Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SSPC Hand/Power Tool Cleaning Requirements

Caricato da

Jake Sparrow88%(8)Il 88% ha trovato utile questo documento (8 voti)

950 visualizzazioni33 pagineSSPC Hand/Power Tool Cleaning Requirements

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSSPC Hand/Power Tool Cleaning Requirements

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

88%(8)Il 88% ha trovato utile questo documento (8 voti)

950 visualizzazioni33 pagineSSPC Hand/Power Tool Cleaning Requirements

Caricato da

Jake SparrowSSPC Hand/Power Tool Cleaning Requirements

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 33

Compliance with SSPC Hand/Power

Tool Cleaning Requirements (11/9/10)

Kenneth A. Trimber

KTA-Tator, Inc.

Compliance with SSPC Hand/Power

Tool Cleaning Requirements

Learning Objectives

Describe written SSPC

hand and power tool

cleaning standards, and

typical equipment used for

each

Describe the use of SSPC-

VIS 3, Guide and Reference

Photographs for Steel

Surfaces Prepared by

Power and Hand Tool

Cleaning

SSPC Surface Cleanliness Standards

SSPC-SP1, Solvent Cleaning

SSPC-SP2, Hand Tool Cleaning

SSPC-SP3, Power Tool Cleaning

SSPC-SP5/NACE 1, White Metal Blast Cleaning

SSPC-SP6/NACE 3, Commercial Blast Cleaning

SSPC-SP7/NACE 4, Brush-Off Blast Cleaning

SSPC-SP8, Pickling

SSPC-SP10/NACE 2, Near-White Metal Blast Cleaning

SSPC-SP11, Power Tool Cleaning to Bare Metal

SSPC-SP12/NACE 5, Water Jetting

SSPC-SP13/NACE 6, Surface Preparation of Concrete

SSPC-SP14/NACE 8, Industrial Blast Cleaning

SSPC-SP15, Commercial Grade Power Tool Cleaning

SSPC-SP16, Brush-Off Blast Cleaning of Coated and Uncoated Galvanized

Steel, Stainless Steels, and Non-Ferrous Metals

SSPC-VIS 3 - Guide

Guide and Reference

Photographs

The photographs

supplement the written

SSPC standards

The written standards are

the means for determining

compliance

The photographs are not to

be used as a substitute for

the written standards

SSPC-SP 2, Hand Tool Cleaning

Wire brushes, scrapers,

sandpaper

Removes loose rust, loose

mill scale, and loose paint

Remaining material must

be tightly adhering

(cannot be lifted using

the blade of a dull putty

knife)

No surface profile

requirement

Dull Putty Knife

Proposed Definition

Commercially manufactured putty knife or scraper containing

a metal blade with the following characteristics: width of

blade 1-1/2 to 3; length of blade 3 to 5; thickness of

blade 30 to 50 mils.

The thickness at end of the blade shall not be less than 25

mils or 75% of its original thickness, whichever is greater.

It shall not be used if the edge is nicked or gouged, or if dry

paint or other material is present along the edge that would

prevent the blade from making intimate contact with the

surface.

The blade shall be held flat against the surface and at a

maximum of 45 degrees to the surface. The corners of the

blade shall not be used to dig at the residues.

6

SSPC-SP 3, Power Tool Cleaning

Power grinders, power wire

brushes, power sanders

Removes loose rust, loose

mill scale, and loose paint

Remaining material must be

tightly adhering (dull putty

knife)

No surface profile

requirement

SSPC-SP 11, Power Tool Cleaning to Bare

Metal

Rotary or reciprocating impact tools

(peening flaps, cutter bundles,

needle guns, wire flail, and hammer

flail assemblies)

Sometimes combinations of tools

are used

Removes all rust, all paint, and all

mill scale, but slight residues of

rust and paint can remain in the

bottoms of pits

Minimum 1.0 mil surface profile

requirement

Viewed without magnification

Developed at the request of the

nuclear industry (1987)

SSPC-SP 15, Commercial Grade Power

Tool Cleaning

Same equipment that is used for SSPC-SP 11

All paint, rust, and mill scale are removed

Staining from rust, paint and mill scale are permitted

to remain, but must not exceed 33% (one third) of

each 9 square inches of prepared surface

Slight residues of rust and paint can remain in the

bottoms of pits

Minimum 1.0 mil surface profile requirement

Viewed without magnification

Developed in 2002

Stain or Staining

Proposed Definition

Stain or Staining: (As related to abrasive blasting surface

preparation methods) An area of a surface which, when compared

to adjacent areas, has an equal surface profile but is discolored

(usually darker) with a material having no apparent volume. The

material cannot be removed by methods commonly used to remove

dust, but can be removed by more thorough abrasive blasting.

