Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pressure Gauge Introduction

Caricato da

Harish SundarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pressure Gauge Introduction

Caricato da

Harish SundarCopyright:

Formati disponibili

INDUMART PRESSURE GAUGES

This section of our catalogue is designed to categorize all Indumart pressure gauges to make it easier for

our customers to order exactly the type of pressure gauge they need. For a careful selection of your

required pressure gauge, the following specifications must be stated:

Pressure Range Environmental Elements

Pressure Element Process Temperature

Movement Over Pressure

Accuracy Shocks and Pulsations

Case & Bezel Dials

Mounting & Connection Position Window

Pressure Connection

Pressure Range

Range of the selected pressure gauge should be about twice the normal operating pressure of the

process. The maximum operating pressure should not exceed 75% of the full scale range. Failure to

select a gauge within these criteria may ultimately result in fatigue failure of the Bourdon Tube.

Indumart standard pressure ranges are in psi and bar scales. Other pressure units such as kPa, MPa,

2

in.H2O, mH2O, in.Hg, kg/cm and mbar are also available. Following tables show the standard pressure

ranges for "C" shaped Bourdon tube and helical Bourdon tube systems. For other pressure systems,

check their data sheets.

0 ... 0.6

0 ... 1

0 ... 1.6

0 ... 2.5

0 ... 4

0 ... 6

0 ... 10

0 ... 16

0 ... 25

0 ... 40

0 ... 60

0 ... 100

0 ... 160

0 ... 250

0 ... 400

0 ... 600

0 ... 1000

0 ... 1600

Table 1- Standard Pressure Ranges in bar

-0.6 ... 0 -1 ... 0

Vacuum Ranges in bar

-1 ... 0.6

-1 ... 1.5

-1 ... 3

-1 ... 5

-1 ... 9

-1 ... 15

-1 ... 24

Compound Ranges in bar

0 ... 160

0 ... 200

0 ... 300

0 ... 400

0 ... 600

0 ... 1000

0 ... 1600

0 ... 3000

0 ... 5000

0 ... 6000

0 ... 10000

0 ... 16000

0 ... 20000

Table 2 - Standard Pressure Ranges in Psi

0 ... 10

0 ... 30

0 ... 60

0 ...100

0 ... 15

-10 ... 0 -15 ... 0

Vacuum Ranges in psi

-30" Hg ... 10

-30" Hg ... 15

-30" Hg ... 30

-30" Hg ... 60

-30" Hg ... 100

-30" Hg ... 160

-30" Hg ... 200

Compound Ranges in psi

Table 3 - Pressure Conversion Table

psi bar kPa mH2O in.H2O

mmHg in.Hg

2

kg/cm atm

1

14.504

0.14504

1.42233

0.03606

0.01926

0.4892

14.223

14.696

0.06894

1

0.01

0.09807

0.00249

0.001333

0.03386

0.98068

1.01325

6.8948

100

1

9.8066

0.24908

0.13332

3.3864

98.068

101.325

0.70307

10.1972

0.10197

1

0.0254

0.0136

0.34532

10

10.332

27.735

401.47

4.0147

39.37

1

0.53418

13.568

394.57

407.69

51.924

750.06

7.5006

73.556

1.8721

1

25.401

738.51

763.07

2.0442

29.530

0.29530

2.8959

0.07368

0.03937

1

29.075

30.042

0.07031

1.0197

0.01019

0.1

0.00254

0.00135

0.03439

1

1.0332

0.06805

0.98692

0.009869

0.09678

0.00245

0.00131

0.03329

0.96784

1

-30" Hg ... 0 psi

-30" Hg ... 350

Pressure Element

Indumart offers pressure elements in a wide variety of materials, such as brass, phosphor bronze, 316L

stainless steel and Kmonel . Since the pressure element is in direct contact with the process fluid,

chemical compatibility of the fluid with the pressure element must be checked. If the correct material is not

available, the use of a diaphragm seal may be necessary to protect the system from the process fluid.

