGY Coal Ash Pond Solidification and Reuse Proposal Page 6

The Concrete Sulfides Partnership 06/12/2014

6.0 DUKE ENERGY ASSISTANCE

In our meeting with Duke Energy, we asked whether Duke Energy is willing to help with several

factors that make a great difference in economically creating, handling, and transporting the concrete

products to end users and the marketplace.

The potential production of concrete aggregate or other products for resale would require Duke

Energy to allocate adequate space at each steam generation facility to house the excavation,

production, curing, refining, and storage of cementitious products.

Duke Energy has buying power with the railroads to help transport concrete products to market.

Transportation is a very important factor in the economic viability of coal ash concrete reuse.

The Concrete Sulfide Partnership will rely on Duke Energy to provide low-cost rail transportation to

make production and transportation of ash pond products feasible. Without reliable low-cost access

to the marketplace, the sequestration, solidification and re-use project would be more costly for

Duke Energy.

7.0 OTHER CONSIDERATIONS

In reviewing the general process and goals of the ash pond remediation, there are issues that will

need to be addressed. The following presents a general list of other items and a quick analysis of

solutions to each.

Health & Safety: Since the CPS is a strong base, injections are hazardous and extreme

care will be required to perform the injections and curing process safely. Once the

product is diluted or reacted there are no harmful by-products.

Chemistry: Since the CPS will be combined with other portions of solid materials and

potentially gases, care will be taken to test and document reactions and by products.

Ash Pond Assessment: Each ash pond would require additional characterization and

assessment to provide basic information on volume, chemical properties, and metals.

Conceptual Site Model (CSM): Each facility and the ash ponds associated with the

facility would need a CSM to look at soil, groundwater and surface water conditions that

may present short and long term risks before full implementation of the remediation.

Sampling & Analysis Planning: Preparation of comprehensive testing and analytical

plans for the ash and reacted material is essential to the future acceptance and reuse of the

concrete products.

Pilot Testing: The initial pilot testing can be completed without permitting since the area

involved is permitted by rule. We will keep DENR informed of the process.

Public Relations : The public relations would be planned in cooperation with Duke

Energy and would target informing the public of the planned benefits and providing

assurance that the USEPA and NC DENR were on board with all that is being done to

solve the problems

DUKE ENERGY Coal Ash Pond Solidification and Reuse Proposal Page 7

The Concrete Sulfides Partnership 06/12/2014

Injection Planning; The injection process will be planned carefully to provide the best

results while maintaining safety of all personnel. During the process factors such as

pressures and mix rations will need to change to accommodate changes in the pond

materials. There will also be variations from locality to locality.

Solidification of Ash Ponds: After completion of the injection planning and procuring

the CPS and other amenities, the process would begin. Adjustments in the process are

expected as we move from pilot scale to full scale treatment.

Concrete Products: Once the material is reacted and stable, the material would be mined

from the ponds for aggregate or other productive re-use. The concrete would be ground

and sorted to size for re-use in the recycled material marketplace.

Product Testing: to assure that the concrete meets general specifications a testing and

analysis plan with procedures will be adopted. The testing will also include long range

testing that will be maintained for decades to assure USEPA, NCDENR, and the general

public that the process and implementation has been competed safely.

Repeatability: The path to success at more than one facility is to create a repeatable

process that can be easily replicated with safeguards at 33 other facilities.

Carbon Sequestration: once the process is operational, additional attention can be paid

to providing CO2 sequestration for each site during the injection and curing process. This

opportunity has the potential to provide Duke Energy with additional benefit of a reduced

carbon signature which will help with public relations.

8.0 CARBON DIOXIDE SEQUESTRATION

The production of concrete is proposed as a solution for several reasons; however, it has the

potential to solve yet another challenge for Duke Energy. The carbon dioxide (CO2) emissions from

coal ash power plants are a concern for Global Warming due to Greenhouse Gasses (GHGs). This

concern has produced a public outcry to reduce GHGs and provide a new business model which is

more sustainable.

The current Federal Government administration has put forward the proposal to reduce carbon

emissions by 25 %. This proposal would place a heavy burden on coal fired plants and might cause

Duke Energy to consider costly new power facility construction projects. The potential to sequester

CO2 into a stable concrete product that will adsorb and hold CO2 may help attenuate the need to

build new facilities and may allow the continued operation of coal fired facilities for some period of

time.

In the production of concrete products, the flue gasses could be used to cure the concrete and the

concrete would adsorb CO2 in the process. The CO2 adsorption could initially be a simple process,

with later enhancements added to increase the percentage as the projects move forward. Concrete

Sulfide Partnership will work in cooperation with Duke Energy to provide sequestration of CO2 in

concrete and increase the percentage of GHG reductions as the process continues.

DUKE ENERGY Coal Ash Pond Solidification and Reuse Proposal Page 8

The Concrete Sulfides Partnership 06/12/2014

9.0 CONCLUSIONS

In preparing this proposal, many areas of the construction, permitting, and environmental cleanup

process were considered. The next step in the process is to complete the following:

Concrete Sulfide Partnership (CSP) will meet with Duke Energy personnel to inspect and

sample a coal ash pond site. The discussions suggest that the coal ash at the Belews Lake

facility or the Hyco Lake facility would be acceptable. Ash samples would be collected from

as many areas of the pond as practical, and prepared for laboratory analysis, reactions, and

subsequent testing.

Confirming through analysis and evaluation that this alternative method is safe and effective

and can be explained as necessary to the public.

These specific tasks would benefit Duke Energy and should be paid for by Duke Energy. The

proposed work will be targeted to provide clear evidence that the proposed metals

sequestration and solidification will succeed in the next phase of the project, the pilot test.

After completing the 10,000 square foot pilot test, additional sampling and laboratory

analyses will be completed to provide Duke Energy and regulatory agencies with data about

the metals sequestration and that the concrete produced is safe for use.

