Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manual - Dust Collector and Bin Vent

Caricato da

frankz89Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manual - Dust Collector and Bin Vent

Caricato da

frankz89Copyright:

Formati disponibili

DUST COLLECTOR / FILTER RECEIVER

2

TABLE OF CONTENTS

Product overview Page 3

Safety precautions Page 4

Equipment storage Page 4

External components Page 5

Internal components Page 6

Installation instructions Page 7

Electrical installation and controls Page 8

Operation and start-up Page 8-9

Maintenance instructions Page 9-10

Filter bag replacement bottom removal Page 11

Filter bag replacement top removal Page 12

Troubleshooting Page 13

Spare parts list Page 14

Equipment warranty Page 15

Manufacturer's cut -sheets,

manuals, and drawings Remaining pages

3

PRODUCT OVERVIEW

The filter bags are usually 16 oz. felt (polyester, acrylic, polypropylene, nomex, teflon r, huyck-glas r, or goretex

r) and are supported by wire cages. The bags and cages are clamped to collars riveted to the tube sheet or a part

of the venturi which extends through the tube sheet. "Blow pipes" with drilled orifices are located above each

row of filter bags such that the orifices are directly above the throat of venturi.

Dust laden air enters the collector under pressure or suction from a fan or another air moving device. Pulse jet

cleaning takes place when the timer actuates a normally closed solenoid pilot valve causing it to open. The

diaphragm valve opens as a result of the decrease in pressure from the opening of the solenoid. A momentary

inrush of high pressure air (80-100 PSIG) flows from the header to the blow pipe, down through each venturi

and into each bag. Thus, all the bags in a single row are cleaned simultaneously.

DCL dust collectors are usually shipped completely assembled. The compressed air header with solenoids and

timer are all installed and prewired. Bags and cages are shipped separately to help prevent unnecessary damage

during shipping. The bags and cages will need to be installed in the field.

Utilities should be connected to the dust collector in accordance with existing codes, along with the solenoids

and timer which are all installed and prewired. Compressed air piping should be sized for the SCFM specified

on the job drawing. Compressed air pressure should be 80 to 100 PSI, unless a lower pressure has been

specified. In this event, the diaphragm valves, blow pipes, and orifices will be larger than usual to

accommodate the lower air pressure.

The 115 volt, single phase, 60 hertz timer is either installed in the enclosure with the solenoid valves or in a

separate NEMA 4, 4X, 7, 9, or 12 enclosure as required. It can also be installed in a master control panel if

desired.

The compressed air supply should be free of contamination. A water tap, filter and/or regulator may be

furnished with the compressed air header to accommodate a manual drain valve, a quick coupler for air tools to

assist in bag changing and either end connection of the main compressed air supply. All openings not used are

plugged at the factory unless otherwise specified.

SAFETY FIRST READ THESE PRECAUTIONS

DCL equipment is generally designed to be operated from a remote operator's station or control room. Extra

caution should be taken when using pendant-type controls or any other time that personnel are in the area of

loading operations. The operator should always be able to see the equipment when it is in operation.

Standard safety lockout procedures must be followed when performing maintenance or repairs on the

equipment, especially if the equipment is equipped with automatic sensors or control mechanisms. Use care to

prevent uncontrolled movement of the equipment, or uncontrolled release of product.

Appropriate personal safety equipment, including required fall protection, should be used while working on or

around DCL equipment. Use the proper tools in good condition to maintain and service the equipment. Safety

is the responsibility of the equipment owners and operators.

4

EQUIPMENT STORAGE

Store the equipment in a dry, cool location, preferably indoors. If outdoor storage is necessary, cover the

equipment with a tarpaulin or other suitable waterproof covering, and raise the equipment off the ground, on

dunnage or pallets. Protect the equipment, including electrical equipment and panels, from dust, dirt, mud,

moisture, snow or ice, and sun.

Note that a number of the components of DCL equipment are pilferable in unattended storage. These include

motors and electrical components. Take appropriate measures to secure the equipment.

Before placing the equipment into operation, inspect for damage that may have occurred during storage. Purge

the factory installed lubricant by pumping fresh lubricant into each grease fitting until any contaminated grease

has been expelled from each bearing. Remove the purged lubricant from the exterior surfaces of the equipment.

Clean off any dirt, rust, or corrosion, and spot paint as necessary.

Dry any moisture or condensation that has entered electrical equipment or panels. Inspect for damage to panels,

boxes, switches, or conduits.

