Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Triaxial Test

Caricato da

Maysara Maawia Mukhtar0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni7 paginem

Titolo originale

Triaxial Test (2)

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentom

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni7 pagineTriaxial Test

Caricato da

Maysara Maawia Mukhtarm

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

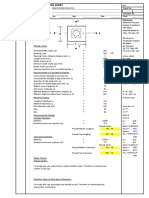

RESULT / CALCULATION

Client UNISEL Lab Ref

Project

Job TEST LAB

Borehole

Sample 1

Test Details

Standard BS 1377 : Part 7 : Clause 8 Particle Density 2.65 Mg/m3

Sample Type Lab. Temperature 27.0 deg.C

Sample Description

Variations from Procedure None

Specimen Details

Specimen Reference

A1

Stage Reference 1

Depth within Sample 0.00mm Description

Initial Height 76.00 mm Orientation within Sample

Preparation Initial Diameter 38.00 mm

Initial Bulk Density 2.09 Mg/m3 Initial Moisture Content* 12.0 %

Initial Dry Density 1.86 Mg/m3 Membrane Thickness 0.20 mm

Comments

* Calculated from initial and dry weights of whole specimen

0

10

20

30

40

50

0 0.5 1 1.5 2 2.5 3

C

o

r

r

e

c

t

e

d

D

e

v

i

a

t

o

r

S

t

r

e

s

s

k

P

a

Axial Strain %

Shearing Stage (Stress Vs Axial Strain %)

Client UNISEL Lab Ref

Project

Job TEST LAB

Borehole

Sample 1

Tested By and

Date:

Checked By

and Date:

Approved By

and Date:

Shear Conditions

Rate of Axial Strain 1.32%/min Cell Pressure 101.0kPa

Conditions at Failure

Failure Criterion Maximum Deviator Stress or Maximum allowed Strain

Maximum Corrected

Deviator Stress

56kPa Shear Strength 28kPa

Axial Strain 1.81%

Deviator Stress Correction 0.3 kPa

Final Density 2.09 Mg/m3 Final Moisture Content 12.0 %

Mode of Failure

Client UNISEL Lab Ref

Project

Job TEST LAB

Borehole

Sample 1

Test Details

Standard BS 1377 : Part 7 : Clause 8 Particle Density 2.65 Mg/m3

Sample Type Lab. Temperature 27.0 deg.C

Sample Description

Variations from Procedure None

Specimen Details

Specimen Reference

B1

Stage Reference 1

Depth within Sample 0.00mm Description

Initial Height 76.00 mm Orientation within Sample

Preparation Initial Diameter 38.00 mm

Initial Bulk Density 2.09 Mg/m3 Initial Moisture Content* 12.3 %

Initial Dry Density 1.86 Mg/m3 Membrane Thickness 0.20 mm

Comments

* Calculated from initial and dry weights of whole specimen

0

10

20

30

40

50

60

70

80

0 0.5 1 1.5 2 2.5

C

o

r

r

e

c

t

e

d

D

e

v

i

a

t

o

r

S

t

r

e

s

s

k

P

a

Axial Strain %

Shearing Stage (Stress Vs Axial Strain %)

Client UNISEL Lab Ref

Project

Job TEST LAB

Borehole

Sample 1

Tested By and

Date:

Checked By

and Date:

Approved By

and Date:

Shear Conditions

Rate of Axial Strain 1.32%/min Cell Pressure 200.7kPa

Conditions at Failure

Failure Criterion Maximum Deviator Stress or Maximum allowed Strain

Maximum Corrected

Deviator Stress

85kPa Shear Strength 43kPa

Axial Strain 2.32%

Deviator Stress Correction 0.3 kPa

Final Density 2.09 Mg/m3 Final Moisture Content 12.3 %

Mode of Failure

Client UNISEL Lab Ref

Project

Job TEST LAB

Borehole

Sample 1

Test Details

Standard BS 1377 : Part 7 : Clause 8 Particle Density 2.65 Mg/m3

Sample Type Lab. Temperature 27.0 deg.C

Sample Description

Variations from Procedure None

Specimen Details

Specimen Reference

C1

Stage Reference 1

Depth within Sample 0.00mm Description

Initial Height 76.00 mm Orientation within Sample

Preparation Initial Diameter 38.00 mm

Initial Bulk Density 2.09 Mg/m3 Initial Moisture Content* 12.3 %

Initial Dry Density 1.86 Mg/m3 Membrane Thickness 0.20 mm

Comments

* Calculated from initial and dry weights of whole specimen

0

20

40

60

80

100

120

0 0.5 1 1.5 2 2.5 3

C

o

r

r

e

c

t

e

d

D

e

v

i

a

t

o

r

S

t

r

e

s

s

k

P

a

Axial Strain %

Shearing Stage (Stress Vs Axial Strain %)

