Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Design and Implementation of Multiple Output Switch Mode Power Supply

Caricato da

seventhsensegroupTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Design and Implementation of Multiple Output Switch Mode Power Supply

Caricato da

seventhsensegroupCopyright:

Formati disponibili

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10-Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4540

Design And Implementation Of Multiple Output

Switch Mode Power Supply

Amit

1

, Dr. Manoj Kumar

2

1

Student of final year B.Tech. E.C.E., Guru Jambheshwar University Of Science & Technology, Hisar

2

Assistant Professor, E.C.E. Dept., Guru Jambheshwar University Of Science & Technology, Hisar Haryana-India

1

ami t _sangwan@l i ve. i n

Abstract In this paper, the design of multiple output power

supply is presented. An Embedded system requires different

voltage levels for its proper functioning because the components

used in any embedded system required different voltage levels as

per their specifications, so this paper proposed a power supply

that includes +15V, -15V, +5V, -5V, +3.3V, +5V Isolated voltage

levels. The input for this power supply is 48V DC which is

available at all telecom sites. This power supply is capable of

providing approximate 40W output power with 80% efficiency.

The power supply design topology selected for this paper is

flyback converter because flyback converter is a better option as

compare to other topologies for low power design and for

generating multiple output voltage levels. This power supply is

designed by low cost and highly efficient discrete components

and the paper also describes the criteria of choosing these

components. This supply designed here can be used for almost all

applications in telecom embedded products due to its versatile

range of constant output voltage levels.

Keywords Switch Mode Power Supplies, flyback converters, DC-

DC converters

I. INTRODUCTION

Modern embedded electronic systems require high quality,

small, lightweight, reliable, and efficient power supplies [1].

SMPS are widely used in Telecommunication applications [2].

The main applications of these SMPS are to provide

supply to the various control parts, sensors, actuators/relay

drives and of course to the different electronic ICs with

high power density, high efficiency and constant operational

frequency. SMPS topologies can be classified according to the

method of power transfer fromthe input to output and are

classified in flyback and forward groups. In the forward group,

power is transferred to the output when the main switch

conducts i.e. during ON state, whereas in the flyback group,

the power is transferred to the output when the main switch

opens i.e. during OFF state [3]. The flyback SMPS topology

has been attractive for a long time because of its simplicity

when compared with other topologies used in low power

applications [4].

II. TOPOLOGY OVERVIEW

The flyback SMPS topology is based on Flyback DC-DC

Converters. DC-DC Converters can be classified as isolated

and non-isolated. Flyback converter is one of the simple

topology in isolated converters [5]. Fig.1 shows the typical

topology of flyback DC-DC converters.

Fig. 1 Simplified flyback converter

The input dc source V

DC

and switch Q is connected in

series with the primary transformer. The diode D and the RC

output circuit are connected in series with the secondary of the

flyback transformer. The Dot-ends of inductors determines the

operation of the DC-DC converter. Polarity of primary

winding (L

p

) and secondary (L

s

) are not same. When the

switch Q is on, the current in the magnetizing inductance

increases linearly and the primary current I

p

raises to peak

value [6]. At this interval, secondary winding is oppositely

polarized to the primary inductor as a result diode D is off and

there is no current in the ideal transformer windings. This is

shown below in fig 2.

Fig. 2 Switch Q in ON state

When switch Q is turned-off, stored energy at the air gap

and magnetic core are transferred to secondary winding and

magnetizing inductance current is supplied to the RC load.

This is shown below in fig 3.

VDC

TXA

1

2

TXB

3

4

Q

2

1

3

D

+

C R

VDC TXA

1

2

TXB

3

4

+

C R

V

P

V

S

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10-Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4541

Fig. 3 Switch Q in OFF state

The dc voltage transfer function defined as the ratio of the

output voltage to the input voltage of the flyback converter is

H

v

=

I

o

I

s

=

n(1)

D is duty ratio of the switch defined as a ratio of the ON time

of the switch to the sumof the ON and the OFF times. For a

constant frequency operation,

=

1

cn

1

cn

+1

c]]

n is the winding turns ratio given by n =

N

P

N

s

Where N

P

and N

s

are the primary and secondary winding

turns.

