Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cable Sizing

Caricato da

ahmadgce04Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cable Sizing

Caricato da

ahmadgce04Copyright:

Formati disponibili

= Cu PVC GSWB

= 75 C

=

= 90 MTRS

= 30 KW

= 415 V

= 47.97401 AMPS

= FUSE

C.B

M.C.C.B

(It)

5s

= 0.89

= 0.82

= 0.7298

25mm = 78 AMPS

35mm = 96 AMPS

25mm = 56.9244 AMPS

35mm = 70.0608 AMPS

= 5%

LENGTH = 90 MTRS

= 0.638 /km

= 0.0826 /km

V

Vd

=

4.376625

{(L/1000)*1.732*I flc*(Rcos+Xsin)}

BASE RATING OF CABLE

INSTALLED CURRENT RATING

VOLTAGE DROP CALCULATION

PERMISSIBLE VOLTAGE DROP

AC RESISTANCE

AC REACTANCE

MAX. PROSPECTIVE FAULT

MELT TIME

CABLE SELECTION BASED ON CURRENT RATING

AMBIENT TEMP. DERATING

GROUP DERATING

CABLE LADDER

VOLTAGE

I flc

= 80

DATA AVAILABLE

CABLE TYPE

OPERATING TEMP

CABLE INSTALLATION

TOTAL DERATING FACTOR

CABLE LENGTH

MOTOR LOAD

PROTECTION

ABOVE GROUND

The normally used equation is the so-called adiabatic equation. For a given fault of I, which lasts for time t, the minimum required cable cross sectional area is given by: -

Initial C]

Thermopl

astic 90C

(PVC)

90

Thermose

tting, 90C

(XLPE,

EDR)

90

Thermose

tting, 60C

(rubber)

60

Thermose

tting, 85C

(rubber)

85

Thermose

tting,

185C

(silicone

rubber)

180

SHORT CIRCUIT TEMPERATURE RISE

VOLTAGE DROP OF

4.376625

=

Temperature

Thermopl

astic 70C

(PVC)

70

t=kA/I

The factor k is dependant on the cable insulation, allowable temperature rise under fault conditions, conductor resistivity and heat capacity. Typical values of k can br foung from the above chart

A=It/k

A - the nominal cross section area, mm2

I - the fault current in, A

t - duration of fault current, s

k - a factor dependant on cable type (see chart)

Alternatively, given the cable cross section and fault current, the maximum time allowable for the protective device can be found from: -

PVC 3C+E 0.6/1KV

BUNCHED 3 CABLE 1 LAYER 30 C Amb tem

= 0.87

= 90 As

= 550 A

35mm

{(L/1000)*1.732*I flc*(Rcos+Xsin)}

CABLE LADDER

POWER FACTOR

AMPS

The normally used equation is the so-called adiabatic equation. For a given fault of I, which lasts for time t, the minimum required cable cross sectional area is given by: -

Final [C] Copper Aluminium Steel

160/140 100/86 66/57 36/31

250 143 94 52

200 141 93 51

220 134 89 48

350 132 87 47

%Vd

1.054608

Temperature Conductor Material

160/140 115/103 76/78 42/37

The factor k is dependant on the cable insulation, allowable temperature rise under fault conditions, conductor resistivity and heat capacity. Typical values of k can br foung from the above chart

Alternatively, given the cable cross section and fault current, the maximum time allowable for the protective device can be found from: -

Value ofk

The factor k is dependant on the cable insulation, allowable temperature rise under fault conditions, conductor resistivity and heat capacity. Typical values of k can br foung from the above chart

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Detailed Scope of Work - SubstationDocumento83 pagineDetailed Scope of Work - Substationahmadgce04Nessuna valutazione finora

- 100 Day Surgery/ Procedure UnitDocumento17 pagine100 Day Surgery/ Procedure Unitahmadgce04Nessuna valutazione finora

- Wood Is Currently Looking For Principal Electrical Engineer To Work On The Engineering and Project Management Services in AlDocumento6 pagineWood Is Currently Looking For Principal Electrical Engineer To Work On The Engineering and Project Management Services in Alahmadgce04Nessuna valutazione finora

- 100 Day Surgery/ Procedure UnitDocumento16 pagine100 Day Surgery/ Procedure Unitahmadgce04Nessuna valutazione finora

- 130 Cardiac Investigation Unit: Draft 1.1 - 28 June 2018Documento22 pagine130 Cardiac Investigation Unit: Draft 1.1 - 28 June 2018ahmadgce04Nessuna valutazione finora

- Infrastructure Transformation - Nexus Technology Update: Belmont ChiaDocumento27 pagineInfrastructure Transformation - Nexus Technology Update: Belmont Chiaahmadgce04Nessuna valutazione finora