Additionally, the pressure range should also be considered for selection of the pressure element. Table 4

shows various types of pressure elements and their range limitations. Definite advantages of Indumart

pressure gauges over other brands are bigger and thicker Bourdon tubes.

Table 4 - Range Limitations of Pressure Elements Supplied by Indumart

For other measurement units, please use the conversion factors.

Range (bar) Pressure Element Min. Range (bar)

"C" shaped Bourdon tube system

Helical Bourdon tube system

Capsule system

Low pressure diaphragm system

Differential capsule system

Differential diaphragm system

Differential tube system

Differential piston system

-1/0 ... 0/40

0/60 ... 0/1,600

-0.6/0 ... 0/0.6

-0.4/0 ... 0/0.4

0...0.4

0...25

0...25

0...10

High pressure diaphragm system

-1/0 ... 0/25

0...0.6

0...60

0...0.025

0...0.01

0...0.004

0...0.1

0...0.6

0...0.25

0...0.6

0% 100%

25% 75%

Proper read out

Maximum safety

The best accuracy

Poor accuracy

Poor read out

only allowed

for short term

peaks

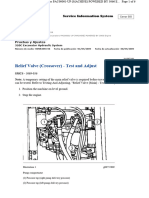

C-shaped Bourdon Tube System Helical Bourdon Tube System

Capsule System Diaphragm System

Case and Bezel

Case and bezel selection of a pressure gauge should be in accordance with the gauge environment.

They vary in size, the material of construction and style.

Pressure gauge cases and bezels are available in ABS plastic, painted steel, chrome-plated steel, brass,

stainless steel, aluminum and phenolic turret.

Indumart offers three types of cases: (1) standard case without blow-out device, (2) case with blow-out

disk, and (3) solid front case with a solid wall between the bourdon tube and the window.

The total of indication errors including hysteresis error

and temperature error at reference temperature of

20C shall not exceed the value given as accuracy

class. For special accuracy classes, certain materials

and procedures will be used.

If usage of liquid filling is required in the pressure

gauges, the accuracy will drop at least one class

compared to the accuracy of the same dry gauges.

Movement

Movements are used to transfer the displacement of the pressure element to the pointer. Reducing the

friction to its minimum, and extending the wear life are the two important factors when designing the

movement parts. The movement systems of Indumart pressure gauges are very sturdy comparing to

those of the others and most models are equipped with various adjustment screws on the movement to

acquire the best pressure measurements.

Dial

(mm)

40

50

63

100

160

250

0.1 0.25 0.5 0.6 1.0 1.6

Accuracy Class

x

x x

x x

x

x

x

x

x

x

x

x

x

x

Table 5 - Nominal Dial Sizes and Accuracy Classes

Accuracy

Accuracy class is the maximum permissible error of indication at the reference temperature, expressed as

a percentage of the span. The various accuracy classes and their availabilities are shown in Table 5.

The bezel is to retain the window. Depending on the application and case type, five types of bezels are

used: (1) bayonet, (2) crimped, (3) threaded, (4) snap-on, and (5) ring with screws.

Type 1

Standard case

Type 2

Case with blow-out disk

Type 3

Solid front case

Mounting and Connection Position

Indumart pressure gauges are offered for five different kinds of mounting:

Direct mounting with bottom connection

Direct mounting with back connection (2 types)

Panel mounting by means of U-clamp

Wall mounting by means of back flange

Panel mounting by means of front flange with 3 fixing holes

Bottom connection Centre back connection Eccentric back connection

U-clamp for centre back and

eccentric back connections

Panel mounting by

means of U-clamp

U-clamp and a nut on

the back connection

U-clamp with 2 welded

bolts on the casing

Wall mounting by means of a back flange Panel mounting by means of a front flange

with 3 fixing holes

For safe installation, pressure restrictors, relief valves, pressure regulators, chemical seals, pulsation

dampeners or snubbers, syphons, manifolds and other similar items are available.

Process Temperature

An important piece of information for selecting the correct pressure gauge is the profile of the process

temperature. For proper operation of the selected pressure gauges, it is essential that the gauge stand

the maximum temperature of the process.