Flyback Converter can easily operate in two modes,

Continuous Conduction Mode (CCM), Discontinuous

Conduction Mode (DCM) [5]. As shown in figure 4, during

the Q on time, there is a fixed voltage across the primary

winding so primary current will ramps up linearly. As

secondary diode is reverse biased so there is no secondary

current during I

on

. Primary current is maximumat the end of

I

on

period. When Q turns-off, the magnetizing current in the

primary winding stops and the voltage of secondary winding

will reverse, to create the flyback action. Due to this reverse

secondary voltage diode start conducting and a decreasing

secondary current flows in the secondary winding as shown in

figure. During this off period, primary winding is not

conducting and so primary current does not exist.

In Discontinuous mode, the output winding current goes to

zero before the end of the I

o]]

period, so that all the stored

energy is transferred to the load.

In Continuous mode, the secondary current is greater than

zero when Q turns-on for the next period hence Secondary

current couldnt fully discharge at any time, so there is some

residual energy stored in the transformer at the end of the

every ON and OFF periods.

Fig.4 Flyback converter waveform:

Discontinuous Mode vs. Continuous Mode

(a) Q Command Voltage (b) Primary Voltage (c) Primary Current

(d) Secondary Voltage (e) Secondary Current.

III. BLOCK DIAGRAM OF THE SYSTEM

The dcdc converter provides a regulated dc output voltage

under varying load and input voltage conditions. The

converter component values are also changing with time,

temperature, pressure, etc. Hence, the control of the output

voltage should be performed in a closed-loop manner using

principles of negative feedback. Two most common closed-

loop control methods for PWM dcdc converters, namely, the

voltage-mode control and the current-mode control. Current-

mode control is presented in the Fig. 5.

Fig.5 Block Diagram

The converter output voltage is sensed and subtracted from

an external reference voltage in an error amplifier. An inner

control loop feeds back an inductor current signal. This

current signal, converted into its voltage Analog, is compared

to the control voltage. The duty ratio of the PWM signal

depends on the value of the control voltage. The frequency of

the PWM signal is the same as the frequency of the current

signal. The comparator produces a PWM signal which is fed

to drivers of controllable switches in the dcdc converter.

IV. SYSTEM DESIGN TECHNIQUE

This section of the paper covers the basics of PWM

controller and magnetic design used in SMPS applications.

VDC TXA

1

2

TXB

3

4

+

C R

t

t

t

t

Voltage

TON TOFF TON TOFF

t

Voltage

( a)

( b)

( c)

( d)

( e)

REFERENCE

VOLTAGE

ERROR

AMPLIFIER

COMPARATOR

DC-DC

CONVERTER

SWITCH OR INDUCTOR CURRENT

OUTPUT

V

P

V

S

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10-Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4542

Fig.6 SMPS Circuit Diagram

After selecting the topology that is best suited to the power

supply specification, the next choice is to fix the switching

frequency and transformer parameters. To do this, it is

necessary to know the numerical relation between maximum

available power and transformer parameters such as magnetic

core area, magnetic length, window area, bobbin area, peak

flux density and coil current density.

A. PWM Controller

PWM controller used in this design is UC3845B which

control the switching time of MOSFET power switch. It

makes efficiency and stability of SMPS higher and at the same

time makes the system cost, volume and weight lower

[7].This integrated circuit has an oscillator, a

temperature compensated reference, high gain error

amplifier, current sensing comparator, and a high

current totem pole output ideally suited for driving a

power MOSFET switch.

The oscillator frequency of this PWM controller is

programmed by the values selected for the timing

components R and C. Capacitor C is charged from the

5.0 V reference through resistor R to approximately 2.8

V and discharged to 1.2 V by an internal current sink.

osc

=

1.72

R C

=

1.72

8.2k 1nF

=209KEz

osc

is the input frequency of PWM controller and output

frequency provided by PWM controller is

]

csc

2

=

104.5KEz which used as the switching pulse of

MOSFET switch. The duty cycle of pulse is controlled by

the feedback control loop.