The potential benefits of the CPS solidification process are many and solve the problems that are

currently plaguing Duke Energy.

The metals in the ash material is rendered non-hazardous in place.

The CPS product is environmentally safe and will solidified the ash into concrete in situ.

The immediate dangers of contamination or unexpected release are removed.

The work to treat all ash ponds can be completed in a reasonable time frame (<10 years).

The ponds which present the greatest risk would be addressed first.

The metals will be converted to insoluble metal sulfides, not transferred to a new location.

The work will take place on Duke Property and not involve trucks carrying hazardous ash

through local communities to lined landfills.

The public can see reasonable progress on the most worrisome sites within a short time.

The resulting concrete is durable and can be prepared for reuse in the marketplace.

The end result would be a plan of action for full scale implementation of the CPS process after

completion of the pilot test. Permits, site ranking, government approvals, and public notification

would all be needed. The ash ponds would each be evaluated and a similar remediation approach

tailored to the project requirements of each location. It is expected that CPS solidification and re-use

of all the ash ponds would be less than a quarter of the current cost projections of 10 billion dollars

for the proposed lined landfill solution.

FIGURES

APPENDIX A

Plant Name Active / Inactive Ash Ponds COUNTY Latitude Longitude State ID

Allen Steam Station Allen Retired Ash Basin Dam Gaston 35.174141 -81.007639 GASTO-061

Allen Steam Station Allen Retired Ash Basin Dam Gaston 35.184200 -81.006300 GASTO-016

Belews Creek Station Belews Creek Active Ash Basin Dam Stokes 36.296506 -80.075149 STOKE-116

Buck Steam Station Buck Steam Station Main Dam Rowan 35.711038 -80.363278 ROWAN-047

Buck Steam Station Buck Steam Sta. New ( Primary) Dam Rowan 35.706355 -80.374217 ROWAN-068

Buck Steam Station Buck Steam Station Basin 1 to Basin 2 Dam Rowan 35.703085 -80.367234 ROWAN-069

Buck Steam Station Buck Steam Station Basin 2 to Basin 3 Dam Rowan 35.707574 -80.364325 ROWAN-070

Buck Steam Station Buck Steam Station Divider Dam Rowan 35.709818 -80.364142 ROWAN-071

Cliffside Steam Station Cliffside Inactive Ash Basin #5 Main Dam Rutherford 35.215617 -81.768651 RUTHE-070

Cliffside Steam Station Cliffside Inactive Ash Basin #5 Saddle Dam Rutherford 35.215731 -81.765724 RUTHE-072

Cliffside Steam Station Cliffside Active Ash Basin Upstream Dam Cleveland 35.214198 -81.755450 CLEVE-050

Cliffside Steam Station Cliffside Active Ash Pond Downstream Dam Cleveland 35.217171 -81.747758 CLEVE-049

Cliffside Steam Station Cliffside Inactive Ash Basin 1-4 Main Dam Cleveland 35.218628 -81.756138 CLEVE-047

Cliffside Steam Station Cliffside Active Ash Basin Internal Dam Cleveland 35.210060 -81.750750 CLEVE-054

Dan River Steam Sta. Dan River Active Primary Ash Basin Rockingham 36.488336 -79.714777 ROCKI-237

Dan River Steam Sta. Dan River Active Secondary Ash Basin Rockingham 36.491900 -79.711400 ROCKI-238

Marshall Steam Station Marshall Active Ash Basin Dam Catawba 35.606000 -80.960200 CATAW-054

Riverbend Steam Sta. Riverbend Active Ash Basin Dam 1 (Primary) Gaston 35.365463 -80.965334 GASTO-097

Riverbend Steam Sta. Riverbend Active Ash Basin Dam 2 (Secondary) Gaston 35.368771 -80.960634 GASTO-098

Riverbend Steam Sta. Riverbend Ash Basin Intermediate Dam Gaston 35.366751 -80.962221 GASTO-099

Asheville Power Station Asheville 1982 Ash Pond Dam Buncombe 35.464593 -82.544190 BUNCO-089

Asheville Power Station Asheville 1964 Ash Pond Dam Buncombe 35.467351 -82.547929 BUNCO-097

Cape Fear Power Sta. Cape Fear 1956 Ash Pond (Inactive) Chatham 35.597094 -79.050885 CHATH-075

Cape Fear Power Sta. Cape Fear 1963 Ash Pond Dam (Inactive) Chatham 35.586546 -79.050961 CHATH-076

Cape Fear Power Sta. Cape Fear 1970 Ash Pond Dam (Inactive) Chatham 35.582911 -79.049864 CHATH-077

Cape Fear Power Sta. Cape Fear 1978 Ash Pond Dam Chatham 35.587562 -79.045533 CHATH-078

Cape Fear Power Sta. Cape Fear 1985 Ash Pond Dam Chatham 35.586380 -79.039548 CHATH-079

Sutton Power Station Sutton 1984 Ash Pond New Hanover 34.299100 -77.992400 NEWHA-005

Sutton Power Station Sutton 1971 Ash Pond (Exempted by HB 119) New Hanover 34.293100 -77.992800 NEWHA-004

Mayo Power Station Mayo Ash Pond Dam Person 36.538002 -78.893593 PERSO-035

Roxboro Power Station Roxboro West Ash Pond Dam Person 36.476569 -79.077296 PERSO-038

Roxboro Power Station Roxboro West Ash Pond South Rock Filter Person 36.464459 -79.070710 PERSO-039

Roxboro Power Station Roxboro East Ash Pond Person 36.480588 -79.067027 PERSO-033

Weatherspoon Power Weatherspoon 1979 Ash Pond Robeson 34.591266 -78.969317 ROBES-009

H.F. Lee Power Station H.F. Lee Active Ash Pond Wayne 35.379079 -78.069845 WAYNE-022

