Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CHERRY MAXIBOLT® Proce Ss Manual

Caricato da

moj33Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CHERRY MAXIBOLT® Proce Ss Manual

Caricato da

moj33Copyright:

Formati disponibili

1

CHERRY MAXIBOLT

PROCESS MANUAL

TABLE OF CONTENTS

Introduction of Cherry MAXIBOLT Fasteners .............................................................................. 1

Installation Sequence ................................................................................................................... 1

Identication ................................................................................................................................ 4

Installation & Inspection ............................................................................................................... 8

Inspection & Troubleshooting ..................................................................................................... 15

Removal ...................................................................................................................................... 21

Installation Tooling Selection Chart ............................................................................................ 22

Decimal Equivalents ...................................................................................................................24

LIMITED WARRANTY

Seller warrants the goods conform to applicable specifications and drawings and will be manufactured and inspected

according to generally accepted practices of companies manufacturing industrial or aerospace fasteners. In the event of

any breach of the foregoing warranty, Buyers sole remedy shall be to return defective goods (after receiving authoriza-

tion from Seller) for replacement or refund of the purchase price, at the Sellers option. Seller agrees to any freight costs

in connection with the return of any defective goods, but any costs relating to removal of the defective or nonconforming

goods or installation of replacement goods shall be Buyers responsibility. SELLERS WARRANTY DOES NOT APPLY WHEN

ANY PHYSICAL OR CHEMICAL CHANGE IN THE FORM OF THE PRODUCT IS MADE BY BUYER. THE FOREGOING EXPRESS

WARRANTY AND REMEDY ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES; ANY IMPLIED

WARRANTY AS TO QUALITY, FITNESS FOR PURPOSE, OR MERCHANTABILITY IS HEREBY SPECIFICALLY DISCLAIMED

AND EXCLUDED BY SELLER. This warranty is void if seller is not notified in writing of any rejection of the goods within

one (1) Year aFter initial use by buyer of any power Riveter or ninety (90) days after initial use of any other product.

Seller shall not be liable under any circumstances for incidental, special or consequential damages arising in whole

or in part from any breach by Seller, AND SUCH INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES ARE HEREBY

EXPRESSLY EXCLUDED.

Our policy is one of continuous development. Specifications shown in this document may be subject to changes intro-

duced after publication.

CHERRY

and MAXIBOLT

are trademarks of Cherry Aerospace.

ATTENTION: Blind fasteners are not always interchangeable with non-blind fasteners. Consult

with the aircraft Original Equipment Manufacturer for proper application of

this product.

1

CHERRY MAXIBOLT

INSTALLATION SEQUENCE

This process manual is for reference on how

to identify and work with Cherry MAXIBOLT

blind bolt fasteners. The manual includes

information on:

Fastener selection and part identifcation

Hole preparation

Inspection procedures

Troubleshooting

Installation tooling

CHERRY MAXIBOLT FEATURES

Cherry MAXIBOLT Blind bolts offer fast

and consistent installation in metallic and

composite structures. The Cherry MAXIBOLT

consists of four components assembled as a

single unit:

A. Fully serrated stem with break notch

B. A shift washer to insure a viable mechanical

lock with each fastener installation*

C. A separate locking collar that mechanically

locks the stem to the sleeve

D. A blind bolt sleeve with a recess in the head

to receive the locking collar.

Information contained in this manual applies

to Cherry MAXIBOLT, Cherry Titanium

MAXIBOLT and Cherry MAXIBOLT PLUS unless

otherwise noted.

*S Type MAXIBOLT and MAXIBOLT PLUS bolts only.

Shift

Washer

Stem

Sleeve

Lock

Collar

2

CHERRY MAXIBOLT

INSTALLATION SEQUENCE

1. The Cherry MAXIBOLT is inserted into the prepared hole. The pulling

head is slipped over the stem. With a rm pressure added to seat the

head, the installation tool is actuated.

2. The pulling action on the stem causes the sleeve to form away

from the backside of the structure, thereby eliminating exit hole

delamination in composite structures.

3. The continued pulling action compresses the large bearing area

against the backside of the structure.

4. The Cherry patented shift washer collapses into itself, driving the

locking collar into the head recess and then into the stem locking

groove to form an integral lock.

5. The stem fractures at the break notch providing a ush, burr-free,

installation.

Note: Installation sequence shown for S type MAXIBOLTs with shifting

washer. Sequence is similar for and U types without shift washer.

3

INSTALLATION

NOTES

- TYPE

- Signies that the 5/32" and

3/16" diameter sizes are installed with a double

action (shifting type) tool.

S TYPE*

The S type fastener has a shift washer and

lock collar. S Signies that the fastener is

installed with a single action (non-shifting) tool

for 5/32" and 3/16" diameters. - signies that

the fastener is installed with a single action (non-

shifting) tool for 1/4" and 5/16" diameters.

U TYPE*

U Signies that the fastener is installed by a

single action (non-shifting) tool for all diameters.

NOTES

1. -05 and -06 dia. fasteners are installed with a

double action (shifting) tool; S05 dia., S06 dia.,

-08 dia., and -10 dia. fasteners are installed

with a single action (non-shifting) tool and are

supplied with shift washer. The lock collar is

solid or split, manufacturers option.

2. Minimum grip for -05 dia. is .094 and -06 dia.

is .120.

3. A special tool nosepiece is required for all U

type fasteners.

* Green paint or dye on stem and/or shift washer

indicates a single action installation tool

requirement.

Lack of green paint or dye on -05 and -06 prod-

ucts indicate that a double action installation

tool system must be used.

Lock Collar

Shift Washer

Lock Collar

4

FASTENER IDENTIFICATION

CHERRY PART NUMBER IDENTIFICATION

CR7310 S 06 -064 D = 3/16" Nominal diameter Cherry MAXIBOLT blind bolt, .219 min.

grip .282 max. grip, with aluminum coat equivalent to MS90353-

0604D

Finish Code

Grip Length in 1/16 inch increments

Diameter in 1/32 inch increments

Installation Method

U = Single action all diameters, uses U type nose piece.