Another benefit of knowing the process temperature is estimation of the accuracy of the pressure

measurement. Accuracies of pressure gauges are usually expressed at the reference temperature of

20C. Variations of process temperature alters the accuracies of Indumart pressure gauges as follows:

Where:

t is the ambient temperature in C,

1

t is the reference temperature in C.

2

Pressure Connection

The position of the process connection and thread size for all pressure gauges are specified in the

technical sheets. Standard threads are taper pipe threads according to ANSI/ASME B1.20.1 with NPT

symbol, and parallel thread with G or BSP symbol. Other threads like SAE flair, specific to certain

industries, are also available as special order.

Environmental Elements

Adequate safety results from intelligent planning, careful selection and proper installation of gauges into

the system. The user should inform the supplier of all conditions pertinent to the application and the

environment, so the supplier be able to recommend the most suitable pressure gauge.

The Ingress Protection (IP) rating of the selected pressure gauge must be such that to protect the gauge

from dust and water penetrations. The IP code always consists of the letters IP followed by a two digit

number. The first digit represents protection against penetration of solid foreign objects, while the second

digit indicates resistance against liquid penetration.

1st Digit

Protection Against Solid Foreign Bodies

0 No protection

1 Objects greater than 50 mm diameter

2 Objects greater than 12 mm diameter

3 Objects greater than 2.5 mm diameter

4 Objects greater than 1.0 mm diameter

5 Dust protected

6 Dust-tight

2nd Digit

Protection Against Liquids

0 No protection

1 Vertically dripping water

2 Angled (15) dripping water

3 Raining; maximum 60angle

4 Splashing from any direction

5 Water jets from any direction

6 Heavy sea waves

7 Immersed in water

8 Immersed in water (specified pressure)

for Bourdon tube gauges

for capsule gauges

for diaphragm gauges

0.04 x (t - t )% of the span

2 1

0.06 x (t - t )% of the span

2 1

0.08 x (t - t )% of the span

2 1

Over-pressure

Any over-pressure creates stress in

the pressure sensing element and

consequently reduces the life and

accuracy of the pressure gauge. It is

therefore always preferable to use a

pressure gauge with a maximum

scal e val ue greater than the

maximum working pressure to absorb

over-pressure and surges more

easily. Surges can be handled in the

same way as pressure pulses.

Shocks and Pulsation

Where pressure shocks and pulsations cause the pointer of the pressure gauge to vibrate, use of a liquid-

filled pressure gauge is recommended. Liquid filled pressure gauges are specifically designed for sever

service applications. When immersed in glycerin, all moving parts of the pressure gauge are lubricated

and dampened from the harmful effects of vibration and pulsation.

Liquid filled pressure gauges are wildly used for agricultural equipments, hydraulic equipments, pressure

washers, oil field equipments, pumps, compressors and other systems which may experience pressure

shocks and vibrations.

Not all pressure gauges should be filled with a liquid (glycerin). For example, in case of capsule element

pressure gauges, external dampeners must be used instead of liquid filling of the case.

Dials

The scale normally covers 270 of arc, but that may be longer for accuracy classes of 0.5% to 0.1%. Dials

with an accuracy of 1.6 % have a stopping and a shortened first block. With an accuracy of 1% or better,

there is no stopping and no shortened first block on the dial.

Window

Indumart pressure gauges are offered with (1) flat instrument glass, (2) laminated safety glass, (3) acrylic /

plexiglas.

IMPORTANT - All pressure gauges sealed for the purpose of liquid-filling have a device to assure

atmospheric compensation. A sticker on the case shows how to cut off or pierce a hole into the rubber

placed at the top of the gauge after installation. If the rubber device is not opened, in addition to false

pressure reading, sever personal damage may be resulted.

