Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ball Valve Testing Procedure

Caricato da

Vipul PanchalDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ball Valve Testing Procedure

Caricato da

Vipul PanchalCopyright:

Formati disponibili

Test

Procedure

for

Floating

ball valves

VTP-01

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 2 of 7

Table of Contents

Sl.No Description Page No

1.0 Scope 01

2.0 Relevant Standard 01

3.0 Test Requirements 01

4.0 Test Fluid 05

5.0 Test Gauges 05

6.0 Test Certification 06

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 3 of 7

1.0 SCOPE

The scope of this document is to define the factory test requirements for floating ball

valves. Standard testing comprises hydrostatic testing of the pressure envelope (body),

and seat tightness testing (hydrostatic and/or pneumatic) as applicable.

2.0 RELEVANT STANDARD

The requirements set out in this document are in accordance with the following national

and international standard:

01. API 598 - Valve Inspection and Testing

02. BS 6755 part1 - Testing of valves

03. BS EN12266 part1 - Industrial valves - Testing

The hydrostatic test pressures expressed in this standard comply with ASME B16.50 for

flanges and fittings and ASME B16.34 for valves and BS EN 17292 for Class 800 valves

3.0 TEST REQUIREMENTS

3.1 General

Surface treatments of pressure containing valve components to prevent

corrosion during storage prior to and during manufacture with a single primer

coat(Minimum 5 microns thickness) or Phosphate/Black oxide coating is

acceptable provided these preservations do not hide any porosity.

3.2 Test Apparatus

Valves which are flanged end connections must not be tested on equipment

which subjects the valve to externally applied loads which may affect the body

joint sealing performance. Single piece bodied valves may be clamped.

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 4 of 7

3.3 HYDROSTATIC SEAT TEST

a) PRINCIPLE :

The seat test assesses the sealing capability of the Valve Seat(s) in the direction

for which the valve is designed. Since ball valve is bi-directional, can be tested in

any direction.

b) PROCEDURE:

Using the clean dry cloth, wipe the Seat(s) clean (Not for Valves where Lubricant

or sealing Compound is the primary means of sealing), if accessible.

Clamp the Valve; fill the Valve including the Body / Cavity, with Test Fluid.

Move the obturator to the closed position, apply and maintain the test pressure

as per standard (Ref. Table 1, 3, 4.) on one side of the valve.

c) CRITERIA FOR ACCEPTANCE:

No visually detectable leakage for the duration of test time as given in the

appropriate valve product standard or test duration mentioned in (Table 2, 5.)

from the vent area.

d) Repeat the same procedure in other stream side and check for leakages.

3.4 HYDROSTATIC SHELL TEST

a) PRINCIPLE:

The shell test assesses the pressure containing capability of the Valve Shell.

b) PROCEDURE

Keep the assembled Valve in partially opened position and clamp the Valve on the Test

Rig.

Fill the cavity with the Test Liquid (Water), vent off the air from the cavity and blank off

the ends of the Valve.

Apply the Test Pressure as per Standards (Ref. Table 1.) and maintain the Test

Pressure to a period specified as per Standard (Ref. Table 2.).

In the mean time inspect the Valve Shell (Body) thoroughly.

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 5 of 7

c) CRITERIA FOR ACCEPTANCE:

Visually detectable leakage / wetting through the pressure Boundary Walls is not

acceptable. Stem Seal Leakage during the Shell test shall not be the cause for rejection,

provided that the stem seals when the internal test pressure is reduced to the maximum

permissible working pressure at 20 C.

3.5) PNEUMATIC SEAT TEST

a) PROCEDURE:

Clamp the Valve, and move the obturator to close position.

Apply the Pneumatic Test Pressure on the upstream side of the closed Valve and

maintain the pressure as per standard.

b) CRITERIA FOR ACCEPTANCE:

No visually detectable leakage for the duration of test time as given in the appropriate

valve product standard or test duration mentioned in Table 2.

Repeat the same procedure in other stream side and check for leakages.

