Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Inspection Steps

Caricato da

Thinesh Shankar Thinesh0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

17 visualizzazioni2 pagineLiquid penetrant is applied to the surface of the item!eing tested. Penetrant allowed dwell time to soak into any flaws &generally'to () minutes. Solvent remover and lint$free cloth are important to not spray the solvent on the surface.

Descrizione originale:

Titolo originale

Inspection steps.doc

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoLiquid penetrant is applied to the surface of the item!eing tested. Penetrant allowed dwell time to soak into any flaws &generally'to () minutes. Solvent remover and lint$free cloth are important to not spray the solvent on the surface.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

17 visualizzazioni2 pagineInspection Steps

Caricato da

Thinesh Shankar ThineshLiquid penetrant is applied to the surface of the item!eing tested. Penetrant allowed dwell time to soak into any flaws &generally'to () minutes. Solvent remover and lint$free cloth are important to not spray the solvent on the surface.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

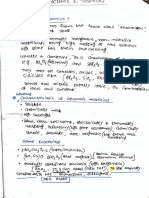

Inspection steps

Below are the main steps of Liquid Penetrant Inspection:

1. Pre-cleaning:

The test surface is cleaned to remove any dirt, paint, oil, grease or any loose scale that could

either keep penetrant out of a defect, or cause irrelevant or false indications. leaning

methods may include solvents, alkaline cleaning steps, vapor degreasing, or media !lasting.

The end goal of this step is a clean surface where any defects present are open to the

surface, dry, and free of contamination. "ote that if media !lasting is used, it may #work over#

small discontinuities in the part, and an etching !ath is recommended as a post$!lasting

treatment.

%pplication of the penetrant to a part in a ventilated test area.

2. Application of Penetrant:

The penetrant is then applied to the surface of the item !eing tested. The penetrant is allowed

#dwell time# to soak into any flaws &generally ' to () minutes*. The dwell time mainly depends

upon the penetrant !eing used, material !eing tested and the si+e of flaws sought. %s

e,pected, smaller flaws require a longer penetration time. -ue to their incompati!le nature

one must !e careful not to apply solvent$!ased penetrant to a surface which is to !e

inspected with a water$washa!le penetrant.

3. Excess Penetrant Removal:

The e,cess penetrant is then removed from the surface. The removal method is controlled !y

the type of penetrant used. .ater$washa!le, solvent$remova!le, lipophilic post$emulsifia!le,

or hydrophilic post$emulsifia!le are the common choices. /mulsifiersrepresent the highest

sensitivity level, and chemically interact with the oily penetrant to make it remova!le with a

water spray. .hen using solvent remover and lint$free cloth it is important to not spray the

solvent on the test surface directly, !ecause this can remove the penetrant from the flaws. If

e,cess penetrant is not properly removed, once the developer is applied, it may leave a

!ackground in the developed area that can mask indications or defects. In addition, this may

also produce false indications severely hindering your a!ility to do a proper inspection.

4. Application of Developer:

%fter e,cess penetrant has !een removed a white developer is applied to the sample. 0everal

developer types are availa!le, including: non$aqueous wet developer, dry powder, water

suspenda!le, and water solu!le. hoice of developer is governed !y penetrant compati!ility

&one can1t use water$solu!le or suspenda!le developer with water$washa!le penetrant*, and

!y inspection conditions. .hen using non$aqueous wet developer &"%.-* or dry powder, the

sample must !e dried prior to application, while solu!le and suspenda!le developers are

applied with the part still wet from the previous step. "%.- is commercially availa!le in

aerosol spray cans, and may employ acetone, isopropyl alcohol, or a propellant that is a

com!ination of the two. -eveloper should form a semi$transparent, even coating on the

surface.