Specifying over-pressure for a

pressure gauge means that the

sensing element will only withstand

that for a short period of time. Use of

an over-range protection unit is highly

recommended for solving the over-

pressure problem.

scale in psi scale in bar over-pressure at 20C

up to 1500 up to 100 1.25 x full scale value

>1500 to 10000 >100 to 600 1.15 x full scale value

>10000 to 20000 >600 to 1600 1.10 x full scale value

Over pressure protector

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Petroleum Storage Tank TrainingDocumento97 paginePetroleum Storage Tank Trainingpadalakirankumar92% (12)

- Lab Report on Pressure Measurement Using ManometersDocumento6 pagineLab Report on Pressure Measurement Using ManometersPashew PirotNessuna valutazione finora

- Short StryDocumento2 pagineShort StryHarish SundarNessuna valutazione finora

- Half StoryDocumento2 pagineHalf StoryHarish SundarNessuna valutazione finora

- Story - BetterDocumento2 pagineStory - BetterHarish SundarNessuna valutazione finora

- WorkDocumento2 pagineWorkHarish SundarNessuna valutazione finora

- Book StoryDocumento2 pagineBook StoryHarish SundarNessuna valutazione finora

- WritingDocumento2 pagineWritingHarish SundarNessuna valutazione finora

- Story - BetterDocumento2 pagineStory - BetterHarish SundarNessuna valutazione finora

- Ancient Egypt novel gets second editionDocumento2 pagineAncient Egypt novel gets second editionHarish SundarNessuna valutazione finora

- StoryDocumento2 pagineStoryHarish SundarNessuna valutazione finora

- Story - BetterDocumento2 pagineStory - BetterHarish SundarNessuna valutazione finora

- FileDocumento2 pagineFileHarish SundarNessuna valutazione finora

- DataDocumento2 pagineDataHarish SundarNessuna valutazione finora

- Story - HalfDocumento2 pagineStory - HalfHarish SundarNessuna valutazione finora

- Story 1Documento2 pagineStory 1Harish SundarNessuna valutazione finora

- English - Short Story ContinuedDocumento2 pagineEnglish - Short Story ContinuedHarish SundarNessuna valutazione finora

- Story - BetterDocumento2 pagineStory - BetterHarish SundarNessuna valutazione finora

- Ancient EnglishDocumento2 pagineAncient EnglishHarish SundarNessuna valutazione finora

- Story Small OneDocumento2 pagineStory Small OneHarish SundarNessuna valutazione finora

- The Marketing Strategy Concept - Classification and ApplicationDocumento9 pagineThe Marketing Strategy Concept - Classification and ApplicationHarish SundarNessuna valutazione finora

- Onshore CablesDocumento184 pagineOnshore CablesHarish Sundar100% (1)

- Pressure Gauge IntroductionDocumento6 paginePressure Gauge IntroductionHarish SundarNessuna valutazione finora

- Free Study (Fluid Mechanics)Documento37 pagineFree Study (Fluid Mechanics)Jeric PonterasNessuna valutazione finora

- Valve DefinitionsDocumento28 pagineValve Definitionsprotech280% (1)

- Measuring Temperature With RTDsDocumento8 pagineMeasuring Temperature With RTDsDonig FermanianNessuna valutazione finora

- Pressure Relief Valve Engineering HandbookDocumento93 paginePressure Relief Valve Engineering Handbookakrouti92% (12)

- Programmable Logic Controllers Basic Level TextbookDocumento18 pagineProgrammable Logic Controllers Basic Level TextbookAhmed Shehab AliNessuna valutazione finora

- RTD Sensors GuideDocumento4 pagineRTD Sensors GuideHarish SundarNessuna valutazione finora

- Pid Tagging Isa s5.1Documento22 paginePid Tagging Isa s5.1vivek1280100% (1)

- Gas Constant ValuesDocumento1 paginaGas Constant ValuesAhmed Hamdy KhattabNessuna valutazione finora

- Industrial Instrumentation - IDocumento4 pagineIndustrial Instrumentation - ISanthosh Kumar JNessuna valutazione finora

- GMS Instruments B.V. Product CatalogueDocumento132 pagineGMS Instruments B.V. Product CatalogueAnticristh6666Nessuna valutazione finora

