Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Autogenous and Non-Autogenous Shrinkage of Cement Paste, Its Course, Impact On The Crack Occurrence and Possibilities of Influence

Caricato da

cemsavant0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

68 visualizzazioni2 paginesetting

Titolo originale

Setting

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentosetting

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

68 visualizzazioni2 pagineAutogenous and Non-Autogenous Shrinkage of Cement Paste, Its Course, Impact On The Crack Occurrence and Possibilities of Influence

Caricato da

cemsavantsetting

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Autogenous and Non-autogenous Shrinkage of Cement

Paste, its Course, Impact on the Crack Occurrence and

Possibilities of Influence

P. Tma

tuma@klok.cvut.cz

CTU, Klokner Institute

olnova 7, 166 08 Praha 6

The setting and hardening of concrete is accompanied by undesirable changes in volume

(shrinkage). The changes in volume of cement mortars and concrete occur right after mixing

of the components. Chemical and autogenous shrinkage prevails in the early stages of setting

and hardening, while shrinkage due to drying gains in significance later.

Chemical shrinkage is caused directly by the reactions of cement, namely those of its

clinker minerals with water, where the volume of the hydration products produced is smaller

than the volume of substances entering the hydration process. A part of chemical shrinkage

manifests itself as a macroscopic change in the dimensions of the element made of cement

mortar or concrete (autogenous shrinkage) and the rest results in the formation or possibly

expansion of pores in the cement matrix. In contrast to this, the contraction due to drying

depends above all on the environment to which the mortar or concrete mix is exposed. The

relative humidity of the environment is the decisive factor of the phenomenon.

One of the methods of reducing or eliminating the shrinkage is the use of special

additives allowing no-shrink or expanding concrete to be manufactured The additives are

essentially based on the idea that a controlled expansion of certain structural phases of cement

will compensate for the contraction. The contraction is thus not eliminated in the true sense of

the word, as the elimination concerns just the change in length caused by the contraction. The

first studies dealing with the problem appeared in the twenties of the last century. Thanks to

increasing interest in these kinds of materials, three basic types of expansion additives or

expansion cements have been developed during the last two decades. The first one, designated

S, is based on cement clinker with an elevated content of aluminium oxide and a higher

addition of gypsum. The second type, K, is based on a combination of the effects of calcium

sulphoaluminates and those of free calcium oxide. The third type, M, is a mixture of Portland

cement, alumina cement and gypsum. Ettringit is the prevailing component ensuring the

expansion of all three types of cement.

The aim of the project was to describe the shrinkage of cement mortar right from the

initial stage of setting and to establish the possibility of controlling the expansion process by

using various amounts of alumina cement and gypsum on the basis of the findings, while at

the same time determining the effects of the additives and their amounts on the performance

properties of the cement, above all its compressive strength and the setting time. Materials

assessed as possible substitutes for these additives were also examined.

In the experimental programme, use was made of several test methods. At first a wide set

of samples was tested using the Le Chatelier sleeve method, in which a sample of the mix is

placed in an open cylindrical sleeve 3cm in diameter, provided with needles. When the

volume increases, the sleeve expands and the needles move apart. Their mutual distance is

used as the test parameter. The method has the advantage of being simple and using a small

test sample amount, and the disadvantage of lower accuracy and difficult interpretation of the

results. For these reasons the method was employed as first orientation and for the selection of

mixes for more detailed study.

Two methods were used for determining the changes in volume on selected mixes, the

method of weighing under water and the dilatometric method. The former method is based on

Archimedes principle of bodies immersed in a fluid. The contraction or expansion is

determined by calculation from the change in upthrust, which is established by weighing the

body immersed under the surface of a fluid. The method allows the change in volume with

respect to the zero value to be established directly after preparing the mix. The measurements

were performed in two modifications, one with the free access of water to the mix and the

other with a prevented exchange of moisture with the ambient environment. In the case of

dilatometric measurement, the sample is placed in a special stand and the change in its length

is measured directly with a precision dial gauge. The measurements were again carried out in

two modifications, in water and in an air environment. The measurements of early and final

set by means of the Vicat instrument were performed on all mixes, and the compressive

strength was tested after 1, 3 and 7 days on selected mixes only.

The tests showed that alumina cement or gypsum alone, when added to Portland cement,

have virtually no effect on its changes in volume, but accelerate the setting of the mix

considerably. The time of early and final set may be as short as a few minutes when large

amounts of the additives are used. Only combinations of the two components have an effect

on the changes in volume. A significant suppression of shrinkage and even expansion was

achieved by certain combinations of the two additives. The efficiency of the additives was

found to depend on the humidity of the environment, while curing in water resulted in

expansion in all the instances, but curing in dry air resulted in expansion only with large

amounts of the additives.

