Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Eng-Study On Utilization of Waste Pet Bottle Fiber-P.ganesh Prabhu

Caricato da

Impact JournalsTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Eng-Study On Utilization of Waste Pet Bottle Fiber-P.ganesh Prabhu

Caricato da

Impact JournalsCopyright:

Formati disponibili

Impact Factor(JCC): 1.5548 - This article can be downloaded from www.impactjournals.

us

IMPACT: International Journal of Research in

Engineering & Technology (IMPACT: IJRET)

ISSN(E): 2321-8843; ISSN(P): 2347-4599

Vol. 2, Issue 5, May 2014, 233-240

Impact Journals

STUDY ON UTILIZATION OF WASTE PET BOTTLE FIBER IN CONCRETE

P. GANESH PRABHU

1

, C. ARUN KUMAR

2

, R. PANDIYARAJ

3

, P. RAJESH

4

& L. SASI KUMAR

5

1

Assistant Professor, Department of Civil Engineering, Kamaraj College of Engineering and Technology,

Virudhunagar, Tamil Nadu, India

2,3,4,5

B.E Student, Department of Civil Engineering, Kamaraj College of Engineering and Technology,

Virudhunagar, Tamil Nadu, India

ABSTRACT

Waste plastic bottles are major reason of solid waste disposal. Polyethylene Terephthalate (PET) is usually used

for carbonated beverage and water bottles. The waste plastic bottles are difficult to biodegrade and involves processes

either to recycle or reuse. The construction industry is in require of finding cost effective materials for increasing the

strength of concrete structures. In this paper deals with the possibility of using the waste PET bottles as the different aspect

ratio of 17, 33, 50, size of fibre added in to the concrete with 0.5%, 1%, and 1.5% PET bottle fibres for fine aggregate were

produced and compared against control mix with no replacement. Cube specimens, cylinder specimens of 27 numbers each

were cast cured and tested for 3 day, 7 day and 28 days strength. Compression test, splitting tensile test and flexural

strength tests were done and the results were compared with control specimens.

Finally, optimum dosages of PET fiber volume fractions, such as 1% to attain maximum compressive strength and

maximum tensile strength were found for the mix.

KEYWORDS: Plastic Bottles, Polyethylene Terephthalate, Biodegrade, Fibre

INTRODUTION

Concrete is the most widely used construction material due to its high compressive strength, long service life, and low

cost etc. However, concrete has inbuilt disadvantages of low tensile strength and crack resistance also. To improve the

weaknesses of the material, number of studies on fiber reinforced concrete has been performed. The research result showed

that addition of fibers considerably improves the performance of concrete. The use of fiber reinforced concrete has

increased in the last decade. Poly Ethylene Terephthalate commonly abbreviated PET. It is thermoplastic polymer resin of

the polyester family and is used in synthetic fibers, PET is one of the most important and extensively used plastics in the world,

especially for manufacturing beverage container, food and other liquid containers PET bottles are also recycled as-is (re-used)

for various purposes PET bottles are filled with water and left in the sun to allow disinfection by ultraviolet radiation.

Most of PET bottles used for beverage container are thrown away after single usage and disposed PET bottles are

treated by landfill and burning, which is create serious environmental problems Waste is the one of the challenge to

dispose and manage. It has one of the major environmental, economical and social issues.

PET bottles in fiber form can be used to get better the mechanical properties of concrete. The compressive strength,

tensile strength and flexural strength behavior of concrete is discussed. The PET fibers addition in concrete is an

innovative material that can be promote in construction field.

234 P. Ganesh Prabhu, C. Arun Kumar, R. Pandiyaraj, P. Rajesh & L. Sasi Kumar

Index Copernicus Value: 3.0 - Articles can be sent to editor@impactjournals.us

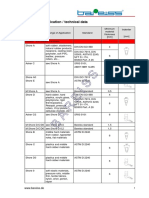

FIBER DIMENSION AND QUANTITY INFORMATION

Dimension Details

Table 1

S. No Aspect Ratio Dimension (mm)

1 17 50 x 3

2 33 100 x 3

3 50 150 x 3

Quantity Details

Table 2

S. No Dimension (mm) Quantity (%)

1 50 X 3 0.5 1 1.5

2 100 X 3 0.5 1 1.5

3 150 X 3 0.5 1 1.5

The percentage of fiber indicates quantity of fiber from the weight of cement.