5

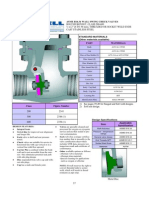

DUST COLLECTOR EXTERNAL COMPONENTS

(DC style dust collector shown on left; FR style filter receiver shown on right.)

1. Main housing 7. Clean air fan assembly

2. Access door 8. Clean air fan outlet

3. Dust laden airstream inlet 9. Clean air outlet

4. Product dust outlet 10. Clean air plenum

5. Dust collector hopper 11. Pulse jet header assembly

6. Clean air fan motor

6

DUST COLLECTOR INTERNAL COMPONENTS

1. Timer (not shown; mounted in enclosure) 8. Venturi

2. Filter bag 9. Blow pipe

3. Filter bag support cage 10. Compressed air header

4. Filter bag clamp 11. Filter housing

5. Diaphragm valve 12. Clean air plenum

6. Solenoid pilot valve 13. Clean air outlet

7. Magnehelic differential pressure gauge

7

INSTALLATION INSTRUCTIONS

The dust collector housing is usually shipped completely assembled, in a wooden shipping cradle on a pallet.

Filter bags and cages are usually shipped separately to help prevent unnecessary damage during shipping.

Always use good safety practices and due care while working on DCL equipment. Adhere

to all applicable OSHA, MSHA, state, and local safety regulations.

Note: The purchaser must use good engineering and operating practice in the design and fabrication of support

structure, interfaces, and power supplies for DCL equipment.

1. Remove the shipping bracing and packing from the pallet. Inspect the dust collector, filter bags, and

hardware for damage or missing parts. Report any damage or breakage to the shipping company.

2. For free-standing models: Make sure that the surface on which the dust collector will be located is clean, is

straight, flat, and level in all directions, and is firm, preferably made of concrete. Using a crane, forklift,

hoist, or other suitable lifting device, set the dust collector into position. Check the orientation and level of

the dust collector. Take care to avoid interferences with other equipment and structures, particularly for

moving equipment. Securely bolt the dust collector into position.

3. For bin-vent style models: Make sure that the flange on which the dust collector will be located is clean, is

straight, flat, and level in all directions, and is the correct size and bolt pattern. Apply an even bead of caulk

or sealant on the mounting flange. The type of caulk used will depend on the expected operating conditions,

but DCL recommends a high quality silicone caulk. Using a crane, forklift, hoist, or other suitable lifting

device, set the dust collector into position. Check the orientation and level of the dust collector. Take care

to avoid interferences with other equipment and structures, particularly for moving equipment. Securely

bolt the dust collector into position.

4. If the exhaust fan is not already installed: Apply an even bead of caulk or sealant on the exhaust fan

mounting flange of the dust collector. The type of caulk used will depend on the expected operating

conditions, but DCL recommends a high quality silicone caulk. Securely install the exhaust fan to the filter

module in the correct orientation. Connect the dust outlet flange to the existing dust withdrawal ducting. A

manual blast gate and/or gravity type bleed damper is recommended to control the air flow and static

pressure in the ductwork system, especially in systems where multiple inlets exist.

Note: Adhere to good industrial ventilation practice when designing dust withdrawal ducting. Improper

design can lead to unacceptably low flow velocities, or high transition losses in the piping. This results in

clogging of dust ducting, and poor dust collection at the spout.

5. Apply an even bead of caulk or sealant on the flanges at the dirty air inlet, product inlet, product outlet, and

clean air outlet as applicable. The type of caulk used will depend on the expected operating conditions, but

DCL recommends a high quality silicone caulk. Install the appropriate system ducting to the flanges as

applicable.

6. Install the filter bags and cages into the dust collector. See the filter bag replacement instructions.

8

ELECTRICAL INSTALLATION AND CONTROLS

Always use good electrical and safety practices and due care while working on DCL

equipment. Adhere to all applicable OSHA, MSHA, state, and local safety regulations and

code requirements.

Note: DCL does all electrical work and prewiring according to the NEC effective at the time of manufacture.

Because of differences in local code requirements, the purchaser is responsible for the compliance of DCL

equipment after installation. Good electrical practice is assumed in the design and installation of power supplies

and connections not supplied by DCL.

Electrical installation consists of making all electrical connections to the fan motor and control panel, pneumatic

connection to the compressed air header, and any optional accessory as specified in the electrical schematic or

pneumatic diagram supplied with the equipment.