4.0 Test Fluid

4.1 Test Liquid

Hydrostatic tests shall be carried out with water at ambient temperatures, within

the range of 41 F (5 C) and 122 F (50 C),unless the use of another liquid is agreed

between the purchaser and the manufacturer. If water is used, it will contain

water-soluble oil or rust inhibitor. Potable water used for pressure test of

austenitic stainless steel valves shall have chloride content less than 30ppm and

for carbon steel valves shall be less than 200ppm.

4.2 Cleaning

Austenitic and duplex stainless steel valves and valves made of 9% nickel alloy

shall be flushed with demineralized water (chloride content of 1ppm maximum)

immediately after the hydrostatic test.

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 6 of 7

4.3 Drying

After Hydrostatic testing, the valves should be blown through using dry

compressed air, followed by a visual inspection for dryness. If moisture is still

found, the above process shall be repeated until visually dry.

5.0 Test Gauges

Test bay gauges shall be calibrated at intervals not exceeding three months.

6.0 Test Certification

When specified by the purchaser, the manufacturer shall issue a BS EN10204

Type 3.1 test certificate confirming that the valves have been tested in

accordance with the requirements of this specification.

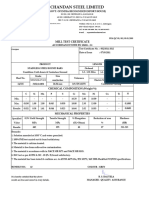

Table 1: Test Pressure

(ASME B 16.34 & BS EN 17292 for Class 800 valves)

Sl.No Valve Class Hydro Shell Hydro seat

Kg/cm2 psig Kg/cm2 psig

01 150 32 450 22 315

02 300 79 1125 58 815

04 800 105 1500 77 1100

03 600 157 2225 115 1630

05 900 236 3350 172 2445

06 1500 396 5575 287 4080

07 2500 649 9280 475 6790

VOLTECH TEJAS VALVES PVT LTD

VTP-01

Test Procedure for Floating Ball Valves

Prepared : KPR Checked : PMK Approved : IRS

Issue Date : Nov 12,2010 Revision No : 00 Revision Date :

VTVPL/VTP-01 Page 7 of 7

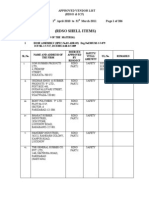

Table 2: Test Duration

Nominal Size (NPS) Minimum Test Duration (seconds)

Hydro shell test Back seat test Hydro seat

test

Air seat

test

< 2 15 15 15 15

2 6 60 60 60 60

8 12 120 60 120 120

>14 300 60 120 120

Note: The test duration is the period of inspection after the valve is fully prepared and is

under full pressure.

Potrebbero piacerti anche

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- QCP-12 Valve Leak Test Procedure PDFDocumento21 pagineQCP-12 Valve Leak Test Procedure PDFIbrahim100% (3)

- API 598 Testing Procedure-20130720-032647Documento2 pagineAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- ROCEDURE - INSPECTION & TEST ValvesDocumento10 pagineROCEDURE - INSPECTION & TEST Valvessabes26Nessuna valutazione finora

- Hydro Test ProceduresDocumento10 pagineHydro Test Proceduresazimr157100% (1)

- Safety Relief Valve Set Pressure and Seat Leakage TestDocumento30 pagineSafety Relief Valve Set Pressure and Seat Leakage TestAnonymous ffje1rpa100% (1)

- Butterfly Valve Info PDFDocumento14 pagineButterfly Valve Info PDFCS100% (1)

- Hydrostatic Shell TestDocumento5 pagineHydrostatic Shell TestsojeckNessuna valutazione finora

- Ball Valve Overhaul ProcedureDocumento7 pagineBall Valve Overhaul Procedurerocket789Nessuna valutazione finora

- Pneumatic TestDocumento3 paginePneumatic Testpuneethkumarr100% (1)

- Report On ValvesDocumento15 pagineReport On ValvesAnonymous b9J5NMNessuna valutazione finora

- Cryogenic Valve Test Procedure PDFDocumento9 pagineCryogenic Valve Test Procedure PDFazimr157100% (1)

- Ball Valve HandbookDocumento13 pagineBall Valve HandbookGanesh Yadav100% (6)

- Helium Leak TestDocumento8 pagineHelium Leak TestHiren Panchal50% (2)

- Piping Pneumatic Test ProcedureDocumento2 paginePiping Pneumatic Test Procedureruzla67% (3)