However, the setting of the expansion has its limits, because other performance properties

of hardened cement paste were negatively affected by increasing the amounts of the additives.

There was in particular a significant shortening of the time of set, in direct proportion to the

amount of the combined additive. The same applies to the compressive strength. However, in

this case the relationship was not linear, as with small amounts of the additive the strength

increased, but decreased with larger amounts. The expansion may even lead to disintegration

of the sample with large amounts of the additive and when curing the mix in water.

Pure aluminium oxide and a ground mineral containing aluminium oxide were examined

as possible substitutes for alumina cement. However, these additives did not exhibit effects

comparable to those of alumina cement.

The results achieved have contributed to the understating of the process of changes in

volume of setting and hardening cement pastes. When the humidity of the curing environment

is known, the extent of the changes in volume can be controlled on the basis of utilising the

results obtained.

References:

[1] TMA, P.: Vliv expanznch psad na smrovn cementovho kamene s ohledem na

vlhkost prosted Symposium SANACE betonovch konstrukc 2001, 2001, pp. 333338.

vsledky budou vyuity zejmna v disertan prci autora a budou publikovny v roce

2002

This research has been supported by CTU grant No. 300113317.

Potrebbero piacerti anche

- Full Paper - ID 9112Documento6 pagineFull Paper - ID 9112effNessuna valutazione finora

- KANTRODocumento8 pagineKANTROFabio Teodoro100% (1)

- Definition of Concrete AdmixturesDocumento13 pagineDefinition of Concrete AdmixturesHassan MohyyuddinNessuna valutazione finora

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsDa EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNessuna valutazione finora

- Isolated Footing Design (ACI 318-11) : ElevationDocumento12 pagineIsolated Footing Design (ACI 318-11) : ElevationAhmed Ben HmidaNessuna valutazione finora

- Understanding CementDocumento196 pagineUnderstanding Cementlcruz06100% (2)

- ASTM C33 Standard Specification For Conc AggregatesDocumento11 pagineASTM C33 Standard Specification For Conc AggregatesTariq Khan100% (3)

- Early Age CrackingDocumento4 pagineEarly Age CrackingAngga Fajar SetiawanNessuna valutazione finora

- Effects of Temperature On The Development of Low Permeability in ConcretesDocumento24 pagineEffects of Temperature On The Development of Low Permeability in ConcretesSamer al sadikNessuna valutazione finora

- 3 - Experimental Observations of Early-Age Drying of Portland Cement PasteDocumento11 pagine3 - Experimental Observations of Early-Age Drying of Portland Cement PasteMehdi BakhshiNessuna valutazione finora

- Shrinkage of ConcreteDocumento16 pagineShrinkage of ConcreteMariwan Mir100% (1)

- Cracking Risks Associated With Early Age Shrinkage: E. Holt, M. LeivoDocumento10 pagineCracking Risks Associated With Early Age Shrinkage: E. Holt, M. LeivoratnasaiNessuna valutazione finora

- The Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsDocumento11 pagineThe Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsTarek ChikerNessuna valutazione finora

- Chemical Shrinkage of Cement Pastes and Mortars at Very Early Age: Effect of Limestone Filler and Granular InclusionsDocumento10 pagineChemical Shrinkage of Cement Pastes and Mortars at Very Early Age: Effect of Limestone Filler and Granular InclusionsratnasaiNessuna valutazione finora

- Drying Shrinkage of ConcreteDocumento6 pagineDrying Shrinkage of Concretecrownguard100% (1)

- Cement & Concrete Composites: Shiho Kawashima, Surendra P. ShahDocumento8 pagineCement & Concrete Composites: Shiho Kawashima, Surendra P. ShahratnasaiNessuna valutazione finora

- 06 - Chapter 2 PDFDocumento26 pagine06 - Chapter 2 PDFpratik chauhanNessuna valutazione finora

- Fulltext01 PDFDocumento6 pagineFulltext01 PDFCatnis TomNessuna valutazione finora

- New Procedure To Investigate External Sulphate Attack On Cementitious MaterialsDocumento8 pagineNew Procedure To Investigate External Sulphate Attack On Cementitious MaterialsCarlos Augusto Sánchez RondónNessuna valutazione finora

- Javier CE152P-2 A72 Experiment4 Module2Documento6 pagineJavier CE152P-2 A72 Experiment4 Module2Rome Lauren JavierNessuna valutazione finora