1. Install wiring/cable from the junction box to the control panel and fan motor. The 3-phase power leads for

the fan motor should be placed in a separate conduit to provide electrical isolation between the high voltage

and the control circuits.

2. Connect the fan motor to the correct voltage. Test for rotation by "bumping" (momentarily energizing) the

motor to determine the direction of rotation. If rotation is incorrect, reverse any two legs of the 3-phase

motor power leads to change direction of rotation.

3. Connect the dust collector to a source of clean, dry compressed air. For best function, the air should be 80 to

110 PSI (check the General Arrangement drawing for air volume requirements).

(If the dust collector has been stored for an extended period or has been exposed to moisture/weather, add a

few drops of good pneumatic lubricating oil to the solenoid valve inlets before connecting the air supply.)

OPERATION AND START-UP

Always use good safety practices while using DCL equipment.

1. Before start-up with material, check for flange and draw band leakage at the inlet, outlet, dust discharge,

duct discharge, duct work and fan connections in the systems.

2. Listen for air noise. Leaks into a collector can cause condensation and moisture problems. Leaks out

can cause dusting. Check the electrical, wiring connections, proper fan rotation, and fuse selection.

3. The pulse timer should usually be connected to 115 volt, 60 hertz, and single phase current only. Refer

to the schematic for special control voltages.

4. During initial start-up with new bags, there will be very little resistance across the collector. If the

operating bag pressure drop is a large percentage of the total system, then fan motor overloading can take

place with clean bags. (The fan will pull more air due to low resistance.) Install a fan discharge or inlet

damper to control BHP within motor limits. The use of this throttling device will also let dust build up

9

slowly and prolong the life of the bags. It will also keep the exhaust volume within design limits and

save energy.

5. A differential pressure gauge is supplied with each collector. Occasional checks of the differential

pressure are desirable. Most installations are designed for a pressure differential of three to four inches

of water column. Readings from one to six inches are normal.

6. Controlling the operation pressure differential:

A. Increase or decrease the compressed air pressure (recommended 80 to 100 PSIG). The result is more

or less vigorous cleaning of the bags. This will then produce a lower or higher static pressure

differential across the bags.

B. An increase or decrease in the time between cleaning pulses will also increase or decrease the static

pressure differential. (If the differential pressure is low, the length of time between pulses may be

increased to conserve compressed air and extend the life of the filter cartridges.) A one-second pulse

is the recommended minimum pulse duration for this installation. The pulse length should only be

increased enough to produce a good, sharp "pulse" for all valves. Longer pulses only waste air with

no noticeable increase in cleaning.

7. A visual operating check should be made of the discharge gases. No dust should be visible at the

exhaust. Should dust be visible, check Troubleshooting.

MAINTENANCE INSTRUCTIONS

Always use good safety practices and due care while working on DCL equipment.

Note: These are general guidelines for maintaining a typical dust collector. Some options may include

equipment with a different maintenance schedule. Instructions direct from the manufacturer for each purchased

maintenance item are located at the rear of this manual, and they may vary from the procedures listed here.

Always use the instructions direct from the manufacturer first. These instructions are obtained as close as

possible to the time of printing. The manufacturer reserves the right to change these instructions without notice.

DAILY:

1. Visually inspect the equipment for damage or wear.

2. Inspect all warning and caution stickers, placards, etc. for legibility or damage. Replace any that are

missing or cannot be read immediately.

3. During operation, observe the equipment for abnormal behavior, malfunction, or damage.

4. Make sure that the equipment is stored properly at the conclusion of loading operations.

MONTHLY:

1. Inspect all electrical connections and conduits for damage or improper installation.

10

2. Inspect for fluid leakage around shaft seals, and on reducers and motors.

3. Check the pressure differential reading. At 5 inches of water column, check the filters for buildup

and wear, and look into filter replacement. At 7 inches of water column, the filters must be replaced.

This interval may be adjusted depending on operating conditions.

4. Inspect the door seals and latches for wear, damage, or improper operation. Make any adjustments

or needed repairs. Lubricate the door latches with a good spray lubricant, such as WD40, and

exercise the latches to maintain free function. A rubber seal lubricant will extend the life of the door

seals.

5. Clean any product or dust build-up from the entire dust collector assembly by sweeping or washing

as needed. Use a warm mild detergent solution for cleaning. Do not use extreme heat or pressure.

Do not use any harsh chemicals or abrasives.

3 MONTH SERVICE INTERVAL:

1. Inspect the inner surfaces for wear or product buildup. Buildup of hygroscopic or sticky product

should be removed.