H.F. Lee Power Station H.F. Lee Ash Pond 1 (Inactive) Wayne 35.381257 -78.110237 WAYNE-031

H.F. Lee Power Station H.F. Lee Ash Pond 2 (Inactive) Wayne 35.382756 -78.104093 WAYNE-032

H.F. Lee Power Station H.F. Lee Ash Pond 3 (Inactive) Wayne 35.375800 -78.106900 WAYNE-033

APPENDIX B

257.71 Design Criteria for Existing CCR Surface

Impoundments (a)(1) 257.72 Design Criteria for New CCR Surface Impoundments and Lateral

Expansions (a)(1)

aph (a)(2) of this section and a leachate collection

system between above the upper and lower components component of the composite liner. The

design of the composite liner and leachate collection system must be prepared by, or under the

direction of, and

New CCR landfills and lateral expansions and New CCR Surface impoundments and lateral

expansions must be constructed with a base that is located a minimum of two four feet above the

upper limit of the

257.40 Disposal standards for

owners/operators of CCR landfills and CCR surface impoundments. (a)(2)

means a disposal facility or part of a facility where CCRs are placed in or on land

and which is not a land treatment facility, a surface impoundment, an underground injection well,

a salt dome formation, a salt bed formation, an underground mine, a cave, or a corrective action

management unit. For purposes of this proposed rule, landfills also include piles, sand and gravel

pits, quarries, and/or, large scale fill operations where CCR exceeds 5,000 cubic yards. Sites that

are excavated so that more coal ash can be used as fill are als

257.40 Disposal standards for owners/operators of CCR

landfills and CCR surface impoundments. (a)(2) Definitions

Active life means the period of operation beginning with the initial placement of CCRs in the

landfill or surface impoundment and ending at completion of closure activities in accordance with

257.110. 257.100.

APPENDIX C

IN-SITU REMEDIATION OF HEAVY METALS USING SULFUR-BASED

TREATMENT TECHNOLOGIES

By J im J acobs, Roy L. Hardison, and J im V. Rouse

THE METALS PROBLEM: Highly toxic and highly soluble metals are contained in numerous waste

streams including those from power, chemical, electronics facilities, general manufacturing plants, and

mining facilities. Lead, chromium, arsenic, zinc, cadmium, copper, and mercury are the most common

metal contaminants found on remediation project sites (US EPA, October, 2000). Cyanide is a common

inorganic contaminant as well. Metal concentrations in excess of established health guidelines have been

shown to create significant health risks to humans.

PAST REMEDIATION OPTIONS: In the

past, conventional remediation of soil

impacted by heavy metals has relied on

excavation, which was expensive and

disruptive. In addition, moving the soil only

moved the problem, without treating the soil

or reducing the long-term liability. For

groundwater, pump and treat remediation

relied on pumps to remove groundwater from

the aquifer through a series of extraction wells

or trenches. The extracted water was then

treated above ground or disposed of off-site.

Pump and treat methods fail to address the

source of the contamination in the vadose

zone. Although the construction of passive

permeable treatment walls containing zero

valent iron filings can reduce some metals to less toxic varieties, the passive barriers are expensive and

do not treat source areas (Thomasser and Rouse, 2001).

707 View Pt. Road Mill Valley, CA 94941 tel: 415-381-5195 fax: 415-381-5816

SULFUR-BASED TREATMENT TECHNOLOGY: Recently, sulfur-based metals treatment

technologies have been the focus of an increasing number of research studies and commercial

applications for treating metals contamination in soil and groundwater. The solubility of these metals is

highly pH dependent. A reagent, such as

calcium polysulfide (CaS

4

; brand name:

Cascade

), precipitates the highly soluble

metals (arsenic, lead, copper, zinc, cadmium,

molybdenum, uranium) as less soluble, and

non-toxic sulfides. As shown in Figure 1,

metal sulfides are far less soluble than metal

hydroxides. Metal hydroxides change

solubility with changes in pH. Metal sulfides

remain insoluble within a pH range of about 5

to 9.

Hexavalent chromium is reduced from Cr (VI)

to trivalent chromium, Cr (III), and then

precipitates as chromium hydroxide (US EPA,

October, 2000). The cyanide ion, a common

inorganic contaminant, reacts with calcium

polysulfide to form thiocyanate, which is

further degraded with excess calcium

polysulfide or lime to ammonia, calcium

carbonate and gypsum, eliminating the CN

-

radical.

Cascade

has a pH of 11.3 to 11.5, a specific

gravity of 1.273 and is deep orange-red

solution. Calcium polysulfide is water soluble and comes as 29% active ingredient solution. Polysulfide

has been used to conduct in situ remediation of uranium, selenium, arsenic, copper, and chromium

contamination.

REMEDIATION PHASES: The authors recommend a review of the existing physical and

chemical data, including pH, permeability, lithology, and water depth, concentrations of metals,

alkalinity, and other data and a simple bench test which can take a few days. Pilot scale tests are

recommended to verify treatability. The in-situ pilot-scale or full-scale remediation can be

performed shortly after the bench test results are available.

DELIVERY SYSTEM: In-situ delivery is one of the key factors in successful remediation,

since the treatment chemicals must fully contact and react withthe contaminant. High-pressure

injection technology, also called jetting, uses a direct push method as well as a specialized lance

system for the delivery of treatment chemicals has proved successful for metals remediation

(J acobs, 2001). Adjustments to pH of the treatment liquids can enhance the metals precipitation

process.

CASE STUDY:

UKIAH, CALIFORNIA WOOD TREATING PLANT: A

high pressure injection delivery system was developed for a

Cr (VI) project in Ukiah, California. The site had been

subjected to more than a decade of conventional pump and

treat remediation, with little impact on the contamination.