- Valve Testing ProcedureDocumento9 pagineValve Testing ProcedureFaiz Zainudin83% (6)

- Neles Seat Leakage SpecDocumento9 pagineNeles Seat Leakage SpecIkhsan Ly100% (1)

- BK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Documento45 pagineBK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Kev Tra100% (1)

- 3.06 A Pressure Testing of PipingDocumento22 pagine3.06 A Pressure Testing of PipingVivek PatilNessuna valutazione finora

- Testing StandardDocumento7 pagineTesting StandardDiego Fernando Pedroza UribeNessuna valutazione finora

- Api 598Documento2 pagineApi 598Nitin Aggarwal78% (9)

- Inspection of ValvesDocumento85 pagineInspection of ValvesAnand Kesarkar86% (7)

- Hydrotest & Pneumatic TestDocumento3 pagineHydrotest & Pneumatic TestjokishNessuna valutazione finora

- Ball Valve Seat Seal Injection SystemDocumento28 pagineBall Valve Seat Seal Injection SystemmudrijasmNessuna valutazione finora

- Testing of Pressure Relief ValveDocumento13 pagineTesting of Pressure Relief ValveVishal Abhiman MeshramNessuna valutazione finora

- Ball Valve: Zhejiangbeiercontrol Valveco.,LtdDocumento16 pagineBall Valve: Zhejiangbeiercontrol Valveco.,LtdSandipan GhoshNessuna valutazione finora

- Valve Leakage Rates Test STDDocumento5 pagineValve Leakage Rates Test STD윤병택Nessuna valutazione finora

- Inspect ValvesDocumento124 pagineInspect ValvesMohd Idris Mohiuddin100% (2)

- Unique Online Leak Repair TechniquesDocumento8 pagineUnique Online Leak Repair TechniquesMario Alfredo MunafóNessuna valutazione finora

- 14.a. Vendor Data Valve - Operation and Maintenance InstructionDocumento128 pagine14.a. Vendor Data Valve - Operation and Maintenance InstructionArieTonang100% (1)

- ValvesDocumento87 pagineValvesbaishakhi_b90100% (3)

- Api 598Documento13 pagineApi 598SurachaiAumongkolNessuna valutazione finora

- Thermal Relief Valve Instructions & Operations ManualDocumento12 pagineThermal Relief Valve Instructions & Operations ManualHiren Panchal100% (1)

- Api-598-En-12266-1 Seat LeakDocumento2 pagineApi-598-En-12266-1 Seat Leakelumalai24100% (10)

- General Control Valves TrainingDocumento37 pagineGeneral Control Valves TrainingMohd Amani100% (2)

- 3LPE Repair ProcedureDocumento3 pagine3LPE Repair Procedurelhanx2Nessuna valutazione finora

- API6D Ball Valves Inspection and Test ProceduresDocumento5 pagineAPI6D Ball Valves Inspection and Test ProceduresChi Cha100% (2)

- AB-522 Standard Pneumatic Test Procedure RequirementsDocumento16 pagineAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerNessuna valutazione finora

- To Commissioning Manual: Appendix No. 1Documento7 pagineTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNessuna valutazione finora

- Safety Relief Valves-Presentation by EILDocumento22 pagineSafety Relief Valves-Presentation by EILSuyog Gawande100% (1)

- Testing Procedure of Ball ValveDocumento2 pagineTesting Procedure of Ball Valverajesh100% (2)

- PRESENTATION Flanges Andd CouplingsDocumento39 paginePRESENTATION Flanges Andd Couplingsashishntpc1309100% (1)

- IENCSEPRO0007-2 - General Leak Test Procedure PDFDocumento9 pagineIENCSEPRO0007-2 - General Leak Test Procedure PDFCatalinNessuna valutazione finora

- Valve Testing ProcedureDocumento10 pagineValve Testing Proceduremoytabura96100% (5)

- Pressure Testing of Pressure VesselDocumento3 paginePressure Testing of Pressure VesselAriq FauzanNessuna valutazione finora

- Pneumatic Test - Write UpDocumento7 paginePneumatic Test - Write UpDilip0% (1)

- Double Piston and Single Piston Effect in Ball ValvesDocumento5 pagineDouble Piston and Single Piston Effect in Ball ValvesPipeline Engineer100% (6)

