Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hacksaw

Caricato da

Simbu Arasan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

269 visualizzazioni5 paginehacksaw specs

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentohacksaw specs

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

269 visualizzazioni5 pagineHacksaw

Caricato da

Simbu Arasanhacksaw specs

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

Page 1 of 5

SPECIFICATION OF HACKSAW BLADES FOR CUTTING RAILS

(No. TM/SM/26 Rev. 01 of 2004)

A specification for hacksaw blades for cutting rails was adopted in 1992 with

the Railway Board issuing it to the zonal railways vide Railway Board letter no.

88/Track III/TK/2 (Vol.III) dated 28.2.1992 on the basis of the erstwhile standing

committees recommendations. This is the first revised version of the same

specification with the following salient modifications :-

(i) A harder grade of steel has been incorporated for hacksaw blades, based on

testing of samples,

(ii) Acceptance criteria has been revised,

(iii) One additional hacksaw blade size 350 x 32 x 1.60 x 4.0 (6 TPI) has been

included.

This specification has been approved by Railway Board and the zonal

railways intimated vide Railway Boards letter no. 96/Track-III/TK/32 (Vol.IV) dated

4.2.2002, on the basis of the recommendations of a standing committee on small

track machines nominated by Railway Board. The first revised version of the above

mentioned specification is being issued by RDSO, Lucknow with Sl. No. TM/SM-26-

2002

1.0 SCOPE: This specification covers the dimensions, material requirement and

test criteria of hacksaw blades to be used for cutting rails upto 880 Grade rails

(90 UTS rails).

2.0 TERMINOLOGY: Terminology used in this specification is same as mentioned

in IS : 2594-1977 (specification for hacksaw blades)

3.0 TYPE : Hacksaw blades for cutting rails shall be of All hard blade (Type A) as

per IS : 2594-1977.

4.0 DIMENSIONS : For manual as well as machine operation following sizes are

hereby recommended. All dimensions given below are in mm . The tolerances in

the dimensions shall be applicable as per IS : 2594-1977.

4.1 For manual cutting of rails (by hand-held hacksaw device):

4.1.1 For rails having sections upto or including 52 Kg rail sections:

i) 300 X 25 X 1.25 X 2.5 (10 TPI)

ii) 350 X 25 X 1.25 X 2.5 (10 TPI)

4.1.2 For rails having section 60 Kg :

i) 350 X 25 X 1.25 X 2.5 (10 TPI*)

ii) 350 X 32 X 1.60 X 4.0 (6 TPI)

* TPI: Teeth per inch.

Page 2 of 5

4.2 For machine operation i.e., cutting rails with the help of self propelled portable

(saw type) cutting machines :

i) 350 X 25 X 1.25 X 2.5 (10 TPI)

ii) 350 X 32 X 1.60 X 4.0 (6 TPI)

5.0 MATERIALS: High speed steel (HS) according to designation XT 87 W6 Mo

5 Cr4V2 of IS : 7291-1981.

6.0 HARDNESS : The hardness when measured as near to the tip of the teeth as

possible, shall be in the range of 850 HV to 900 HV and the hardness around pin

holes shall be in between 400 to 500 HV.

7.0 GENERAL REQUIREMENTS.

7.1 The blades shall be manufactured reasonably straight, true to shape and size. The

pin hole shall be neatly punched. The out of straightness per 100 mm length of

the blade in the longitudinal direction shall not exceed 0.6 mm for all sizes of

hacksaw blades.

7.2 The teeth shall be clean and uniform along toothed edge. The teeth of the blades

shall be set staggered. The formation of the set shall be symmetrical along the

length of toothed side.

7.3 The blades shall be heat-treated in such a manner that they shall fulfil the

requirements of hardness as mentioned in clause no. 6.0

7.4 The area around the pin-hole shall be suitably heat-treated to reduce the risk of

end fracture during use. The hardness around the pin-holes shall be in between

400 to 500 HV.