The developer draws penetrant from defects out onto the surface to form a visi!le indication,

commonly known as !leed$out. %ny areas that !leed$out can indicate the location, orientation

and possi!le types of defects on the surface. Interpreting the results and characteri+ing

defects from the indications found may require some training and2or e,perience 3the indication

si+e is not the actual si+e of the defect4

5. Inspection:

The inspector will use visi!le light with adequate intensity &5)) foot$candles or 55)) lu, is

typical* for visi!le dye penetrant. 6ltraviolet &67$%* radiation of adequate intensity &5,)))

micro$watts per centimeter squared is common*, along with low am!ient light levels &less than

8 foot$candles* for fluorescent penetrant e,aminations. Inspection of the test surface should

take place after 5) to () minute development time, depends of product kind. This time delay

allows the !lotting action to occur. The inspector may o!serve the sample for indication

formation when using visi!le dye. It is also good practice to o!serve indications as they form

!ecause the characteristics of the !leed out are a significant part of interpretation

characteri+ation of flaws.

. Post !leaning:

The test surface is often cleaned after inspection and recording of defects, especially if post$

inspection coating processes are scheduled.

Potrebbero piacerti anche

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&ADa EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANessuna valutazione finora

- Dye Penetration TestDocumento7 pagineDye Penetration Testezarul321Nessuna valutazione finora

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEDa EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENessuna valutazione finora

- Dye Penetrant TestDocumento14 pagineDye Penetrant TestSaif FaridiNessuna valutazione finora

- Dye Penetrant ProcedureDocumento2 pagineDye Penetrant ProcedureunikmyquestarNessuna valutazione finora

- Penetrant Tetsing: Dye Penetrant Inspection (DPI), Also Called Liquid Penetrant Inspection (LPI)Documento4 paginePenetrant Tetsing: Dye Penetrant Inspection (DPI), Also Called Liquid Penetrant Inspection (LPI)Raul2307Nessuna valutazione finora

- Automotive Actuators and EVAP System TestingDa EverandAutomotive Actuators and EVAP System TestingValutazione: 4.5 su 5 stelle4.5/5 (4)

- Dye Penetrant Inspection: From Wikipedia, The Free EncyclopediaDocumento59 pagineDye Penetrant Inspection: From Wikipedia, The Free EncyclopediaPratik Karekar0% (1)

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocumento5 pagineDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Detailers Dictionary: Detailers Little Black BookDa EverandDetailers Dictionary: Detailers Little Black BookNessuna valutazione finora

- Dye Penetrant InspDocumento5 pagineDye Penetrant InspVysakh VasudevanNessuna valutazione finora

- Dye Penetrant InspectionDocumento5 pagineDye Penetrant InspectiontechzonesNessuna valutazione finora

- Module 2 Surface Gears MethodsDocumento12 pagineModule 2 Surface Gears MethodsNAVEEN H V MENessuna valutazione finora

- Dye PenetrantDocumento17 pagineDye Penetrantsen_subhasis_58Nessuna valutazione finora

- Materials: Non-Porous Magnetic-Particle Inspection Porosity Fatigue CracksDocumento3 pagineMaterials: Non-Porous Magnetic-Particle Inspection Porosity Fatigue CracksArfanAliNessuna valutazione finora

- Dye Penetrant InspectionDocumento15 pagineDye Penetrant InspectionUwaiz Qurni IINessuna valutazione finora

- Campeche Technological University: Eng. Marcelo Morales ClementeDocumento44 pagineCampeche Technological University: Eng. Marcelo Morales ClementeCECILIA GUADALUPE HERNANDEZ HERNANDEZNessuna valutazione finora

- Dye Penetrant InspectionDocumento5 pagineDye Penetrant Inspectionrashm006ranjanNessuna valutazione finora

- Non Destructive TestingDocumento7 pagineNon Destructive Testingk_mughalNessuna valutazione finora

- Unit Ii: Surface Nde MethodsDocumento62 pagineUnit Ii: Surface Nde MethodsSaravana Kumar MNessuna valutazione finora

- Penetrant Testing ReportDocumento8 paginePenetrant Testing ReportBabar Ali BaigNessuna valutazione finora

- Dye Penetrant InspectionDocumento6 pagineDye Penetrant InspectionHabib ur RehmanNessuna valutazione finora

- EXPERIMENT No.: - Liquid Penetrant TestDocumento6 pagineEXPERIMENT No.: - Liquid Penetrant TestVandan GundaleNessuna valutazione finora