- Inspection and Test Plan For Line Pipe PDFDocumento4 pagineInspection and Test Plan For Line Pipe PDFsherviny100% (1)

- Perar Trunnion Ball ValvesDocumento54 paginePerar Trunnion Ball ValvesUday GokhaleNessuna valutazione finora

- Procedure Manual: Ball Valve Hydro TestDocumento5 pagineProcedure Manual: Ball Valve Hydro Testnima_h10Nessuna valutazione finora

- C22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test ProceduresDocumento8 pagineC22-Yb60-F-4765 - 0 Sa3-Ps2, Butterfly Valve, Test Proceduressartaj100% (1)

- Shop Inspection & Test procedure-GVK-1Documento7 pagineShop Inspection & Test procedure-GVK-1Sungil ChoiNessuna valutazione finora

- Procedure Manual: Cast Valve ProductionDocumento10 pagineProcedure Manual: Cast Valve ProductionParveen Kohli0% (1)

- 4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Documento8 pagine4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Randu WatangNessuna valutazione finora

- Valves Valve LeakageDocumento5 pagineValves Valve Leakagearson5646100% (1)

- Hydrotesting of VALVE AND REFURBISHMENT PROCEDUREDocumento16 pagineHydrotesting of VALVE AND REFURBISHMENT PROCEDUREISAACNessuna valutazione finora

- Boiler Hydrotest Procedure Boiler BDFB 350-1004Documento10 pagineBoiler Hydrotest Procedure Boiler BDFB 350-1004Gunung A E SinamnbelaNessuna valutazione finora

- Valve) - 2. End Fittings For ClosureDocumento10 pagineValve) - 2. End Fittings For ClosureNaveen Vel100% (1)

- Hydo Test ProcedureDocumento2 pagineHydo Test ProcedureAbdulMajidYousoffNessuna valutazione finora

- Spe 77 - 307Documento5 pagineSpe 77 - 307Dunamis Joe100% (1)

- Sample Test Cert. 07.09.2011 - 02Documento1 paginaSample Test Cert. 07.09.2011 - 02Vipul PanchalNessuna valutazione finora

- Sample Form For VisaDocumento2 pagineSample Form For VisaVipul Panchal100% (1)

- HAVI Takes Utmost Care While Producing A Product From Material Sourcing Till On-Site InstallationDocumento1 paginaHAVI Takes Utmost Care While Producing A Product From Material Sourcing Till On-Site InstallationVipul PanchalNessuna valutazione finora

- HAVI BrochureDocumento4 pagineHAVI BrochureVipul PanchalNessuna valutazione finora

- Gvba 8SW150 8N S6L CLDocumento1 paginaGvba 8SW150 8N S6L CLVipul PanchalNessuna valutazione finora

- Icf & Rdso Vendor ListDocumento206 pagineIcf & Rdso Vendor ListVipul PanchalNessuna valutazione finora

- Gvba 8N 16MGT S6L CLDocumento1 paginaGvba 8N 16MGT S6L CLVipul PanchalNessuna valutazione finora

- 02 Master List of Machine & EquipmentsDocumento1 pagina02 Master List of Machine & EquipmentsVipul Panchal50% (2)

- NCR-CC 001 12-13Documento1 paginaNCR-CC 001 12-13Vipul Panchal100% (1)

- Richard Dennis Sonterra Capital Vs Cba Nab Anz Macquarie Gov - Uscourts.nysd.461685.1.0-1Documento87 pagineRichard Dennis Sonterra Capital Vs Cba Nab Anz Macquarie Gov - Uscourts.nysd.461685.1.0-1Maverick MinitriesNessuna valutazione finora

- Nickel 200 201 PDFDocumento20 pagineNickel 200 201 PDFwdavid81Nessuna valutazione finora

- TTC 1000Documento2 pagineTTC 1000svismaelNessuna valutazione finora

- Chapter 04 - Motion and Force - DynamicsDocumento24 pagineChapter 04 - Motion and Force - DynamicsMohamad SyazwanNessuna valutazione finora

