Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bien Tan Mitsubishi

Caricato da

Thinh DaoDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bien Tan Mitsubishi

Caricato da

Thinh DaoCopyright:

Formati disponibili

Quick start and

reference guide

INVERTERS

DRIVE SYSTEMS

Installation /// Wiring /// Settings ///

Basic parameters /// Simple error codes ///

Regular maintenance ///

Drives to rely on

As a major global supplier of inverters, Mitsubishi has a reputation

for using leading technology to produce the most reliable products.

Did you know:

Mitsubishi is the largest volume producer of inverters in the world.

IMS, the International market research company, has voted

Mitsubishis inverters most reliable in the past years.

Mitsubishi invests over 6 % of its turnover in research and development.

www.mitsubishi-automation.com

Quick start guide /// Quick start guide /// Quick start guide ///

Getting started 4

Knowyour inverter 5

Mitsubishi inverter ranges 5/6

Programming panels 7

Inverter programming panels 7/8

Installation and mounting 9

General precautions 9/10

Wiring 11

Good earthing practice 11/12

Basic operation 13

Setting a frequency 13

Setting a parameter 14

Monitoring operation 15

Basic parameters 16/17

Common error codes 18/19

Regular maintenance 20

Common installation problems 21

My drive settings / Safety warning 22

Contents

Quick start guide /// Quick start guide /// Quick start guide ///

4 www.mitsubishi-automation.com

Getting started /// Getting started /// Getting started /// Know

Start

Installation and

mounting

Wiring of the power

supply and motor

Starting the inverter

End

Start-up route map

Set basic

parameters

REGULAR MAINTENANCE

Once the Inverter has been set-up and commissioned a series of regular

maintenance checks should be performed to monitor the Inverter and

motor performance is still at an optimum.

MITSUBISHI

MITSUBISHI

5

Mitsubishi Inverter Ranges

FR-D700

Aluminium heat sink

Power input and

motor wiring point

FR-E700

Power input and motor

wiring point

Network connection is

located underneath

front cover

wyour inverter /// Knowyour inverter /// Knowyour inverter

Programming and

operation display

7 segment

Removable front cover

Quick setting

control dial

Main body of Inverter

Standard display

Removable

front cover

Aluminium

heat sink

Main body

of Inverter

Option and

network

boards are

fitted

underneath

front cover

Know your inverter /// Know your inverter /// Know your in

FR-F700

FR-A700 Hz MON

MITSUBISHI

PU

REV

REV

SET

EXT

PU

EXT

STOP

RESET

NET

FWD

FWD

MODE

P.RUN

FR-DU07

FRF7402.2K

DANGER: Risk of injury and electric shock

CAUTION: Risk of fire

l a u n a m e h t d a e R

and follow the safety instruct s u e r o f e b s n o i e.

Iso s m o r f e t a l upply and wait 10 minutes before removing this cover.

Ensure proper earth connection

c - n o n a n o r e t r e v n i e h t t n u o M

ombustible surface.

A

V

FREQROL- F700

400V

!

!

Option and network

boards are fitted

underneath front cover

6 www.mitsubishi-automation.com

Replaceable fan

Aluminium

heat sink

Main body

of Inverter

Programming and

operation display

7 segment

Quick setting

control dial

Removable

front cover

Power input and

motor wiring point

Using the digital dial

The digital setting dial allows quick and easy selection

of parameters and the setting of parameter values.

The digital setting dial performs the function of the

traditional keys as found on the FR-PU04 and

FR-PU07 etc. All other buttons operate in a similar way

to those found on traditional control units.

Using the setting key

At power-on the inverter is put in the external operation

mode. The operation mode can be changed between the

PU and External operation mode by pressing the key or

the key (dependent on control panel

FR-D700/E700

embedded control panel

FR-F700/A700

removable control panel

nverter /// Programming panels /// Programming panels ///

FR-DU07

Control Panels

7

model)

Programming panels /// Programming panels /// Programming

Optional removable

control panel

Standard FR-F700/A700

removable control panel

Optional comprehensive control panel for use with FR-D, FR-E, FR-F and

FR-A series inverters. This unit can operate in 8 languages.