Up to 300 gallons (up to 20 gallons per minute) of calcium

polysulfide was injected into the groundwater in 114

injection ports to a maximum depth of 20 feet in 1997. The

result was an almost instant decline in chromium

concentration in the groundwater (Thomasser and Rouse,

2001). A second injection program was used to address

local areas of remaining contamination. The site is now

conducting a program of monitoring of existing wells.

SUMMARY:

Sulfur based metals treatment technologies show promise

in being able to precipitate toxic and highly soluble metals

into less soluble, less toxic metal sulfides for arsenic, lead,

copper, zinc, cadmium, molybdenum, and uranium. Mobile

hexavalent chromium is reduced to the insoluble chromium

hydroxide, while cyanide forms less toxic thiocyanate. In

all cases, treatment is pH dependent and can be an attractive

remedial action compared to more conventional metals

remediation methods such as excavation and pump and

treat.

ACKNOWLDGEMENTS:

The authors thank Rick Thomasser of Montgomery Watson, a firm which has pioneered in

sulfur-based metals treatment technologies. The authors also thank Marc Ashcroft of FAST-

TEK Engineering Support Services for developing and improving efficient in-situ remediation

injection technology over the past three years.

REFERENCES:

J acobs, J ., 2001, In-Situ Liquid Delivery Systems for Chemical Oxidation, Bioremediation and Metals

Stabilization, Association for Environmental Health and Sciences, 11

th

Annual West Coast Conf. on

Contaminated Soils, Sediments and Water, March 21, 2001, San Diego, California, Abstracts.

Thomasser, R. and Rouse, J .V., 2001, In-Situ Remediation of Chromium Contamination of Soil and

Groundwater, Montgomery-Watson.

707 View Pt. Road Mill Valley, CA 94941 tel: 415-381-5195 fax: 415-381-5816

707 View Pt. Road Mill Valley, CA 94941 tel: 415-381-5195 fax: 415-381-5816

United States Environmental Protection Agency (EPA), 1981, US EPA Chart Comparing Sulfide and

Hydroxide Solubilities; EPA publication, EPA-600/2-82-OIIC.

United States Environmental Protection Agency, October, 2000, In Situ Treatment of Soil and

Groundwater Contaminated with Chromium, EPA/625/R-00/005

AUTHORS:

J im J acobs is a certified hydrogeologist and president of FAST-TEK Engineering Support

Services where he has designed dozens of in-situ remediation projects. Mr. J acobs is on the

GRA Board of Directors; Tel: 510-232-2728; ext. 222; augerpro@jps.net.

Roy Hardison is technical manager of Best Sulfur Products where he has specialized in metals

stabilization technologies. He has been involved with numerous metals treatment projects. Tel:

800-447-5826; ; rhardison@att.net

J im V. Rouse is a geohydrologist with almost 40 years of relevant experience in the subsurface

behavior of heavy metals and radionuclides. He developed the concept of in-situ metals

remediation in the early 1980s, and has been involved in projects across the United States and

Australia. He is Principal Geohydrologist with Montgomery Watson in Colorado, 303-410-4029;

jim.rouse@mw.comT

APPENDIX D

30

31

5

32

33

5

10

15

20

25

30

35

40

APPENDIX E

Coal Combustion Residual

Beneficial Use Evaluation:

Fly Ash Concrete and

FGD Gypsum Wallboard

February 2014

Final

United States Environmental Protection Agency

Office of Solid Waste and Emergency Response

Office of Resource Conservation and Recovery

Disclaimer

This document was prepared by the Environmental Protection Agencys Office of Solid Waste and

Emergency Response and reviewed by appropriate offices within the Agency. Any opinions, findings,

conclusions, or recommendations do not change or substitute for any statutory or regulatory provisions.

This document does not impose legally binding requirements, nor does it confer legal rights, impose

legal obligations, or implement any statutory or regulatory provisions. Mention of trade names or

commercial products is not intended to constitute endorsement or recommendation for use.

i

Executive Summary

Purpose

The goal of this document is to use sound science based on accepted and standard practices to

determine whether the United States Environmental Protection Agency (EPA or the Agency) should

support the beneficial use of coal fly ash in concrete and flue gas desulfurization (FGD) gypsum in

wallboard. Coal fly ash used as a direct substitute for portland cement in concrete (hereafter referred to

as fly ash concrete) and FGD gypsum used as a replacement for mined gypsum in wallboard (hereafter

referred to as FGD gypsum wallboard) are the two largest encapsulated beneficial uses of coal

combustion residuals (CCRs) in the United States.

In addition, this document provides an example of how to conduct similar analyses using EPAs

Methodology for Evaluating Encapsulated Beneficial Uses of Coal Combustion Residuals (US EPA,

2013a). This example also demonstrates an appropriate level of documentation for such analyses.

Conclusions

Based on the analysis set forth in this document, the evaluation concludes that environmental

releases of constituents of potential concern (COPCs) from CCR fly ash concrete and FGD gypsum

wallboard during use by the consumer are comparable to or lower than those from analogous non-CCR

products, or are at or below relevant regulatory and health-based benchmarks for human and ecological

receptors.

The beneficial use of CCRs, when conducted in an environmentally sound manner, can contribute

significant environmental and economic benefits. Environmental benefits can include reduced

greenhouse gas emissions, reduced need for disposing of CCRs in landfills, and reduced use of virgin

resources. Economic benefits can include job creation in the beneficial use industry, reduced costs

associated with CCR disposal, increased revenue from the sale of CCRs, and savings from using CCRs

in place of other more costly materials.

Based on the conclusion of the analysis in this document stated above, and the available

environmental and economic benefits, EPA supports the beneficial use of coal fly ash in concrete and

FGD gypsum in wallboard. The Agency believes that these beneficial uses provide significant

opportunities to advance Sustainable Materials Management (SMM).