- Module1 Testing and Flaw Detection of Materials and ComponentsDocumento12 pagineModule1 Testing and Flaw Detection of Materials and ComponentsHari GovindNessuna valutazione finora

- Non Destructive Testing - Dye Penetrant InspectionDocumento6 pagineNon Destructive Testing - Dye Penetrant InspectionKevin ThomasNessuna valutazione finora

- Penetrant RaportDocumento6 paginePenetrant RaportMeritan BaballariNessuna valutazione finora

- NDT of MaterialsDocumento10 pagineNDT of MaterialsSuresh HaldipurNessuna valutazione finora

- Department of Mechanical Engineering: Unit-2Documento65 pagineDepartment of Mechanical Engineering: Unit-2aman jainNessuna valutazione finora

- Liquid or Dye Penetrant InspectionDocumento43 pagineLiquid or Dye Penetrant InspectionTrinadh Venkata Kumar NillaNessuna valutazione finora

- Penetrant Testing, or PT, Is A NondestructiveDocumento10 paginePenetrant Testing, or PT, Is A NondestructiveMastram HatheshNessuna valutazione finora

- Liquid Penetrant Testing PDFDocumento20 pagineLiquid Penetrant Testing PDFgueridiNessuna valutazione finora

- Manual Visible Dye Penetrant PDFDocumento16 pagineManual Visible Dye Penetrant PDFAndik SetyawanNessuna valutazione finora

- Dye Penetrant InspectionDocumento5 pagineDye Penetrant Inspectionrajasekar21Nessuna valutazione finora

- PTDocumento217 paginePTkhaled saadnehNessuna valutazione finora

- DPTDocumento10 pagineDPTShabbir HassanNessuna valutazione finora

- Experiment No.3 Dye Penetration TestDocumento4 pagineExperiment No.3 Dye Penetration TestChristian D. AllanaNessuna valutazione finora

- Liquid Penetrant TestingDocumento20 pagineLiquid Penetrant Testingajayghosh3140Nessuna valutazione finora

- NDT - Unit 2Documento30 pagineNDT - Unit 2Pratap KumarNessuna valutazione finora

- ASNT Sample TestDocumento71 pagineASNT Sample Testshabbir626Nessuna valutazione finora

- Liquid Penetrant TestingDocumento20 pagineLiquid Penetrant TestingsanjibkrjanaNessuna valutazione finora

- Dye Penetration Test: Fig. 1: Surface Cleanser, Developer and PenetrantDocumento3 pagineDye Penetration Test: Fig. 1: Surface Cleanser, Developer and PenetrantAmeenNessuna valutazione finora

- LPTDocumento22 pagineLPTPratik SalveNessuna valutazione finora

- Material Science AlfathiDocumento5 pagineMaterial Science AlfathiAnonymous UdOhqLMNessuna valutazione finora

- Dye Penetrant TestDocumento4 pagineDye Penetrant Testarunkumarnoola100% (1)

- NDTM 2 LPT 200818082453 PDFDocumento21 pagineNDTM 2 LPT 200818082453 PDFMECHANICAL SMCETNessuna valutazione finora

- Dye Penetration TestDocumento3 pagineDye Penetration Testzhuxueyun55Nessuna valutazione finora

- LPTDocumento58 pagineLPTShrikant MojeNessuna valutazione finora

- NDT Module 2Documento21 pagineNDT Module 2Sajeesh Saji100% (1)

- PT Test & SafetyDocumento42 paginePT Test & SafetyRushabh KapadiaNessuna valutazione finora

- Ndte Notes Unit 2Documento36 pagineNdte Notes Unit 2Kanda SamyNessuna valutazione finora

- PT NITTDocumento37 paginePT NITTLipika GayenNessuna valutazione finora

- Non Destructive Testing and Evaluation Course Module Topic - Dye Penetrant TestingDocumento118 pagineNon Destructive Testing and Evaluation Course Module Topic - Dye Penetrant TestingV.Muthu KumarNessuna valutazione finora

- Often Referenced StandardsDocumento18 pagineOften Referenced StandardssriramNessuna valutazione finora