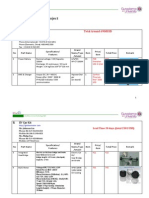

B. Transformer Design

The transformer design parameters were selected such that the

SMPS could provide outputs according to the specification

table given below

TABLE I

OUTPUT CURRENT AND VOLTAGES THROUGH DIFFERENT WINDINGS

Through

winding

1

Through

winding

2

Through

winding

3

Through

winding

4

Through

winding

5

Output

voltage 15V 8V 8V 12V 18V

Output

current 2A 0.5A 0.5A 0.1A 0.1A

So the total Output Power, P

out

which we get, is(I I)

40 w. This power supply is designed with efficiency () of

80 %. For deliver this much output power with this much

efficiency we require our Input Power to be

Input Powcr,P

n

=

0utput Powcr

Eicicncy(in %)/ 100

50w

The minimum Input Voltage, I

InmIn

to the transformer is

36Vdc and the maximum Voltage, I

Inmax

to transformer is

72Vdc. We choose maximum Duty cycle,

mux

to be 0.47 and

our sampling frequency, F

s

as calculated earlier was 104.5

KHz.

R2

33R R1206

C28

100NF

R1

3K9

D4

1N4007

C2

4N7 1KV

C37

1nF/1KV

+ C4

100uF/100V C12

4N7 1KV

D5

BYV27/200V

VDC+

VDC-

C19 10nF

C33

1nF

R12

100K

N2

SG3845

COMP

1

FB

2

CS

3

OSC

4

G

N

D

5

OUT

6

V

C

C

7

VREF

8

C5

1nF

R3

R4 R6

D7

15v

R5

TX1D

7

8

R10

5R6

C35

1nF

U2

VIN

2

VOUT

1

G

N

D

5

VIN

3

VIN

6

VIN

7

D8

TX1A

1

2

N5

TL431

2

3

1

R23

1R

C36

R25

1R

R24

1R

+15V

N3

1

2

4

3

C21

R11

4K7

R15

4K7

R26

33K

C27

100NF

R14

15K

9

1

0

R27

3K3

L3B1

D6 15v

R13

33R

R19

47K

C1

4N7 1KV

+

C14 100uF/35V

C41

10UF

Q1

I RF530

2

1

3

R17

47R

C20 100N

L5

C39

0.1uF

D12

D11

C22

1NF

C40

0.1uF

R28

10K

C38

0.1uF

-15V

+3V3

C29

100nF

R18

C32

100nF

U1

TSP73733

G

N

D

3

EN

5

IN

1

OUT

2

G

N

D

6

FB

4

C34

100nF

5

6

C10

0.1uF

C11

0.1uF

+ C9

330UF/35V

R7

10K

L2 +15V D3

C7

0.1uF

+

C6

100uF

C23

0.1uF

D10

BYV27/200V

C24

0.1uF

D9

1N4007 L4

N4

7805

2

GND

VIN

1 3

VOUT

C31

0.1uF

+ C25

100uF

R21

10K

+5V

+ C26

100uF

C43

10uf U3

MC79L05AC

VIN

2

VOUT

1

G

N

D

5

VIN

3

VIN

6

VIN

7

-5V

D13

1N4007

C42

10uf

TX1B

3

4

C16

0.1uF

D1

BYV27/200V

C13

0.1uF

D2

1N4007

R22

10K

L1

N1

7805

2

GND

VIN

1 3

VOUT

C18

0.1uF

+ C15

100uF

R8

10K

ISO+5V

ISOGND

+C17

100uF

C8

1N

R9

100K

1

1

1

2

R20

1K

C30

1NF

L3

1

4

2

3

R16

18K

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10-Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4543

From all these parameters the Primary winding Inductance can

be found using formula

I

p

=

(I

nmux

mux

)

2

p

2 P

out

F

s

which gives I

p

=217 E.

Design transformer is a course of repeating calculation. For

cutting down the works of design, Power Integrations Inc.

offers a set of Excel table to design the transformer [7]. So

according to that Excel table we found our secondary winding

turns.

C. Current Sensing Feedback Loop

The SMPS is made such that maximumload is on +15V

supply so we have used that section to provide feedback to the

PWM controller. The +15V supply is connected to the input

of TL431 which is three-terminal adjustable shunt regulator,

whose output voltage can be set to any value between V

ref

(approximately 2.5 V) and 36 V according to the input

supplied. We have used a voltage divider such that the input to

TL431 is 2.5V when our supply gives +15V. At this voltage

the TL431 is fully short and the optocoupler drives very high

current due to which feedback to the UC3845s FB pin is very

high which will cause the output PWM to switch off and the

MOSFET will not get triggered and no EMF will be induced

in the primary winding. When the +15V falls below 15V then

the input to TL431 will fall below 2.5 V and it will get fully

shorted but will have some resistance due to which small

amount of current will flow through optocoupler and feedback

to the PWM controller will be small and it will generate

output pulse of high duty cycle to the MOSFET. Similarly

when the +15V has supply greater than 15V the PWM will

remain switch off and our MOSFET will remains off.