Background

Beneficial use of industrial materials has the potential to provide economic benefits, preserve virgin

resources, and avoid negative environmental impacts associated with the acquisition and processing of

virgin materials. Beneficially using these materials presents significant opportunities to advance SMM

and the Agencys SMM Program. The SMM Program supports the productive and sustainable use/reuse

of resources throughout all stages of their lifecycles, from resources acquisition through disposal. The

SMM Program seeks to avoid or minimize impacts to the environment while accounting for economic

ii

efficiency and social considerations. CCRs are one of the industrial materials produced in the greatest

quantity each year. The beneficial use of CCRs when conducted in a manner protective of human health

and the environment can advance these SMM goals.

While the beneficial use of CCRs has been shown to have economic and material benefits, the

environmental impacts associated with their use must also be considered. To do this, EPAs Office of

Solid Waste and Emergency Response (OSWER) developed the Methodology for Evaluating

Encapsulated Beneficial Uses of Coal Combustion Residuals (US EPA, 2013a). While in this document

the Agency has used the methodology to evaluate the beneficial use of CCRs in certain encapsulated

uses, this methodology can be useful to states, tribes, local governments, the public, and the regulated

community for making informed decisions about any encapsulated beneficial uses of CCRs. The

methodology has undergone an independent external letter peer review. A summary of the comments

received from peer reviewers is available in the document Peer Review Summary Report: Independent

External Peer Review of the Preliminary Draft Report Methodology for Evaluating Encapsulated

Beneficial Uses of Coal Combustion Residuals (US EPA, 2012a). Responses to these comments are

available in the document Responses to External Peer Review Comments: Methodology for Evaluating

Encapsulated Beneficial Uses of Coal Combustion Residuals (US EPA, 2013b).

The methodology establishes a series of five steps that can be used to determine whether

environmental releases of COPCs from an encapsulated beneficial use product made with CCRs are

comparable to or lower than those from an analogous product made without CCRs, or are at or below

relevant regulatory and health-based benchmarks developed for human and ecological receptors, during

use by the consumer. The methodology allows evaluation of the range of possible encapsulated

beneficial uses for any CCR. As developed, the methodology is quite flexible. The party conducting the

evaluation can choose to begin at the first step and follow the methodology in the order presented or,

based on the type and amount of data available on the CCR and corresponding product, can choose to

begin the evaluation at any other step of the methodology. If releases of COPCs from the CCR

beneficial use are found to be comparable to or lower than those from an analogous non-CCR product,

or are at or below relevant regulatory and health-based benchmarks at any step of the methodology, then

no further evaluation is necessary for those particular COPCs.

Summary of the Analysis

The Agency used the methodology to evaluate the potential environmental impacts associated with

fly ash concrete and FGD gypsum wallboard. These beneficial use products may be variable in their

composition. However, this evaluation only addressed those products that meet relevant physical and

performance standards established by voluntary consensus standard bodies; that conform to specific

design criteria identified in this evaluation (e.g., a 40 percent fly ash replacement rate); and that

incorporate fly ash and FGD gypsum from common pollution control devices used in the United States.

This evaluation also did not address products that contain additional additives or industrial materials that

may alter releases from the products. In this specific evaluation, the Agency began with the first step and

followed subsequent steps in the order presented in the methodology. The findings at each step of this

specific conservative evaluation are summarized below.

iii

Step 1 (Literature Review and Data Collection): From the available literature, the evaluation

identified the following releases that may occur during use of fly ash concrete and FGD gypsum

wallboard: 1) generation of dust, 2) emanation to air, 3) leaching to ground and surface water, and 4)

decay of naturally occurring radionuclides (also referred to simply as radioactive decay). In addition,

this literature review found several existing evaluations to be of sufficient applicability and quality to

rely upon in the current evaluation. For fly ash concrete, the findings from these evaluations were used

to eliminate radioactive decay from further consideration. For FGD gypsum wallboard, the findings

from these existing evaluations were used to eliminate all releases from further consideration, except for

emanation to air. The evaluation then used the available literature to identify COPCs for each of the

remaining releases.

Step 2 (Comparison of Available Data): The Step 2 evaluation used the data identified in Step 1 to

compare releases from fly ash concrete and FGD gypsum wallboard to releases from their respective

analogous products (i.e., portland cement concrete and mined gypsum wallboard) during use by the

consumer. The evaluation found that concentrations of silver and manganese in dust from fly ash

concrete were comparable to or lower than those in dust from portland cement concrete. The evaluation

also found that concentrations of arsenic, cadmium, lead, molybdenum, and thallium in leachate from fly

ash concrete and portland cement concrete were comparable. Therefore, the evaluation did not carry

these COPCs forward for further consideration, but retained all other COPCs from fly ash concrete and

FGD gypsum wallboard for further consideration.

Step 3 (Exposure Review): The Step 3 evaluation reviewed the releases carried forward from Step

2 to identify exposures that may occur during use of the product. Where multiple exposure pathways

associated with a given release were identified, the evaluation retained only those pathways likely to

drive exposures for further consideration. The evaluation did not eliminate any releases or associated

COPCs at this step.

Step 4 (Screening Assessment): The Step 4 evaluation conducted a screening assessment for each

exposure pathway carried forward from Step 3 of the evaluation. The evaluation used conservative (i.e.,

likely to overestimate exposures) environmental, fate and transport, and exposure data to estimate COPC

exposures that may occur during use of the CCR beneficial use products. The evaluation then compared

these conservative exposure concentrations to relevant screening benchmarks to determine whether to

conduct more in-depth evaluation. At the end of this step, the evaluation found that all remaining

COPCs were below relevant screening benchmarks. Therefore, this evaluation did not proceed to the

final Step 5 (Risk Assessment).