7.5 The center of the hole shall be located on the central line of the blade.

8.0 SAMPLING.

8.1 Unless otherwise agreed between the manufacturer and the purchaser, the criteria

of sampling given in Appendix A of IS : 2594-1977 shall be followed.

8.2 For the testing of cutting performance the number of blades to be selected shall be

as per clause A-3 of Appendix A of IS : 2594-1977 reproduced as below.

For performance test that is machine test or hand test the number of blades to be

selected shall be one per thousand blades or part thereof in the lot subject to a

maximum of six blades.

9.0 DESIGNATION: All Hacksaw blades shall be designated by the name, type,

nominal length, width, thickness, pitch and the symbol for material as mentioned

in clause 8 of IS : 2594 : 1977.

10.0 WORKMANSHIP AND FINISH : The blades shall be free from burrs, rust,

scale and other defects.

Page 3 of 5

11.0 MARKING.

11.1 Each blade shall be distinctly and indelibly marked with the symbol for material,

manufacturers name and initial or trade mark.

11.2 The year and month of manufacture shall also be marked on each blade.

12.0 PRESERVATION AND PACKING : The blade surface shall be coated with a

suitable preservative or paint. Each wrapped packet shall contain five or ten

blades and a suitable number of packets shall be packed in a carton. Each carton

shall contain bearing the designation, manufacturers name, initial or trade-mark.

Each contain shall contain one size of blades.

13.0 ACCEPTANCE CRITERIA: Before supplying the material, the supplier shall

test and certify that all blades conforms to the requirements i.e., material,

hardness, dimensions, finish, workmanship and cutting performance etc as

mentioned in this specification. The certificate shall be for and on behalf of the

manufacturer and shall be submitted in duplicate to the inspecting official.

Following tests shall be carried out on the samples collected as per clauses 8.1 and

8.2.

(i) Visual check,

(ii) Hardness test,

(iii) Cutting performance test.

13.1 VISUAL CHECK.

13.1.1 All dimensions of the hacksaw blades i.e., overall length, nominal length,

width, thickness and pitch shall be measured. All the dimensions shall fulfil the

requirements as mentioned in clause 3.1 and 3.2 of IS : 2594-1977.

13.1.2 The amount of deviation from straightness per 100 mm length of blade in

longitudinal direction shall not exceed 0.6 mm for all sizes of hacksaw blades.

This requirement of straightness of hacksaw blades should satisfied each of the

two tests given below:-

(a) The blade shall be placed horizontally flat on a surface plate and the

deviation from flatness is measured with the help of a filler gauge or slip

gauge, and

(b) The blade shall be held vertically with toothed edge touching the surface

plate and the vertical gap between toothed edge and surface plate shall be

measured.

13.2 HARDNESS TEST : Hardness test of the blade samples shall include following

compulsory tests:-

13..2.1 Hardness at nearer point of teeth and near the pin hole of selected blades shall be

checked in the manufacturers premises by suitable hardness testing machine and

should conform to the following results :

Page 4 of 5

Hardness near to the teeth shall be in the range of 850 HV to 900 Hv and hardness

around the pinholes shall be in between 400 to 500 HV. Manufacturer shall also

submit a certificate that hardness of all the hacksaw blades has been tested by him

and results are found as per stipulations given in the specification.

13.2.2 The manufacturer shall issue a certificate that quality and grade of raw material

used conforms to the stipulations of the specification. The manufacturer shall

also submit a certificate from a reputed or Govt. approved test house mentioning

detailed chemical composition of raw material used for the manufacture of

hacksaw blades.

13.3 CUTTING PERFORMANCE TEST :

13.3.1 Supply of each size of blade shall be subjected to cutting test after drawing the

sample as mentioned in clause 8.2.

13.3.2 Blades for hand operation as well as machine operation shall be tested on 52 Kg

880 Grade ( 90 UTS) rails or 52Kg 710 Grade (72 UTS) rails in stress free

condition. Cutting test shall be done on self propelled (mechanically /

electrically driven) portable hacksaw cutting machine (saw type). This test shall

satisfy the following criteria.