S = Single action Shift Cap Washer

= Double action 5/32 and 3/16 only,

Single action 1/4 and 5/16

Single action with Shift Cap Washer

Basic Part Number (materials and head style)

Note: Refer to Cherry MAXIBOLT catalogue for complete list of nish alternates and codes.

See page 6 for cross reference of Cherry MAXIBOLT and MS part numbers.

MILITARY PART NUMBER IDENTIFICATION

MS90353 S 06 04 ( )

Finish Code/Installation Type W = Blunt Nosed Tooling

Grip Length in 1/16 inch increments

Diameter in 1/32 inch increments

Installation Method

U = Single action all diameters, with u type nose piece.

S = Single action Shift Cap Washer

= Double action 5/32" and 3/16 only1/4 and 5/16

Single action with Shift Cap Washer

Basic Part Number (materials and head style)

5

FASTENER IDENTIFICATION

HEAD MARKINGS

STANDARD MAXIBOLT OVERSIZE MAXIBOLT MAXIBOLT PLUS

Sleeve Material Code

Grip Identication

Manufacturers

Identication

Sleeve Material Code

Grip Identication

Manufacturers

Identication

Designates

Oversize

1. Single digit marking is permissible for grip dash numbers less than 10

2. Sleeve Material

MAXIBOLT STANDARD AND OVERSIZE

Material Code Sleeve Material

C Stainless Steel A-286 CRES, AMS 5737

MV or 7774 CP Titanium per ASTM - B348, Gr. 1

none 4037 Alloy Steel ASTM-A-331

MAXIBOLT PLUS

Product Number Material Head Style

CR7680S Stainless Steel 100 Flush Head (AN509)

CR7683S Stainless Steel Protruding Head

CR7684S Stainless Steel 130 Flush Head

CR7686S Stainless Steel 100 Flush Head (MS20426)

CR7784S Titanium 130 Flush Head

6

FASTENER IDENTIFICATION

MILITARY PART NUMBER CROSS REFERENCE

Fastener

Diameter

A286 CRES Per NASM8975

95 KSI Shear

Alloy Steel Per NASM81177

112 KSI Shear

Installation Criteria

MS Part No. Cherry Part No. MS Part No. Cherry Part No. Riveter** Nose Piece Type***

05

5/32" (0.164)

MS21140-05*

MS21140S05*

MS21140U05*

MS21141-05*

MS21141S05*

MS21141U05*

CR7620-05-*

CR7620S-05-*

CR7620U-05-*

CR7621-05-*

CR7621S-05-*

CR7621U-05-*

MS90353-05*

MS90353S05*

MS90353U05*

MS90354-05*

MS90354S05*

MS90354U05*

CR7310-05-*

CR7310S-05-*

CR7310U-05-*

CR7311-05-*

CR7311S-05-*

CR7311U-05-*

DA

S

S

DA

S

S

N/A

B or U

U

N/A

B or U

U

Oversize 05

5/32 (0.179)

None

None

CR7650S-05-*

CR7651S-05-*

None

None

CR7340S-05-*

CR7341S-05-*

S

S

B or U

B or U

06

3/16" (0.199)

MS21140-06*

MS21140S06*

MS21140U06*

MS21141-06*

MS21141S06*

MS21141U06*

CR7620-06-*

CR7620S-06-*

CR7620U-06-*

CR7621-06-*

CR7621S-06-*

CR7621U-06-*

MS90353-06*

MS90353S06*

MS90353U06*

MS90354-06*

MS90354S06*

MS90354U06*

CR7310-06-*

CR7310S-06-*

CR7310U-06-*

CR7311-06-*

CR7311S-06-*

CR7311U-06-*

DA

S

S

DA

S

S

N/A

B or U

U

N/A

B or U

U

Oversize 06

3/16" (.215)

None

None

CR7650S-06-*

CR7651S-06-*

None

None

CR7340S-06-*

CR7341S-06-*

S

S

B or U

B or U

08

1/4" (0.260)

MS21140-08*

MS21140U08*

MS21141-08*

MS21141U08*

CR7620-08-*

CR7620U-08-*

CR7621-08-*

CR7621U-08-*

MS90353-08*

MS90353U08*

MS90354-08*

MS90354U08*

CR7310-08-*

CR7310U-08-*

CR7311-08-*

CR7311U-08-*

S

S

S

S

B or U

U

B or U

U

Oversize 08

1/4" (0.260)

None

None

CR7650S-08-*

CR7651S-08-*

None

None

CR7340S-08-*

CR7341S-08-*

S

S

B or U

B or U

10

5/16" (0.312)

MS21140-10*

MS21140U10*

MS21141-10*

MS21141U10*

CR7620-10-*

CR7620U-10-*

CR7621-10-*

CR7621U-10-*

MS90353-10*

MS90353U-10*

MS90354-10*

MS90354U10*

CR7620-10-*

CR7620U-10-*

CR7621-10-*

CR7621U-10-*

S

S

S

S

B or U

U

B or U

U

Oversize 10

5/16" (0.328)

None

None

CR7650S-10-*

CR7651S-10-*

None

None

CR7340S-10-*

CR7341S-10-*

S

S

B or U

B or U

* Grip Length dash number see page XXXX

** Installation Riveter Codes: DA=Double Action, S=Single Action,

***B - Blunt type; U - Special Nose

P- Sufx to MS21140 and MS21141 indicates cadmium plate

D- Sufx to MS90353 and MS90354 indicates aluminum IVD coating

P- Sufx to Cherry Part No.for A286 CRES parts indicate cadmium plate

D- Sufx to Cherry indicates aluminum IVD coating;

Note: There is no cross-reference between the Cherry Titanium MAXIBOLT and any MS no.

