Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

VFX5UR0203CA10

Caricato da

TungstenCarbideCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

VFX5UR0203CA10

Caricato da

TungstenCarbideCopyright:

Formati disponibili

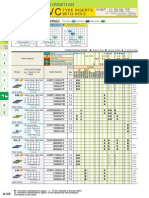

For Titanium Alloy Milling

DEEP SHOULDER

MILLING

Roughing

VFX5

D7

W1

D9

a Vertical inserts with high

D8

D1

L7

L8

strength cutting edge.

a Screw-on type clamping.

a High efficiency milling of

ap (Max. Depth of Cut)

L1

titanium alloys.

Right hand tool holder only.

VFX5UR0203CA10

0203CA15

0204AA10

0204AA15

0204CA15

0204AA20

0204CA20

2505CA10

2505CA24

0306DA29

a

a

a

a

a

a

a

a

a

a

D1

3

3

4

4

4

4

4

5

5

6

6

9

8

12

12

16

16

10

25

36

2.0

2.0

2.0

2.0

2.0

2.0

2.0

2.5

2.5

3.0

Tool Weight

Total Inserts

Number of Flutes

Order Number

Stock

y SHELL TYPE

Dimensions (inch)

L1

D9

L7

D8

D7

W1

L8

ap

(lbs)

2.0

2.5

2.0

2.5

2.5

2.75

3.0

2.5

3.5

4.25

1.00

1.00

.75

.75

1.00

.75

1.00

1.00

1.00

1.25

.95

1.00

.75

.75

1.00

.75

1.00

1.25

1.25

1.375

.520

.520

.395

.395

.520

.395

.520

.520

.520

.645

1.929

1.929

1.929

1.929

1.929

1.929

1.929

2.421

2.421

2.894

.375

.375

.313

.313

.375

.313

.375

.375

.375

.500

.219

.219

.187

.187

.219

.187

.219

.219

.219

.281

1.0

1.5

1.0

1.5

1.5

2.0

2.0

1.0

2.4

2.9

.20

.26

.24

.30

.27

.32

.33

.49

.68

1.21

SPARE PARTS

*2

*3

Number of Insert

Peripheral 1

cutting edge

End cutting

edge

Order Number

Clamp Screw Number Seal Washer

VFX5UR0203CA10

0203CA15

0204AA10

0204AA15

0204CA15

0204AA20

0204CA20

2505CA10

2505CA24

0306DA29

TS352

TS352

TS352

TS352

TS352

TS352

TS352

TS352

TS352

TS352

6

9

8

12

12

16

16

10

25

36

WU500-S1

WU500-S1

WU375-S1

WU375-S1

WU500-S1

WU375-S1

WU500-S1

WU500-S1

WU500-S1

WU625-S1

Wrench

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

Coolant Nozzle Number Anti-seize Lubricant

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

9

12

12

16

16

20

20

15

30

42

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

Set Bolt

XNMU1607

ooR-oo

XNMU1607

08R-oo

HSCUF50014

HSCUF50018

HSCUF37513

HSCUF37520

HSCUF50018

HSCUF37520

HSCUF50023

HSCUF50018

HSCUF50028

HSCUF62535

3

3

4

4

4

4

4

5

5

6

3

6

4

8

8

12

12

5

20

30

corner radius Re.031 can be used.

*1.2. Only

Clamp Torque (lbf-in) : TS352=22

*3. The

.031" nozzels are installed in the standard. Select and use alternate nozzles from below list depending on coolant pressure.

*

< 140PSI

( < 5.3gal/min)

.024"

Order Number HSD04004H06

Nozzle Dia.

(140PSI-720PSI)

Standard

> 720PSI

( > 7.9gal/min)

> 1000PSI

( > 13.2gal/min)

.031"

HSD04004H08

.047"

HSD04004H12

.063"

HSD04004H16

Torque (lbf-in) : HSD0400Hpp=13

Clamp

part number for a plug screw without a through nozzle is HSS04004.

The

Insert with a corner radius of .125" and above, as corner radius increases the L1 dimension increases.

Corner

radius .125": L1+.028" Corner radius .157": L1+.059"

a

: Inventory maintained. (10 insert in one case)

s : Inventory maintained in Japan.