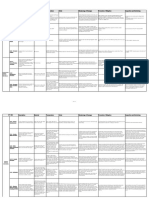

S.No. Size of blade (in mm) Minimum number of rail sections to

be cut by each sample blade

1. 300 X 25 X 1.25 X 2.5 (10 TPI) 12 Nos. on 52 Kg 72 UTS rails.

2. 350 X 25 X 1.25 X 2.5 (10 TPI) 15 Nos on 52 Kg 72 UTS rails or 07

Nos. on 52 Kg 90 UTS rails.

3. 350 X 32 X 1.60 X 4.0 (6 TPI) 08 Nos. on 52 Kg 90 UTS rails.

NOTES :

i) Maximum time consumed in each cut shall not exceed 30 Minutes. Preferably

it shall be in the range of 10 to 25 minutes.

ii) The test shall be carried out on stress free rail in a shade.

iii) Cutting test shall be performed using water as lubricant.

14.0 INSPECTION :

Inspection of blades shall be carried out by the Chief Track Engineer (CTE) or

his authorised representatives either at firms/suppliers premises or consignee

premises as desired by purchaser or at any other place agreed mutually.

15.0 SUPPLY :

15.1 Supplier shall either be an approved manufacturer or his authorized agent/dealer.

Page 5 of 5

Supplier shall attach necessary certificate of authorisation to this effect with the

tender/quotations. In case of doubt/suspicion. Purchaser is free to verify

credentials from manufacturer.

15.2 Hacksaw blades shall be supplied either by the manufacturer himself or by his

authorized agent/dealer. However, in case of bulk supply the supply shall be made

by the manufacturer only, even though tender/quotation has been submitted by

agent/dealer.

15.3 The supply shall be termed as bulk supply when number of blades per size shall

exceeds 3,000.

` ************

Potrebbero piacerti anche

- M 54-07 (2011) (Welded Deformed Steel Bar Mats For Concrete Reinforcement)Documento4 pagineM 54-07 (2011) (Welded Deformed Steel Bar Mats For Concrete Reinforcement)tran_lamNessuna valutazione finora

- Welded Steel Wire Fabric For General Use - Specification: Indian StandardDocumento8 pagineWelded Steel Wire Fabric For General Use - Specification: Indian Standardssaurav89Nessuna valutazione finora

- Welded Steel Plain Bar or Rod Mats For Concrete ReinforcementDocumento2 pagineWelded Steel Plain Bar or Rod Mats For Concrete ReinforcementGustavo SuarezNessuna valutazione finora

- Astm - A704Documento3 pagineAstm - A704masoud132Nessuna valutazione finora

- Disc Fitting Spec for 70kN OHLDocumento4 pagineDisc Fitting Spec for 70kN OHLPasupuleti007Nessuna valutazione finora

- AAAC Conductor SpecificationsDocumento9 pagineAAAC Conductor SpecificationsShrikant KajaleNessuna valutazione finora

- DGMS circulars on mining safety standardsDocumento61 pagineDGMS circulars on mining safety standardsravimutyamNessuna valutazione finora

- Dgms All Circular 2002 PDFDocumento61 pagineDgms All Circular 2002 PDFravimutyamNessuna valutazione finora

- MSEDCL technical specs for AA ACSR conductorsDocumento7 pagineMSEDCL technical specs for AA ACSR conductorskamarajinNessuna valutazione finora

- Disc Fitting 45 KN (T&C) TypeDocumento4 pagineDisc Fitting 45 KN (T&C) TypePasupuleti007Nessuna valutazione finora

- WBSEB TUBULAR STEEL POLES TECHNICAL SPECIFICATIONDocumento8 pagineWBSEB TUBULAR STEEL POLES TECHNICAL SPECIFICATIONVarun SharmaNessuna valutazione finora