If the definition is approved in 2011, it needs to be modified to

include power tools (SSPC-SP15)

Suggested Field Test (note that this is not an SSPC test): Use a

utility knife to scrape the surface and to press into the residue. If

the residue is dislodged from the surface, it is not a stain.

10

9 Square Inches

Prior to the start of publishing joint abrasive blast cleaning

standards in 1994, SSPC and NACE produced their own versions.

The percentages of allowable staining were the same, but the unit

area was different:

SSPC used square inch

NACE applied the percentage to the entire surface provided the staining

was evenly dispersed

In order to reconcile the differences when developing the joint blast

cleaning standards, 9 square inches was ultimately agreed upon,

which was based on the area of the reference photographs (SSPC)

and blast cleaned reference coupons (NACE)

Even though SP15 is not a joint standard and is unrelated to blast

cleaning, the same rationale for defining the unit area was used,

matching the approximate size of the VIS 3 photographs

11

Vacuum-Shrouded Power Tool Cleaning

Vacuum-shrouding is

available for most power

tools

The vacuum-shrouding

collects the debris as it is

being generated

The vacuum system is

typically fitted with HEPA

filtration, enabling the

systems to be used for

removing paints that contain

toxic metals

SSPC Visual Guides and Reference

Photographs for Surface Cleanliness

SSPC-VIS 1 (Abrasive

Blast Cleaning)

SSPC-VIS 3 (Power and

Hand Tool Cleaning)

SSPC-VIS 4/NACE VIS 7

(Water Jetting)

SSPC-VIS 5/NACE VIS 9

(Wet Abrasive Blast

Cleaning)

SSPC-VIS 3 (1993; 2004)

Photographs represent the appearance of surfaces both prior

to and after hand and power tool cleaning

Surface conditions depicted prior to cleaning:

Previously unpainted (1993)

Condition A - Intact mill scale

Condition B - Rust and mill scale

Condition C - Totally rusted

Condition D - Totally rusted and pitted

Previously painted (added in 2004)

Condition E - Intact light colored paint with minimal rusting

Condition F - Zinc rich paint with rusting along a weld

Condition G - Heavy old coating with rust and mill scale

Degrees of cleaning depicted for each initial surface condition:

SSPC-SP2, Hand Tool Cleaning

SSPC-SP3, Power Tool Cleaning

SSPC-SP11, Power Tool Cleaning to Bare Metal

SSPC-SP15, Commercial Grade Power Tool Cleaning (added 2004)

14

SSPC-VIS 3 Initial Conditions

SSPC-VIS 3 Appearance of Cleaning

Condition B Steel

SSPC-VIS 3 Appearance of Cleaning

Condition D Steel

SSPC-VIS 3 Appearance of Cleaning

Condition E Steel

SSPC-VIS 3 Appearance of Cleaning

Condition G Steel

SSPC-VIS 3 Appearance of Cleaning

Condition A Steel

SSPC-VIS 3 Appearance of Cleaning

Condition B Steel

Restoring an Existing Profile

Two photos show the use of

non-woven disks to restore

an existing profile

Condition E (light colored

coating with minimal rusting

Condition F (zinc-rich paint

with rusting along the weld

SSPC-VIS 3 Initial Condition Affects

Appearance of Cleaning (e.g., SP2)

SSPC-VIS 3 Initial Condition Affects

Appearance of Cleaning (e.g., SP11)

SSPC-VIS 3 Initial Condition Affects

Appearance of Cleaning (e.g., SP15)

SSPC-VIS 3 Initial Condition Affects

Appearance of Cleaning (e.g., SP11)

SSPC-VIS 3 Tool Used Affects

Appearance of Cleaning (e.g., SP3)