D. Protection

1) Current Protection UC3845 has an internal current

comparator which has a reference of 1V. Whenever

input to the CS pin of UC3845 which is other input of

CS comparator gets beyond a limit of 1V the output of

the IC automatically gets switched off. So we have fed

back the CS pin fromthe MOSFET source through a

voltage divider such that the input to the CS pin is less

than 1V. If the output supply at secondary sides get

shorted than the MOSFET will drive very large amount

of current due to which voltage at the CS pin will get

above 1V and the UC3845 will stop generating PWM

pulses and our SMPS will get switch off and our circuit

will remain protected.

2) Snubbers - There are two basic ways to solve the

problem of a semiconductor device that is stressed

beyond its rating. Either the device can be replaced

with a higher rated device to meet the stress level, or a

snubber circuit can be added to reduce the stress to a

safe level. Both options are trade-offs between cost,

availability of the higher rated device, complexity,

component count and the cost of using a snubber

circuit. A snubber circuit is typically used to limit the

rate of rise of voltage (V/t), the voltage applied

across the device during turn-off, the rate of rise of

current (I/t) and the current through the device

during turn-on. We have used snubber protection for

our MOSFET because when the MOSFET gets

switched ON, it gets a very high peck voltage which

gets stabilized after some time. To save our MOSFET

fromthis voltage peak we have used a snubber circuit

in parallel to MOSFET so that the snubber suppresses

the peak and our MOSFET remains protected.

E. Selection of other Components used

The MOSFET that is being used as a switch in this SMPS

design is IRF530. This is an N-Channel enhancement mode

silicon gate power field effect transistor. This power

MOSFET is designed for applications such as switching

regulators, switching converters, motor drivers, relay drivers,

and drivers for high power bipolar switching transistors

requiring high speed and low gate drive power. This MOSFET

can be operated directly fromICs.

Following ICs have been used to provide different regulated

voltages

1) IC7805- This is a positive Voltage regulator which

provides an output voltage of +5V when its input

ranges from+7 V to +15 V.

2) IC7809- This is a negative Voltage regulator which

provides an output voltage of -5V when its input

ranges from-7V to -15 V.

3) IC7915- This is a negative Voltage regulator which

provides an output voltage of -15V when its input

ranges from-17.5V to -30 V.

4) TSP7373- The TPS737xx family of linear low-

dropout (LDO) voltage regulators which uses an

NMOS pass element in a voltage-follower

configuration to provide an output voltage 0f +3.3 V

when its input voltage ranges between 2.2 to 5.5V.

V. RESULTS

This systemdesigned in this paper is very efficient, reliable,

easy to implement, low cost and generate maximumnumber

of multiple constant outputs that are required for any telecom

embedded system. This SMPS designed in this paper is so

reliable that it can be used in telecom industry for their

embedded products. The various waveforms at different

points in the systemare as shown below. The waveform in fig

7(B) shows the output oscillations produced by the PWM

Controller which has frequency of 104.5 KHz as described in

Section IV (A). The fig 7(B) shows the MOSFET drain output.

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10-Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4544

Fig.7 PWM Controller and MOSFET output

Fig.8 Hardware Design

Figure 8 shows the hardware implementation of multiple

output SMPS. The next waveforms shown here in, Fig. 9, Fig.

10, Fig. 11, Fig. 12 and Fig 13 are of different output voltages.

The different voltage levels obtained can be seen clearly from

the respective figures shown below.

Fig.9 Output Voltage (Isolated +5V)

Fig.10 Output Voltage (+15V)

Fig.11 Output Voltage (+5V)

Fig.12 Output Voltage (+3.3V)

International Journal of Engineering Trends and Technology (IJETT) Volume 4 Issue 10-Oct 2013

ISSN: 2231-5381 http://www.ijettjournal.org Page 4545

Fig.13 Output Voltage (+5V)

REFERENCES

[1] Muhammad H. Rashid,Power Electronics Handbook, Second Edition

Devices, Circuits and Applications, Academic Press.

[2] AbrahamI. Pressman, Switching Power Supply Design, McGraw-

Hill.