Client UNISEL Lab Ref

Project

Job TEST LAB

Borehole

Sample 1

Tested By and

Date:

Checked By

and Date:

Approved By

and Date:

Shear Conditions

Rate of Axial Strain 1.32%/min Cell Pressure 401.1kPa

Conditions at Failure

Failure Criterion Maximum Deviator Stress or Maximum allowed Strain

Maximum Corrected

Deviator Stress

126kPa Shear Strength 63kPa

Axial Strain 2.82%

Deviator Stress Correction 0.4 kPa

Final Density 2.09 Mg/m3 Final Moisture Content 12.3 %

Mode of Failure

SUMMARY

All Stages

Conditions at Failure

Ref

Cell

Pressure

Max. Corrected

Deviator Stress

Cumulative

Strain

Mode of Failure Shear

Strength

Stage1 101.0kPa 56kPa 1.81% Maximum Deviator Stress

or Maximum allowed

Strain

28kPa

Stage2 200.7kPa 85kPa 2.32% Maximum Deviator Stress

or Maximum allowed

Strain

43kPa

Stage3 401.1kPa 126kPa 2.82% Maximum Deviator Stress

or Maximum allowed

Strain

63kPa

Potrebbero piacerti anche

- Final ExamDocumento5 pagineFinal ExamMaysara Maawia MukhtarNessuna valutazione finora

- Biomass Energy LectureDocumento9 pagineBiomass Energy LectureRishant YadavNessuna valutazione finora

- Recap - Final ExamDocumento6 pagineRecap - Final ExamMaysara Maawia MukhtarNessuna valutazione finora

- Assignment#1 RecapDocumento2 pagineAssignment#1 RecapMaysara Maawia MukhtarNessuna valutazione finora

- Member AE EG EF BC BDDocumento1 paginaMember AE EG EF BC BDMaysara Maawia MukhtarNessuna valutazione finora

- Biomass Energy LectureDocumento9 pagineBiomass Energy LectureRishant YadavNessuna valutazione finora

- Assignment PDFDocumento2 pagineAssignment PDFMaysara Maawia MukhtarNessuna valutazione finora

- Assignment PDFDocumento2 pagineAssignment PDFMaysara Maawia MukhtarNessuna valutazione finora

- Biomass Energy LectureDocumento9 pagineBiomass Energy LectureRishant YadavNessuna valutazione finora

- IntroductionDocumento1 paginaIntroductionMaysara Maawia MukhtarNessuna valutazione finora

- 6-Energy Loss in BendsDocumento12 pagine6-Energy Loss in BendsMaysara Maawia Mukhtar60% (10)

- Fluid Mechanics: Laboratory ManualDocumento8 pagineFluid Mechanics: Laboratory Manualloki654321Nessuna valutazione finora

- Glass Fiber Manufacturing Is The HighDocumento10 pagineGlass Fiber Manufacturing Is The HighMaysara Maawia MukhtarNessuna valutazione finora

- Losses in Bends FittingsDocumento26 pagineLosses in Bends Fittingsdainer08Nessuna valutazione finora

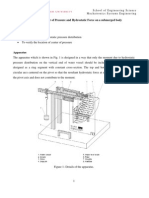

- Center of Pressure and Hydrostatic Force On A Submerged Body-RevDocumento7 pagineCenter of Pressure and Hydrostatic Force On A Submerged Body-RevAnkit MittalNessuna valutazione finora

- Hooke's Law Lab Report 1 SunealDocumento5 pagineHooke's Law Lab Report 1 SunealMonari Perera67% (3)

- STR AnalysisDocumento136 pagineSTR AnalysisWeha Yu100% (1)

- CE 428 Trickling Filters-StuDocumento4 pagineCE 428 Trickling Filters-StuMaysara Maawia MukhtarNessuna valutazione finora

- Exp 3 - Impact of A Jet - NewDocumento5 pagineExp 3 - Impact of A Jet - NewaadhanNessuna valutazione finora

- As Highway Engineering EquipmentDocumento6 pagineAs Highway Engineering EquipmentMaysara Maawia MukhtarNessuna valutazione finora

- National PolicenvironmentalDocumento12 pagineNational PolicenvironmentalMaysara Maawia MukhtarNessuna valutazione finora

- Announcement For Prof Chin Lecture 2013 FinalDocumento2 pagineAnnouncement For Prof Chin Lecture 2013 FinalMaysara Maawia MukhtarNessuna valutazione finora