Refer to Page 22 for Installation Tool Selection Chart

7

FASTENER IDENTIFICATION

HOLE PREPARATION

BLIND BOLT HOLE DIAMETER LIMITS

Nominal

Fastener

Diameter

Standard

Diameter Hole

Limits

Recommended

Drill Size

1/64 Oversize

Diameter Hole

Limits

Recommended

Drill Size D Min D Max D Min D Max

1/8 (-04) .129 .132 #30

5/32 (-05) .164 .167 #19 .180 .183 #14

3/16 (-06) .199 .202 #7 .215 .218 5.5mm

1/4 (-08) .260 .263 G .276 .279 J

5/16 (-10) .312 .315 5/16 .328 .331 21/64

100 COUNTERSINK DIMENSIONS

Fastener

Diameter

Nominal and Oversize Maximum Radius or Chamfer

C Min C Max B Max

1/8 (-04) .222 .228 .015

5/32 (-05) .327 .335 .020

3/16 (-06) .380 .388 .025

1/4 (-08) .500 .509 .030

5/16 (-10) .627 .637 .035

HOLE SIZE LIMITS

(100)

D

C

B (rad.)

No chamfer or

radius on blind side

2 4 6 8 10 12 14 16

8

INSTALLATION AND INSPECTION

HOLE PREPARATION

DRILLING PROCEDURE

Use a clean, sharp properly ground drill.

Improperly ground drills will create oval or

oversized holes.

Center the drill in the chuck so that the

drill will run true. A wobble in the drill will

create an oversize hole.

Hold the drill perpendicular to the surface

being drilled. Do not force the drill through

the material.

To ensure proper hole alignment and to

prevent burrs and chips from lodging between

the sheets, the materials to be fastened

should be clamped tightly together. Hole

lling hollow tack rivets should be used in

conjunction with spring-loaded fasteners to

prevent material creep and hole misalign-

ment during the drilling operation.

Improperly

Ground

Properly

Ground

Drill "Wobble

wrcng

Chlps

Mlsallgnment

k|ght

Wreng

Sprlng

Lcaded

Fastener

Clean

Fcle

"Tack"

klvet

o

9

INSTALLATION AND INSPECTION

HOLE PREPARATION

COUNTERSINKING

Accurate countersinking is of primary

importance to the structural integrity of a

ush riveted joint. Standard countersinking

procedures as used with solid rivets are also

applicable to MAXIBOLT Rivets. The following

points, however, should be carefully noted.

The countersink pilot should be no more than

.001 smaller than the hole diameter. A great-

ly undersize pilot will produce a countersink

which is not concentric with the hole, creating

head gap problems.

A countersink pilot which is too small may

also create a countersink whose axis is not in

line with the axis of the drilled hole. This will

create a cocked rivet head condition.

HOLE MISALIGNMENT

When drilling contoured surfaces, hole

misalignment often becomes evident during

fastener insertion. Avoid reinserting a drill

into the hole to straighten it out. This may

result in varying degrees of hole elongation on

the blind side of the structure, which can lead

to fastener malfunction. Drill the components

together to avoid this condition.

Hole eccentricity tolerance

Hole/Countersink angularity tolerance

Cap

Ccoked

Head

Cap

Ccoked

Head

2.5 max

.001" max .001" max

2.5 max

.001" max .001" max

10

INSTALLATION AND INSPECTION

HOLE PREPARATION

DE-BURRING

All drilling operations cause

burrs to form on each end

of the hole being drilled, as

well as between the sheets.

Whenever possible, all

burrs should be removed.

Do not chamfer on blind

side of sheet as this will

affect clamp-up during the

installation of the fastener.

When removing burrs, care

must be taken to remove

ONLY the burr. Do not

countersink the sheets, as

this may materially affect the

strength of the riveted joint,

particularly with respect to

the blind sheet.

Poor

Remove Chips Remove Burrs

Good

Burr

Burr

Poor

Remove Chips Remove Burrs

Good

Burr

Burr

Poor

Remove Chips Remove Burrs

Good

Burr

Burr

11

INSTALLATION AND INSPECTION

269B12 GAGE

FASTENER SELECTION

MEASURING THE PROPER GRIP LENGTH

To determine proper grip, measure material

thickness with a 269B12 Grip Gage as shown

below. Insert the grip gage into the prepared

hole, draw gage back until lip contacts

backside of structure and read where front

side of structure coincides with numbers and

lines on gage.

Note: Gage does not include grip overlap.

PROTRUDING HEAD

Correct blind bolt grip is a -02, since grip

range of -02 MAXIBOLT is .094 to .154.

MACHINE COUNTERSUNK

Read correct blind bolt grip to the top of the

sheet. Grip is sheet thickness plus blind bolt

head height. In this example, grip is -04 since

range of -04 MAXIBOLT is .219 to .282.

Note: Grip gage and grip ranges shown do not

apply to Titanium MAXIBOLT or MAXIBOLT Plus fasteners. For grip ranges of these fasteners,

see applicable part number Standard Page or contact Cherry Aerospace.

Grip

Dash No.

Grip Range

Min Max

01 .031 .095

02 .094 .157

03 .156 .220

04 .219 .282

05 .281 .345

06 .344 .407

07 .406 .470

08 .469 .532

09 .531 .595

10 .594 .657

11 .656 .720

12 .719 .782

13 .781 .845

14 .844 .907

15 .906 .970

16 .969 1.032

2468

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

CHERRY MAXBOLT GRP GAGE

2468

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

2468

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

2468

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

CHERRY MAXBOLT GRP GAGE

2468

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

2468

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

2468

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

CHERRY MAXBOLT GRP GAGE

2468

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

2468

1

0

1

2

1

4

1

6

1

8

2

0

2

2

2

4

2

6

2

8

3

0

12

DO NOT

apply

sealant

to these

areas

Apply

sealant

here ONLY

INSTALLATION AND INSPECTION

PROPER SEALANT APPLICATION

Blind bolts depend on a balance of lubricity

to friction, compression and radial expansion

during installation. In the manufacturing

process, lubricants are typically used to

ensure the blind bolt installs correctly.

Sealant should be applied ONLY around the

bolt sleeve (see illustration). It is critical that

the sealant does not touch the exposed areas

of the stem.

When sealant is applied to the fastener

incorrectly, two conditions may occur. Either

the stem of the fastener will pull high or all

the way through the bolt sleeve, or the stem

will break prematurely and will be too deep

in the bolt sleeve to be properly locked by

the lock collar. In either case, the bolt must

be removed and replaced. Initial care in the

application of sealant will eliminate this

replacement process.