[3] Babak Abdi, J afar Milimonfared, Ahmad Mahin Fallah,A High-

Performance 1.3 KW SMPS with Single Switch Forward Topology,

9th International Multitopic Conference, IEEE INMIC 2005, pg. 1 5.

[4] Vishnu P.Nambiar, Azli Yahya and Thayala R. Selvaduray, SPICE

Modelling of a Valley Switching Flyback Power Supply Controller for

Improved Efficiency in Low Cost Devices, Circuits and Systems

(ICCAS), 2012 IEEE International Conference, pg. 10-14

[5] Nasir Coruh, Satilmis Urgun, Tarik Erfidan, Design and

Implementation of Flyback Converters, Industrial Electronics and

Applications (ICIEA), 5th IEEE Conference, 2010, pg. 1189 1193.

[6] Pressman A.I., "Switching Power Supply Design", Second Ed.

McGraw-Hill, 1998, pp. 105-140.

[7] Yang Li, Chen Ying, Xiao Qianhua, A Small Power Switching Mode

Power Supply Based on TOP Switch, 2009 International J oint

Conference on Artificial Intelligence, pg. 298-300.

Potrebbero piacerti anche

- Design of A Power Converter Based On UC3842 For Blade Electric VehicleDocumento6 pagineDesign of A Power Converter Based On UC3842 For Blade Electric VehicleHossam SobhyNessuna valutazione finora

- AN1114 - Switch Mode Power Supply (SMPS) Topologies (Part I) - MicrochipDocumento48 pagineAN1114 - Switch Mode Power Supply (SMPS) Topologies (Part I) - MicrochipbmmostefaNessuna valutazione finora

- A Two-Phase Interleaved Power Factor Correction Boost Converter With A Variation-Tolerant Phase Shifting TechniqueDocumento56 pagineA Two-Phase Interleaved Power Factor Correction Boost Converter With A Variation-Tolerant Phase Shifting TechniqueVineetKumarNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Uc3842 Provides Low-Cost Current-Mode Control: Application NoteDocumento16 pagineUc3842 Provides Low-Cost Current-Mode Control: Application NoteLeonardo Ortiz100% (1)

- UC3845 Technical ExplanationDocumento15 pagineUC3845 Technical ExplanationankurmalviyaNessuna valutazione finora

- Unit 1: 18Cs206 Basic of Electrical and Electronics EngineeringDocumento21 pagineUnit 1: 18Cs206 Basic of Electrical and Electronics EngineeringAJAY SNessuna valutazione finora

- Tech Doc RFDocumento9 pagineTech Doc RFwrite2arshad_mNessuna valutazione finora

- EC6401 Electronics Circuits II - Notes - AnnaunivupdatesDocumento96 pagineEC6401 Electronics Circuits II - Notes - Annaunivupdatesmanimangai100% (2)

- Switch Mode Power Supply Topologies Compared - Wurth Electronics MidcomDocumento4 pagineSwitch Mode Power Supply Topologies Compared - Wurth Electronics Midcommayank shuklaNessuna valutazione finora

- Digital Phase Selector: A Mini-Project Report Submitted in Partial Fulfillment Requirements For The Award ofDocumento53 pagineDigital Phase Selector: A Mini-Project Report Submitted in Partial Fulfillment Requirements For The Award ofdondbNessuna valutazione finora

- Bob Blue2 Ring TesterDocumento4 pagineBob Blue2 Ring Testerbybu74Nessuna valutazione finora

- Regulated Power Supply1Documento4 pagineRegulated Power Supply1hamed razaNessuna valutazione finora

- Optocoupler Solutions Guide PDFDocumento24 pagineOptocoupler Solutions Guide PDFBen Salah IssamNessuna valutazione finora

- Ultra-Low Power Phase-Locked LoopDocumento4 pagineUltra-Low Power Phase-Locked Loophawking1122Nessuna valutazione finora

- Regulated Power SupplyDocumento12 pagineRegulated Power SupplySachie1912Nessuna valutazione finora

- Power SupplyDocumento9 paginePower SupplyMuhammed HuzaifaNessuna valutazione finora

- Power Supply ReviewDocumento4 paginePower Supply Reviewramesh ranjitNessuna valutazione finora

- The Art of SuccessDocumento50 pagineThe Art of SuccessYasin BakarNessuna valutazione finora