- Chapter 1 Lecture1 Kcs3233Documento40 pagineChapter 1 Lecture1 Kcs3233Maysara Maawia MukhtarNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- On The Move - Exam Style QsDocumento8 pagineOn The Move - Exam Style QsAdam ChiangNessuna valutazione finora

- Cad Cam SyllabusDocumento4 pagineCad Cam SyllabuskrishrathoreNessuna valutazione finora

- Pilecap Sizing: Bukit Keteri (Pg3-Pc1)Documento8 paginePilecap Sizing: Bukit Keteri (Pg3-Pc1)azwanNessuna valutazione finora

- Fuel System With Unit Injector PDE and EDC MS6: Issue 2Documento60 pagineFuel System With Unit Injector PDE and EDC MS6: Issue 2Musharraf KhanNessuna valutazione finora

- Abutment (7m Hight)Documento8 pagineAbutment (7m Hight)Kamran AhmedNessuna valutazione finora

- Wheel Loaders VocabularyDocumento10 pagineWheel Loaders VocabularyLyanHyangNessuna valutazione finora

- Bala CVDocumento3 pagineBala CVMukesh RavalNessuna valutazione finora

- Sl20 Cg20 Parts Manual Ph7 Opl Pn-450222 (Rev-2) 042803Documento29 pagineSl20 Cg20 Parts Manual Ph7 Opl Pn-450222 (Rev-2) 042803naokito AkemiNessuna valutazione finora

- D7918-En (LHT)Documento15 pagineD7918-En (LHT)Asa ReidNessuna valutazione finora

- Analysis of Continuous Folded Plate Roofs PDFDocumento75 pagineAnalysis of Continuous Folded Plate Roofs PDFMohammed AbidNessuna valutazione finora

- Compressor and Compressed Air SystemDocumento34 pagineCompressor and Compressed Air Systemrashm006ranjanNessuna valutazione finora

- Internal FlowDocumento7 pagineInternal FlowLester Lim0% (1)

- An 400Documento475 pagineAn 400Александр КобзарьNessuna valutazione finora

- Nptel Assignments & Solutions: Chapter 1: Introduction and Fundamental ConceptsDocumento7 pagineNptel Assignments & Solutions: Chapter 1: Introduction and Fundamental ConceptsPanneer SelvamNessuna valutazione finora

- GMX Complete KnowledgeDocumento36 pagineGMX Complete KnowledgeSoumen PandaNessuna valutazione finora

- Chemical CompositionDocumento6 pagineChemical CompositionAkbar DarmawansyahNessuna valutazione finora

- Rocker 400 Introduction Manual en - V2016.03 enDocumento5 pagineRocker 400 Introduction Manual en - V2016.03 endayanara886Nessuna valutazione finora

- Economic Surge Tank DesignDocumento6 pagineEconomic Surge Tank DesigncsimsekNessuna valutazione finora

- SEM816D Track Type Tractor - TSU - LowDocumento2 pagineSEM816D Track Type Tractor - TSU - LowRivandho AnangNessuna valutazione finora

- BUFAB Order From Chaos 2012Documento134 pagineBUFAB Order From Chaos 2012JacobNessuna valutazione finora

- L-600 Parts ManualDocumento64 pagineL-600 Parts Manualheartofdixie71% (7)

- Robotics and Vision SystemDocumento64 pagineRobotics and Vision Systemasuras1234Nessuna valutazione finora

- Advanced Aerodynamics: Lecture 2: Turbulence Models Applied To AerodynamicsDocumento66 pagineAdvanced Aerodynamics: Lecture 2: Turbulence Models Applied To AerodynamicsCarlos Aparisi CanteroNessuna valutazione finora

- Fire Pump Proposal Summary: WeightDocumento3 pagineFire Pump Proposal Summary: WeightDerkung BenowatNessuna valutazione finora

- CFD Is 456 200Documento80 pagineCFD Is 456 200Ali BaghbanNessuna valutazione finora

- Calendering MachineDocumento15 pagineCalendering MachineKumar Gaurav100% (1)

- Atomic Term SymbolsDocumento4 pagineAtomic Term SymbolsM IkhsanNessuna valutazione finora

- Assignment 1: Part 1 Locate of Relief Dehydrogenation of Isopropyl Alcohol (IPA) To Acetone Piping & Instrumentation DiagramDocumento3 pagineAssignment 1: Part 1 Locate of Relief Dehydrogenation of Isopropyl Alcohol (IPA) To Acetone Piping & Instrumentation DiagramHewYanNessuna valutazione finora

- Honda E-StormDocumento104 pagineHonda E-StormJaimeDiazDiazNessuna valutazione finora

- U 25Documento90 pagineU 25baracuss323iNessuna valutazione finora