- Inspecting Welds With Liquid PenetrantDocumento4 pagineInspecting Welds With Liquid PenetrantHizbul WathanNessuna valutazione finora

- Penetrant Non Destructive Testing. Theory and Application?Documento3 paginePenetrant Non Destructive Testing. Theory and Application?SimranAhluwaliaNessuna valutazione finora

- Chemistry MCQs - Qualitative Analysis: AIPMT Old Questions (Solved) - Makox MCQsDocumento6 pagineChemistry MCQs - Qualitative Analysis: AIPMT Old Questions (Solved) - Makox MCQsNisar Ali Mphil-Chem ANessuna valutazione finora

- Minimum VentilationDocumento4 pagineMinimum VentilationNathan Smith100% (1)

- CDB2043 - CH 03 - StoichiometryDocumento36 pagineCDB2043 - CH 03 - StoichiometryAqilah HanimNessuna valutazione finora

- Industrial Crops & Products: SciencedirectDocumento8 pagineIndustrial Crops & Products: SciencedirectJyotsana DwivediNessuna valutazione finora

- Stainless EnstainlessDocumento27 pagineStainless EnstainlessVinaya Almane DattathreyaNessuna valutazione finora

- Article WJPR 1467266667Documento10 pagineArticle WJPR 1467266667Atthapu ThirupathaiahNessuna valutazione finora

- Bs en 357 - 2004 Glass-Frp ClassDocumento16 pagineBs en 357 - 2004 Glass-Frp ClassKwong chi hoNessuna valutazione finora

- Ajax Disinfectant CleanserDocumento11 pagineAjax Disinfectant CleanserMateusPauloNessuna valutazione finora

- Hazen - William Coeficiente FBEDocumento10 pagineHazen - William Coeficiente FBEOrlandoNessuna valutazione finora

- AMINE UNIT EVALUATION FORM Metric UnitDocumento4 pagineAMINE UNIT EVALUATION FORM Metric Unitandrey.glinskyNessuna valutazione finora

- Clay Notes (4th Sem)Documento21 pagineClay Notes (4th Sem)SamNessuna valutazione finora

- Nesrine-2021-2016 P4 QPDocumento686 pagineNesrine-2021-2016 P4 QPMostafa HaithamNessuna valutazione finora

- Experilab Breinwave: Bubble BlowersDocumento4 pagineExperilab Breinwave: Bubble BlowersHirenkumarNessuna valutazione finora

- Stoichiometry: Calculations With Chemical Formulas and EquationsDocumento47 pagineStoichiometry: Calculations With Chemical Formulas and EquationsAngelo Miguel GarciaNessuna valutazione finora

- YLAA InstallationDocumento62 pagineYLAA InstallationJoe YoungNessuna valutazione finora

- Manual On Pavement Design PDFDocumento31 pagineManual On Pavement Design PDFAnil Kumsr T B100% (3)

- En 10263-1Documento30 pagineEn 10263-1Mogos PaulNessuna valutazione finora

- Suelo, Agua Subterranea y Sedimento Norma CanadienseDocumento40 pagineSuelo, Agua Subterranea y Sedimento Norma CanadiensehensilNessuna valutazione finora

- PAMG-PA3 5052 Aluminum Honeycomb: DescriptionDocumento2 paginePAMG-PA3 5052 Aluminum Honeycomb: Descriptionsahiljain_146Nessuna valutazione finora

- Jurnal International AmilumDocumento17 pagineJurnal International AmilumGhiyatsKalukuNessuna valutazione finora

- Energy Brochure 26-04-2012Documento6 pagineEnergy Brochure 26-04-2012michaelvillameNessuna valutazione finora

- College of Nursing: Cebu Normal UniversityDocumento5 pagineCollege of Nursing: Cebu Normal UniversityChelsea WuNessuna valutazione finora

- Project 4 Ethylene OxideDocumento12 pagineProject 4 Ethylene OxideNhan Nguyen Van100% (4)

- Atoms and Elements (Chemistry Notes)Documento4 pagineAtoms and Elements (Chemistry Notes)wlkernanNessuna valutazione finora