CONCRETE MIX PROPORTIONING

Table 3

Contents Cement Fine Aggregate Coarse Aggregate W/c Ratio

Mix proportion per m

3

437.77 kg 650kg 1108.548kg 197 kg

Mix ratio 1 1.48 2.54 0.45

TESTING OF MATERIALS

Testing of Mortar Cube

Table 4(i)

S. No

Type of

Specimen

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Mortar Cube 7.58 13.11 43.88

Figure 1: Compressive Strength of Mortar

TESTING OF STANDARD CONCRETE

Table 4(ii)

S. No

Type of

Specimen

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Cube 16.43 21.16 26.0

2 Cylinder 2.86 3.47 3.56

Study on Utilization of Waste Pet Bottle Fiber in Concrete 235

Impact Factor(JCC): 1.5548 - This article can be downloaded from www.impactjournals.us

TESTING OF FIBER CONCRETE

Conditional Concrete for 50 X 3 mm Fibre

Table 5(i)

S. No

Type of

Specimen

Percentage of

Fibre Used

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Cube 0.5% 17.97 25.88 30.16

2 Cylinder 0.5% 2.72 2.85 10.37

Table 5(ii)

S. No

Type of

Specimen

Percentage of

Fibre Used

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Cube 1.0% 25.10 36.20 41.64

2 Cylinder 1.0% 11.70 11.76 11.90

Table 5(iii)

S. No

Type of

Specimen

Percentage of

Fibre Used

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Cube 1.5% 25.16 33.87 36.70

2 Cylinder 1.5% 9.43 9.96 11.12

Conditional Concrete for 100 X 3 mm Fibre

Table 5(iv)

S. No

Type of

Specimen

Percentage of

Fibre Used

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Cube 0.5% 18.80 20.20 31.84

2 Cylinder 0.5% 5.91 7.69 11.0

Table 5(v)

S. No

Type of

Specimen

Percentage of

Fibre Used

3rd Day Strength

(N/mm2)

7th Day Strength

(N/mm2)

28th Day Strength

(N/mm2)

1 Cube 1.0% 25.19 35.06 41.64

2 Cylinder 1.0% 9.42 11.08 13.25

Table 5(vi)

S. No

Type of

Specimen

Percentage of

Fibre Used

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Cube 1.5% 25.16 34.07 38.88

2 Cylinder 1.5% 9.11 10.86 11.20

Conditional Concrete for 150 X 3 mm Fibre

Table 5(vii)

S. No

Type of

Specimen

Percentage of

Fibre Used

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Cube 0.5% 23.40 34.52 35.58

2 Cylinder 0.5% 10.42 10.53 11.04

Table 5(viii)

S. No

Type of

Specimen

Percentage of

Fibre Used

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Cube 1.0% 24.32 33.56 36.64

2 Cylinder 1.0% 9.30 10.11 10.81

236 P. Ganesh Prabhu, C. Arun Kumar, R. Pandiyaraj, P. Rajesh & L. Sasi Kumar

Index Copernicus Value: 3.0 - Articles can be sent to editor@impactjournals.us

Table 5(ix)

S. No

Type of

Specimen

Percentage of

Fibre Used

3

rd

Day Strength

(N/mm

2

)

7

th

Day Strength

(N/mm

2

)

28

th

Day Strength

(N/mm

2

)

1 Cube 1.5% 23.43 34.15 37.94

2 Cylinder 1.5% 9.1 9.87 10.82

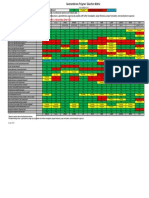

COMPARISION TABLES

Compressive Strength for 0.5% Fiber Used Concrete

Table 6(1.1)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

3 16.43 17.97 18.80 23.40

Table 6(1.2)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

7 21.16 25.88 20.20 34.52

Table 6(1.3)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

28 26.0 30.16 31.84 35.58

Compressive Strength for 1% Fiber Used Concrete

Table 6(2.1)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

3 16.43 25.10 25.19 24.32

Table 6(2.2)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

7 21.16 36.20 35.06 33.56

Table 6(2.3)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

28 26.0 41.64 41.64 36.64

Compressive Strength for 1.5% Fiber Used Concrete

Table 6(3.1)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

3 16.43 25.16 25.16 23.43

Table 6(3.2)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

7 21.16 33.87 34.07 34.15

Study on Utilization of Waste Pet Bottle Fiber in Concrete 237

Impact Factor(JCC): 1.5548 - This article can be downloaded from www.impactjournals.us

Table 6(3.3)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

28 26.0 36.70 38.88 37.94

Figure 2: Compressive Strength in 3 Days

Figure 3: Compressive Strength in 7 Days

Figure 4: Compressive Strength in 28 Days

Tensile Strength for 0.5% Fiber Used Concrete

Table 6(4.1)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

3 2.86 2.72 5.91 10.42

Table 6(4.2)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

7 3.47 2.85 7.69 10.53

238 P. Ganesh Prabhu, C. Arun Kumar, R. Pandiyaraj, P. Rajesh & L. Sasi Kumar

Index Copernicus Value: 3.0 - Articles can be sent to editor@impactjournals.us

Table 6(4.3)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

28 3.56 10.37 11.0 11.04

Tensile Strength for 1% Fiber Used Concrete

Table 6(5.1)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

3 2.86 11.70 9.42 9.30

Table 6(5.2)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

7 3.47 11.76 11.08 10.11

Table 6(5.3)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

28 3.56 11.90 13.25 10.81

Tensile Strength for 1.5% Fiber Used Concrete

Table 6(6.1)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

3 2.86 9.43 9.11 9.1

Table 6(6.2)