- Optocoupler Selection GuideDocumento28 pagineOptocoupler Selection GuideAnonymous 0CnvpxSNessuna valutazione finora

- Digital Control of Switching Power SupplyDocumento11 pagineDigital Control of Switching Power Supplyilluminatissm100% (1)

- Electronic ProjectsDocumento1 paginaElectronic ProjectsSanthosh SanNessuna valutazione finora

- Safety-enhanced-high-step-up-DC-DC-converter-for-ac-photovoltaic-module-applications Chapter 2 DC-DC Converters 12 PageDocumento16 pagineSafety-enhanced-high-step-up-DC-DC-converter-for-ac-photovoltaic-module-applications Chapter 2 DC-DC Converters 12 PageVenkatesh ChintalaNessuna valutazione finora

- Report On Power SupplyDocumento16 pagineReport On Power SupplyKshitij GuptaNessuna valutazione finora

- Capacitor ESR, Dissipation Factor, Loss Tangent and QDocumento2 pagineCapacitor ESR, Dissipation Factor, Loss Tangent and QIrfan UllahNessuna valutazione finora

- Advanced Impedance MatchingDocumento31 pagineAdvanced Impedance MatchingkivetiNessuna valutazione finora

- Doc-A.9-Driver Card For Single Phase Inverter Using Skhi22br PDFDocumento66 pagineDoc-A.9-Driver Card For Single Phase Inverter Using Skhi22br PDFsivananda11Nessuna valutazione finora

- AdhocDocumento17 pagineAdhocSripriya GunaNessuna valutazione finora

- 12-RF Electronics Kikkert Ch9 MatchingPowerAmplifiersDocumento20 pagine12-RF Electronics Kikkert Ch9 MatchingPowerAmplifiersThanhha NguyenNessuna valutazione finora

- Digitally Controlled Oscillator ReportDocumento18 pagineDigitally Controlled Oscillator ReportVinidhra ShivakumarNessuna valutazione finora

- Semiconductor Device and Physics ApplicationDocumento336 pagineSemiconductor Device and Physics ApplicationNguyenPhucTruong100% (1)

- Dual Adjustable Power Supply Circuit LM317 LM387Documento4 pagineDual Adjustable Power Supply Circuit LM317 LM387andree w100% (1)

- 02A Lesson Proper For Week 7Documento9 pagine02A Lesson Proper For Week 7Maxela CastroNessuna valutazione finora

- Antenna Matching Within An EnclosureDocumento5 pagineAntenna Matching Within An EnclosureNitin PatelNessuna valutazione finora

- DC DC Book of KnowledgeDocumento287 pagineDC DC Book of KnowledgeJose Simon Bolivar MoranNessuna valutazione finora

- Power Topologies HandbookDocumento199 paginePower Topologies HandbookCarlos OrtegaNessuna valutazione finora

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsDa EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNessuna valutazione finora

- Switch Mode Power Supply and Switching RegulatorsDocumento13 pagineSwitch Mode Power Supply and Switching Regulatorsyuj oNessuna valutazione finora

- Free Report: Brought To You by Jestine YongDocumento9 pagineFree Report: Brought To You by Jestine YongrajuNessuna valutazione finora

- Class-D Power AmplifierDocumento30 pagineClass-D Power AmplifierSidney O. EbotNessuna valutazione finora

- Triacs and DiacsDocumento4 pagineTriacs and Diacsssami670Nessuna valutazione finora

- S Mps InterviewDocumento16 pagineS Mps InterviewStrati YovchevNessuna valutazione finora

- Project Status Review Semester: 7 EE (Group No: 2) Project I (2170001)Documento51 pagineProject Status Review Semester: 7 EE (Group No: 2) Project I (2170001)UmangNessuna valutazione finora

- UC3842 Inside SchematicsDocumento17 pagineUC3842 Inside Schematicsp.c100% (1)

- High-Speed Design TechniquesDocumento28 pagineHigh-Speed Design TechniquesHemantkumarNessuna valutazione finora

- DC Power SupplyDocumento4 pagineDC Power SupplySohaib Ahmed100% (1)

- Troubleshooting Linear Power Supply Was Quite EasyDocumento2 pagineTroubleshooting Linear Power Supply Was Quite EasyNAYEEMNessuna valutazione finora

- EE2203-Electronic Device and Circuits Question BankDocumento11 pagineEE2203-Electronic Device and Circuits Question BankAnbarasan Annamalai100% (1)