2. Inspect the solenoid and diaphragm valve assemblies for damage. Remove the exhaust mufflers and

clean out any debris or dirt that may have accumulated inside. Inspect electrical conduits and

connections for security or damage.

6 MONTH SERVICE INTERVAL:

1. Inspect all electrical equipment for moisture, corrosion, or arcing contacts. Clean any dust or debris

out of all electrical enclosures.

2. Lubricate the exhaust fan motor bearings with a good quality lithium-based grease. Refer to the

motor instructions for the proper lubrication procedure.

3. Inspect the exhaust fan damper for wear or damage. Lubricate the friction points with a good quality

lithium-based grease. Exercise the damper to maintain free function.

ANNUALLY:

1. Check all hoses, conduits, and cables for dry rot, cuts, wear or abrasion.

2. Inspect all hose clamps, fittings, restraints, and terminations for rust, corrosion, and wear or damage.

These service intervals are based on normal use and conditions. In severe conditions, intervals should be

shortened. Product sizes under 35 mesh will also shorten intervals, especially for lubrication.

11

FILTER BAG REPLACEMENT - BOTTOM REMOVAL

1. Remove the filter bag clamp from the top of the filter bag assembly. Discard the clamp.

2. Slide the filter bag and cage assembly off the mounting cup.

3. Remove the worn filter bag from the support cage. Check the cage for damage.

4. Install the new filter bag over the support cage and fold the top of the filter bag into the top of the

support cage. If the new filter bag is equipped with an anti-static line, make sure that it is folded over to

make contact with the filter bag mounting cup.

5. Slide the new filter bag clamp over the bag assembly and slide the assembly over the mounting cup.

Tighten the clamp.

6. Operate the system as usual, observing the fan discharge for dust emissions. If any dust emissions are

observed, one or more of the filter bags have been improperly installed.

BOTTOM REMOVAL

1. Mounting cup

2. Venturi

3. Filter bag clamp

4. Filter bag support cage

5. Filter bag

12

FILTER BAG REPLACEMENT - TOP REMOVAL

1. Remove the bolt securing the blow pipe to the support angle. Loosen the locking collar on the bulkhead

fitting, and remove the blow pipe.

2. Remove the blow pipe support angles from the rear of the clean air plenum.

3. Remove the bulkhead fitting by removing the outside locking collar and locknut from the fitting. The

bulkhead fitting may now be pulled inside the clean air plenum without dismantling the compressed air

header and diaphragm valve assembly.

4. To install the filter bag, place the bag through the hole in the tube sheet. Squeeze the top band of the

bag, and the lower unit edge of the tube sheet hole will nest in the groove in the top of the bag. This

ensures a tight seal and complete support of the filter bag.

5. Lower the cage and venturi assembly into the filter bag. The cage is completely installed when the cage

and venturi are supported on the tube sheet by the top ring of the cage assembly.

6. Assemble the pulse jet cleaning system in the reverse order of steps 1, 2, and 3.

TOP REMOVAL

1. Venturi, cage, and mounting

ring assembly

2. Filter bag media

3. Filter bag sealing ring

13

TROUBLESHOOTING

Always use good safety practices while working on DCL equipment.

Common system faults

1. Bag(s) installed improperly or missing. Check bags and reinstall if necessary.

2. Loose bag clamps. Do not use clamps more than once. Check clamps and tighten or replace if

necessary.

3. Bag(s) damaged during installation. Check bags and replace if necessary

4. Operating temperature too high for filter material. Lower the operating temperature, or switch to bags

that are designed for the operating temperature. Consult DCL if necessary.

5. Operating humidity, free moisture, etc. Consult DCL if necessary

6. Hopper bridging - use sponge rubber seal with drum, larger slide gate, airlock or vibration.

7. Collector overload with too much air - check system design, fan speed, damper adjustment.

8. Compressed air supply pressure too low 80-100 PSIG required. Check air supply and adjust or service

if necessary. Check all connections for leakage.

9. Solenoid valve(s) stuck, damaged, or inoperative. Check valves and repair or replace if necessary.

10. Diaphragm valve(s) ruptured or stuck. Check valves and repair or replace if necessary.

11. Blinding of filter bags - high static pressure. Consult DCL if necessary.

12. Static electricity. Switch to grounded filter bags. Consult DCL if necessary.

13. Wrong direction of rotation for fan. Check fan and reverse the rotation if necessary. See the section on

electrical installation and controls.