Testing

Day

Standard

Concrete

Fiber Concrete(Aspect Ratio)

50 * 3 100*3 150*3

7 3.47 9.96 10.86 9.87

Table 6(6.3)

Testing

Day

Standard

Concrete

Fiber Concrete (Aspect Ratio)

50 * 3 100*3 150*3

28 3.56 11.12 11.20 10.82

Figure 5: Tensile Strength in 3 Days

Study on Utilization of Waste Pet Bottle Fiber in Concrete 239

Impact Factor(JCC): 1.5548 - This article can be downloaded from www.impactjournals.us

Figure 6: Tensile Strength in 7 Days

Figure 7: Tensile Strength in 28 Days

CONCLUSIONS

The maximum percentage increase in compressive strength, split tensile strength at 1% of fiber content were

0.5 %, 1% and 1.5 % for aspect ratio 17, 33 and 50aspect ratio 50 respectively over control concrete (0% fibers).

The significant improvements in strengths were observed with inclusion of plastic fibers in concrete.

The optimum strength was observed at 1% of fiber content for all type of strengths.

From this experimental investigation, the PET bottles would appear to be low-cost materials which would help to

resolve solid waste problems and preventing environment pollution.

It can be Identified form test results that development in strength was higher for aspect ratio 33.

PET fibers increased both ductility and energy absorption of the axially compressed concrete samples.

The highest ductility belonged to the specimens with PC=1.5%. However, the ductility and energy capacity

decreases as the fiber increases.

Indirect tensile strength test result demonstrate that inclusion of 0.5% PET fiber volume fraction enhanced tensile

strength a maximum value by 23%.

The empirical assumption that tensile strength of concrete is approximately one-tenth of compressive strength was

verified.

From this experimental project work about 30-35 % strength of concrete will be increased.

240 P. Ganesh Prabhu, C. Arun Kumar, R. Pandiyaraj, P. Rajesh & L. Sasi Kumar

Index Copernicus Value: 3.0 - Articles can be sent to editor@impactjournals.us

REFERENCES

1. G. Murali, C. M. VivekVardhan, R. Prabu, Z. MohammedSadaquath Ali Khan, T. Aarif Mohamed and T. Suresh

(2012) Experimental investigation on fibre reinforced concrete using waste materials, International Journal of

Engineering Research and Applications (IJERA) ISSN: 2248-9622 www.ijera.com Vol. 2, Issue 2,

Mar-Apr 2012, pp.278-283.

2. Youjiang Wang H. C. Wu and Vitor C. Li (2000), Concrete Reinforcement with Recycled Fibers, Journal of

Materials In Civil Engineering / November 2000.

3. R. Kandasamy and R. Murugesan(2011), Fibre Reinforced Concrete Using Domestic Waste Plastics as Fibres,

ARPN Journal of Engineering and Applied Sciences, Volume 6, No.3, ISSN 1819- 6608.

4. Malagavelli v. Rao P. N., (2010), "Effect of non bio Degradable waste in concrete slabs", International

Journal of Civil and Structural Engineering, 1, 3, 449-457.

5. Betioli A. M., Silva D. A., (2005). "Evaluation of Durability of PET Fibers under diverse Aggressive

Environments", 10DBMC International Conference on Durability of Building Materials and Components,

Lyon-France (2005).

6. Silva D. A., Betioli A. M., Gleize P. J. P., Roman Gomez L. A., Riberio J. L.D., (2005), "Degradation

recycled PET fibers in Portland cement-based materials" Cement and Concrete Research, 35: 1741-1746.

Potrebbero piacerti anche

- MIL DTL 27500 Cable DesignationsDocumento5 pagineMIL DTL 27500 Cable DesignationsTeboho RamakatsaNessuna valutazione finora

- 1.1 Background and Overview of Composites Understanding CompositesDocumento14 pagine1.1 Background and Overview of Composites Understanding CompositesSarabjot Azrot100% (1)

- Plastic WeldingDocumento40 paginePlastic Weldingsukhbir sarpanch78% (9)

- Plastic, PVC, PP Finishing Products (All Types) Data 2020Documento1.121 paginePlastic, PVC, PP Finishing Products (All Types) Data 2020vaibhavNessuna valutazione finora

- FIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanDocumento8 pagineFIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanIvan KotNessuna valutazione finora

- Study of Strength Property of Concrete Using Waste Plastics and Steel FiberDocumento3 pagineStudy of Strength Property of Concrete Using Waste Plastics and Steel FibertheijesNessuna valutazione finora