D7

W1

D9

a Vertical inserts with high

D8

D1

L7

L8

strength cutting edge.

a Screw-on type clamping.

a High efficiency milling of

METRIC Standard

ap (Max. Depth of Cut)

L1

titanium alloys.

For metric arbors

Right hand tool holder only.

VFX5-040A03A026R

-040A03A038R

-050X03A026R

-050X03A038R

-050A04A026R

-050A04A038R

-050X04A038R

-050A04A050R

-063A05A026R

-063A05A063R

-080A06A075R

s

s

s

s

s

s

s

s

s

s

s

3

3

3

3

4

4

4

4

5

5

6

6

9

6

9

8

12

12

16

10

25

36

Tool Weight

Total

Number of Flutes

Order Number

Stock

y SHELL TYPE

Dimensions (mm)

D1

L1

D9

L7

D8

D7

W1

L8

ap

(kg)

40

40

50

50

50

50

50

50

63

63

80

50

60

50

60

50

60

60

70

60

85

100

16

16

27

27

22

22

27

22

27

27

32

21

21

23

23

21

21

23

21

28

28

28

8.5

8.5

12.5

12.5

10.5

10.5

12.5

10.5

12.5

12.5

16.5

38.2

38.2

48.2

48.2

48.2

48.2

48.2

48.2

61

61

77.3

8.4

8.4

12.4

12.4

10.4

10.4

12.4

10.4

12.4

12.4

14.4

5.6

5.6

7.0

7.0

6.3

6.3

7.0

6.3

7.0

7.0

8.0

26

38

26

38

26

38

38

50

26

63

75

0.3

0.4

0.4

0.5

0.5

0.6

0.5

0.7

1.0

1.4

2.8

SPARE PARTS

*2

*3

Number of Insert

Peripheral 1

cutting edge

End cutting

edge

Order Number

Clamp Screw Number Seal Washer

VFX5-040A03A026R

-040A03A038R

-050X03A026R

-050X03A038R

-050A04A026R

-050A04A038R

-050X04A038R

-050A04A050R

-063A05A026R

-063A05A063R

-080A06A075R

TS352

TS352

TS352

TS352

TS352

TS352

TS352

TS352

TS352

TS352

TS352

6

9

6

9

8

12

12

16

10

25

36

W8-S1

W8-S1

W12-S1

W12-S1

W10-S1

W10-S1

W12-S1

W10-S1

W12-S1

W12-S1

W16-S1

Wrench

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

TKY10D

Coolant Nozzle Number Anti-seize Lubricant

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

HSD04004H08

9

12

9

12

12

16

16

20

15

30

42

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

MK1KS

Set Bolt

XNMU1607

ooR-oo

XNMU1607

08R-oo

HSC08040

HSC08050

HSC12035

HSC12045

HSC10035

HSC10045

HSC12045

HSC10055

HSC12045

HSC12070

HSC16080

3

3

3

3

4

4

4

4

5

5

6

3

6

3

6

4

8

8

12

5

20

30

corner radius Re.031 can be used.

*1.2. Only

Clamp Torque (lbf-in) : TS352=22

*3. The

.031" nozzels are installed in the standard. Select and use alternate nozzles from below list depending on coolant pressure.

*

< 140PSI

( < 5.3gal/min)

.024"

Order Number HSD04004H06

Nozzle Dia.

(140PSI-720PSI)

Standard

> 720PSI

( > 7.9gal/min)

> 1000PSI

( > 13.2gal/min)

.031"

HSD04004H08

.047"

HSD04004H12

.063"

HSD04004H16

Torque (lbf-in) : HSD0400Hpp=13

Clamp

part number for a plug screw without a through nozzle is HSS04004.

The

Insert with a corner radius of .125" and above, as corner radius increases the L1 dimension increases.