- TM 32Documento4 pagineTM 32Rakesh SrivastavaNessuna valutazione finora

- Sailtender: Rsp/Cp/Forged Rolls/2014-17 /02 Appendix - 6Documento4 pagineSailtender: Rsp/Cp/Forged Rolls/2014-17 /02 Appendix - 6William Harper LanghorneNessuna valutazione finora

- Fabricated Deformed Steel Bar Mats For Concrete ReinforcementDocumento4 pagineFabricated Deformed Steel Bar Mats For Concrete ReinforcementBa Lestari WijanarkoNessuna valutazione finora

- 2 0.2 Acsr Panther Conductor 1 14Documento14 pagine2 0.2 Acsr Panther Conductor 1 14Anurag SanodiaNessuna valutazione finora

- A 704 - A 704M - 96 Qtcwnc9bnza0ts1sruqDocumento4 pagineA 704 - A 704M - 96 Qtcwnc9bnza0ts1sruqdelta lab sangliNessuna valutazione finora

- Irst 19 2012Documento65 pagineIrst 19 2012krischaever100% (1)

- TSC-1Documento6 pagineTSC-1Praveen BandariNessuna valutazione finora

- Specification For Machine For AbrasionDocumento3 pagineSpecification For Machine For AbrasionSajidAliKhanNessuna valutazione finora

- Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocumento3 pagineCarbon Steel Girder Rails of Plain, Grooved, and Guard TypesMichele DeckerNessuna valutazione finora

- Design and Construction of Prestressed Concrete Bridge BeamsDocumento12 pagineDesign and Construction of Prestressed Concrete Bridge BeamsCarlos SYNessuna valutazione finora

- 2-Asme BPVC Section Ix-2013Documento2 pagine2-Asme BPVC Section Ix-2013Reda ElsawyNessuna valutazione finora

- 6-15-0003 Rev 4Documento9 pagine6-15-0003 Rev 4cynideNessuna valutazione finora

- Astm C490Documento5 pagineAstm C490Horacio ApolayoNessuna valutazione finora

- Aashto M-180 PDFDocumento11 pagineAashto M-180 PDF48181Nessuna valutazione finora

- En 60889Documento3 pagineEn 60889Pankaj Goyal0% (1)

- PUBLIC POWER CORPORATION SPECIFICATION FOR STOCKBRIDGE VIBRATION DAMPERSDocumento10 paginePUBLIC POWER CORPORATION SPECIFICATION FOR STOCKBRIDGE VIBRATION DAMPERSgiorgis072Nessuna valutazione finora

- Asme Section II A-2 Sa-476 Sa-476mDocumento6 pagineAsme Section II A-2 Sa-476 Sa-476mAnonymous GhPzn1xNessuna valutazione finora

- Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocumento3 pagineCarbon Steel Girder Rails of Plain, Grooved, and Guard TypesAjesh Kumar MuraleedharanNessuna valutazione finora

- 1321 Part 1 - Sisal Ropes (Untarred Varieties)Documento10 pagine1321 Part 1 - Sisal Ropes (Untarred Varieties)Kaushik SenguptaNessuna valutazione finora

- Fabricated Deformed Steel Bar Mats For Concrete ReinforcementDocumento3 pagineFabricated Deformed Steel Bar Mats For Concrete ReinforcementJosé Ramón GutierrezNessuna valutazione finora

- UIC Code: International Union of RailwaysDocumento20 pagineUIC Code: International Union of RailwaysHARINessuna valutazione finora

- Irst 19 1994 11 12 PDFDocumento51 pagineIrst 19 1994 11 12 PDFRITES LTD. SITE OFFICE ,ROURKELANessuna valutazione finora

- Is 210Documento16 pagineIs 210Debopriyo GhoshNessuna valutazione finora

- Steel Strand, Seven-Wire, Uncoated, Compacted, Stress-Relieved For Prestressed ConcreteDocumento4 pagineSteel Strand, Seven-Wire, Uncoated, Compacted, Stress-Relieved For Prestressed ConcreteGustavo Suarez0% (1)