- International Journal of Chemtech Research: J. Shri Indhu, E. Prabakaran, K. Saranya, D. GokilaDocumento5 pagineInternational Journal of Chemtech Research: J. Shri Indhu, E. Prabakaran, K. Saranya, D. GokilaChegue BureNessuna valutazione finora

- Mohd Irwan Juki, Mazni Awang, Mohd Khairil Annas Mahamad, Koh Heng Boon, Norzila Othman, Aeslina Abdul Kadir, Muhammad Asyraf Roslan, FaisalDocumento4 pagineMohd Irwan Juki, Mazni Awang, Mohd Khairil Annas Mahamad, Koh Heng Boon, Norzila Othman, Aeslina Abdul Kadir, Muhammad Asyraf Roslan, FaisalmuhannedNessuna valutazione finora

- Compressive Strength of Concrete by Using Coconut Shell: Parag S. Kambli, Sandhya R. MathapatiDocumento7 pagineCompressive Strength of Concrete by Using Coconut Shell: Parag S. Kambli, Sandhya R. MathapatiIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- v1 CoveredDocumento19 paginev1 CoveredIbrahim Tuhin PICUNessuna valutazione finora

- Soil Stabilization Using Polypropylene Fiber MaterialsDocumento7 pagineSoil Stabilization Using Polypropylene Fiber Materialsiplogu100% (1)

- College of Engineering, PhaltanDocumento45 pagineCollege of Engineering, PhaltanU No MiNessuna valutazione finora

- Performance of Steel Fiber Reinforced Self Compacting ConcreteDocumento5 paginePerformance of Steel Fiber Reinforced Self Compacting ConcreteInternational Journal of computational Engineering research (IJCER)Nessuna valutazione finora

- Auce10082 11 PDFDocumento9 pagineAuce10082 11 PDFBabar AliNessuna valutazione finora

- Concrete Recycled Aggregate PDFDocumento7 pagineConcrete Recycled Aggregate PDFakshay cvNessuna valutazione finora

- J Korean Acad Conserv DentDocumento22 pagineJ Korean Acad Conserv Dentsweet_apple921587Nessuna valutazione finora

- 10.1201 9781003323020-147 ChapterpdfDocumento8 pagine10.1201 9781003323020-147 ChapterpdfFarjallah Al-AssãadNessuna valutazione finora

- Effect of Glass Fibres On Ordinary Portland Cement Concrete: Deshmukh S.H., Bhusari J. P, Zende A. MDocumento5 pagineEffect of Glass Fibres On Ordinary Portland Cement Concrete: Deshmukh S.H., Bhusari J. P, Zende A. Mkaadal12Nessuna valutazione finora

- Glass Waste in Concrete: Effect On Workability and Compressive StrengthDocumento9 pagineGlass Waste in Concrete: Effect On Workability and Compressive StrengthJenny ValderramaNessuna valutazione finora

- IJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchDocumento7 pagineIJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchInternational Journal of computational Engineering research (IJCER)Nessuna valutazione finora

- Experimental Study On The Hardened Properties of Concrete by Using Soft Drink Bottle Caps As Partial Replacement For Coarse AggregatesDocumento7 pagineExperimental Study On The Hardened Properties of Concrete by Using Soft Drink Bottle Caps As Partial Replacement For Coarse AggregatesSajjad AhmadNessuna valutazione finora

- USE OF PLASTIC IN A CONCRETE TO IMPROVE ITS PROPERTIES by Raghatate Atul M.Documento3 pagineUSE OF PLASTIC IN A CONCRETE TO IMPROVE ITS PROPERTIES by Raghatate Atul M.Ivan Kot100% (1)

- Wear Analysis of Rice Husk Shell Powder Reinforced Epoxy CompositeDocumento8 pagineWear Analysis of Rice Husk Shell Powder Reinforced Epoxy CompositeTJPRC PublicationsNessuna valutazione finora

- 9 I January 2021Documento7 pagine9 I January 2021IJRASETPublicationsNessuna valutazione finora

- WPFRC 7Documento13 pagineWPFRC 7Tesema LegeseNessuna valutazione finora

- DEVI, OLYVIA, EDI - Pengaruh Penambahan Serat Kawat Bendhrat Terhadap Kuat Tekan Dan Kuat Tarik BetonDocumento9 pagineDEVI, OLYVIA, EDI - Pengaruh Penambahan Serat Kawat Bendhrat Terhadap Kuat Tekan Dan Kuat Tarik BetonExcellenza Nafidzun AzzamNessuna valutazione finora

- Experimental Study On Self Curing Concrete Using Sodium LignosulphonateDocumento5 pagineExperimental Study On Self Curing Concrete Using Sodium LignosulphonateijeteeditorNessuna valutazione finora

- Glass Waste in Concrete Effect On Workability andDocumento10 pagineGlass Waste in Concrete Effect On Workability andimen.bourahlaNessuna valutazione finora