14. Leaking duct work or access doors, airlock or discharge valve on hopper - air is short circuited. Repair

or replace door seals, check ductwork and repair if necessary.

15. Slipping fan belt. Check belt and tighten or replace if necessary.

16. Clogged ductwork or closed damper. Check ductwork and damper adjustment.

17. Improper duct size. Check system design.

18. Bad electrical connections. Make sure all connections are clean, tight, and there are no arcing contacts.

If the above steps do not resolve the problem, consult DCL for assistance.

Potrebbero piacerti anche

- Zeks Compressed Air SolutionsDocumento39 pagineZeks Compressed Air SolutionsChristian MabayaNessuna valutazione finora

- EBook - Dust Collector MaintenanceDocumento33 pagineEBook - Dust Collector MaintenancejcpolicarpiNessuna valutazione finora

- Industrial Ventilation and ExhaustDocumento50 pagineIndustrial Ventilation and Exhaustk1l2d3Nessuna valutazione finora

- Dust Control HandbookDocumento215 pagineDust Control Handbookmarianiko1985100% (5)

- DM-Envrt TG - 30 Paint Spray BoothsDocumento6 pagineDM-Envrt TG - 30 Paint Spray Boothsaspire79Nessuna valutazione finora

- Quencher ProductinfoDocumento9 pagineQuencher ProductinfojohnNessuna valutazione finora

- Zeppelin Filter SystemsDocumento4 pagineZeppelin Filter Systemsshashikanth79Nessuna valutazione finora

- Belt Tear Detector.20160126Documento4 pagineBelt Tear Detector.20160126MikiNessuna valutazione finora

- Donaldson Dust Collector System - Catalogue PDFDocumento8 pagineDonaldson Dust Collector System - Catalogue PDFnidhincletusNessuna valutazione finora

- Ingersoll Rand Oil Free Centac Compressor PDFDocumento16 pagineIngersoll Rand Oil Free Centac Compressor PDFAbhiNessuna valutazione finora

- Compressed Air Installation Guide Ebook 0415-Tcm266-695991Documento83 pagineCompressed Air Installation Guide Ebook 0415-Tcm266-695991Escuela Animacion EspiNessuna valutazione finora

- Centrifugal Damper CatDocumento8 pagineCentrifugal Damper CatAdil Shahzad100% (2)

- Conveyor Safety 1Documento40 pagineConveyor Safety 1Mkhishwa100% (1)

- A Guidebook On Performance Monitoring of Bag Filter Dust CollectorDocumento80 pagineA Guidebook On Performance Monitoring of Bag Filter Dust CollectorAnh Nhật Eco100% (1)

- Rupture Disk+Safety Valve CombinationDocumento5 pagineRupture Disk+Safety Valve CombinationHamza NoumanNessuna valutazione finora

- BaghouseDocumento7 pagineBaghouseJayandi Fitra100% (1)

- Activated Carbon For VOC PDFDocumento4 pagineActivated Carbon For VOC PDFrocotroncosoNessuna valutazione finora

- 1 Burner PDFDocumento117 pagine1 Burner PDFA Nofianto100% (1)

- Ammonia Mechanical IntegrityDocumento11 pagineAmmonia Mechanical IntegrityDave CNessuna valutazione finora

- Pneumatic Grain Conveying Systems GuideDocumento16 paginePneumatic Grain Conveying Systems GuideMusheer BashaNessuna valutazione finora

- Fume Exhaust Duct Catalog 10 12 8 PDFDocumento86 pagineFume Exhaust Duct Catalog 10 12 8 PDFJonathan Arboleda GenesNessuna valutazione finora

- General Exhaust SystemsDocumento14 pagineGeneral Exhaust Systemsamg007Nessuna valutazione finora

- 3 UEq Book Excerpt PDFDocumento38 pagine3 UEq Book Excerpt PDFunnoted100% (1)

- Visolite InstructionsDocumento4 pagineVisolite InstructionsVo Haianh100% (1)

- 671 Vaneaxial FansDocumento20 pagine671 Vaneaxial FansEMRE GULERNessuna valutazione finora

- Se Andritz KMPT Peeler Centrifuge HZ EnglDocumento16 pagineSe Andritz KMPT Peeler Centrifuge HZ EnglKeith ContrerasNessuna valutazione finora

- Airmaster User ManualDocumento333 pagineAirmaster User ManualedgarNessuna valutazione finora