Conclusion: At the end of Step 4 the analysis was concluded as all identified COPCs had been

eliminated in Steps 1 through 4. Thus, based on application of the methodology and the lines of

evidence set forth in this document, the evaluation concludes that environmental releases of COPCs

from CCR fly ash concrete and FGD gypsum wallboard during use by the consumer are comparable to

or lower than those from analogous non-CCR products, or are at or below relevant regulatory and

health-based benchmarks for human and ecological receptors.

iv

Table of Contents

Executive Summary .................................................................................................................. i

Table of Contents ..................................................................................................................... iv

Introduction ............................................................................................................................... 1

Selection of Beneficial Uses for Evaluation ................................................................................ 1

Properties of Fly Ash and FGD Gypsum ..................................................................................... 2

Fly Ash ................................................................................................................................... 2

Flue Gas Desulfurization Gypsum ......................................................................................... 3

Overview of Methodology Steps ................................................................................................. 4

1 Step 1: Literature Review and Data Collection ............................................... 1-1

1.1 Fly Ash Concrete .......................................................................................................... 1-1

1.1.1 Existing Evaluations for Fly Ash Concrete ............................................................ 1-1

1.1.2 Data Collection for Fly Ash Concrete .................................................................... 1-7

1.1.3 Summary of Releases Identified for Fly Ash Concrete .......................................... 1-8

1.2 FGD Gypsum Wallboard ............................................................................................ 1-10

1.2.1 Existing Evaluations for FGD Gypsum Wallboard .............................................. 1-10

1.2.2 Data Collection for FGD Gypsum Wallboard ...................................................... 1-12

1.2.3 Summary of Releases Identified for FGD Gypsum Wallboard ............................ 1-13

1.3 Conclusions of Step 1 ................................................................................................. 1-13

2 Step 2: Comparison of Available Data ............................................................... 2-1

2.1 Releases from Fly Ash Concrete and Portland Cement Concrete ................................ 2-1

2.1.1 Generation of Dust .................................................................................................. 2-1

2.1.2 Leaching to Ground and Surface Water.................................................................. 2-3

2.1.3 Emanation to Indoor Air ......................................................................................... 2-9

2.2 Releases from FGD Gypsum Wallboard and Mined Gypsum Wallboard .................... 2-9

2.2.1 Emanation to Indoor Air ....................................................................................... 2-10

2.3 Conclusions of Step 2 ................................................................................................. 2-10

3 Step 3: Exposure Review ........................................................................................ 3-1

3.1 Fly Ash Concrete .......................................................................................................... 3-1

3.1.1 Potential Exposure Pathways for Fly Ash Concrete ............................................... 3-1

3.1.2 Potential Receptors for Fly Ash Concrete .............................................................. 3-3

3.2 FGD Gypsum Wallboard .............................................................................................. 3-5

3.2.1 Potential Exposure Pathways for FGD Gypsum Wallboard ................................... 3-5

v

3.2.2 Potential Receptors for FGD Gypsum Wallboard .................................................. 3-6

3.3 Conclusions of Step 3 ................................................................................................... 3-6

4 Step 4: Screening Assessment .............................................................................. 4-8

4.1 Fly Ash Concrete .......................................................................................................... 4-8

4.1.1 Exposure to Concrete Dust ..................................................................................... 4-8

4.1.2 Exposure to Ground and Surface Water ............................................................... 4-10

4.1.3 Exposure to Indoor Air ......................................................................................... 4-11

4.2 FGD Gypsum Wallboard ............................................................................................ 4-13

4.2.1 Exposure to Indoor Air ......................................................................................... 4-13

4.3 Conclusions of Step 4 ................................................................................................. 4-14

5 Section 5: Results, Uncertainties, and Conclusions ...................................... 5-1

5.1 Summary of Results ...................................................................................................... 5-1

5.1.1 Fly Ash Concrete .................................................................................................... 5-1

5.1.2 Flue Gas Desulfurization Gypsum Wallboard ........................................................ 5-4

5.2 Sources of Uncertainty .................................................................................................. 5-5

5.2.1 Uncertainties for Dust Exposures ........................................................................... 5-6

5.2.2 Uncertainties for Ground and Surface Water Exposures ...................................... 5-10

5.2.3 Uncertainties for Air Exposures............................................................................ 5-17

5.2.4 General Uncertainties............................................................................................ 5-22

5.3 Final Conclusions........................................................................................................ 5-25

6 References .................................................................................................................. 6-1

vi

List of Appendices

Appendix A: Summary of Raw Data

Appendix B: Identification of Relevant Screening Benchmarks

Appendix C: Ground Water Modeling

List of Tables

Table 1-1: Releases from Fly Ash Concrete and Associated COPCs ...................................................... 1-9

Table 1-2: List of COPCs Remaining Following Step 1 ....................................................................... 1-14

Table 2-1: Comparison of COPC Concentrations in Fly Ash and Portland Cement (mg/kg) ................. 2-2

Table 2-2: Comparison of Mercury Emanation Rates from Concretes (ng/m

2

-hr) ................................. 2-9

Table 2-3: Comparison of Mercury Emanation Rates from Wallboards (ng/m

2

-hr) ............................. 2-10

Table 2-4: List of COPCs Remaining Following Step 2 ....................................................................... 2-11

Table 3-1: List of COPCs Remaining Following Step 3 ......................................................................... 3-7

Table 4-1: Comparison of the Fly Ash Contribution to Concrete Dust Concentrations to Human

Health and Ecological Screening Benchmarks for Soil (mg/kg) ........................................... 4-9

Table 4-2: Comparison of Undiluted Leachate to Human Health Screening Benchmarks for

Ground and Surface Water (g/L) ....................................................................................... 4-10

Table 4-3: Comparison of Undiluted Leachate to Ecological Screening Benchmarks for Surface

Water (g/L) ........................................................................................................................ 4-11

Table 4-4: Comparison of Modeled Well Concentrations to Remaining Human Health Screening

Benchmark for Ground Water (g/L) .................................................................................. 4-11

Table 4-5: Comparison of Indoor Air Mercury Concentration from Fly Ash Concrete to Human

Health Screening Benchmark (ng/m

3

) ................................................................................. 4-13