FR-DU07

FR-PU07

7 8 9

4 5 6

1

0

2 3

MON PrSET

FUNC SHIFT ESC

PU

FWD

REV

WRITE

READ

POWER

FR-PU07

MITSUBISHI

PARAMETER UNIT

ALARM

- - - STOP EXT

50 0 0 Hz

- - - STOP EXT

50 0 0 Hz

EXT

STOP

RESET

8 www.mitsubishi-automation.com

LED-Display

Monitor indication

Operation mode indication

Rotation direction indication

Monitor

ALARM lamp

POWER lamp

Operation keys

General Precautions

A major component of an Inverters design is a capacitor bank.

The capacitors used can hold their charge for up to 15 minutes after

power down. For your own protection from electrical shock please wait at

least 15 minutes before checking the residual voltage level by placing

a meter between terminals P/+ and N/- (resp. + and - for FR-D700 series).

The voltage measured should not be more than 30 V DC.

General installation notes

Install the inverter securely, using bolts, in a vertical plane

Install the inverter on a non combustable surface

NOTE

For specific installation information please refer to the dedicated

installation, hardware or operation manual for your inverter

g /// Installation and mounting /// Installation and mounting ///

9

Installation and mounting /// Installation and mounting ///

Avoid installing the inverter in places where it will be exposed to

direct sunlight, high temperatures or high humidity/moisture

Leave enough clearance around the inverter to allow it to self-cool

Clearance in cm

Note 1: This temperature may vary if the inverter is de-rated.

Please refer to the full instruction manual for details.

10 www.mitsubishi-automation.com

Ambient temperature -10 C to +50 C, 14 F to 122 F (non freezing) see note 1

Ambient humidity 90 % RH or less (non condensating)

Storage temperature -20 C to +65 C (-4 F to 149 F) for short time e.g.

during transit

Ambience Indoors (free from corrosive gas, flammable gas, oil mist,

dust and dirt)

Altitude Up to 1000 m (3280 ft). Above this level de-rate by 3 % for

every 500 m (1690 ft) upto a maximum 2500 m (8202 ft) or

91 % of operation

Vibration 5.9 m/s

2

or less

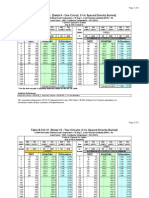

Model A B C

D700 < 5.5 kW 1 10 1

>= 5.5 kW 5 10 5

E700 < 5.5 kW 1 10 1

>= 5.5 kW 5 10 5

F700/A700 <= 00083 1 10 10

5 10 10

>= 01800 10 20 20

All electrical products have to comply with European EMC regulations,

but an important part of keeping that compliance is to use good

wiring practice. The wiring schematics used in this section are shown

demonstrating some of these practises, i.e the use of good earthing,

and where required the use of filters.

General wiring for single-phase inverter

General wiring for three-phase inverter

Wiring /// Wiring /// Wiring /// Wiring /// Wiring /// Wiring ///

General Wiring

11

AC power

supply

Protective

earth

AC power

supply

Protective

earth

EMC filter Inverter Motor

EMC filter Inverter Motor

L1

N

R/L1

S/L2

T/L3

L

N

L*

N*

U

V

W

L1

N

U

V

W

L1

L2

L3

L1*

L2*

L3*

R/L1

S/L2

T/L3

IM

IM

Wiring /// Wiring /// Wiring /// Wiring /// Wiring /// Wiring //

Good earthing practice

From both LVD and EMC and a safety point of view it is essential that

earthing connections are always made in the most thorough way

possible. See below for examples of good EMC grounding.

Using P andU clips for maximum surface contact and stable connection

Ensure that paint or other surface treatments are removed where a cable

gland connects to the body of an enclosure.

12 www.mitsubishi-automation.com

Shield

P clip

U clip

Shield

OK BAD

OK

Insulating material, such as paint, should be

scraped away from the cable gland area

Cable gland

Metal cable gland designed for shield

connection

When a value or parameter needs to be set, the following

symbol has been used. For inverters without a digital

setting dial, the value should be set using their keys.

Setting a frequency

1. Press the to put the inverter into PU operation

this is indicated by the PU LED being lit e.g.

2. Adjust the frequency value with the setting

dial/keys. When the desired value is found

press . The display will alternate between

F for frequency and the value set in Hz, e.g.

3. Press the or keys to start the

inverter/motor rotation

4. Press the key to stop rotation

STOP

// Basic operation /// Basic operation /// Basic operation ///

Note regarding symbols used

13

Basic operation/// Basic operation/// Basic operation/// Basic op

6.2 Setting a parameter

1. Ensure step #1 is completed as before.

2. Press the key to put the inverter into parameter mode

the display will change like this

3. Select the desired parameter with the setting dial/keys.

When the desired parameter is found press the key to see

the current value for the selected parameter, e.g.