- Tugas 1 PPADocumento29 pagineTugas 1 PPAlulalalaNessuna valutazione finora

- UV Coating Flooring - Radtech 2003 - D. Bontinck M. IdacageDocumento6 pagineUV Coating Flooring - Radtech 2003 - D. Bontinck M. IdacageJuan Antonio Tito Esp CalNessuna valutazione finora

- 70 Penetration Grade BitumenDocumento1 pagina70 Penetration Grade BitumenJohn SnowNessuna valutazione finora

- ASTM B188-2002 Tubos de CobreDocumento10 pagineASTM B188-2002 Tubos de Cobrelinealmen100% (1)

- Factors Affecting Drug Absorption PDFDocumento2 pagineFactors Affecting Drug Absorption PDFRobNessuna valutazione finora

- A1.2.3 Method Statement 4a Redacted Version2Documento98 pagineA1.2.3 Method Statement 4a Redacted Version2ChanelNessuna valutazione finora

- Sodium Bicarbonate: Nature's Unique First Aid RemedyDa EverandSodium Bicarbonate: Nature's Unique First Aid RemedyValutazione: 5 su 5 stelle5/5 (21)

- Piping Engineering Leadership for Process Plant ProjectsDa EverandPiping Engineering Leadership for Process Plant ProjectsValutazione: 5 su 5 stelle5/5 (1)

- Process Plant Equipment: Operation, Control, and ReliabilityDa EverandProcess Plant Equipment: Operation, Control, and ReliabilityValutazione: 5 su 5 stelle5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisDa EverandGuidelines for Chemical Process Quantitative Risk AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlDa EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlValutazione: 4 su 5 stelle4/5 (4)

- An Applied Guide to Water and Effluent Treatment Plant DesignDa EverandAn Applied Guide to Water and Effluent Treatment Plant DesignValutazione: 5 su 5 stelle5/5 (4)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersDa EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersValutazione: 4.5 su 5 stelle4.5/5 (2)

- Water-Based Paint Formulations, Vol. 3Da EverandWater-Based Paint Formulations, Vol. 3Valutazione: 4.5 su 5 stelle4.5/5 (6)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDa EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNessuna valutazione finora

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- Distillation Design and Control Using Aspen SimulationDa EverandDistillation Design and Control Using Aspen SimulationValutazione: 5 su 5 stelle5/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- The Perfumed Pages of History: A Textbook on Fragrance CreationDa EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationValutazione: 4 su 5 stelle4/5 (1)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsDa EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNessuna valutazione finora

- A New Approach to HAZOP of Complex Chemical ProcessesDa EverandA New Approach to HAZOP of Complex Chemical ProcessesNessuna valutazione finora

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksDa EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksNessuna valutazione finora

- Handbook of Cosmetic Science: An Introduction to Principles and ApplicationsDa EverandHandbook of Cosmetic Science: An Introduction to Principles and ApplicationsH. W. HibbottValutazione: 4 su 5 stelle4/5 (6)

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksDa EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNessuna valutazione finora

- Coulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesDa EverandCoulson and Richardson’s Chemical Engineering: Volume 2B: Separation ProcessesAjay Kumar RayNessuna valutazione finora

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesDa EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesValutazione: 5 su 5 stelle5/5 (1)

- Bioinspired Materials Science and EngineeringDa EverandBioinspired Materials Science and EngineeringGuang YangNessuna valutazione finora

- Mastering Biochemistry: A Comprehensive Guide to ExcellenceDa EverandMastering Biochemistry: A Comprehensive Guide to ExcellenceNessuna valutazione finora

- Transport Phenomena in Heat and Mass TransferDa EverandTransport Phenomena in Heat and Mass TransferJ.A. ReizesValutazione: 5 su 5 stelle5/5 (1)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringDa EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillValutazione: 3.5 su 5 stelle3.5/5 (3)

- Fundamentals of Risk Management for Process Industry EngineersDa EverandFundamentals of Risk Management for Process Industry EngineersNessuna valutazione finora