Table 4-6: Comparison of Indoor Air Mercury Concentrations from FGD Gypsum Wallboard to

Human Health Screening Benchmark (ng/m

3

) .................................................................... 4-14

Table 5-1: 90

th

Percentile Fly Ash Concentration with Different Non-Detect Treatments (mg/kg) ....... 5-7

vii

List of Figures

Figure 1: Diagram of generic coal combustion processes. ......................................................................... 3

Figure 2-1: Comparison of cumulative leaching of antimony from concrete. ......................................... 2-4

Figure 2-2: Comparison of cumulative leaching of arsenic from concrete. ............................................ 2-5

Figure 2-3: Comparison of cumulative leaching of boron from concrete. .............................................. 2-5

Figure 2-4: Comparison of cumulative leaching of cadmium from concrete. ......................................... 2-6

Figure 2-5: Comparison of cumulative leaching of chromium from concrete. ....................................... 2-6

Figure 2-6: Comparison of cumulative leaching of lead from concrete. ................................................. 2-7

Figure 2-7: Comparison of cumulative leaching of molybdenum from concrete. ................................... 2-7

Figure 2-8: Comparison of cumulative leaching of selenium from concrete. ......................................... 2-7

Figure 2-9: Comparison of cumulative leaching of thallium from concrete. .......................................... 2-8

Figure 3-1: Human conceptual exposure model for fly ash concrete. ..................................................... 3-4

Figure 3-2: Ecological conceptual exposure model for fly ash concrete. ................................................ 3-5

Figure 3-3: Human conceptual exposure model for FGD gypsum wallboard. ........................................ 3-6

viii

Abbreviations and Acronyms

AASHTO American Association of State Highway and Transportation Officials

ACAA American Coal Ash Association

ACH Air Changes per Hour

AEA Air Entrainment Admixture

ANSI American National Standards Institute

ASHRAE American Society of Heating, Refrigerating and Air Conditioning Engineers

ASTM American Society for Testing and Materials

ATSDR Agency for Toxic Substances and Disease Registry

AWQC Ambient Water Quality Criteria

BCF Bioconcentration Factor

CalEPA California Environmental Protection Agency

CASRN Chemical Abstract Service Registry Number

CCR Coal Combustion Residual

COPC Constituent of Potential Concern

CPSC Consumer Product Safety Commission

CV-AFS Cold Vapor Atomic Fluorescence Spectrometry

DOE United States Department of Energy

DOT United States Department of Transportation

EC European Commission

Eco-SSL Ecological Soil Screening Levels

EERC University of North Dakota Energy and Environmental Research Center

EPA United States Environmental Protection Agency

EPRI Electric Power Research Institute

FBC Fluidized Bed Combustion

FGD Flue Gas Desulfurization

FHWA Federal Highway Administration

HBN Health-Based Number

HEI Highly Exposed Individual

HELP Hydrologic Evaluation of Landfill Performance

HPS Health Physics Society

HQ Hazard Quotient

IAEA International Atomic Energy Agency

IBC International Building Code

ICC International Code Council

ICP Inductively Coupled Plasma

ICRP International Commission on Radiological Protection

IRIS Integrated Risk Information System

IWEM Industrial Waste Evaluation Model

LEAF Leaching Evaluation Assessment Framework

LOI Loss of Ignition

ix

MCL Maximum Contaminant Level

MDL Method Detection Limit

ML Minimum Level of Quantitation

NJ DEP New J ersey Department of Environmental Protection

NCRP National Council on Radiological Protection

NOAA National Oceanic and Atmospheric Administration

NOAEL No Observable Affects Evaluation Level

NPDWR National Primary Drinking Water Regulation

NRC Nuclear Regulatory Commission

OSWER Office of Solid Waste and Emergency Response

PCA Portland Cement Association

PFA Pulverized Fuel Ash

PPRTV Provisional Peer Reviewed Toxicity Values for Superfund

PSI Pounds per Square Inch

RAGS Risk Assessment Guidance for Superfund

RfC Reference Concentration

SMM Sustainable Materials Management

SPLP Synthetic Precipitation Leaching Procedure

T3 Third Trophic Level

T4 Fourth Trophic Level

TCLP Toxicity Characteristic Leaching Procedure

TEL Threshold Effect Level

TENORM Technologically-Enhanced, Naturally Occurring Radioactive Materials

TL Trophic Level

UNSCEAR United Nations Scientific Committee on the Effects of Atomic Radiation

U.S. United States

UKHPA United Kingdom Health Protection Agency

UKNRPB United Kingdom National Radiation Protection Board

USGS United States Geological Survey

1

Introduction

Coal combustion residuals (CCRs) are the byproducts of coal combustion that are captured from

plant effluent and flue gases prior to discharge to the environment. Once generated, CCRs may be either

disposed of or beneficially used. Beneficial use, as defined in this document, is the reuse of CCRs in a

product that: 1) provides a functional benefit; 2) meets relevant product specifications and performance

standards for the proposed use; and 3) may replace virgin raw materials in a product on the market

(referred to as an analogous product or analogous non-CCR product), thus conserving natural

resources that would otherwise need to be obtained through other practices, such as extraction. The

reason CCRs can be used to replace virgin materials is that they possess physical and chemical

properties similar to those of the virgin materials.

The United States Environmental Protection Agency (EPA or the Agency) Sustainable Materials

Management (SMM) Program supports the productive and sustainable use/reuse of resources throughout

all stages of their life cycles, from resource acquisition through disposal. The SMM Program seeks to

avoid or minimize impacts to the environment while accounting for economic efficiency and social

considerations. The beneficial use of CCRs, when done in a manner protective of human health and the

environment, can advance these goals. The purpose of this beneficial use evaluation is to determine

whether environmental releases of constituents of potential concern (COPCs) from these encapsulated

1

CCR products are comparable to or lower than those from analogous products made without CCRs, or

are at or below relevant regulatory and health-based benchmarks for human and ecological receptors,

during use by the consumer. This document details the evaluation process as well as the findings and

conclusions of this beneficial use evaluation.