- DSP Based Real Time Implementation of AC-DC-AC Converter Using SPWM TechniqueDocumento18 pagineDSP Based Real Time Implementation of AC-DC-AC Converter Using SPWM Techniquebalamurugan041992Nessuna valutazione finora

- Multilevel Inverters: Introduction and Emergent TopologiesDa EverandMultilevel Inverters: Introduction and Emergent TopologiesNessuna valutazione finora

- DSPDocumento57 pagineDSPhamidr_karamiNessuna valutazione finora

- Philips 40pfl3505df7 Chassis Pl10 5Documento87 paginePhilips 40pfl3505df7 Chassis Pl10 5latino52Nessuna valutazione finora

- Power Supply Unit DesignDocumento37 paginePower Supply Unit DesignfamtaluNessuna valutazione finora

- TTL Logic FamilyDocumento32 pagineTTL Logic FamilyRamesh KumarNessuna valutazione finora

- Embedde, D SystemsDocumento91 pagineEmbedde, D SystemsVijay PreethamNessuna valutazione finora

- Mastering Electronics DesignDocumento14 pagineMastering Electronics DesignArunabh BhattacharyaNessuna valutazione finora

- Schematic DiagramDocumento12 pagineSchematic Diagramalfredo_izquierdo_12Nessuna valutazione finora

- Solar-Powered Battery Charging With Highly Efficient Buck ConverterDocumento20 pagineSolar-Powered Battery Charging With Highly Efficient Buck ConverterSusanNessuna valutazione finora

- Fabrication of High Speed Indication and Automatic Pneumatic Braking SystemDocumento7 pagineFabrication of High Speed Indication and Automatic Pneumatic Braking Systemseventhsensegroup0% (1)

- Ijett V5N1P103Documento4 pagineIjett V5N1P103Yosy NanaNessuna valutazione finora

- Design, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)Documento7 pagineDesign, Development and Performance Evaluation of Solar Dryer With Mirror Booster For Red Chilli (Capsicum Annum)seventhsensegroupNessuna valutazione finora

- Implementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationDocumento6 pagineImplementation of Single Stage Three Level Power Factor Correction AC-DC Converter With Phase Shift ModulationseventhsensegroupNessuna valutazione finora

- FPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorDocumento4 pagineFPGA Based Design and Implementation of Image Edge Detection Using Xilinx System GeneratorseventhsensegroupNessuna valutazione finora

- Non-Linear Static Analysis of Multi-Storied BuildingDocumento5 pagineNon-Linear Static Analysis of Multi-Storied Buildingseventhsensegroup100% (1)

- An Efficient and Empirical Model of Distributed ClusteringDocumento5 pagineAn Efficient and Empirical Model of Distributed ClusteringseventhsensegroupNessuna valutazione finora

- Ijett V4i10p158Documento6 pagineIjett V4i10p158pradeepjoshi007Nessuna valutazione finora

- Experimental Analysis of Tobacco Seed Oil Blends With Diesel in Single Cylinder Ci-EngineDocumento5 pagineExperimental Analysis of Tobacco Seed Oil Blends With Diesel in Single Cylinder Ci-EngineseventhsensegroupNessuna valutazione finora

- Analysis of The Fixed Window Functions in The Fractional Fourier DomainDocumento7 pagineAnalysis of The Fixed Window Functions in The Fractional Fourier DomainseventhsensegroupNessuna valutazione finora

- DC To DC Converter 12V To + - 40V Using LM3524 - EleccircuitDocumento8 pagineDC To DC Converter 12V To + - 40V Using LM3524 - EleccircuitIonut Alexandru AneiNessuna valutazione finora

- IRF7809A/IRF7811A IRF7809A/IRF7811A: Provisional DatasheetDocumento4 pagineIRF7809A/IRF7811A IRF7809A/IRF7811A: Provisional DatasheetZak zsNessuna valutazione finora

- TPK Isolated 2W DC/DC ConvertersDocumento3 pagineTPK Isolated 2W DC/DC ConverterstoppowerNessuna valutazione finora

- Small-Signal MATLAB/Simulink Model of DC-DC Buck Converter Using State-Space Averaging MethodDocumento9 pagineSmall-Signal MATLAB/Simulink Model of DC-DC Buck Converter Using State-Space Averaging MethodArambya Ankit KallurayaNessuna valutazione finora