13

INSTALLATION AND INSPECTION

MAXIBOLT

INSTALLATION

PLACING THE MAXIBOLT IN

THE HOLE

The holes in the sheets to be

fastened must be of correct

size and aligned properly.

Do not force the bolt into the

hole! Tack Rivets and/or

spring loaded fasteners are

recommended to minimize

material creep and sheet gap.

PLACING THE

PULLING HEAD ON

THE MAXIBOLT STEM

Hold the installation tool

and pulling head in line with

the axis of the bolt. Press

rmly against head of bolt to

minimize head gapping and

sheet gap.

Wreng Mlsallgned

Maxlbclt

Wreng Mlsallgned

Maxlbclt

"u" 1ype "5" 1ype

Pulllng

Fead

Pulllng

Fead

Pulllng

Fead

lnsert

Position of Pulling Head on MAXIBOLT

S Type U Type

Installation Alignment

Pulling

Head

Insert

14

INSTALLATION AND INSPECTION

MAXIBOLT INSTALLATION

(CONTINUED)

Hold the riveter

perpendicular to the work

piece as accurately as

possible. Apply a steady, rm

pressure and pull the trigger.

The MAXIBOLT clamping

action will hold the sheets

together, seat the head and

break the stem ush with the

head of the MAXIBOLT.

When the MAXIBOLT is

completely installed, release

the trigger and the stem will

be passed through the riveter

head. A stem catcher bag

may be obtained to collect

the spent stems.

15

MAXIBOLT INSPECTION & TROUBLE SHOOTING

Inspection for proper installation of the Cherry MAXIBOLT can be made from the visible side

of the work. The installation condition outlined below can be used to determine whether a

malfunction has been caused by:

Worker error

Incorrect hole preparation

Incorrect fastener selection

Improper tool function

MALFUNCTION CHARACTERISTICS

Malfunction of the Blind Bolt may be recognized by and identied as:

1. High Stem

2. Low Stem

3. Low Collar

4. High Collar

5. Head not seated

STEM POSITION

C max collar depth Low stem protrusion

C max

B max collar protrusion A max

Blind head

diameter

Protruding head Flush Head .002" feeler gage .002" feeler gage

C max collar depth Low stem protrusion

C max

B max collar protrusion A max

Blind head

diameter

Protruding head Flush Head .002" feeler gage .002" feeler gage

HIGH STEM LOW STEM

16

MAXIBOLT INSPECTION & TROUBLESHOOTING

STEM POSITIONS

ALLOY STEEL POSITIONS

Fastener

Diameter

A Max.

Acceptable Stem

Protrusion Limits

C Max

Acceptable Stem

Recession Limits

(2)

Blind Head

Minimum Diameter

5/32 (05) 0.020

.000

0.195

3/16 (06) 0.024 0.238

1/4 (08) 0.030 0.315

5/16 (10) 0.038 .0373

(1) Per NASM 81177.

(2) Stem nominal fracture surface may not recede below top of fastener head.

STAINLESS STEEL STEM POSITIONS

(3)

Fastener

Diameter

A Max

Acceptable Stem

Protrusion Limits

C Max

Acceptable Stem

Recession Limits

Blind Head

Minimum Diameter

1/8 (04) 0.010 0.010 0.154

5/32 (05) 0.010 0.010 0.195

3/16 (06) 0.010 0.010 0.238

1/4 (08) 0.015 0.015 0.315

5/16 (10) 0.020 0.020 0.373

(3) Per NASM 8975

TITANIUM STEM POSITIONS

(4)

Fastener

Diameter

A Max

Acceptable Stem

Protrusion Limits

C Max

Acceptable Stem

Recession Limits

Blind Head

Minimum Diameter

1/8 (04) 0.010 0.010 0.185

5/32 (05) 0.010 0.010 0.235

3/16 (06) 0.010 0.010 0.275

1/4 (08) 0.015 0.015 0.350

(4) Per Cherry Aerospace specification PS-CMB-7000

17

MAXIBOLT INSPECTION STEM POSITIONS

HIGH STEM

Probable causes for high stem break are:

Oversize hole

Overgrip fastener

Broken or worn down driving inner anvil

LOW STEM

Probable causes for low stem break are:

Undergrip fastener

Misaligned holes

Shallow, countersink for fush head

Blind side sheet angle over 5.

18

MAXIBOLT INSPECTION

COLLAR POSITION

C max collar depth Low stem protrusion

C max

B max collar protrusion A max

Blind head

diameter

Protruding head Flush Head .002" feeler gage .002" feeler gage

C max collar depth Low stem protrusion

C max

B max collar protrusion A max

Blind head

diameter

Protruding head Flush Head .002" feeler gage .002" feeler gage

LOW COLLAR HIGH COLLAR

ALLOY STEEL

(1)

Fastener

Diameter

B Max C Max

5/32 (05) 0.017 0.017

3/16 (06) 0.022 0.022

1/4 (08) 0.029 0.029

5/16 (10) 0.037 0.037

(1) Per NASM81177

STAINLESS STEEL AND TITANIUM

(2)

The collar must be ush or below top of

sleeve head.

Fastener

Diameter

C Max

1/8 (04) 0.015

5/32 (05) 0.017

3/32 (06) 0.022

1/4 (08) 0.029

5/16 (10) 0.037

(2) Per NASM8975 and Cherry Aerospace PS-CMB-7000

19

MAXIBOLT INSPECTION

COLLAR POSITION

Low collar position in excess of the maximum limit are probably caused by:

Excessive sheet gap

Over maximum grip

Incorrect shift pressure on double action tool

High collar position in excess of maximum limit are probably caused by

Installation tool being tipped during driving cycle

Interference between installation tool and some adjoining member, forcing tool out-

of-sequence

Inner anvil missing on double action tool

Broken or worn anvil

Shift pressure too high on double action tool

Blind side angle over 5.

20

MAXIBOLT INSPECTION

HEAD NOT SEATED

Improperly seated heads are probably caused by:

Misaligned or slanted hole

Installation tool tipped during driving cycle

Blind side angle over 5

Hole too small for extruding sleeve

Bad countersink

.002 gap permissible for 40% of fastener head diameter and must not penetrate to fastener

shank.