Corner

radius .125": L1+.028" Corner radius .157": L1+.059"

For Titanium Alloy Milling

INSERTS

Stock

Dimensions (inch)

.630 .276 .437 .256 .039 .063

.630 .276 .437 .256 .039 .094

a

a

.681 .276 .437 .256

.744 .276 .437 .256

.630 .276 .437 .256 .039 .031

.126

.157

Re

S1

.630 .276 .437 .256 .039 .031

.630 .276 .437 .256 .039 .047

S1

Geometry

Re

S1

F1

L2

S1

L2

L3

L2

L2

L1

F1

*11

*

XNMU160708R-MS

160712R-MS

160716R-MS

160724R-MS

160732R-MS

160740R-MS

XNMU160708R-HS

L1

F1

Order Number

L3

Shape

MP9030

MP9130

Coated

L1

L3

Re

.630 .276 .437 .256 .039 .031

F1

XNMU160708R-LS

L1

L3

Re

for insert with a corner radius of .125" and above, as corner radius increases the L1 dimension increases.

*1 Note

Corner radius .125": L1+.028" Corner radius .157": L1+.059"

: Inventory maintained. (10 insert in one case)

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Bell 429 Helicopter - High Resolution PanelDocumento1 paginaBell 429 Helicopter - High Resolution Panelguicordova0% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Versa 2015 JF414Documento272 pagineVersa 2015 JF414Jhonny Beltran DiazNessuna valutazione finora

- TLE Project ProposalDocumento11 pagineTLE Project ProposalAlvin Charles Lopez95% (21)

- Calibration of AmmeterDocumento4 pagineCalibration of Ammeterpks_facebook33% (3)

- CC CC: Type Inserts With HoleDocumento4 pagineCC CC: Type Inserts With HoleTungstenCarbideNessuna valutazione finora

- Any Size Kits Are All $400.00: Steel ApplicationsDocumento2 pagineAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideNessuna valutazione finora

- Cpmt1205zpen-M2 VP15TFDocumento1 paginaCpmt1205zpen-M2 VP15TFTungstenCarbideNessuna valutazione finora

- Nnmu200608zen-Hk MC5020Documento1 paginaNnmu200608zen-Hk MC5020TungstenCarbideNessuna valutazione finora

- CBN InsertsDocumento27 pagineCBN InsertsTungstenCarbideNessuna valutazione finora

- Through Holes Steam Oxide External Cooling: Series 4402Documento8 pagineThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideNessuna valutazione finora

- Gy2g0200d020n-Mf VP10RTDocumento6 pagineGy2g0200d020n-Mf VP10RTTungstenCarbideNessuna valutazione finora

- CCMXDocumento1 paginaCCMXTungstenCarbideNessuna valutazione finora

- Aemw150304er Up20mDocumento1 paginaAemw150304er Up20mTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocumento1 paginaType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNessuna valutazione finora

- Aemw150304er Up20mDocumento1 paginaAemw150304er Up20mTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: XCMT 15 03 02-SVXDocumento1 paginaType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNessuna valutazione finora

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocumento2 pagineAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WCGT 02 01 02 RDocumento1 paginaType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VBMT 11 03 04 - SVDocumento2 pagineType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WNMG 08 04 04-FHDocumento4 pagineType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VPET 08 02 01 R-SRFDocumento1 paginaType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VNMG 16 04 02-FHDocumento3 pagineType Inserts With Hole: VNMG 16 04 02-FHTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: TEGX 16 03 02 RDocumento1 paginaType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocumento1 paginaType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VDGX 16 03 02 RDocumento1 paginaType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: TPMH 08 02 02-FVDocumento3 pagineType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VCMT 11 03 02-FPDocumento2 pagineType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNessuna valutazione finora

- TNDocumento6 pagineTNTungstenCarbideNessuna valutazione finora

- SNDocumento4 pagineSNTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: SCMT 09 T3 04-FPDocumento2 pagineType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: SPMT 09 03 04Documento1 paginaType Inserts With Hole: SPMT 09 03 04TungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: TCMT 09 02 02-FPDocumento2 pagineType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNessuna valutazione finora

- Type Inserts Without Hole: Posi 6ºDocumento1 paginaType Inserts Without Hole: Posi 6ºTungstenCarbideNessuna valutazione finora

- List of Instruments and Pressure GaugesDocumento1 paginaList of Instruments and Pressure Gaugesram dhukeNessuna valutazione finora

- OkkkDocumento14 pagineOkkkUmmu Hamnah DewiNessuna valutazione finora

- Design of Screw JackDocumento12 pagineDesign of Screw JackKunal Ahiwale75% (4)