- Power Management Ic: Package: 16-Bump WLCSP, 4x4 Array, 1.73mmx1.73mmDocumento12 paginePower Management Ic: Package: 16-Bump WLCSP, 4x4 Array, 1.73mmx1.73mmSebastian IgnacioNessuna valutazione finora

- A Control Methodology of Three Phase Grid Connected PV SystemDocumento8 pagineA Control Methodology of Three Phase Grid Connected PV SystemBojan BankovicNessuna valutazione finora

- Power Electronics IiscDocumento1 paginaPower Electronics IiscVineel PanakalaNessuna valutazione finora

- A Novel Oil-Immersed Medium Frequency Transformer For Offshore HVDC Wind FarmsDocumento11 pagineA Novel Oil-Immersed Medium Frequency Transformer For Offshore HVDC Wind FarmsCarlynMNessuna valutazione finora

- L3+Hash Board Repair Guide ManualDocumento11 pagineL3+Hash Board Repair Guide ManualdadanetnetNessuna valutazione finora

- The Implementation of Photovoltaic System and DC-DC Converter For The Production Process of Hydrogen Gas Through ElectrolysisDocumento8 pagineThe Implementation of Photovoltaic System and DC-DC Converter For The Production Process of Hydrogen Gas Through ElectrolysisInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- KPIT Technologies Limited Information Memorandum April 12 2019Documento186 pagineKPIT Technologies Limited Information Memorandum April 12 2019Vishwas ChaturvediNessuna valutazione finora

- AN5004Documento5 pagineAN5004rdc02271Nessuna valutazione finora

- Nondissipative Clamping Benefits DC-DC ConvertersDocumento5 pagineNondissipative Clamping Benefits DC-DC ConvertersMateusz LiszczykNessuna valutazione finora

- An Improved State Space Average Model of Buck DC-DC Converter With All of TheDocumento15 pagineAn Improved State Space Average Model of Buck DC-DC Converter With All of TheAminaNessuna valutazione finora

- Infineon Selection-Guide+2011 Low ResDocumento165 pagineInfineon Selection-Guide+2011 Low ResJJJohannesNessuna valutazione finora

- Ilicore: 4-Ch Drive +power Controller For Portable CD D5901Documento16 pagineIlicore: 4-Ch Drive +power Controller For Portable CD D5901vetchboyNessuna valutazione finora

- Adum6400 6401 6402 6403 6404Documento28 pagineAdum6400 6401 6402 6403 6404mar_barudjNessuna valutazione finora

- UGHEV Parts Version 1.0 Price ListDocumento10 pagineUGHEV Parts Version 1.0 Price ListMamah NadineNessuna valutazione finora

- Lineage Infinity D Power SupplyDocumento20 pagineLineage Infinity D Power Supplyfultontech100% (1)

- Doubly Fed Electrical MachinesDocumento282 pagineDoubly Fed Electrical MachinesjalilemadiNessuna valutazione finora

- A Review On TopologiesDocumento6 pagineA Review On Topologiesirfan_nitNessuna valutazione finora

- Liebert Gxt4 230V, 5000-10,000VA: User ManualDocumento56 pagineLiebert Gxt4 230V, 5000-10,000VA: User ManualEmerson Müller Juarez AvilaNessuna valutazione finora

- DC-DC ConverterDocumento7 pagineDC-DC Converterraza239Nessuna valutazione finora

- Compendium2020 PDFDocumento69 pagineCompendium2020 PDFronyjohnson100% (1)

- Optimization Design of Planar Transformer in DC-DC ConverterDocumento6 pagineOptimization Design of Planar Transformer in DC-DC Converterигорь сидоренкоNessuna valutazione finora

- Power Management Guide TIDocumento121 paginePower Management Guide TINaveen ReddyNessuna valutazione finora

- Analysis and Implementation of A Bidirectional Converter With High Conversion RatioDocumento6 pagineAnalysis and Implementation of A Bidirectional Converter With High Conversion RatiosamuraiNessuna valutazione finora

- Submodule Configuration of HVDC-DC Auto Transformer Considering DC FaultDocumento24 pagineSubmodule Configuration of HVDC-DC Auto Transformer Considering DC FaultratheeshkumardNessuna valutazione finora

- TH D7 English PDFDocumento112 pagineTH D7 English PDFJuan TorresNessuna valutazione finora