To adjust the setting, move the setting dial/keys to the

required value. To set the value, press the ,

key, e.g.

The display will alternate

between the parameter number

and its new set value, e.g.

14 www.mitsubishi-automation.com

peration/// Basic operation/// Basic operation/// Basic operation

6.3 Monitoring operation

1. Ensure step #1 is completed.

2. Press the key, current being drawn by the motor in Amps

and present voltage level in Volts, e.g.

15

Basic parameters /// Basic parameters /// Basic parameters //

*1 differ according to capacities

Basic parameters for FR-D700 and FR-E700

Each inverter has a wide range of parameters that can be set to tune the

inverter-motor system to the very best performance necessary, but to get

an inverter working and to check it is installed correctly etc. you only need

a handful of parameters.

Parameter Factory

setting

Description

0 6/4/3/2 % *1 Torque boost

1 120 Hz Maximum frequency

2 0 Hz Minimum frequency

3 50 Hz Base frequency

4 50 Hz Multi-speed setting (high speed)

5 30 Hz Multi-speed setting (middle speed)

6 10 Hz Multi-speed setting (low speed)

7 5/10 s *1 Acceleration time

8 5/10 s *1 Deceleration time

9

Rated inverter

output current

Electronic thermal

O/L relay

19 8888 Base frequency voltage

20 50 Hz Acceleration/deceleration reference frequency

79 0 Operation mode selection

16 www.mitsubishi-automation.com

// Basic parameters /// Basic parameters /// Basic parameters

* 1 differ according to capacities, 1.5 % for FR-F700 only

Basic parameters for FR-F700 and FR-A700

17

Parameter Factory

setting

Description

0

6/4/3/2/

1.5/1 % *1

Torque boost

1 60/120 Hz Maximum frequency

2 0 Hz Minimum frequency

3 50 Hz Base frequency

4 50 Hz Multi-speed setting (high speed)

5 30 Hz Multi-speed setting (middle speed)

6 10 Hz Multi-speed setting (low speed)

7 5/15 s *1 Acceleration time

8 10/30 s *1 Deceleration time

9

Rated inverter

output current

Electronic thermal

O/L relay

19 8888 Base frequency voltage

20 50 Hz Acceleration/deceleration reference frequency

79 0 Operation mode selection

Common error codes /// Common error codes /// Common err

Remedy

Look for one of the following faults:

A) A short circuit or ground fault

across the main outputs.

B) An excessive moment of inertia

from the Load.

C) Acceleration or deceleration

times are too short.

D) A restart during motor idling

occurred.

E) A motor with an excessive

capacity has been used.

F) Over heating occurred due

to insufficient cooling (defective

cooling fan or choked heat sink)

Remedy

In most cases the protective

function is activated due to a

too short deceleration time preset

causing a regenerative overload.

Increase the deceleration time or

connect an external brake unit.

An overvoltage in the mains power

supply activates this protective

function.

18 www.mitsubishi-automation.com

Model Error code

FR-D700, FR-E700, FR-F700, FR-A700 E.OC[]

Model Error code

FR-D700, FR-E700, FR-F700, FR-A700 E.OV[]

The number in the parenthesis, indicates

[]= 1 acceleration, 2 constant speed, 3 deceleration

Error

A) The output current of the

inverter has reached or exceeded

200 % of the rated current.

B) The temperature of the main

circuits of the inverter rises

rapidly.

Error

The converter voltage has increased

highly due to regenerative energy.

The overvoltage limit was exceeded

during acceleration, constant

speed or deceleration.

ror codes /// Common error codes /// Common error codes ///

19

Model Error code

FR-D700, FR-E700, FR-F700, FR-A700 E.THM

Error

The electronic motor protection

switch continually detects the

motor current and the output

frequency of the inverter.

If a self-cooling motor operates

over a long period at low speed

but high torque, the motor is

thermally overloaded and the

protective function is activated.

If several motors are operated by

one inverter, use independent

motor thermal protection.

Remedy

Decrease the motor load to avoid

fault activation.

Check whether the performance

range of the motor and inverter

correspond.