- Study On Strength and Durability Properties of Polypropylene and Carbon Fiber Reinforced Concrete CompositeDocumento6 pagineStudy On Strength and Durability Properties of Polypropylene and Carbon Fiber Reinforced Concrete CompositeIJRASETPublicationsNessuna valutazione finora

- (794-803) V10N8CT JournalDocumento10 pagine(794-803) V10N8CT JournalMudduKrishna shettyNessuna valutazione finora

- Study of Tensile Strength and Hardness Property For EpoxyDocumento10 pagineStudy of Tensile Strength and Hardness Property For EpoxychethanapraoNessuna valutazione finora

- An Overview On Characteristic Strength of Concrete by Using Plastic FibreDocumento6 pagineAn Overview On Characteristic Strength of Concrete by Using Plastic FibreIJRASETPublicationsNessuna valutazione finora

- of ProjectDocumento24 pagineof ProjectamarparimiNessuna valutazione finora

- Dry Self-Lubricating Composites: Shin Jen Shiao and Te Zei WangDocumento7 pagineDry Self-Lubricating Composites: Shin Jen Shiao and Te Zei WangAhda Dapong Rizqy MaulanaNessuna valutazione finora

- Effect of Recycled Aggregate With Glass Fiber On Concrete PropertiesDocumento22 pagineEffect of Recycled Aggregate With Glass Fiber On Concrete PropertiesSuresh KomurajuNessuna valutazione finora

- tmp4D96 TMPDocumento5 paginetmp4D96 TMPFrontiersNessuna valutazione finora

- Experimental Investigation On Reinforced Concrete With Plastic FiberDocumento6 pagineExperimental Investigation On Reinforced Concrete With Plastic FiberIJRASETPublicationsNessuna valutazione finora

- Archives of Civil Engineering) A Performance Study On Partial Replacement of Polymer Industries Waste (PIW) As Fine Aggregate in ConcreteDocumento12 pagineArchives of Civil Engineering) A Performance Study On Partial Replacement of Polymer Industries Waste (PIW) As Fine Aggregate in Concretemjrobust05Nessuna valutazione finora

- Partial Replacement of Coarse Aggregates by ExpandedDocumento4 paginePartial Replacement of Coarse Aggregates by ExpandedInternational Journal of Research in Engineering and TechnologyNessuna valutazione finora

- The Economics, Performance, and Sustainability of Internally Cured Concrete, Part 3Documento9 pagineThe Economics, Performance, and Sustainability of Internally Cured Concrete, Part 3masteriragaNessuna valutazione finora

- Ultra High Performance Fiber Reinforced Concrete-A ReviewDocumento6 pagineUltra High Performance Fiber Reinforced Concrete-A ReviewAhmed EsamNessuna valutazione finora

- Ijer 2014 306Documento5 pagineIjer 2014 306Innovative Research PublicationsNessuna valutazione finora

- Major Finl cd67Documento49 pagineMajor Finl cd67Onkar BhosaleNessuna valutazione finora

- Finite Element Analysis of IPN Reinforced Woven Fabric CompositeDocumento6 pagineFinite Element Analysis of IPN Reinforced Woven Fabric CompositeCody LeeNessuna valutazione finora

- Kuat Tekan Dan Lentur Paving Blok BerporiDocumento8 pagineKuat Tekan Dan Lentur Paving Blok BerporiSteve SupitNessuna valutazione finora

- ASIF 04 MS Thesis Presentation (Update)Documento27 pagineASIF 04 MS Thesis Presentation (Update)tanvir_austNessuna valutazione finora

- GFRP & Pistachio in EpoxyDocumento6 pagineGFRP & Pistachio in EpoxyKirti Vardhan PantNessuna valutazione finora

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Documento5 pagineIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationNessuna valutazione finora

- Major Project RSMD 24-03-2016Documento58 pagineMajor Project RSMD 24-03-2016divyaNessuna valutazione finora

- Article 1Documento11 pagineArticle 1Vinod KanapathyNessuna valutazione finora

- Optimum Fly Ash and Fiber Content For M20 Grade ConcreteDocumento5 pagineOptimum Fly Ash and Fiber Content For M20 Grade ConcreteIJMER0% (1)

- Effect of PET Bottle Pieces and Waste Wrapper Fibe PDFDocumento8 pagineEffect of PET Bottle Pieces and Waste Wrapper Fibe PDFjuan paulo tenias domenechNessuna valutazione finora

- T0 NUMTQy MDMDocumento5 pagineT0 NUMTQy MDMRaj DuttNessuna valutazione finora

- Reading 1 PDFDocumento10 pagineReading 1 PDFGabriela HuertaNessuna valutazione finora

- International Journal of Chemtech Research: A.R.Krishnaraja, S.KandasamyDocumento7 pagineInternational Journal of Chemtech Research: A.R.Krishnaraja, S.KandasamyZrar IsqeliNessuna valutazione finora