- Effect of Superplasticizer Dosage On WorDocumento6 pagineEffect of Superplasticizer Dosage On WorLee TaiNessuna valutazione finora

- Case Studies of Expanding Cement To Prevent Microannular FormationDocumento8 pagineCase Studies of Expanding Cement To Prevent Microannular FormationEmad JamshidiNessuna valutazione finora

- Assignment ConcreteDocumento10 pagineAssignment ConcreteMuhammad NaqibNessuna valutazione finora

- Pro054 032Documento6 paginePro054 032I MixNessuna valutazione finora

- Shrinkage Behavior of Foam Concrete E. K Kunhanandan Nambiar, K. RamamurthyDocumento25 pagineShrinkage Behavior of Foam Concrete E. K Kunhanandan Nambiar, K. RamamurthyThippeswamy G N ThippuNessuna valutazione finora

- High Performance ConcreteDocumento9 pagineHigh Performance ConcreteneivockNessuna valutazione finora

- Multi Scale Experimental Study of Concrete Rheology: From Water Scale To Gravel ScaleDocumento11 pagineMulti Scale Experimental Study of Concrete Rheology: From Water Scale To Gravel ScaleTarek ChikerNessuna valutazione finora

- Effect of Silica Fume On Mechanical Properties of High-Strength ConcreteDocumento11 pagineEffect of Silica Fume On Mechanical Properties of High-Strength ConcreteMmm HhhhNessuna valutazione finora

- Case Studies of Expanding Cement To Improve Wellbore SealingDocumento15 pagineCase Studies of Expanding Cement To Improve Wellbore Sealingwang xiangyuNessuna valutazione finora

- Thesis Proposal CHAPTER IIIDocumento17 pagineThesis Proposal CHAPTER IIIJonathanNessuna valutazione finora

- Effect of SuperplasticizerDocumento7 pagineEffect of SuperplasticizerKanishkNessuna valutazione finora

- 2.0 Review of LiteratureDocumento24 pagine2.0 Review of Literatureknight1729Nessuna valutazione finora

- Volume Changes of ConcreteDocumento17 pagineVolume Changes of ConcreteAljawhara AlnadiraNessuna valutazione finora

- Hu 2017Documento9 pagineHu 2017Ashik Black HandsNessuna valutazione finora

- Concrete Tech. - Report 4Documento14 pagineConcrete Tech. - Report 4JYOTHSNA POOLANessuna valutazione finora

- Dimensional Stability - Shrinkage: Figure 1. Relative Magnitudes of Different Types of ShrinkageDocumento1 paginaDimensional Stability - Shrinkage: Figure 1. Relative Magnitudes of Different Types of ShrinkageericNessuna valutazione finora

- Shrinkage in Concrete, Definition, Types, and Factors Affecting Concrete ShrinkageDocumento13 pagineShrinkage in Concrete, Definition, Types, and Factors Affecting Concrete Shrinkagevishnu ksNessuna valutazione finora

- SegregationDocumento4 pagineSegregationdevil destroyerNessuna valutazione finora

- Method For Simultaneous Determination of Sorption Isotherms and Diffusivity of Cement-Based MaterialsDocumento6 pagineMethod For Simultaneous Determination of Sorption Isotherms and Diffusivity of Cement-Based MaterialstereNessuna valutazione finora

- The Effects of Limestone Addition, Clinker Type and Fineness PDFDocumento5 pagineThe Effects of Limestone Addition, Clinker Type and Fineness PDFHazem DiabNessuna valutazione finora

- Silica Fume As An Admixture in ConcreteDocumento15 pagineSilica Fume As An Admixture in ConcreteNithya Gowda100% (1)

- Effect of The Water Saturation of Aggregates On The Shrinkage InducedDocumento9 pagineEffect of The Water Saturation of Aggregates On The Shrinkage InducedNagesh ThotaNessuna valutazione finora

- Re of ConcreteDocumento77 pagineRe of ConcretepremNessuna valutazione finora

- Effect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsDocumento8 pagineEffect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsgeostaterNessuna valutazione finora

- Research CementDocumento2 pagineResearch Cementnatarajan_arulNessuna valutazione finora

- INTRODUCTION ConcreteDocumento15 pagineINTRODUCTION ConcreteRavindu ThilakarathneNessuna valutazione finora

- Shrinkage-Reducing Admixtures and Early-Age Desiccation in Cement Pastes and MortarsDocumento11 pagineShrinkage-Reducing Admixtures and Early-Age Desiccation in Cement Pastes and MortarsNandhini NallasamyNessuna valutazione finora