- KSA Part A - Draft 1.2 With AppendicesDocumento233 pagineKSA Part A - Draft 1.2 With Appendicesahmadgce04Nessuna valutazione finora

- 23.5 MW (ANSI), Chilled Water, 270000 FT: (Reference Design 106)Documento9 pagine23.5 MW (ANSI), Chilled Water, 270000 FT: (Reference Design 106)ahmadgce04Nessuna valutazione finora

- 48 KW, Pod-Based Build, Tier I, 646 FT: Design OverviewDocumento6 pagine48 KW, Pod-Based Build, Tier I, 646 FT: Design Overviewahmadgce04Nessuna valutazione finora

- 110 Admissions Unit & Discharge: 100 Day Surgery/ Procedure UnitDocumento18 pagine110 Admissions Unit & Discharge: 100 Day Surgery/ Procedure Unitahmadgce04Nessuna valutazione finora

- 780 KW, Pod-Based Build, Tier I, 1873 FT: Design OverviewDocumento6 pagine780 KW, Pod-Based Build, Tier I, 1873 FT: Design Overviewahmadgce04Nessuna valutazione finora

- 90 KW, Tier II, Direct Expansion, 142.1 M, All-In-One Prefab Data Center Module - Busway or PDUDocumento7 pagine90 KW, Tier II, Direct Expansion, 142.1 M, All-In-One Prefab Data Center Module - Busway or PDUahmadgce04Nessuna valutazione finora

- Guest House Power Caculations-0Documento123 pagineGuest House Power Caculations-0ahmadgce04Nessuna valutazione finora

- Installation and Operation Manual: VRV IV+ Heat Pump For High Ambient TemperaturesDocumento44 pagineInstallation and Operation Manual: VRV IV+ Heat Pump For High Ambient Temperaturesahmadgce04Nessuna valutazione finora

- 46 MW (IEC), Chilled Water, 40000 M: (Reference Design 102)Documento8 pagine46 MW (IEC), Chilled Water, 40000 M: (Reference Design 102)ahmadgce04Nessuna valutazione finora

- 56 MW (IEC), OCP-compatible, Indirect Air Cooling, 55000 M: (Reference Design 101)Documento8 pagine56 MW (IEC), OCP-compatible, Indirect Air Cooling, 55000 M: (Reference Design 101)ahmadgce04Nessuna valutazione finora

- 23.5 MW (IEC), Chilled Water, 25000 M: (Reference Design 103)Documento9 pagine23.5 MW (IEC), Chilled Water, 25000 M: (Reference Design 103)ahmadgce04Nessuna valutazione finora

- MODA - Lighting Design - R1 - ReportDocumento235 pagineMODA - Lighting Design - R1 - Reportahmadgce04Nessuna valutazione finora

- 11.2 MW, Indirect Air Economizer, 10875m: Design OverviewDocumento10 pagine11.2 MW, Indirect Air Economizer, 10875m: Design Overviewahmadgce04Nessuna valutazione finora

- IEC 61850 Simplifies Data Center Power InfrastructureDocumento5 pagineIEC 61850 Simplifies Data Center Power Infrastructureahmadgce04Nessuna valutazione finora

- White Paper - Data Center High Speed MigrationDocumento10 pagineWhite Paper - Data Center High Speed Migrationahmadgce04Nessuna valutazione finora

- Data CentreDocumento65 pagineData Centreahmadgce04Nessuna valutazione finora

- Etabs ReportDocumento976 pagineEtabs Reportahmadgce04Nessuna valutazione finora

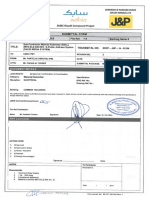

- Response To Material Submittal For Lighting FixturesDocumento2 pagineResponse To Material Submittal For Lighting Fixturesahmadgce04Nessuna valutazione finora

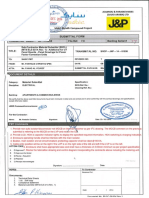

- Company Logo: Cable Size CalculationDocumento7 pagineCompany Logo: Cable Size Calculationahmadgce04Nessuna valutazione finora

- MTS-ELE-021A Rev. 1 PDFDocumento1 paginaMTS-ELE-021A Rev. 1 PDFahmadgce04Nessuna valutazione finora

- SRCP-JNP-14-1256 Rev. 3 PDFDocumento8 pagineSRCP-JNP-14-1256 Rev. 3 PDFahmadgce04Nessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Make Your MEP Design Better Using Autodesk CFD Simulation: Dr. Munirajulu. MDocumento78 pagineMake Your MEP Design Better Using Autodesk CFD Simulation: Dr. Munirajulu. MArun CherianNessuna valutazione finora