- Behaviour of Glass Fiber Wrapped ConcreteDocumento10 pagineBehaviour of Glass Fiber Wrapped ConcreteB.r. AnirudhNessuna valutazione finora

- Structural Behaviour of Fibrous Concrete Using Polypropylene FibresDocumento4 pagineStructural Behaviour of Fibrous Concrete Using Polypropylene FibresPatricia ClarkNessuna valutazione finora

- Indirect Tensile Strength of Modified Bitumen MixtureDocumento6 pagineIndirect Tensile Strength of Modified Bitumen Mixturedbpublications100% (1)

- 11 X October 2023Documento35 pagine11 X October 2023Sohail ShaikhNessuna valutazione finora

- Recycled Plastic Used in Concrete Paver BlockDocumento3 pagineRecycled Plastic Used in Concrete Paver BlockInternational Journal of Research in Engineering and TechnologyNessuna valutazione finora

- Performance of Concrete Incorporating Industrial and Agricultural WastesDocumento11 paginePerformance of Concrete Incorporating Industrial and Agricultural WastesIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNessuna valutazione finora

- Biomimetic Principles and Design of Advanced Engineering MaterialsDa EverandBiomimetic Principles and Design of Advanced Engineering MaterialsNessuna valutazione finora

- 19-11-2022-1668838190-6-Impact - Ijrhal-3. Ijrhal-A Study of Emotional Maturity of Primary School StudentsDocumento6 pagine19-11-2022-1668838190-6-Impact - Ijrhal-3. Ijrhal-A Study of Emotional Maturity of Primary School StudentsImpact JournalsNessuna valutazione finora

- 09-12-2022-1670567569-6-Impact - Ijrhal-05Documento16 pagine09-12-2022-1670567569-6-Impact - Ijrhal-05Impact JournalsNessuna valutazione finora

- 19-11-2022-1668837986-6-Impact - Ijrhal-2. Ijrhal-Topic Vocational Interests of Secondary School StudentsDocumento4 pagine19-11-2022-1668837986-6-Impact - Ijrhal-2. Ijrhal-Topic Vocational Interests of Secondary School StudentsImpact JournalsNessuna valutazione finora

- 12-11-2022-1668238142-6-Impact - Ijrbm-01.Ijrbm Smartphone Features That Affect Buying Preferences of StudentsDocumento7 pagine12-11-2022-1668238142-6-Impact - Ijrbm-01.Ijrbm Smartphone Features That Affect Buying Preferences of StudentsImpact JournalsNessuna valutazione finora

- 14-11-2022-1668421406-6-Impact - Ijrhal-01. Ijrhal. A Study On Socio-Economic Status of Paliyar Tribes of Valagiri Village AtkodaikanalDocumento13 pagine14-11-2022-1668421406-6-Impact - Ijrhal-01. Ijrhal. A Study On Socio-Economic Status of Paliyar Tribes of Valagiri Village AtkodaikanalImpact JournalsNessuna valutazione finora

- 12-10-2022-1665566934-6-IMPACT - IJRHAL-2. Ideal Building Design y Creating Micro ClimateDocumento10 pagine12-10-2022-1665566934-6-IMPACT - IJRHAL-2. Ideal Building Design y Creating Micro ClimateImpact JournalsNessuna valutazione finora

- 28-10-2022-1666956219-6-Impact - Ijrbm-3. Ijrbm - Examining Attitude ...... - 1Documento10 pagine28-10-2022-1666956219-6-Impact - Ijrbm-3. Ijrbm - Examining Attitude ...... - 1Impact JournalsNessuna valutazione finora

- 25-08-2022-1661426015-6-Impact - Ijrhal-8. Ijrhal - Study of Physico-Chemical Properties of Terna Dam Water Reservoir Dist. Osmanabad M.S. - IndiaDocumento6 pagine25-08-2022-1661426015-6-Impact - Ijrhal-8. Ijrhal - Study of Physico-Chemical Properties of Terna Dam Water Reservoir Dist. Osmanabad M.S. - IndiaImpact JournalsNessuna valutazione finora

- 09-12-2022-1670567289-6-Impact - Ijrhal-06Documento17 pagine09-12-2022-1670567289-6-Impact - Ijrhal-06Impact JournalsNessuna valutazione finora

- 22-09-2022-1663824012-6-Impact - Ijranss-5. Ijranss - Periodontics Diseases Types, Symptoms, and Its CausesDocumento10 pagine22-09-2022-1663824012-6-Impact - Ijranss-5. Ijranss - Periodontics Diseases Types, Symptoms, and Its CausesImpact JournalsNessuna valutazione finora

- 21-09-2022-1663757902-6-Impact - Ijranss-4. Ijranss - Surgery, Its Definition and TypesDocumento10 pagine21-09-2022-1663757902-6-Impact - Ijranss-4. Ijranss - Surgery, Its Definition and TypesImpact JournalsNessuna valutazione finora