Jobsite Standards

Final appearance is dictated by

initial steel condition and the tools

used for cleaning

The existing coating/corrosion,

color, texture, lighting, tools used,

etc. will never be identical to the

conditions under which SSPC-VIS 3

photos were prepared therefore,

the prepared steel will not look the

same as the photographs

Preparation of jobsite standards

before work begins can help to

clarify cleaning expectations

Actual steel on the structure and/or

small steel samples

SSPC-VIS 2 can help to asses

percentages

SSPC-VIS 2, Standard Method

of Evaluating Degree of

Rusting on Painted Steel

Surface

Purpose standard means

for estimating percentage of

visible corrosion

SSPC-VIS 2 (cont)

Standard consists of

photographs showing

various percentages of

corrosion and

corresponding black and

white images of the same

percentages

The photographs depict

0.03% to 50% corrosion

in 9 increments for each

of :

Spot rusting

General rusting

Pinpoint rusting

SSPC-VIS 2 (cont)

The black and white

images can help to

train the eye to judge

percentages

Relevance is for SSPC-

SP15, Commercial

Grade Power Tool

Cleaning, which allows

staining on up to 33%

of the surface

Summary

SSPC-SP2, Hand Tool Cleaning

removes loose rust, paint, mill scale; tight material may remain

SSPC-SP3, Power Tool Cleaning

removes loose rust, paint, mill scale; tight material may remain

SSPC-SP15, Commercial Grade Power Tool Cleaning

Removes all rust, paint, mill scale except in bottom of pits;

stains can remain on up to 33% of each unit area; 1 mil

minimum surface profile

SSPC-SP11, Power Tool Cleaning to Bare Metal

Removes all rust, paint, mill scale except in bottom of pits; 1 mil

minimum surface profile

SSPC VIS 3, Guide and Reference Photographs for

Steel Surfaces Prepared by Power and Hand Tool

Cleaning

Supplements, but does not replace, the written standards

Compliance with SSPC Hand/Power

Tool Cleaning Requirements -

Questions

Potrebbero piacerti anche

- Surface PreparationDocumento8 pagineSurface PreparationimyparkarNessuna valutazione finora

- Surface Preparation Commentary GuideDocumento32 pagineSurface Preparation Commentary Guidesflynn79100% (2)

- Handbook of LNGDocumento3 pagineHandbook of LNGKai Yuan Teo0% (1)

- Batch Release (VHS QA 027 R0)Documento8 pagineBatch Release (VHS QA 027 R0)Ajay patel Patel100% (1)

- Radiographic Testing Procedure GuideDocumento12 pagineRadiographic Testing Procedure GuideJake SparrowNessuna valutazione finora

- SSPC SP3Documento2 pagineSSPC SP3Jose AngelNessuna valutazione finora

- SSPC AB1 Standard For Mineral and Slag AbrasivesDocumento5 pagineSSPC AB1 Standard For Mineral and Slag Abrasiveslonglong3003100% (1)

- SSPC PAINTING MANUAL Vol 1 PDFDocumento551 pagineSSPC PAINTING MANUAL Vol 1 PDFLeuman Teran100% (17)

- How To Use SSPC StandardsDocumento7 pagineHow To Use SSPC StandardsTimbo6808100% (1)

- Coating Defects GuideDocumento36 pagineCoating Defects Guiderajesh100% (1)

- SSPC Vis 3Documento4 pagineSSPC Vis 3EstrellaLazoRomero100% (3)

- API Calcs Rev1 (Version 2)Documento112 pagineAPI Calcs Rev1 (Version 2)Jake Sparrow100% (1)

- VSC SSPC Visual Guide To Surface Prep PDFDocumento8 pagineVSC SSPC Visual Guide To Surface Prep PDFABCNessuna valutazione finora

- TxDMV Motor Vehicle Registration ManualDocumento315 pagineTxDMV Motor Vehicle Registration ManualJake SparrowNessuna valutazione finora

- Coating InspectionDocumento11 pagineCoating InspectionManoranjan Nayak100% (1)

- SSPC SP 7 Brush OffDocumento6 pagineSSPC SP 7 Brush OffPipeMelgarejoLopezNessuna valutazione finora

- Protective Coating Article-1Documento173 pagineProtective Coating Article-1Sivaratnam Navatharan100% (1)

- Coating DFT-RulesDocumento2 pagineCoating DFT-RulesAnand100% (1)

- Surface Preparation Standards OverviewDocumento38 pagineSurface Preparation Standards OverviewEric So100% (1)