ADD NEW SECTION: INTERPRETATION OF BLIND HEAD SHAPES???

C max collar depth Low stem protrusion

C max

B max collar protrusion A max

Blind head

diameter

Protruding head Flush Head .002" feeler gage .002" feeler gage

C max collar depth Low stem protrusion

C max

B max collar protrusion A max

Blind head

diameter

Protruding head Flush Head .002" feeler gage .002" feeler gage

21

MAXIBOLT REMOVAL

Should it be necessary to remove an installed

MAXIBOLT, the following procedures are

recommended:

1. Center punch, center drill.

2. It is recommended that a small center drill be

used to provide a guide for a larger drill on top

of the blind bolt stem, and the upper portion of

the stem be drilled away to destroy the lock.

3. Drive out the stem using a punch pin.

4. Drill into blind bolt head avoiding contact with

the top sheet material.

5. Break off the blind bolt head using a punch pin

as a pry.

6. Drive out the remaining blind bolt shank with a

punch pin having a diameter equal to the bolt

shank.

CAUTION DO NOT drill completely through the

head or the sleeve to remove a blind bolt as this

will enlarge the hole.

Small

Center

urlll

Punch

Pln

22

INSTALLATION TOOL SELECTION CHART

CHERRY MAXIBOLT INTERCHANGEABILITY

Head

Style Material

Part Number

Cherry MS

Flush Head Alloy Steel CR7310S

CR7310U

CR7310

MS90353S

MS90353U

MS90353

Protruding Head Alloy Steel CR7311S

CR7311U

CR7311

MS90354S

MS90354U

MS90354

Flush Head A-286 CRES CR7620S

CR7620U

CR7620

MS21140S

MS21140U

MS21140

Protruding Head A-286 CRES CR7621S

CR7621U

CR7621

MS21141S

MS21141U

MS21141

MECHANICAL PROPERTIES

Diameter

Single Shear - lbs. Tensile - lbs.

Alloy Steel

112KSI

A-286

95KSI Alloy Steel A-286

-04 1222 675

-05 2340 1980 1350 1150

-06 3450 2925 2100 1690

-08 5900 5000 3650 2900

-10 8500 7200 5200 4170

CHERRY OVERSIZE MAXIBOLT

HEAD STYLE / MATERIAL

Head

Style Material

Part Number

Cherry

Flush

Head

Alloy

Steel

CR7340S

CR7340

Protruding

Head

Alloy

Steel

CR7341S

CR7341

Flush

Head

A-286

CRES

CR7650S

CR7650

Protruding

Head

A-286

CRES

CR7651S

CR7651

CHERRY MAXIBOLT PLUS

HEAD STYLE / MATERIAL

Head

Style Material

Part Number

Cherry

100 Flush Head

(AN509)

Stainless

Steel

CR7680S

Protruding Head Stainless

Steel

CR7683S

130 Flush Head Stainless

Steel

CR7684S

100 Flush Head

(MS20426)

Stainless

Steel

CR7686S

130 Flush Head Titanium CR7784S

23

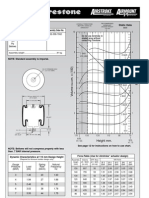

INSTALLATION TOOL SELECTION CHART

The tooling and pulling head combinations shown in the chart below will install the diameter

MAXIBOLTs indicated by the shaded areas, in all grip lengths, head styles and materials. Cherry

shift washer style only. (For U and - type MAXIBOLT installation tooling, please contact

Cherry Aerospace at 714-545-5511 or at the address listed on the back cover of this catalog.)

Riveter

Model

Pulling

Capacity

Height

Inches

Base

Dia.

Inches

Weight

Lbs.

Pulling

Head

Diameter (3)

1/8" 5/32" 3/16" 1/4" 5/16"

G704B 3136 11.0 4.9 4.5

H701B-456

H781-456

H782

H753A-456

G747 2100 11.37 4.56 3.5

H701B-456

H781-456

H782

H753A-456

G750A 3800 6.4 N/A 1.9

H750A-456

H781-456 (1)

H782(1)

H753A-456 (1)

H750A-5MB

H750A-6MB

G83 3750 11.5 4.9 4.7

H701B-456 (2)

H83B-5MB

H83B-6MB

G744 3800 12.6 6.25 7.0

H846A-456

H744-5MB

H744-6MB

G84 5750 13.25 6.25 7.7 H84A-8MB

G85D-S 6500 15.25 6.0 10.5 H652-8MB

G87D 9400 15.25 6.0 10.5 H652-8MB

(1) Requires 750A-088 adapter. (2) Requires 744-300 adapter. (3) For 5/16" MAXIBOLT installation tooling contact Cherry

Aerospace.

MAXIBOLT PLUS

Installation Tool Pulling Head Fastener Diameter

G83 H84B-568 -05, -06

G84 H84B-568 -05, -06, -08

24

DECIMAL EQUIVALENT CHART

NOM.

SIZE M/M DECIMAL

NOM.

SIZE M/M DECIMAL

NOM.

SIZE M/M DECIMAL

NOM.

SIZE

M/M DECIMAL

.1 .0039 45 .0820 5 .2055 7/16

.4375

.2 .0079 44 .0860 4 .2090 29/64

.4531

.3 .0118 43 .0890 3 .2130 15/32

.4687

80 .0135 42 .0935 7/32 .2187

12. .4724

79 .0145 3/32 .0937 2 .2210 31/64

.4844

1/64 .0156 41 .0960 1 .2280 1/2

.5000

.4 .0157 40 .0980 A .2340

13. .5118

78 .0160 39 .0995 15/64 .2344 33/64

.5156

77 .0180 38 .1015 6. .2362 17/32

.5312

.5 .0197 37 .1040 B .2380 35/64

.5469

76 .0200 36 .1065 C .2420

14. .5512

75 .0210 7/64 .1094 D .2460 9/16

.5625

74 .0225 35 .1100 1/4 .2500 37/64

.5781

.6 .0236 34 .1110 E .2500

15. .5906

73 .0240 33 .1130 F .2570 19/32

.5937

72 .0250 32 .1160 0 .2610 39/64

.6094

71 .0260 3. .1181 17/64 .2656 5/8

.6250

.7 .0276 31 .1200 H .2660

16. .6299

70 .0280 1/8 .1250 1 .2720 41/64

.6406

69 .0292 30 .1285 7. .2756 21/32

.6562

68 .0310 29 .1360 1 .2770

17. .6693

1/32 .0312 28 .1405 K .2810 43/64

.6719

.8 .0315 9/64 .1406 9/32 .2812 11/16

.6875

67 .0320 27 .1440 L .2900 14/64

.7031

66 .0330 26 .1470 M .2950

18. .7087

65 .0350 25 .1495 19/64 .2969 23/32

.7187

25

NOM.