- 05-09-2022-1662375638-6-Impact - Ijranss-1. Ijranss - Analysis of Impact of Covid-19 On Religious Tourism Destinations of Odisha, IndiaDocumento12 pagine05-09-2022-1662375638-6-Impact - Ijranss-1. Ijranss - Analysis of Impact of Covid-19 On Religious Tourism Destinations of Odisha, IndiaImpact JournalsNessuna valutazione finora

- 19-09-2022-1663587287-6-Impact - Ijrhal-3. Ijrhal - Instability of Mother-Son Relationship in Charles Dickens' Novel David CopperfieldDocumento12 pagine19-09-2022-1663587287-6-Impact - Ijrhal-3. Ijrhal - Instability of Mother-Son Relationship in Charles Dickens' Novel David CopperfieldImpact JournalsNessuna valutazione finora

- 29-08-2022-1661768824-6-Impact - Ijrhal-9. Ijrhal - Here The Sky Is Blue Echoes of European Art Movements in Vernacular Poet Jibanananda DasDocumento8 pagine29-08-2022-1661768824-6-Impact - Ijrhal-9. Ijrhal - Here The Sky Is Blue Echoes of European Art Movements in Vernacular Poet Jibanananda DasImpact JournalsNessuna valutazione finora

- 23-08-2022-1661248618-6-Impact - Ijrhal-6. Ijrhal - Negotiation Between Private and Public in Women's Periodical Press in Early-20th Century PunjabDocumento10 pagine23-08-2022-1661248618-6-Impact - Ijrhal-6. Ijrhal - Negotiation Between Private and Public in Women's Periodical Press in Early-20th Century PunjabImpact JournalsNessuna valutazione finora

- Monitoring The Carbon Storage of Urban Green Space by Coupling Rs and Gis Under The Background of Carbon Peak and Carbon Neutralization of ChinaDocumento24 pagineMonitoring The Carbon Storage of Urban Green Space by Coupling Rs and Gis Under The Background of Carbon Peak and Carbon Neutralization of ChinaImpact JournalsNessuna valutazione finora

- 23-08-2022-1661248432-6-Impact - Ijrhal-4. Ijrhal - Site Selection Analysis of Waste Disposal Sites in Maoming City, GuangdongDocumento12 pagine23-08-2022-1661248432-6-Impact - Ijrhal-4. Ijrhal - Site Selection Analysis of Waste Disposal Sites in Maoming City, GuangdongImpact JournalsNessuna valutazione finora

- 08-08-2022-1659935395-6-Impact - Ijrbm-2. Ijrbm - Consumer Attitude Towards Shopping Post Lockdown A StudyDocumento10 pagine08-08-2022-1659935395-6-Impact - Ijrbm-2. Ijrbm - Consumer Attitude Towards Shopping Post Lockdown A StudyImpact JournalsNessuna valutazione finora

- 25-08-2022-1661424708-6-Impact - Ijranss-7. Ijranss - Fixed Point Results For Parametric B-Metric SpaceDocumento8 pagine25-08-2022-1661424708-6-Impact - Ijranss-7. Ijranss - Fixed Point Results For Parametric B-Metric SpaceImpact JournalsNessuna valutazione finora

- 06-08-2022-1659783347-6-Impact - Ijrhal-1. Ijrhal - Concept Mapping Tools For Easy Teaching - LearningDocumento8 pagine06-08-2022-1659783347-6-Impact - Ijrhal-1. Ijrhal - Concept Mapping Tools For Easy Teaching - LearningImpact JournalsNessuna valutazione finora

- 24-08-2022-1661313054-6-Impact - Ijranss-5. Ijranss - Biopesticides An Alternative Tool For Sustainable AgricultureDocumento8 pagine24-08-2022-1661313054-6-Impact - Ijranss-5. Ijranss - Biopesticides An Alternative Tool For Sustainable AgricultureImpact JournalsNessuna valutazione finora

- The Analysis On Environmental Effects of Land Use and Land Cover Change in Liuxi River Basin of GuangzhouDocumento16 pagineThe Analysis On Environmental Effects of Land Use and Land Cover Change in Liuxi River Basin of GuangzhouImpact JournalsNessuna valutazione finora

- 25-08-2022-1661424544-6-Impact - Ijranss-6. Ijranss - Parametric Metric Space and Fixed Point TheoremsDocumento8 pagine25-08-2022-1661424544-6-Impact - Ijranss-6. Ijranss - Parametric Metric Space and Fixed Point TheoremsImpact JournalsNessuna valutazione finora

- The Analysis On Tourist Source Market of Chikan Ancient Town by Coupling Gis, Big Data and Network Text Content AnalysisDocumento16 pagineThe Analysis On Tourist Source Market of Chikan Ancient Town by Coupling Gis, Big Data and Network Text Content AnalysisImpact JournalsNessuna valutazione finora