- Solvent Recovery and VOC Emission Control SystemsDocumento8 pagineSolvent Recovery and VOC Emission Control SystemsAnonymous ocCa18RNessuna valutazione finora

- Tecnología en Spray y Control de PolvoDocumento20 pagineTecnología en Spray y Control de PolvoAmbyLopezNessuna valutazione finora

- Compressed Air Installation GuideDocumento85 pagineCompressed Air Installation GuideDario DorkoNessuna valutazione finora

- Energy From Waste: A Good Practice Guide (CIWM)Documento76 pagineEnergy From Waste: A Good Practice Guide (CIWM)MisgatesNessuna valutazione finora

- As 2683-2000 Hose and Hose Assemblies For Distribution of Petroleum and Petroleum Products (Excepting LPG)Documento7 pagineAs 2683-2000 Hose and Hose Assemblies For Distribution of Petroleum and Petroleum Products (Excepting LPG)SAI Global - APACNessuna valutazione finora

- Turflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochureDocumento8 pagineTurflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochurePablo Angel ToiaNessuna valutazione finora

- Local Exhaust VentilationDocumento25 pagineLocal Exhaust Ventilationfariyashoeb100% (1)

- Experimental Study of Pleated Fabric Cartridges in A Pulse-JDocumento9 pagineExperimental Study of Pleated Fabric Cartridges in A Pulse-JumanathrpNessuna valutazione finora

- Spirax Trap Review GST - 33 PDFDocumento22 pagineSpirax Trap Review GST - 33 PDFFrank UrsNessuna valutazione finora

- Dust Collector DesignDocumento13 pagineDust Collector DesignAekJay50% (2)

- ScrollDocumento8 pagineScrolltrung2iNessuna valutazione finora

- Rupture Disc 2Documento7 pagineRupture Disc 2venkeekuNessuna valutazione finora

- Osha 3146Documento48 pagineOsha 3146s sanjaiNessuna valutazione finora

- Proper Dryer AlignmentDocumento33 pagineProper Dryer AlignmentNguyễn Thanh SơnNessuna valutazione finora

- A Guide To Fans For IndustryDocumento12 pagineA Guide To Fans For IndustryCarlos PintoNessuna valutazione finora

- Osha 3124Documento15 pagineOsha 3124theunknown076Nessuna valutazione finora

- 09 WMI-Policy For Opening Ammonia Refrigeration SystemsDocumento10 pagine09 WMI-Policy For Opening Ammonia Refrigeration SystemsDave CNessuna valutazione finora

- Donaldson Torit General CatalogDocumento24 pagineDonaldson Torit General CatalogBharath OrvaNessuna valutazione finora

- HandteFarr APC - Wet Scrubbers STZV, Catalogo)Documento12 pagineHandteFarr APC - Wet Scrubbers STZV, Catalogo)mario aviles torresNessuna valutazione finora

- Guide to Optimizing Fabric Dust Collector SystemsDocumento51 pagineGuide to Optimizing Fabric Dust Collector SystemsRawat100% (3)

- Confined Space VentilationDocumento31 pagineConfined Space VentilationSusan WillisNessuna valutazione finora

- FD Dryers CatalogDocumento13 pagineFD Dryers CatalogmasrooorNessuna valutazione finora

- OSHA Regulations Stair RailsDocumento6 pagineOSHA Regulations Stair Railsjuillet_jfNessuna valutazione finora

- Most Mikro ACM® - Air Classifying Mill SystemsDocumento12 pagineMost Mikro ACM® - Air Classifying Mill SystemsCesar EnochNessuna valutazione finora

- Sulphuric Acid Plant Converter Replacement ProjectsDocumento73 pagineSulphuric Acid Plant Converter Replacement ProjectsabderrahimnNessuna valutazione finora

- Selecting Right Air DryerDocumento7 pagineSelecting Right Air DryerMukund FarjandNessuna valutazione finora

- 3 SOP For Cleaning of Clinker Cooler DischargeDocumento3 pagine3 SOP For Cleaning of Clinker Cooler DischargekakaNessuna valutazione finora

- Health, Safety and Environment Policy: Israr EnterprisesDocumento1 paginaHealth, Safety and Environment Policy: Israr EnterprisesMuhammad HassaanNessuna valutazione finora

- Emergency Eyewash Station and Safety Shower GuidelinesDocumento15 pagineEmergency Eyewash Station and Safety Shower GuidelinesMAHMUD100% (1)