Increase the thermal setting in

Pr. 9

Maintenance/// Maintenance/// Maintenance/// Maintenance/// C

An inverter is a static unit mainly consisting of semiconductor devices pro-

cessing high voltages and currents. Daily inspection should be performed

to prevent faults from occuring due to adverse effects of the operating

environment and to monitor the service life of the inverter.

Other specific inspections should be carried out periodically.

General

Check there is no change in the ambient environment and that

it remains within the specified levels (see installation & mounting)

Check for unusual vibration and audible noise

Check that the main circuit voltages are normal measure across

inverter terminals R/L1, S/L2 and T/L3 (values should be in accor-

dance with those specified in the specific product manual)

Cooling system

Check the cooling fan (where fitted) for unusual vibration and

noise turn by hand with the power off and perform a visual

check

Display

Check for blown LED lamps

Display-meter: check that readings of the current and voltage

meters are within specified limits

Motor

Check for unusual vibration and noise

Check for unusual odour

20 www.mitsubishi-automation.com

Commonproblems /// Commonproblems /// Commonproblems

Dont guess!

If you do not know or you are not sure check the manual or ask!

Get the right voltage!

Always check the voltage requirements of the inverter before wiring it to

the supply. A simple check of the model name will identify the required

input voltage.

40 = 400 V, three phase ... e.g. FR-F740

20S = 200 V, single phase ... e.g. FR-D720S

Dont forget to connect the earth!

Its for your safety and its good EMC practice

Installing brake units

Some form of braking may be needed to help the applications

performance. In these cases please be aware of the following "brake"

configuration rules.

FR-D700/E700 series A brake resistor can be fitted

(not for FR-D720S-008/014). Alternatively a full brake unit can be added.

FR-F700 series A full brake unit can be added.

FR-A700 series A brake transistor and low duty resistor is included on

units up to 00250. Transistors are fitted from 00310 to 00620 activated

by an additional resistor. A full brake unit can be added to any size.

21

My drive settings

Note: ..........................................................................................................................................

....................................................................................................................................................

Mitsubishi Electric makes all possible efforts to provide only the highest

quality automation products, meeting appropriate European legislation

and requirements for Safety, EMC and hazardous materials etc. Before

using any Mitsubishi automation product, installers and users should read

the appropriate related installation, hardware, users and operation manu-

als where available.

IMPORTANT SAFETY WARNINGS

You should only be installing electrical equipment if you have

been trained to do so.

All installations should be made in accordance to the specific manufac-

turers installation, hardware and operation manuals and

be compliant to local wiring rules and regulations.

If you have any doubt about how to install and commission an inverter

stop immediately and seek advice from a trained and qualified installer.

Parameter Description Setting

My drive settings /// My drive settings /// My drive settings //

22 www.mitsubishi-automation.com

A world of automation solutions

Mitsubishi offer a wide range of automation equipment from PLCs and HMIs to CNC and EDM machines.

HMI and GOTs

Robots

LV circuit protection

Motion control and servos

Inverters

Micro PLCs

Modular PLCs

EDM machines

CNC

controllers

Laser machines

A name to trust

Since its beginnings in 1870, some

45 companies use the Mitsubishi

name, covering a spectrum of

finance, commerce and industry.

The Mitsubishi brand name is

recognized around the world as

a symbol of premium quality.

Mitsubishi Electric Corporation

represents space development,

transportation, semiconductors,

energy systems, communications

and information processing, audio

visual equipment, home electronics,

building and energy management

and automation systems, and has

237 factories and laboratories

worldwide in over 121 countries.

// Quick start guide /// Quick start guide /// Quick start guide

23

Mitsubishi Electric Europe B.V. /// FA - European Business Group ///

Gothaer Strasse 8 /// D-40880 Ratingen /// Germany ///

Tel.: +49 (0) 2102-4860 /// Fax: +49 (0) 2102-4861120 ///

info@mitsubishi-automation.com/// www.mitsubishi-automation.com///

All trademarks and copyrights acknowledged. /// Specifications subject to change /// Art. no. 192913-C /// 08.2008

Global Partner. Local Friend.