- UntitledDocumento22 pagineUntitledイルハスNessuna valutazione finora

- Materials Used For Packaging of Pharmaceutical Products: PlasticDocumento8 pagineMaterials Used For Packaging of Pharmaceutical Products: PlasticAnuj ZanjurneNessuna valutazione finora

- Dichtomatik: Matik Dichtomatik Dichtomatik Dic Htomatik Dichtom Atik DichtomatikDocumento29 pagineDichtomatik: Matik Dichtomatik Dichtomatik Dic Htomatik Dichtom Atik Dichtomatikpavel10082020Nessuna valutazione finora

- Specifications For Polymers 29-5-2018Documento5 pagineSpecifications For Polymers 29-5-2018Mohammad Rashad BarakatNessuna valutazione finora

- 2016 Fluid Seals and Packings Hydraulic and Pneumatic Seals CatalogueDocumento372 pagine2016 Fluid Seals and Packings Hydraulic and Pneumatic Seals Cataloguehebert perezNessuna valutazione finora

- C. Molecular Forces or Thermal Behavior: FibersDocumento14 pagineC. Molecular Forces or Thermal Behavior: FibersKuldeep singh ChandelNessuna valutazione finora

- Lab Report No.2Documento20 pagineLab Report No.2Ibrahim ShahidNessuna valutazione finora

- Polymers: Year 11 RevisionDocumento11 paginePolymers: Year 11 RevisionGanta BooomNessuna valutazione finora

- Fibres Classification and CharacteristicsDocumento53 pagineFibres Classification and CharacteristicsParul Bhatnagar78% (9)

- Pls Fill Up Column Ah&Ai - Jan 10-16 DataDocumento21 paginePls Fill Up Column Ah&Ai - Jan 10-16 DataTRISTAN JAYSON MUNARNessuna valutazione finora

- 乳膠英文目錄Documento8 pagine乳膠英文目錄Kʜʌn SʜaʜzʌʌdNessuna valutazione finora

- EPR Vs EPDMDocumento1 paginaEPR Vs EPDMSrinivasan RaviNessuna valutazione finora

- Fatigue Characteristics of High Glass Content Sheet Molding Compound (SMC) MaterialsDocumento4 pagineFatigue Characteristics of High Glass Content Sheet Molding Compound (SMC) MaterialsCaio OliveiraNessuna valutazione finora

- Polymers Used As Drug Delivery SystemsDocumento39 paginePolymers Used As Drug Delivery SystemsmahaNessuna valutazione finora

- Source - Wiki Engineering Plastics: ApplicationsDocumento3 pagineSource - Wiki Engineering Plastics: ApplicationsWolfMensch1216Nessuna valutazione finora

- TR-610 - Material Compatibility in Envirotemp Fluids-Gaskets & Polymers - April - 23 - 2015Documento11 pagineTR-610 - Material Compatibility in Envirotemp Fluids-Gaskets & Polymers - April - 23 - 2015rodineicarraroNessuna valutazione finora

- Coming To Terms: M.F.F.T. Minimum Film Forming TemperatureDocumento1 paginaComing To Terms: M.F.F.T. Minimum Film Forming TemperatureRaymond TanumiharjaNessuna valutazione finora

- Synthetic Polymers NotesDocumento3 pagineSynthetic Polymers NotesajspspNessuna valutazione finora

- Report - Plastic IdentificationDocumento4 pagineReport - Plastic IdentificationMai HoangNessuna valutazione finora

- Ranges of Application / Technical Data: WWW - Bareiss.deDocumento3 pagineRanges of Application / Technical Data: WWW - Bareiss.deEnrique AntonioNessuna valutazione finora

- Process Optimization in A Filament Yarn PlantDocumento3 pagineProcess Optimization in A Filament Yarn PlantGhulam HussainNessuna valutazione finora

- Technical Technical Data Sheet: 1. IdentificationDocumento2 pagineTechnical Technical Data Sheet: 1. IdentificationVipin DasNessuna valutazione finora

- Chimassorb 944 TdsDocumento3 pagineChimassorb 944 TdsRodrigo Esteban Ramirez CanalesNessuna valutazione finora

- Dental Polymers: Typical Applications of Polymers in DentistryDocumento9 pagineDental Polymers: Typical Applications of Polymers in DentistryEuro UndisaNessuna valutazione finora

- Polymers Listed in Alphabetical Order Only: Yes Possible Not ApplicableDocumento1 paginaPolymers Listed in Alphabetical Order Only: Yes Possible Not ApplicableElif SarıoğluNessuna valutazione finora

- Eng-Study On Utilization of Waste Pet Bottle Fiber-P.ganesh PrabhuDocumento8 pagineEng-Study On Utilization of Waste Pet Bottle Fiber-P.ganesh PrabhuImpact JournalsNessuna valutazione finora

- Polyester Staple Fibre Product ListDocumento2 paginePolyester Staple Fibre Product Listnunu7478Nessuna valutazione finora