- His Leaflet Provides Information On The Fire and Explosion Hazards in The Use of OxygenDocumento16 pagineHis Leaflet Provides Information On The Fire and Explosion Hazards in The Use of Oxygenapi-19990246100% (1)

- McQuay PFS C Installation Manual EngDocumento17 pagineMcQuay PFS C Installation Manual EngAnbarasan Nagarajan100% (1)

- Regenerative Heatless Desiccant Dryer GuideDocumento16 pagineRegenerative Heatless Desiccant Dryer GuideRoberto Sanchez100% (1)

- Overland ConveyorDocumento1 paginaOverland Conveyorfrankz89Nessuna valutazione finora

- Plant 3DDocumento1 paginaPlant 3Dfrankz89Nessuna valutazione finora

- Software TankDocumento2 pagineSoftware Tankfrankz89Nessuna valutazione finora

- Gas NaturalDocumento7 pagineGas Naturalfrankz89Nessuna valutazione finora

- Piping MineriaDocumento2 paginePiping Mineriafrankz890% (1)

- Valvulas Tipo CuchillaDocumento8 pagineValvulas Tipo Cuchillafrankz89Nessuna valutazione finora

- Piping ArrangementDocumento2 paginePiping Arrangementfrankz89Nessuna valutazione finora

- Industrial PipingDocumento1 paginaIndustrial Pipingfrankz89Nessuna valutazione finora

- Piping InstallationDocumento1 paginaPiping Installationfrankz89Nessuna valutazione finora

- Pressure VesselDocumento2 paginePressure Vesselfrankz89Nessuna valutazione finora

- Pressure Vessel TanksDocumento2 paginePressure Vessel Tanksfrankz89Nessuna valutazione finora

- PV Elite ImagesDocumento3 paginePV Elite Imagesfrankz89Nessuna valutazione finora

- Valve CatalogueDocumento4 pagineValve Cataloguefrankz89Nessuna valutazione finora

- Manual Valvula PinchDocumento8 pagineManual Valvula Pinchfrankz89Nessuna valutazione finora

- Annexure 2 - Requisition For Pipe 4inch & AboveDocumento11 pagineAnnexure 2 - Requisition For Pipe 4inch & Abovefrankz89Nessuna valutazione finora

- Vent-O-Mat - Nozzle Check ValveDocumento8 pagineVent-O-Mat - Nozzle Check Valvefrankz89Nessuna valutazione finora

- Tipos de Bombas CentrifugasDocumento43 pagineTipos de Bombas Centrifugasfrankz89Nessuna valutazione finora

- Valvulas Tipo CuchillaDocumento8 pagineValvulas Tipo Cuchillafrankz89Nessuna valutazione finora

- 06 Mantenimiento de Calderas Industriales BOSCH Fenercom 2013.desbloqueadoDocumento43 pagine06 Mantenimiento de Calderas Industriales BOSCH Fenercom 2013.desbloqueadoAlex H. De la CruzNessuna valutazione finora

- Tipos de Bombas CentrifugasDocumento43 pagineTipos de Bombas Centrifugasfrankz89Nessuna valutazione finora

- Technical Catalogue: Pipes Tubes Fittings FlangesDocumento121 pagineTechnical Catalogue: Pipes Tubes Fittings FlangesDANIELVENZUELAANessuna valutazione finora

- Pipe Systems PDFDocumento108 paginePipe Systems PDFfrankz89Nessuna valutazione finora

- HANBOOK Jaw Crushers PDFDocumento8 pagineHANBOOK Jaw Crushers PDFfrankz89Nessuna valutazione finora

- CATALOGO Check Criogenica PDFDocumento6 pagineCATALOGO Check Criogenica PDFfrankz89Nessuna valutazione finora

- HANDBOOK Blanket Gas Regulators PDFDocumento8 pagineHANDBOOK Blanket Gas Regulators PDFfrankz89Nessuna valutazione finora

- Valvula Esferica Criogenica TBVDocumento20 pagineValvula Esferica Criogenica TBVfrankz89Nessuna valutazione finora

- HANDBOOK Blanket Gas Regulators PDFDocumento8 pagineHANDBOOK Blanket Gas Regulators PDFfrankz89Nessuna valutazione finora

- Automatic Fuel Oil Transfer Pump Set - DatasheetDocumento5 pagineAutomatic Fuel Oil Transfer Pump Set - Datasheetfrankz89Nessuna valutazione finora

- Cascho Modelo DDocumento16 pagineCascho Modelo Dfrankz89Nessuna valutazione finora