SIZE M/M DECIMAL

NOM.

SIZE M/M DECIMAL

NOM.

SIZE M/M DECIMAL

NOM.

SIZE

M/M DECIMAL

.9 .0354 24 .1520 N .3020 47/64

.7344

64 .0360 23 .1540 5/16 .3125

19. .7480

63 .0370 5/32 .1562 8. .3150 3/4

.7500

62 .0380 22 .1570 0 .3160 49/64

.7656

61 .0390 4. .1575 P .3230 25/32

.7812

1. .0394 21 .1590 21/64 .3281

20. .7874

60 .0400 20 .1610 0 .3320 51/64

.7969

59 .0410 19 .1660 P .3390 13/16

.8125

58 .0420 18 .1695 11/32 .3437

21. .8268

57 .0430 11/64 .1719 S .3480 53/64

.8281

56 .0465 17 .1730 9. .3543 27/32

.8437

3/64 .0469 16 .1770 T .3580 55/64

.8594

55 .0520 15 .1800 23/64 .3594

22. .8661

54 .0550 14 .1820 U .3680 7/8

.8750

53 .0595 13 .1850 3/8 .3750 57/64

.8906

1/16 .0625 3/16 .1875 V .3770

23. .9055

52 .0635 12 .1890 W .3860 29/32

.9062

51 .0670 11 .1910 25/64 .3906 59/64

.9219

50 .0700 10 .1935 10. .3937 15/16

.9375

49 .0730 9 .1960 X .3970

24. .9449

48 .0760 5. .1968 V .4040 61/64

.9531

5/64 .0781 8 .1990 13/32 .4062 31/32

.9687

47 .0785 7 .2010 Z .4130

25. .9842

2. .0787 13/64 .2031 27/64 .4219 63/64

.9844

46 .0810 6 .2040 11. .4331 1

25.4 1.000

2009 Cherry Aerospace

Suppliers Federal I.D. Code 11815

CA-1039 Date: 1-10-09 CR#: 08-1628

1224 East Warner Avenue, Santa Ana, CA 92705

voice: 714-545-5511 fax: 714-850-6093

www.cherryaerospace.com

Potrebbero piacerti anche

- Ca 1015 PDFDocumento32 pagineCa 1015 PDFArjun PanditNessuna valutazione finora

- Stressing CatalogueDocumento24 pagineStressing CatalogueAdinarayana RaoNessuna valutazione finora

- FIS113eng Hi Temp BellowsDocumento8 pagineFIS113eng Hi Temp Bellowsmahesh_eilNessuna valutazione finora

- Fire Damper Installation 2Documento9 pagineFire Damper Installation 2Mirza Mohammed Yousuf BaigNessuna valutazione finora

- Catálogo de Camisas MELLINGDocumento24 pagineCatálogo de Camisas MELLINGricassterNessuna valutazione finora

- Self-Locking Fasteners: 4 Tips Every Engineer Should KnowDocumento7 pagineSelf-Locking Fasteners: 4 Tips Every Engineer Should Knowcamohunter71100% (1)

- Shaft Strain Gaging Guide v4Documento11 pagineShaft Strain Gaging Guide v4craigNessuna valutazione finora

- Flupec Catalog Etansari Translatie PDFDocumento446 pagineFlupec Catalog Etansari Translatie PDFRadu VasileNessuna valutazione finora

- BIG Kaiser Accessories Vol. 2Documento24 pagineBIG Kaiser Accessories Vol. 2lizarazojavierNessuna valutazione finora

- Mechanical Seal Installation InstructionDocumento4 pagineMechanical Seal Installation InstructionSandi AslanNessuna valutazione finora

- Melling Cylinder Sleeves 2014 CatalogDocumento40 pagineMelling Cylinder Sleeves 2014 CatalogBzidroglioNessuna valutazione finora

- 2100d Installation GuideDocumento20 pagine2100d Installation GuideJazz TubaNessuna valutazione finora

- Textar Fitting Instructions enDocumento8 pagineTextar Fitting Instructions enKhristina StefanovaNessuna valutazione finora

- ATA70standard Practice EngineDocumento24 pagineATA70standard Practice EnginearunNessuna valutazione finora

- Heli-Coil Catalog HC2000 Rev12Documento40 pagineHeli-Coil Catalog HC2000 Rev12anon_512891835Nessuna valutazione finora

- Ba 42-06Documento16 pagineBa 42-06Thameemul BuhariNessuna valutazione finora

- Superline & Implantium: Product CatalogDocumento74 pagineSuperline & Implantium: Product Cataloghaidangvta38Nessuna valutazione finora

- Melling Cylinder Sleeves CatalogDocumento49 pagineMelling Cylinder Sleeves Catalogfishhunter18100% (1)

- Rotary Products 5632Documento40 pagineRotary Products 5632Pablo AbalosNessuna valutazione finora

- Impact Socket PDFDocumento40 pagineImpact Socket PDFMr. S.L. AdvaniNessuna valutazione finora

- Specifications TorqueDocumento20 pagineSpecifications Torquethoma111s100% (2)

- Installation and maintenance instructions for John Crane seal models 670 and 680Documento6 pagineInstallation and maintenance instructions for John Crane seal models 670 and 680Steve EbenezerNessuna valutazione finora

- 600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)Documento8 pagine600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)LeonardNessuna valutazione finora

- O Ring Catalogue 2022Documento179 pagineO Ring Catalogue 2022Muhammad Kamran AsgharNessuna valutazione finora