- Ajuste de Traslacion de Cat 320 C LuDocumento6 pagineAjuste de Traslacion de Cat 320 C LuJose romeroNessuna valutazione finora

- Fluid Mechanics Course OverviewDocumento148 pagineFluid Mechanics Course OverviewPriyesh SinghNessuna valutazione finora

- Product Overview UK BDDocumento28 pagineProduct Overview UK BDNaser Jahangiri100% (1)

- Mathcad - 3B - Tut - 2 - PumpsDocumento2 pagineMathcad - 3B - Tut - 2 - PumpsFabrizio NEBESSENessuna valutazione finora

- Jenbacher: I 0103 6 InspectionDocumento6 pagineJenbacher: I 0103 6 InspectionArîfNessuna valutazione finora

- Fluid Mechanics Chp-2a-1Documento33 pagineFluid Mechanics Chp-2a-1Muhd SyahmiNessuna valutazione finora

- Saturation Pressure & Vapor Quality ChapterDocumento17 pagineSaturation Pressure & Vapor Quality ChapterFrank.JNessuna valutazione finora

- Pressure Transducers and MeasurementDocumento76 paginePressure Transducers and MeasurementMohamed AbohassanNessuna valutazione finora

- Hydraulic Power UnitsDocumento5 pagineHydraulic Power UnitsKhaled ZaherNessuna valutazione finora

- HVACR Series Study GuideDocumento64 pagineHVACR Series Study GuideHARISHKIRTHI MECH50% (2)

- Astm D5191 19Documento9 pagineAstm D5191 19Claudia Barrera100% (1)

- Level CalculationDocumento4 pagineLevel Calculationshinojbaby4148Nessuna valutazione finora

- Manual de Taller Subaru Impreza 99-01 (Motor)Documento233 pagineManual de Taller Subaru Impreza 99-01 (Motor)Jorge RodríguezNessuna valutazione finora

- Spe 146394 MSDocumento5 pagineSpe 146394 MSDr-Jitendra Vaish100% (1)

- Exp 3.1pressure in LiquidsDocumento3 pagineExp 3.1pressure in LiquidsNazirah Rohanip0% (1)

- I-CAL-GUI-017 Calibration Guideline No. 17 WebDocumento45 pagineI-CAL-GUI-017 Calibration Guideline No. 17 WebSafa ChaariNessuna valutazione finora

- Chapter 2Documento39 pagineChapter 2Brian King CrosdaleNessuna valutazione finora

- Hydac FAMH ManualDocumento28 pagineHydac FAMH ManualDavid A. LópezNessuna valutazione finora

- Tourniquet Systems Pressure Infusion: Medizintechnik GMBHDocumento24 pagineTourniquet Systems Pressure Infusion: Medizintechnik GMBHSantiagoNessuna valutazione finora

- 031-Procedure For Hydro and Pneumatic Testing PDFDocumento36 pagine031-Procedure For Hydro and Pneumatic Testing PDFKöksal PatanNessuna valutazione finora

- Mass ProBar FlowmeterDocumento130 pagineMass ProBar FlowmeterUn Chubacca YetiNessuna valutazione finora

- Thermodynamics Tug As 1Documento10 pagineThermodynamics Tug As 1misrakandiNessuna valutazione finora

- Types of Steam Flowmeters: Orifice Plates, Turbines & MoreDocumento20 pagineTypes of Steam Flowmeters: Orifice Plates, Turbines & MoreLidijaSpaseskaNessuna valutazione finora

- Operating Manual-Eps600Documento21 pagineOperating Manual-Eps600Miguel ChaconNessuna valutazione finora

- CC19 Group 1 Lab Report 10Documento6 pagineCC19 Group 1 Lab Report 10PHƯỚC DƯƠNG THANHNessuna valutazione finora

- Chapter 1 Metrology Basics: Understand Basics of Metrology, Standards and Calculate Least Count of Measuring InstrumentsDocumento34 pagineChapter 1 Metrology Basics: Understand Basics of Metrology, Standards and Calculate Least Count of Measuring InstrumentsAswaja313Nessuna valutazione finora