- December 2022 Issue: More Transparency, P S An R T e R o M, y C en Ar P P, y PDocumento24 pagineDecember 2022 Issue: More Transparency, P S An R T e R o M, y C en Ar P P, y Pwpp8284Nessuna valutazione finora

- Focus GroupDocumento20 pagineFocus GroupItzel H. ArmentaNessuna valutazione finora

- PA SystemDocumento4 paginePA SystemSnehal DambhareNessuna valutazione finora

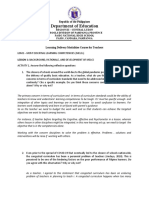

- Department of Education: Republic of The PhilippinesDocumento6 pagineDepartment of Education: Republic of The PhilippinesLalaine QuitoNessuna valutazione finora

- Republic V Mangotara DigestDocumento3 pagineRepublic V Mangotara DigestMickey Ortega100% (1)

- (Application Transfer Manual Volume: Be The CadreDocumento2 pagine(Application Transfer Manual Volume: Be The CadreVishnu MuralidharanNessuna valutazione finora

- Exponential Smoothing-Trend and SeasonalDocumento11 pagineExponential Smoothing-Trend and SeasonalsuritataNessuna valutazione finora

- Resume Of: Name: Kingshuk Saha Address: Mobile: E-MailDocumento2 pagineResume Of: Name: Kingshuk Saha Address: Mobile: E-MailKingshuk Saha PalasNessuna valutazione finora

- Canon JX 500 - 200 - Service ManualDocumento154 pagineCanon JX 500 - 200 - Service ManualFritz BukowskyNessuna valutazione finora

- EASA CS-22 Certification of SailplanesDocumento120 pagineEASA CS-22 Certification of SailplanessnorrigNessuna valutazione finora

- Small Scale IndustriesDocumento6 pagineSmall Scale IndustriesMangesh KadamNessuna valutazione finora

- Hex 33 X 80Documento1 paginaHex 33 X 80PurchaseNessuna valutazione finora

- Nanoimprint Lithography: Presented by Group 7Documento27 pagineNanoimprint Lithography: Presented by Group 7Samia SafaNessuna valutazione finora

- 3 - 0 - D Copia403mfen 404mfen Smy113840 1Documento253 pagine3 - 0 - D Copia403mfen 404mfen Smy113840 1Serge MaciaNessuna valutazione finora

- Tcs IntroDocumento12 pagineTcs IntroRomi.Roy1820 MBANessuna valutazione finora

- AAR Safety Fact SheetDocumento2 pagineAAR Safety Fact Sheetrogelio mezaNessuna valutazione finora

- Determination of Iron in Water - SpectrophotometryDocumento4 pagineDetermination of Iron in Water - Spectrophotometryhanif ahmadNessuna valutazione finora

- Catalogue Colorants TextilesDocumento5 pagineCatalogue Colorants TextilesAs Des As BenedictionNessuna valutazione finora

- Chen Probable Cause Affidavit 050714Documento7 pagineChen Probable Cause Affidavit 050714USA TODAYNessuna valutazione finora

- Seinfelt - The CheesecakeDocumento31 pagineSeinfelt - The Cheesecakeseinfelt100% (2)

- Downloaded From Manuals Search EngineDocumento14 pagineDownloaded From Manuals Search EngineAl AlNessuna valutazione finora

- Mrr2 Why The Future Doesnt Need UsDocumento3 pagineMrr2 Why The Future Doesnt Need UsSunshine Glory EgoniaNessuna valutazione finora

- MSDS Potassium DichromateDocumento8 pagineMSDS Potassium DichromateAyu Lakshemini OkaNessuna valutazione finora

- English Paper 1 Mark Scheme: Cambridge Lower Secondary Sample Test For Use With Curriculum Published in September 2020Documento11 pagineEnglish Paper 1 Mark Scheme: Cambridge Lower Secondary Sample Test For Use With Curriculum Published in September 2020ABEER RATHINessuna valutazione finora

- Attention: 6R60/6R75/6R80 Installation GuideDocumento4 pagineAttention: 6R60/6R75/6R80 Installation GuideEdwinferNessuna valutazione finora

- Genie Awp SpecsDocumento4 pagineGenie Awp SpecsIngrid Janet GuardadoNessuna valutazione finora