- Fiitjee AitsDocumento2 pagineFiitjee AitsRaj Nayan Datta0% (2)

- Draughtsman (Mechanical)Documento28 pagineDraughtsman (Mechanical)Umang SoniNessuna valutazione finora

- Cooling Tower Exp 3Documento16 pagineCooling Tower Exp 3mahmudNessuna valutazione finora

- German Calibration Service: DKD-R 5-4 Temperature Block CalibratorsDocumento11 pagineGerman Calibration Service: DKD-R 5-4 Temperature Block Calibratorssmartbell100% (3)

- BCA Energy Performance Points CalculatorDocumento69 pagineBCA Energy Performance Points Calculatorသူ ရိန်Nessuna valutazione finora

- ..Heat Transfer Through Falling Film Evaporators (Han and Fletcher 1990)Documento7 pagine..Heat Transfer Through Falling Film Evaporators (Han and Fletcher 1990)Ahmed JamilNessuna valutazione finora

- 11th JEE SyllabusDocumento1 pagina11th JEE SyllabusPujan JainNessuna valutazione finora

- Carnot's Theorem (Thermodynamics) - WikipediaDocumento20 pagineCarnot's Theorem (Thermodynamics) - WikipediaEndhy Wisnu NovindraNessuna valutazione finora

- Cooling Load CalculationDocumento14 pagineCooling Load CalculationVũ Hằng PhươngNessuna valutazione finora

- PNG 520 - Course On Phase RelationsDocumento172 paginePNG 520 - Course On Phase RelationsDenstar Ricardo SilalahiNessuna valutazione finora

- Light DLL Grade 8Documento2 pagineLight DLL Grade 8Shemae Obni100% (2)

- ASHRAE Fundamentals of Thermodynamics and PsychrometricsDocumento323 pagineASHRAE Fundamentals of Thermodynamics and PsychrometricsBING_DING_RING90% (31)

- PPE-IPE (Edited) Final CoachingDocumento13 paginePPE-IPE (Edited) Final CoachingNelson Naval CabingasNessuna valutazione finora

- Evaluation and Selection of Energy Storage SystemsDocumento12 pagineEvaluation and Selection of Energy Storage SystemsMarco Antonio Miranda Rodriguez100% (1)

- Thermo FilesDocumento35 pagineThermo FilesSANLU HTUT67% (3)

- Physics - An Introduction For Early Grades PDFDocumento14 paginePhysics - An Introduction For Early Grades PDFsadriddin ariayeeNessuna valutazione finora

- Heat Transfer Enhancement by Using Dimpled Surface: Hemant C. Pisal, Avinash A. RanawareDocumento9 pagineHeat Transfer Enhancement by Using Dimpled Surface: Hemant C. Pisal, Avinash A. Ranawareashoku2Nessuna valutazione finora

- Engineering Research Paper PDFDocumento7 pagineEngineering Research Paper PDFafnhekkghifrbm100% (1)

- Physics 9th BISE LHRDocumento12 paginePhysics 9th BISE LHRATHARNessuna valutazione finora

- Thermal Processes 1 QPDocumento12 pagineThermal Processes 1 QPmomentum bdNessuna valutazione finora

- Hot Wire AnemometerDocumento16 pagineHot Wire AnemometerjennybunnyomgNessuna valutazione finora

- Ventilated Facades INT PDFDocumento42 pagineVentilated Facades INT PDFMayre Rachel RodriguezNessuna valutazione finora

- Vertical HabitatDocumento6 pagineVertical HabitatAbdul SakurNessuna valutazione finora

- Calculations in Furnace TechnologyDocumento277 pagineCalculations in Furnace Technologysakthivel100% (2)

- Wilson Plot MethodDocumento13 pagineWilson Plot MethodThomas Teh Qian HuaNessuna valutazione finora

- Solved Examples On Thermodynamics and Gas Laws635538601134455219 PDFDocumento4 pagineSolved Examples On Thermodynamics and Gas Laws635538601134455219 PDFshubhamkhande100% (1)

- Prof. Dr. Jamal Saleh Yassin: Misurata University - Faculity of Engineering Misurata - LibyaDocumento44 pagineProf. Dr. Jamal Saleh Yassin: Misurata University - Faculity of Engineering Misurata - Libyaشركة الطليعةNessuna valutazione finora

- Trends in Food Science & Technology: SciencedirectDocumento10 pagineTrends in Food Science & Technology: Sciencedirectcitra widyasariNessuna valutazione finora

- Diesel Cycle: P-V Diagram T-S DiagramDocumento3 pagineDiesel Cycle: P-V Diagram T-S DiagramJJ100% (1)