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 51-SDMS-02 Specifications For Distribution Transformers Up To 36KV 400/230 VoltsDocumento22 pagine51-SDMS-02 Specifications For Distribution Transformers Up To 36KV 400/230 VoltsQatada1100% (1)

- Miller Dynasty 200sd DX Technical-Manual PDFDocumento122 pagineMiller Dynasty 200sd DX Technical-Manual PDFkazambo78100% (3)

- Electrical Circuits III PDFDocumento42 pagineElectrical Circuits III PDFRolando Cruz50% (2)

- CT SizingDocumento62 pagineCT SizingNoli OtebaNessuna valutazione finora

- Automatic Power Factor CorrectionDocumento4 pagineAutomatic Power Factor CorrectionvictNessuna valutazione finora

- Chapter 6. Capacitor and Capacitance - 1Documento22 pagineChapter 6. Capacitor and Capacitance - 1Yakub ChannelNessuna valutazione finora

- DTC B1185/57 Short in P Squib (2Nd Step) CircuitDocumento3 pagineDTC B1185/57 Short in P Squib (2Nd Step) CircuitPhang KumwingNessuna valutazione finora

- IV Semester ElectricalDocumento30 pagineIV Semester ElectricalSpectre ZeroNessuna valutazione finora

- BY329X1500Documento7 pagineBY329X1500AhmedHelmyNessuna valutazione finora

- Hettich Mikro22 - Service Manual PDFDocumento51 pagineHettich Mikro22 - Service Manual PDFCarlos GonzálezNessuna valutazione finora

- Key Features: ESM 390/395/400/405/410SDocumento2 pagineKey Features: ESM 390/395/400/405/410SMulcue ProfeNessuna valutazione finora

- Analog Ch5 Multistage AmplifierDocumento12 pagineAnalog Ch5 Multistage Amplifierskgupta4281Nessuna valutazione finora

- Three Phase Synchronous MachinesDocumento14 pagineThree Phase Synchronous MachinesMohdFirdausNessuna valutazione finora

- AC Centrifugal Fan: R2E280-AE52-05Documento5 pagineAC Centrifugal Fan: R2E280-AE52-05GRUPOENERMECNessuna valutazione finora

- Surge Arresters: Selection, Application and Testing: Pass YouDocumento30 pagineSurge Arresters: Selection, Application and Testing: Pass YouOoi Ban JuanNessuna valutazione finora

- Industrial Trainning Gladni JammuDocumento34 pagineIndustrial Trainning Gladni Jammumohasan aliNessuna valutazione finora

- Export Product Catalog 2018Documento35 pagineExport Product Catalog 2018REZKINessuna valutazione finora

- Fuji Contactor & Overload PDFDocumento77 pagineFuji Contactor & Overload PDFElias Adiel Madangi WigunaNessuna valutazione finora

- Transmission LinesDocumento8 pagineTransmission LinesKopi143Nessuna valutazione finora

- Alstom Otcf Ansi WebDocumento8 pagineAlstom Otcf Ansi WebReji KurianNessuna valutazione finora

- ELOTOP 510 BrochureDocumento1 paginaELOTOP 510 BrochureVALERYA_LUPUNessuna valutazione finora

- NTE31000 IR Receiver Module For Remote Control Systems: DescriptionDocumento3 pagineNTE31000 IR Receiver Module For Remote Control Systems: DescriptionHECTOR FABIAN OROZCO GARCIANessuna valutazione finora

- Nec B310-10Documento3 pagineNec B310-10ICerebro ElengkumaranNessuna valutazione finora

- Annex C Site PAT DocumentDocumento7 pagineAnnex C Site PAT DocumentShahbaz AhmedNessuna valutazione finora

- Power Systems ClipperDocumento8 paginePower Systems ClipperBilly SeasonsNessuna valutazione finora

- Simple Tests To Assure Proper DC Motor Performance: Drop Testing Fields (Shunt, Series, Interpoles)Documento2 pagineSimple Tests To Assure Proper DC Motor Performance: Drop Testing Fields (Shunt, Series, Interpoles)edgarlimasNessuna valutazione finora

- Chapter 4 TransformerDocumento20 pagineChapter 4 Transformershahmi nordinNessuna valutazione finora

- Arduino Controlled Light Dimmer: InstructablesDocumento34 pagineArduino Controlled Light Dimmer: InstructablesAmarlo EuNessuna valutazione finora

- Pole Top Equipment Voltage Regulators PDFDocumento0 paginePole Top Equipment Voltage Regulators PDFSalman FaisalNessuna valutazione finora

- Ed sqr2 3ph 400 50 s4 50 enDocumento2 pagineEd sqr2 3ph 400 50 s4 50 enMea AurelieNessuna valutazione finora