- VFD Pumping SystemsDocumento22 pagineVFD Pumping Systemsrajurajangam100% (1)

- Qian, Hrnjak - Void Fraction Measurement and Flow Regimes Visualization of R134a in Horizontal and Vertical ID 7 MM Circular Tubes PDFDocumento41 pagineQian, Hrnjak - Void Fraction Measurement and Flow Regimes Visualization of R134a in Horizontal and Vertical ID 7 MM Circular Tubes PDFHanim BasarudinNessuna valutazione finora

- Integrate Planck's Function Using Gamma FunctionDocumento14 pagineIntegrate Planck's Function Using Gamma FunctionMaxtron Evelyn MoonNessuna valutazione finora

- Sibco CatalogueDocumento112 pagineSibco CatalogueMonika SenNessuna valutazione finora

- Strain Gauges DatasheetDocumento100 pagineStrain Gauges DatasheetSantiago UrgilesNessuna valutazione finora

- Case Studies in Boiler FailuresDocumento14 pagineCase Studies in Boiler Failuresparthi2006576880% (5)

- Inorganic NotesDocumento4 pagineInorganic NotesMr. XNessuna valutazione finora

- Redox 2Documento366 pagineRedox 2Ana Emily Prentiss100% (1)

- Onqor: Product BulletinDocumento2 pagineOnqor: Product BulletinAhmed ChahineNessuna valutazione finora

- Aerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionDocumento16 pagineAerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionAlberto De La CruzNessuna valutazione finora

- Global Warming TextsDocumento3 pagineGlobal Warming TextsAnonymous NbKeZIGDVMNessuna valutazione finora

- 113 DR Fixit FastflexDocumento3 pagine113 DR Fixit FastflexreshmitapallaNessuna valutazione finora

- Renown Chemical BrochureDocumento44 pagineRenown Chemical BrochureSalih OzerNessuna valutazione finora

- Pump JTN B1Documento8 paginePump JTN B1Patricia J ÁngelesNessuna valutazione finora

- College Physics 7th Ed Serway Chapter 11Documento30 pagineCollege Physics 7th Ed Serway Chapter 11Jorge GomezNessuna valutazione finora

- MSDS Lasco Underbody CoatDocumento5 pagineMSDS Lasco Underbody CoatMarshall TerreceNessuna valutazione finora

- ADMIX CATALOG 2015 16 WEB Links PDFDocumento248 pagineADMIX CATALOG 2015 16 WEB Links PDFdan0427Nessuna valutazione finora

- Sun & McDonough (1989) PDFDocumento34 pagineSun & McDonough (1989) PDFVictor ValdiviaNessuna valutazione finora

- XH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsDocumento9 pagineXH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsprabuNessuna valutazione finora

- EOR Screening-TaberDocumento14 pagineEOR Screening-TaberAjeng AyuNessuna valutazione finora

- BC7068 E-TdsDocumento3 pagineBC7068 E-TdsHoài NguyễnNessuna valutazione finora

- Patrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossDocumento9 paginePatrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossBrahian Alexander RinconNessuna valutazione finora

- Everything About Alkynes - Q&ADocumento22 pagineEverything About Alkynes - Q&AJoostGoNessuna valutazione finora

- Gasket Assembly Stress Recommendations: Compressed Sheet, GRAPH-LOCK®, GYLON® and Gylon Epix™Documento1 paginaGasket Assembly Stress Recommendations: Compressed Sheet, GRAPH-LOCK®, GYLON® and Gylon Epix™dilo0987Nessuna valutazione finora

- Lecture Planner - Chemistry PDF OnlyDocumento1 paginaLecture Planner - Chemistry PDF OnlyJai ChandNessuna valutazione finora

- Equal Percentage Control Valves and Applications - Control NotesDocumento6 pagineEqual Percentage Control Valves and Applications - Control NotesShubham PisalNessuna valutazione finora

- Lipids Classification and FunctionsDocumento4 pagineLipids Classification and FunctionsThalia PacamalanNessuna valutazione finora

- Qualitative Analysis of Groups 3-5 CationsDocumento45 pagineQualitative Analysis of Groups 3-5 CationsMerrene Bright Divino JudanNessuna valutazione finora

- Catalogo Herramientas CaterpillarDocumento112 pagineCatalogo Herramientas CaterpillarJorge Perez100% (2)

- Bet Muestra 6Documento7 pagineBet Muestra 6Eli GutierrezNessuna valutazione finora