- SECTION 20710 Flash Butt Rail Welding: Caltrain Standard SpecificationsDocumento8 pagineSECTION 20710 Flash Butt Rail Welding: Caltrain Standard SpecificationsminchanmonNessuna valutazione finora

- Sec612 - Post-Tensioning of Concrete UnitsDocumento11 pagineSec612 - Post-Tensioning of Concrete UnitsAmr Adel HameedNessuna valutazione finora

- Gi Earth SpikeDocumento5 pagineGi Earth SpikemangalamtestingbureaNessuna valutazione finora

- A 748 - A 748M - 87 R03 Qtc0oc9bnzq4tq - PDFDocumento2 pagineA 748 - A 748M - 87 R03 Qtc0oc9bnzq4tq - PDFMung Duong XuanNessuna valutazione finora

- Acsr ConductorsDocumento10 pagineAcsr ConductorsPhani KumarNessuna valutazione finora

- Page 1 of 7Documento7 paginePage 1 of 7arjun prajapatiNessuna valutazione finora

- Concretevibrators-Immersiontype - / ' Generalrequirements: Indian StandardDocumento8 pagineConcretevibrators-Immersiontype - / ' Generalrequirements: Indian StandardVaibhav SengarNessuna valutazione finora

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Documento4 pagineApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNessuna valutazione finora

- Draft - Is - Code PDFDocumento12 pagineDraft - Is - Code PDFdbhawal6388Nessuna valutazione finora

- Aa Spec 377002Documento9 pagineAa Spec 377002jonodo89Nessuna valutazione finora

- 2192 PDFDocumento8 pagine2192 PDFSushil DhunganaNessuna valutazione finora

- Is 5522 1992Documento6 pagineIs 5522 1992psewagNessuna valutazione finora

- Lowcarbongalvanizedsteelwires, Formedwiresandtapesfor Armouringofcables - SpecificationDocumento8 pagineLowcarbongalvanizedsteelwires, Formedwiresandtapesfor Armouringofcables - SpecificationShrikant KajaleNessuna valutazione finora

- 583 Ankle Boot For Heavy DutyDocumento11 pagine583 Ankle Boot For Heavy DutyRavi ShahNessuna valutazione finora

- Spiral Wound GasketsDocumento7 pagineSpiral Wound GasketsPrem NautiyalNessuna valutazione finora

- WD-03-misc-86 (Rev. 4)Documento16 pagineWD-03-misc-86 (Rev. 4)ROH BKSCNessuna valutazione finora

- C 4 - 02 - QzqtmdiDocumento6 pagineC 4 - 02 - Qzqtmdimhamed1Nessuna valutazione finora

- BOLTS (New Section) 972Documento6 pagineBOLTS (New Section) 972Nisa_nisheNessuna valutazione finora

- Astm A184Documento3 pagineAstm A184racingspirit800% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Spot Welding Interview Success: An Introduction to Spot WeldingDa EverandSpot Welding Interview Success: An Introduction to Spot WeldingNessuna valutazione finora

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDa EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNessuna valutazione finora

- TWI Welding Training 4Documento36 pagineTWI Welding Training 4Simbu Arasan100% (1)

- Serag4000 NotesDocumento19 pagineSerag4000 NotesSimbu ArasanNessuna valutazione finora

- Mitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateDocumento4 pagineMitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateSimbu ArasanNessuna valutazione finora

- Pipe Schedule PDFDocumento1 paginaPipe Schedule PDFSrinivasan SeenuNessuna valutazione finora

- Uts, Utn, Dry - Weld History Sheet - MasterDocumento461 pagineUts, Utn, Dry - Weld History Sheet - MasterSimbu ArasanNessuna valutazione finora

- Steam Turbine Q & ADocumento47 pagineSteam Turbine Q & Asrikanth9555100% (1)

- My Desk: Time Is GoldDocumento22 pagineMy Desk: Time Is GoldSimbu ArasanNessuna valutazione finora

- Fe-C Phase DiagramDocumento34 pagineFe-C Phase DiagramYoung-long Choi100% (1)