Selection of Beneficial Uses for Evaluation

CCR is a broad term used to refer to the byproducts generated either directly by coal combustion or

as a result of applying certain pollution control devices to emissions from coal-fired combustion units.

Types of CCRs generated from coal combustion include fly ash, bottom ash, boiler slag, flue gas

desulfurization (FGD) waste, and fluidized bed combustion (FBC) waste. All coal-fired electric utility

plants in the United States generate at least one of these types of CCRs. Each different type of CCR has

unique properties and, as a result, different potential uses. This evaluation chose to examine those

encapsulated beneficial uses that divert the greatest quantity of CCRs from disposal and have been most

extensively studied in the literature. The following text provides the rationale for the selection of the

CCR products evaluated.

1

In the J une 2010 Proposed Rule, Hazardous and Solid Waste Management System; Identification and Listing of Special

Wastes; Disposal of Coal Combustion Residuals from Electric Utilities (the 2010 Proposed CCR Disposal Rule) (75 FR

35127), the Agency defined encapsulated beneficial use as one that binds the CCRs into a solid matrix that minimizes their

mobilization into the surrounding environment. Examples of encapsulated uses are concrete, wallboard, and brick. In

contrast, unencapsulated beneficial uses include road embankments, structural fills, or agricultural applications (e.g.,

substitute for lime).

2

The American Coal Ash Association (ACAA) conducts a voluntary, annual survey of the coal-fired

electric utility industry to track the quantities of CCRs generated and beneficially used. According to the

latest survey, the electric utility industry generated nearly 110 million tons of CCRs during the 2012

calendar year. Approximately 39 million tons of these CCRs were identified by ACAA as beneficially

used in either encapsulated or unencapsulated products. An additional 12.8 million tons were placed in

mine-fill operations, while the remaining 57.8 million tons were disposed of in landfills and surface

impoundments (ACAA, 2013).

2

Based on the beneficial use rates reported by ACAA, the evaluation chose fly ash used as a direct

substitute for portland cement during the production of concrete (referred to as fly ash concrete) and

FGD gypsum used as a replacement for mined gypsum in wallboard (referred to as FGD gypsum

wallboard) during use by the consumer. Specifically, the 2012 ACAA survey indicates that the largest

encapsulated beneficial uses of CCRs, by more than a factor of two, are fly ash used in

concrete/concrete products/grout (11.8 million tons) and FGD gypsum used in gypsum panel

products (7.6 million tons). That is, these two beneficial uses make-up nearly 50 percent of the total

amount of CCRs beneficially used on an annual basis. While fly ash and FGD gypsum may not be the

only CCR or industrial material that may be beneficially used in concrete or wallboard, this evaluation

does not address the beneficial use of other industrial materials. This evaluation also draws no

conclusions about other beneficial uses of fly ash and FGD gypsum.

Properties of Fly Ash and FGD Gypsum

The following subsection describes the production process and properties of fly ash and FGD

gypsum as well as the associated beneficial uses evaluated in this document. Figure 1 illustrates a

generalized layout of a coal-fired plant and the collection points for fly ash and FGD gypsum.

Fly Ash

Fly ash is the fraction of combusted coal that becomes suspended in plant flue gases. The fly ash

available for beneficial use is captured primarily by mechanical particulate collection devices, such as an

electrostatic precipitator or baghouse. The remaining fly ash that passes through these particulate

collection devices either escapes into the atmosphere or is captured through sulfur dioxide [SO

2

] control

devices (i.e., scrubbers), resulting in its incorporation into the FGD solids. The chemical composition of

the beneficially used fly ash is variable and dependent on multiple factors, such as the geographic source

of the coal burned.

2

In 2012, the survey response rate was equivalent to 59 percent of the total US coal-fired electric generation capacity. This

estimated response rate is based on a ratio of the generating capacity of the individual plants reporting and the total United

States coal-fired generation capacity reported by the Energy Information Administration (EIA) in 2012. These data are

available online at: http://www.eia.gov/coal/data.cfm. Reported beneficial use rates were extrapolated for the entire

industry sector using the 2012 survey data, historical ACAA survey data, EIA data, and other miscellaneous data sources.

The survey groups similar beneficial uses into generalized categories. As a result, a given ACAA category may include

some data on beneficial uses beyond those evaluated in this document.

3

Figure 1: Diagram of generic coal combustion processes.

Fly ash may be used as a partial substitute for the portland cement in concrete because it is a

pozzolan, a material that reacts with calcium oxide [CaO], also known as lime, in the presence of water

to produce a cementitious compound. Silica dioxide [SiO

2

], aluminum trioxide [Al

2

O

3

], and iron oxide

[Fe

2

O

3

] are the primary chemical constituents that may contribute to this reaction. In addition, fly ash

may contain significant amounts of lime, causing it to be self-cementing in the presence of water. The

American Society for Testing and Materials (ASTM) classifies fly ashes based on the amount of lime

present as either Class F (low lime/high iron) or Class C (high lime/high calcium) (ASTM C618).

Depending on the composition of the fly ash and the intended use of the fly ash concrete, a wide range

of cement substitution rates may be considered. Class F fly ash is often used to replace portland cement

at rates between 15 percent and 25 percent by mass, while Class C fly ash is often used to replace

portland cement at rates between 15 percent and 40 percent by mass (PCA, 2003). However, specific

replacement rates vary based both on the characteristics of the specific fly ash and on the desired

characteristics of the concrete. ASTM specifies a maximum cement replacement rate of 40 percent for

blended fly ash-cement mixtures based on engineering specifications (ASTM C595). Therefore, the

findings of this evaluation are limited to portland cement replacement rates at or below 40 percent by

mass.

Flue Gas Desulfurization Gypsum