- Definition of Slump ValueDocumento4 pagineDefinition of Slump ValueJinyan YangNessuna valutazione finora

- Resume 3 JurnalDocumento11 pagineResume 3 Jurnalanindia.nurauliaNessuna valutazione finora

- Concrete, Creep and ShrinkageDocumento9 pagineConcrete, Creep and ShrinkageBabarinde OluwatobiNessuna valutazione finora

- 1-S2.0-S0958946510001782-Main - PDF CreepDocumento9 pagine1-S2.0-S0958946510001782-Main - PDF CreepratnasaiNessuna valutazione finora

- Internal CuringDocumento22 pagineInternal CuringfahimipoNessuna valutazione finora

- Polymer-Cement Mortars For Repairing Ancient Masonries Mechanical PropertiesDocumento6 paginePolymer-Cement Mortars For Repairing Ancient Masonries Mechanical PropertiesNadiah AUlia SalihiNessuna valutazione finora

- Self Healing 6Documento12 pagineSelf Healing 6Toni ArangelovskiNessuna valutazione finora

- Ecological Concrete and Workability: A Marriage With Future?Documento11 pagineEcological Concrete and Workability: A Marriage With Future?Daniel MaftNessuna valutazione finora

- Miro TRR 2Documento19 pagineMiro TRR 2amirboysNessuna valutazione finora

- Cement and Concrete ResearchDocumento6 pagineCement and Concrete ResearchShahid Lima KhanNessuna valutazione finora

- 70030044Documento5 pagine70030044Ammar A. Ali100% (1)

- In Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteDocumento9 pagineIn Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteA M Yasin ArmanNessuna valutazione finora

- Concrete Admixtures - Plasticizers FD PDFDocumento20 pagineConcrete Admixtures - Plasticizers FD PDFHARSHITA JAINNessuna valutazione finora

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Storage Temperature: Impact On Cement Usage Qualities: ChecklistDocumento2 pagineStorage Temperature: Impact On Cement Usage Qualities: ChecklistcemsavantNessuna valutazione finora

- Vapor Liquid SequenceDocumento11 pagineVapor Liquid SequencecemsavantNessuna valutazione finora

- Bleeding PDFDocumento10 pagineBleeding PDFcemsavantNessuna valutazione finora

- BS en 196-3, 1995-Cement Setting Time and SoundnessDocumento15 pagineBS en 196-3, 1995-Cement Setting Time and Soundnesscemsavant33% (3)

- Chemical AnalysisDocumento9 pagineChemical AnalysiscemsavantNessuna valutazione finora

- EENS 3050 Angle of ReposeDocumento18 pagineEENS 3050 Angle of ReposecemsavantNessuna valutazione finora

- Valve Proving SystemDocumento5 pagineValve Proving SystemcemsavantNessuna valutazione finora

- Bottle Role TestDocumento12 pagineBottle Role TestcemsavantNessuna valutazione finora

- Sulfates Topic: Synthesis of The Setting Kinetics ProjectDocumento10 pagineSulfates Topic: Synthesis of The Setting Kinetics ProjectcemsavantNessuna valutazione finora

- Bateson Thinking Level Hand OutDocumento2 pagineBateson Thinking Level Hand Outcemsavant100% (1)

- MiniPalCementPressedLimestonePellets707 27511Documento2 pagineMiniPalCementPressedLimestonePellets707 27511cemsavantNessuna valutazione finora

- Lessons Learned When Handling Synthetic Gypsum Rev 5Documento6 pagineLessons Learned When Handling Synthetic Gypsum Rev 5cemsavantNessuna valutazione finora

- WHL Particle Size AnalyzersDocumento3 pagineWHL Particle Size AnalyzerscemsavantNessuna valutazione finora

- 2600T Sensor TechnologyDocumento23 pagine2600T Sensor TechnologycemsavantNessuna valutazione finora

- XRF Quality Assurance/Instrument Performance FormDocumento1 paginaXRF Quality Assurance/Instrument Performance FormcemsavantNessuna valutazione finora

- CombustionDocumento35 pagineCombustionBernard Tan100% (1)

- SPP Particle Size AnalyzersDocumento17 pagineSPP Particle Size AnalyzerscemsavantNessuna valutazione finora

- Mbelwa Office Block: Beam B1 Section 230x600Documento6 pagineMbelwa Office Block: Beam B1 Section 230x600Justin MusopoleNessuna valutazione finora

- 2016.04.21 - FRWK - AS - Aluma Systems Rollback PDFDocumento2 pagine2016.04.21 - FRWK - AS - Aluma Systems Rollback PDFbetopagoadaNessuna valutazione finora