- 510 - May 2017 Jan 2018 - PublicationsEffectivity - Final 12 05 16 PDFDocumento1 pagina510 - May 2017 Jan 2018 - PublicationsEffectivity - Final 12 05 16 PDFshakeelahmadjsrNessuna valutazione finora

- XtrasDocumento3 pagineXtrasSimbu ArasanNessuna valutazione finora

- CSWIP-WI-6-92 13th Edition July 2015 PDFDocumento17 pagineCSWIP-WI-6-92 13th Edition July 2015 PDFjaisonaeroNessuna valutazione finora

- Fe-C Phase DiagramDocumento34 pagineFe-C Phase DiagramYoung-long Choi100% (1)

- Electrode Backing RegisterDocumento4 pagineElectrode Backing RegisterSimbu Arasan100% (1)

- 003 - Standard Procedure For Coating and WrappingDocumento6 pagine003 - Standard Procedure For Coating and WrappingSimbu ArasanNessuna valutazione finora

- Thermal fatigue and brittle fracture mechanismsDocumento3 pagineThermal fatigue and brittle fracture mechanismsSimbu Arasan100% (1)

- SWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtyDocumento2 pagineSWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtySimbu ArasanNessuna valutazione finora

- 004 - Standard Procedure For Surface Preparation and PaintingDocumento9 pagine004 - Standard Procedure For Surface Preparation and PaintingSimbu ArasanNessuna valutazione finora

- 001 - Standard Procedure For Hydrostatic Pressure Test of PipingDocumento8 pagine001 - Standard Procedure For Hydrostatic Pressure Test of PipingSimbu Arasan0% (1)

- 2645r - Waterproofing Compounds For Concrete and Cement MortarsDocumento13 pagine2645r - Waterproofing Compounds For Concrete and Cement MortarsSimbu ArasanNessuna valutazione finora

- TATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Documento4 pagineTATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Simbu ArasanNessuna valutazione finora

- BHEL Earthing SystemDocumento8 pagineBHEL Earthing SystemSimbu ArasanNessuna valutazione finora

- SaarnaDocumento3 pagineSaarnagueridiNessuna valutazione finora

- UF NF Dispatch Master Data 04-11-15Documento47 pagineUF NF Dispatch Master Data 04-11-15Simbu ArasanNessuna valutazione finora

- Hot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 MannessmanDocumento3 pagineHot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 Mannessmandnageshm4n244Nessuna valutazione finora

- 006 CBCRDT Tata ProjectsDocumento3 pagine006 CBCRDT Tata ProjectsSimbu ArasanNessuna valutazione finora

- Structural Tank Instructions 11967-ADocumento22 pagineStructural Tank Instructions 11967-Aiftikhar_khalid_1Nessuna valutazione finora

- EPS Withdrawal FormDocumento5 pagineEPS Withdrawal FormArun AbNessuna valutazione finora

- RO Plant Operation GuidelinesDocumento5 pagineRO Plant Operation GuidelinesSimbu ArasanNessuna valutazione finora

- UF Membrane Storage & PreservationDocumento1 paginaUF Membrane Storage & PreservationSimbu ArasanNessuna valutazione finora

- TPL-US-QMD-002 - Surface Preparation and Painting ProcedureDocumento4 pagineTPL-US-QMD-002 - Surface Preparation and Painting ProcedureSimbu ArasanNessuna valutazione finora

- HacksawDocumento5 pagineHacksawSimbu ArasanNessuna valutazione finora

- Handbook of Aircraft Armament PDFDocumento98 pagineHandbook of Aircraft Armament PDFcpt_suzukiNessuna valutazione finora

- Project Report On Pedal Operated Hack Saw MachineDocumento45 pagineProject Report On Pedal Operated Hack Saw MachineTejasDhebe74% (80)

- Solar Wood CutterDocumento13 pagineSolar Wood Cuttern_amarsinh9938Nessuna valutazione finora