- Electrical TOOLS and Its FunctionDocumento21 pagineElectrical TOOLS and Its FunctionJoseph OmpadNessuna valutazione finora

- DWD Summo AllDocumento4 pagineDWD Summo AllMario Allesina JuniorNessuna valutazione finora

- Eaton Fuller RTLO 16918B As Transmission Parts ManualDocumento34 pagineEaton Fuller RTLO 16918B As Transmission Parts ManualRoy Hernandez100% (1)

- Pen InkDocumento32 paginePen InkPrajakta Divekar100% (1)

- Veritas Router Table Assembly InstructionsDocumento8 pagineVeritas Router Table Assembly Instructionssalvador LuqueNessuna valutazione finora

- Week 2 - DraftingDocumento3 pagineWeek 2 - DraftingmerylNessuna valutazione finora

- Single-Reduction Differential Carriers: Single Rear Drive Axles, Rear-Rear Tandem Drive Axles and Front Drive Steer AxlesDocumento94 pagineSingle-Reduction Differential Carriers: Single Rear Drive Axles, Rear-Rear Tandem Drive Axles and Front Drive Steer AxlesTavyLocNessuna valutazione finora

- Ivi 5VM2R 8NF 8NF SS6Documento1 paginaIvi 5VM2R 8NF 8NF SS6Ganesh ZambreNessuna valutazione finora

- Jig BushDocumento24 pagineJig BushnilamNessuna valutazione finora

- Hand Tools: (Contained in Individual Sets or The Tool Crib in Sufficient Quantities To Permit Efficient Instruction)Documento14 pagineHand Tools: (Contained in Individual Sets or The Tool Crib in Sufficient Quantities To Permit Efficient Instruction)Dan DumbravescuNessuna valutazione finora

- KC-20VS Service ManualDocumento8 pagineKC-20VS Service Manualbill_gator20059105Nessuna valutazione finora

- Gambar 13 Clutch: Nomor Nomor Part Nama Part KeteranganDocumento2 pagineGambar 13 Clutch: Nomor Nomor Part Nama Part KeteranganHendriM89Nessuna valutazione finora

- (Test 2) : Unit 9. What Colour Is It?Documento5 pagine(Test 2) : Unit 9. What Colour Is It?Hàn HươngNessuna valutazione finora

- Gear TrainDocumento25 pagineGear TrainDhanashree PanchawatkarNessuna valutazione finora

- Alcantara Luis ResumeDocumento2 pagineAlcantara Luis ResumeJohn Laurence Gonzaga AlcantaraNessuna valutazione finora

- Vernier, Dial, and Electronic Digital Calipers: Session 3Documento40 pagineVernier, Dial, and Electronic Digital Calipers: Session 3adrianram1Nessuna valutazione finora

- PCDO April2020Documento39 paginePCDO April2020TENDER CELL DIESEL SHED GONDANessuna valutazione finora

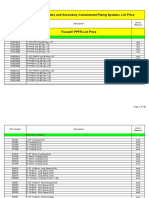

- Waste Piping Systems and Secondary Containment Piping Systems List PriceDocumento146 pagineWaste Piping Systems and Secondary Containment Piping Systems List PriceAaron Marius JuliusNessuna valutazione finora

- Hydraulic Jack For Main Bearing Cap: Vasa 32 Spare Parts List 100-02Documento4 pagineHydraulic Jack For Main Bearing Cap: Vasa 32 Spare Parts List 100-02mazlum doğan DemirkolNessuna valutazione finora

- Qelectrotech ElementDocumento2 pagineQelectrotech ElementAnggy Anggraini UsmanNessuna valutazione finora

- HOOD CalculationDocumento3 pagineHOOD CalculationhimajcpNessuna valutazione finora

- Section 35 - Hydraulic System - Chapter 10Documento36 pagineSection 35 - Hydraulic System - Chapter 10احمد الشبراوى الشبراوىNessuna valutazione finora

- OptiX OSN 6800 Intelligent Optical Transport PlatformDocumento55 pagineOptiX OSN 6800 Intelligent Optical Transport PlatformErnestoLopezGonzalezNessuna valutazione finora