- (Paper) Method To Calculate The Fire Resistance of Reinforced Concrete Columns With Rectangular Cross Section (NRCC 33114)Documento12 pagine(Paper) Method To Calculate The Fire Resistance of Reinforced Concrete Columns With Rectangular Cross Section (NRCC 33114)Gregory SimmonNessuna valutazione finora

- ITB, Design and Layout, BOQ and Scope of Works and Technical Specifications For Installation of UPOU Water Supply LinesDocumento20 pagineITB, Design and Layout, BOQ and Scope of Works and Technical Specifications For Installation of UPOU Water Supply LinesUpou SpmoNessuna valutazione finora

- RoofConstuction - FinalDocumento59 pagineRoofConstuction - FinalDiep TuNessuna valutazione finora

- Bill of QuantityDocumento35 pagineBill of QuantityJoshua LopezNessuna valutazione finora

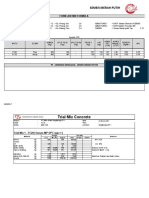

- Semen Merah Putih: Form Job Mix FormulaDocumento21 pagineSemen Merah Putih: Form Job Mix FormulaMochamad Abdul Mu'thiNessuna valutazione finora

- Ic 38 QuestionsDocumento3 pagineIc 38 QuestionsUtkarsh AgarwalNessuna valutazione finora

- Structural Masonry Special InspectionDocumento132 pagineStructural Masonry Special InspectionFrancisco Bonilla100% (1)

- Experimental Investigation On Structural Lightweight Concrete by Partial Replacement of Coarse Aggregate Using Pumice AggregateDocumento5 pagineExperimental Investigation On Structural Lightweight Concrete by Partial Replacement of Coarse Aggregate Using Pumice AggregateAniruddha DalviNessuna valutazione finora

- Hydraulic Design of Small Hydro PlantsDocumento63 pagineHydraulic Design of Small Hydro Plantsmassi99100% (3)

- Ground ImprovementDocumento47 pagineGround ImprovementCharlotte TilburyNessuna valutazione finora

- Analysis and Design On Pipe RacksDocumento43 pagineAnalysis and Design On Pipe RacksAmanpreet Singh67% (3)

- Guidance On The Use of BS EN 40-3.1 and BS EN 40-3.3 (+A12009)Documento18 pagineGuidance On The Use of BS EN 40-3.1 and BS EN 40-3.3 (+A12009)sid viciousNessuna valutazione finora

- ShaliGrout 65Documento2 pagineShaliGrout 65Anupam ShilNessuna valutazione finora

- Dekguard Primer WBDocumento2 pagineDekguard Primer WBmohamedbossilyNessuna valutazione finora

- 3 Effect of Transportation of Fly Ash Life Cycle Assessment and Life Cycle Cost PDFDocumento11 pagine3 Effect of Transportation of Fly Ash Life Cycle Assessment and Life Cycle Cost PDFRheza RahadianNessuna valutazione finora

- 1 s2.0 S223878542300652X MainDocumento14 pagine1 s2.0 S223878542300652X MainFahra Aqilla AzzurahNessuna valutazione finora

- Hardened ConcreteDocumento3 pagineHardened ConcreteEng Aidaruos Abdi MatanNessuna valutazione finora

- HomeGuard Installation Manual 5C 2015Documento112 pagineHomeGuard Installation Manual 5C 2015_Asylum_Nessuna valutazione finora

- Adingpaver: Admixture For Production of Prefabricated Concrete and Pave ElementsDocumento2 pagineAdingpaver: Admixture For Production of Prefabricated Concrete and Pave ElementsFilip PopordanoskiNessuna valutazione finora

- Final CoTm Curriculum Draft@2nd HarmonizationDocumento113 pagineFinal CoTm Curriculum Draft@2nd Harmonizationamare ayeleNessuna valutazione finora

- Ultra 1Documento27 pagineUltra 1VishnuNessuna valutazione finora

- Si Load Seismic PH SDocumento5 pagineSi Load Seismic PH SJoseNessuna valutazione finora

- Effect of Ripe and Unripe Plantain Peel Ash On Concrete Compressive StrengthDocumento4 pagineEffect of Ripe and Unripe Plantain Peel Ash On Concrete Compressive StrengthOluwaseun AdetayoNessuna valutazione finora

- Supercast SW30 (UK)Documento2 pagineSupercast SW30 (UK)Gry ArdiansyahNessuna valutazione finora

- Aci 522R-06 PDFDocumento25 pagineAci 522R-06 PDFaldi raimon100% (2)