- Hacksaws & FilesDocumento27 pagineHacksaws & FilesCiwing CiwingNessuna valutazione finora

- Machine Design 2Documento16 pagineMachine Design 2syammcNessuna valutazione finora

- Tolsen Tools v1510.1Documento44 pagineTolsen Tools v1510.1Robin OhanyanNessuna valutazione finora

- Module 7 (Maintenance Practices) Sub Module 7.14 (Material Handling) PDFDocumento20 pagineModule 7 (Maintenance Practices) Sub Module 7.14 (Material Handling) PDFshareyhouNessuna valutazione finora

- Welder 1St Sem Practicalwm 1 1Documento204 pagineWelder 1St Sem Practicalwm 1 1RNessuna valutazione finora

- Declaration: by Yohannes, Migbaru, Yalew &masrie (Wukiot)Documento63 pagineDeclaration: by Yohannes, Migbaru, Yalew &masrie (Wukiot)Sibhat GebregziabherNessuna valutazione finora

- Bow SawDocumento3 pagineBow SawRafishfullNessuna valutazione finora

- TOPL FSRU Buyer Supply Items Final ListDocumento52 pagineTOPL FSRU Buyer Supply Items Final ListPiyush KumarNessuna valutazione finora

- Metalworking Tools Guide for Cutting, Filing & Fastening MetalDocumento6 pagineMetalworking Tools Guide for Cutting, Filing & Fastening MetalHoai nam100% (1)

- Bench FittingDocumento161 pagineBench FittingMichael Castro Abudu100% (2)

- Chapter 2 Cutting ToolsDocumento33 pagineChapter 2 Cutting Toolskaleab hintsaNessuna valutazione finora

- 16 Scroll Saw 2017Documento49 pagine16 Scroll Saw 2017chockalingam athilingam100% (1)

- Fabrication of Pedal Powered Hacksaw Using Dual Chain DriveDocumento4 pagineFabrication of Pedal Powered Hacksaw Using Dual Chain DriveNitin SakpalNessuna valutazione finora

- Fitting ToolsDocumento14 pagineFitting ToolsManoj Lohumi100% (2)

- Fitter Lesson Plans 2Documento138 pagineFitter Lesson Plans 2sureshsharmamkNessuna valutazione finora

- Laboratory Manual: Mechanical Engineering WorkshopDocumento73 pagineLaboratory Manual: Mechanical Engineering WorkshopNEELIMANessuna valutazione finora

- Luray II Barangay High School Summative Test in SMAW 8Documento3 pagineLuray II Barangay High School Summative Test in SMAW 8Krizzie Jade Cailing100% (1)

- Cut CLX For 15 KV CableDocumento4 pagineCut CLX For 15 KV CableJorge BaqueNessuna valutazione finora

- Gegas ReportDocumento4 pagineGegas ReportOmar DonNessuna valutazione finora

- Module 1 - Maintaining and Repairing Audio Products and SystemDocumento52 pagineModule 1 - Maintaining and Repairing Audio Products and SystemAko Lang Poh70% (20)

- Everest Tools - Valisons & CompanyDocumento24 pagineEverest Tools - Valisons & CompanyMurtuza LucknowwalaNessuna valutazione finora

- קטלוג אקליפס 2020Documento76 pagineקטלוג אקליפס 2020חברת גוטמן ברזיליNessuna valutazione finora

- Cutting Tools WorksheetDocumento5 pagineCutting Tools WorksheetAbrigondo, Vindel J.Nessuna valutazione finora

- Schedule-J - List of Maintenance Tools and TacklesDocumento6 pagineSchedule-J - List of Maintenance Tools and TacklesPrasanna kumar subudhiNessuna valutazione finora

- Full Hacksaw ReportDocumento7 pagineFull Hacksaw ReportIqbalRifat0% (1)

- MODULE - Maintaining Plumbing Tool and EquipmentDocumento14 pagineMODULE - Maintaining Plumbing Tool and EquipmentJanine ReyesNessuna valutazione finora