- W02 M58 3001Documento30 pagineW02 M58 3001MROstop.comNessuna valutazione finora

- W02 358 7010Documento30 pagineW02 358 7010MROstop.comNessuna valutazione finora

- Installation and Operating Instructions for RLK 402 Cone Clamping ElementsDocumento5 pagineInstallation and Operating Instructions for RLK 402 Cone Clamping ElementshamishjbadamsonNessuna valutazione finora

- 02 Circular Duct SystemsDocumento42 pagine02 Circular Duct SystemsDiki PrayogoNessuna valutazione finora

- Corona Piñon de MolinosDocumento31 pagineCorona Piñon de Molinosstoneblind100% (1)

- Remove & Install Connecting Rod BearingsDocumento4 pagineRemove & Install Connecting Rod BearingsRichard ChuaNessuna valutazione finora

- Brochure Complete Instrument Valve Solution Tescom Anderson Greenwood Instrumentation en 6272716Documento8 pagineBrochure Complete Instrument Valve Solution Tescom Anderson Greenwood Instrumentation en 6272716Joshua Garcia CarrilloNessuna valutazione finora

- W02 358 7012Documento30 pagineW02 358 7012MROstop.comNessuna valutazione finora

- W02 M58 3019Documento30 pagineW02 M58 3019MROstop.comNessuna valutazione finora

- Understanding - Unbrako Fasteners (Technical Brochure)Documento48 pagineUnderstanding - Unbrako Fasteners (Technical Brochure)pavan_jssatebNessuna valutazione finora

- W02 M58 5001Documento30 pagineW02 M58 5001MROstop.comNessuna valutazione finora

- Gets InglesDocumento1.088 pagineGets InglesKjatunMayu Gutierrez100% (6)

- Cherry MS RivetsDocumento17 pagineCherry MS RivetsKamal Jit Dhiman100% (1)

- Installation Instructions 8-Point Roll BarDocumento6 pagineInstallation Instructions 8-Point Roll BarDamien DrakeNessuna valutazione finora

- Description Assembly Order No.: Static DataDocumento30 pagineDescription Assembly Order No.: Static DataMROstop.comNessuna valutazione finora

- Mechanical Face Seals enDocumento20 pagineMechanical Face Seals endafy1986Nessuna valutazione finora

- Installation - Ring Gear Installation ManualDocumento31 pagineInstallation - Ring Gear Installation ManualManuel Ortiz86% (7)

- W02 M58 3002Documento30 pagineW02 M58 3002MROstop.comNessuna valutazione finora

- Rebitadora Rivit Riv938ManualDocumento48 pagineRebitadora Rivit Riv938ManualRobson LimeiraNessuna valutazione finora

- W02 358 7002Documento30 pagineW02 358 7002MROstop.comNessuna valutazione finora

- Api Plan 11Documento6 pagineApi Plan 11johnsaballaNessuna valutazione finora

- Flowserve Seal - ISC2 - Install - LTRDocumento8 pagineFlowserve Seal - ISC2 - Install - LTRjame11inNessuna valutazione finora

- Conveyor Assembly Manual PDFDocumento68 pagineConveyor Assembly Manual PDFzaiayra71Nessuna valutazione finora

- Installation Manual Ra r3Documento17 pagineInstallation Manual Ra r3Carlos EscalonaNessuna valutazione finora

- Aircraft Hardware FastenersDocumento36 pagineAircraft Hardware FastenersUmar HasanNessuna valutazione finora

- SBC (Safety Break-Away Couplings) v140630Documento16 pagineSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- 101i-Super C Hydraulic Saw ManualDocumento68 pagine101i-Super C Hydraulic Saw Manualgeorge israelNessuna valutazione finora

- Small Block Chevrolet: Stock and High-Performance RebuildsDa EverandSmall Block Chevrolet: Stock and High-Performance RebuildsValutazione: 4 su 5 stelle4/5 (6)

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallDa EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallValutazione: 4 su 5 stelle4/5 (8)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderDa EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderValutazione: 5 su 5 stelle5/5 (2)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDa EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreValutazione: 4.5 su 5 stelle4.5/5 (11)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionDa EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNessuna valutazione finora

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDa EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNessuna valutazione finora

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Helicopter Sizing and CalculationsDocumento117 pagineHelicopter Sizing and Calculationsmoj33Nessuna valutazione finora

- Helicopter Sizing and CalculationsDocumento117 pagineHelicopter Sizing and Calculationsmoj33Nessuna valutazione finora

- Basic Airframe RepairDocumento105 pagineBasic Airframe Repairmoj33Nessuna valutazione finora

- Advanced Composite Rotor Blade-United TechnologiesDocumento7 pagineAdvanced Composite Rotor Blade-United Technologiesmoj33Nessuna valutazione finora

- Optimising The Lamination Properties of Textile CompositesDocumento181 pagineOptimising The Lamination Properties of Textile Compositesmoj33100% (2)

- Longitudinal Static Stability and Control - Effect of AccelerationDocumento12 pagineLongitudinal Static Stability and Control - Effect of Accelerationmoj33Nessuna valutazione finora

- US Army Aviation Course - Basic Airframe Repair AL0992Documento104 pagineUS Army Aviation Course - Basic Airframe Repair AL0992Anand R NairNessuna valutazione finora

- Abaqus Simulating Thermal Expansion PDFDocumento20 pagineAbaqus Simulating Thermal Expansion PDFhasib75% (4)

- Process Characterization of Composite Structures Manufactured Using Resin Impregnation TechniquesDocumento140 pagineProcess Characterization of Composite Structures Manufactured Using Resin Impregnation Techniquesmoj33Nessuna valutazione finora

- Abaqus Simulating Thermal Expansion PDFDocumento20 pagineAbaqus Simulating Thermal Expansion PDFhasib75% (4)

- Mechanic of Materials (Normal Stress)Documento44 pagineMechanic of Materials (Normal Stress)moj33Nessuna valutazione finora

- (Balke Et Al) Tail Rotor Design Part II Structural Dynamics PDFDocumento15 pagine(Balke Et Al) Tail Rotor Design Part II Structural Dynamics PDFmoj33Nessuna valutazione finora

- Aircraft RotorcraftDocumento26 pagineAircraft Rotorcraftmoj33Nessuna valutazione finora

- (Lynn Et Al) Tail Rotor Design Part I Aerodynamics PDFDocumento14 pagine(Lynn Et Al) Tail Rotor Design Part I Aerodynamics PDFmoj33Nessuna valutazione finora

- Helicopter EngineeringDocumento35 pagineHelicopter Engineeringmoj33Nessuna valutazione finora

- Influence of Surface Finish On Bending Fatigue of Forged Steel Including Heating Method, Hardness, and Shot Cleaning EffectsDocumento237 pagineInfluence of Surface Finish On Bending Fatigue of Forged Steel Including Heating Method, Hardness, and Shot Cleaning Effectsmoj33Nessuna valutazione finora

- Polymer CompositeDocumento7 paginePolymer Compositemoj33Nessuna valutazione finora

- BS 2782-8-Method 820A-1996 (1998) Methods of Testing Plastics. Other Properties. Determination of Water Vapour Transmission Rate (Dish Method) .Documento17 pagineBS 2782-8-Method 820A-1996 (1998) Methods of Testing Plastics. Other Properties. Determination of Water Vapour Transmission Rate (Dish Method) .ironfaceNessuna valutazione finora

- Nalco at A Glance: Chapter - 2Documento74 pagineNalco at A Glance: Chapter - 2Aditya AnandNessuna valutazione finora

- Pem NutDocumento16 paginePem Nut최영현Nessuna valutazione finora

- Liberating valuables from tailings with ball mill designDocumento5 pagineLiberating valuables from tailings with ball mill designEngineering Office ShahrakNessuna valutazione finora

- Filter-Regulator Introduction & SpecificationsDocumento2 pagineFilter-Regulator Introduction & SpecificationsPeter RhoadsNessuna valutazione finora

- Mounting and Maintenance of LM GuidesDocumento14 pagineMounting and Maintenance of LM GuidesAmudha BoobalanNessuna valutazione finora

- AS 1167.1 - 1993 Welding & Brazing - Filler Metals - FillerDocumento13 pagineAS 1167.1 - 1993 Welding & Brazing - Filler Metals - FillerRobart JacobNessuna valutazione finora

- Techniques Tips For Polishing PDFDocumento6 pagineTechniques Tips For Polishing PDFrobin parmarNessuna valutazione finora

- AWS A5-8 2004 Filler Metals For BrazingDocumento47 pagineAWS A5-8 2004 Filler Metals For BrazingEmelda JulianNessuna valutazione finora

- WLD 222 Gas Tungsten Arc Welding AluminumDocumento97 pagineWLD 222 Gas Tungsten Arc Welding Aluminumalejandro chavezNessuna valutazione finora

- Budget & Budgetary Control 2Documento113 pagineBudget & Budgetary Control 2Sunita Sarkar100% (5)

- BULLDOG Industrial CatalogueDocumento12 pagineBULLDOG Industrial CatalogueHYDRO-LECNessuna valutazione finora

- CGS Catalog Summer 2020Documento45 pagineCGS Catalog Summer 2020Angel Adan Llamas YañezNessuna valutazione finora

- Class 10 Manufacturing Question BankDocumento20 pagineClass 10 Manufacturing Question BankBadma VebushiniNessuna valutazione finora

- Petronas Technical Standards: GratingsDocumento18 paginePetronas Technical Standards: GratingsFirdausi Fauzi100% (1)

- Three Roll Mills Quality Dispersing Finest ResultsDocumento20 pagineThree Roll Mills Quality Dispersing Finest ResultsLuis Miguel Lopez CarrilloNessuna valutazione finora

- 875c Series Api Dust Cap Data SheetDocumento2 pagine875c Series Api Dust Cap Data SheetL.kolekarNessuna valutazione finora

- Catalogue-Spiral Wound Gasket PDFDocumento85 pagineCatalogue-Spiral Wound Gasket PDFHoang DungNessuna valutazione finora

- 1a Arc Weld ProcessesDocumento45 pagine1a Arc Weld ProcessesskgcNessuna valutazione finora

- Chapter 03 Standard ComponentsDocumento101 pagineChapter 03 Standard ComponentsFilipe GiesteiraNessuna valutazione finora

- BS 7079-2009 General Introduction To Standards For The Preparation of Steel Substrates Before Application of Paints and Related ProductsDocumento18 pagineBS 7079-2009 General Introduction To Standards For The Preparation of Steel Substrates Before Application of Paints and Related ProductsGavinNessuna valutazione finora

- Fabrication Requirements For Radiant Coils of SCORE FurnacesDocumento10 pagineFabrication Requirements For Radiant Coils of SCORE FurnacesAleem QureshiNessuna valutazione finora

- AVK Water Supply BrochureDocumento52 pagineAVK Water Supply BrochureHARSHANessuna valutazione finora

- Creep Fatigue Behaviour of Type 321 Stainless Steel at 650 UcDocumento22 pagineCreep Fatigue Behaviour of Type 321 Stainless Steel at 650 Ucadarshravindran1991Nessuna valutazione finora

- Edge Gilding and Edge Coloring of Books: Peter Geraty Praxis BookbinderyDocumento19 pagineEdge Gilding and Edge Coloring of Books: Peter Geraty Praxis BookbinderyEnrique WoolfolkNessuna valutazione finora

- Lecture 1 Introduction Sem 1 2022 23 Bmfb3323Documento54 pagineLecture 1 Introduction Sem 1 2022 23 Bmfb3323Idham NasrulNessuna valutazione finora

- Kanhaiya Brass IndustriesDocumento20 pagineKanhaiya Brass IndustriesAnonymous eZyrYDWAZNessuna valutazione finora

- NTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Documento18 pagineNTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Corrosion Factory100% (1)

- Saudi Aramco Inspection ChecklistDocumento5 pagineSaudi Aramco Inspection Checklistnisha_khanNessuna valutazione finora

- Experiment No. 1: Introduction To Metal Joining Process 1. WeldingDocumento4 pagineExperiment No. 1: Introduction To Metal Joining Process 1. Weldingprasoon pathakNessuna valutazione finora