- 4996 RCC Fence PostDocumento28 pagine4996 RCC Fence Postnaveen100% (1)

- Painting Inspector Hand BookDocumento5 paginePainting Inspector Hand BookAmaan Khan100% (7)

- Polaroid Case StudyDocumento4 paginePolaroid Case Studyrishabi90Nessuna valutazione finora

- Coating Inspectors HandbookR3Documento62 pagineCoating Inspectors HandbookR3Ahmed GaballaNessuna valutazione finora

- SSPC VIS-3 Steel Surfaces Prepared by Hand and Power Tool Cleaning PDFDocumento8 pagineSSPC VIS-3 Steel Surfaces Prepared by Hand and Power Tool Cleaning PDFSiva SubramaniNessuna valutazione finora

- Blister Packaging Using Thermoforming Technique, Products of Blister Packaging India, VELPACK Industries, Blister Packing, Vacuum Formed Packing Trays, Material Handling Trays, Custom Made ProductsDocumento3 pagineBlister Packaging Using Thermoforming Technique, Products of Blister Packaging India, VELPACK Industries, Blister Packing, Vacuum Formed Packing Trays, Material Handling Trays, Custom Made ProductsAbhishek AgrawalNessuna valutazione finora

- SSPC Pa-Guide 5 (2004)Documento12 pagineSSPC Pa-Guide 5 (2004)Pubcrawl100% (2)

- SSPC Guide 12Documento6 pagineSSPC Guide 12kishorekumar.animuNessuna valutazione finora

- API 571 Exercises, Rev2Documento11 pagineAPI 571 Exercises, Rev2ariyamanjula2914100% (4)

- Painting and CoatingDocumento132 paginePainting and Coatingmohammad ali100% (2)

- Api Q1Documento4 pagineApi Q1Sandra Sanders33% (3)

- An Overview of How To Execute EPCCDocumento17 pagineAn Overview of How To Execute EPCCZAB236100% (2)

- Profile Measurement WebinarDocumento39 pagineProfile Measurement WebinarAlex CarreraNessuna valutazione finora

- Surface PreparationDocumento5 pagineSurface PreparationPT Bahtera AgungNessuna valutazione finora

- LNG 01Documento24 pagineLNG 01Abhijeet Mukherjee100% (1)

- Paint Inspection and ControlDocumento129 paginePaint Inspection and ControlMuhammad Issa93% (14)

- Sspc-Ab1 - 2017Documento5 pagineSspc-Ab1 - 2017Selvakpm06100% (1)

- 38DL Plus Ultrasonic Thickness Gage User's ManualDocumento308 pagine38DL Plus Ultrasonic Thickness Gage User's ManualJake Sparrow100% (3)

- 38DL Plus Ultrasonic Thickness Gage User's ManualDocumento308 pagine38DL Plus Ultrasonic Thickness Gage User's ManualJake Sparrow100% (3)

- Heat Treating of Aluminum AlloysDocumento39 pagineHeat Treating of Aluminum AlloysMahdalena JuliaNessuna valutazione finora

- Painting STDSDocumento4 paginePainting STDSAshok KsNessuna valutazione finora

- Inspection Thermal Spray WebinarDocumento29 pagineInspection Thermal Spray WebinarShriya Soni100% (1)

- Painting - Training PPT 1Documento24 paginePainting - Training PPT 1vijay padale80% (5)

- SSPC SP11Documento6 pagineSSPC SP11บวรลักษณ์ จ้อยโหมด50% (2)

- Technical Presentation Coating InspectionDocumento44 pagineTechnical Presentation Coating InspectionRengarajan ThiruvengadaswamyNessuna valutazione finora

- Painting Measures and StandartsDocumento69 paginePainting Measures and StandartsNostalgy1981Nessuna valutazione finora

- Bellow Seal ValvesDocumento36 pagineBellow Seal ValvesJake SparrowNessuna valutazione finora

- API 570 FormulasDocumento2 pagineAPI 570 FormulasArif Mokhtar89% (9)

- Painting DFT Rules-SSPC-PA-2Documento16 paginePainting DFT Rules-SSPC-PA-2Michael AlbuquerqueNessuna valutazione finora

- Current SSPC Standards June2019Documento7 pagineCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- Surface Preparation StandardsDocumento3 pagineSurface Preparation StandardsSajeesh KrishnanNessuna valutazione finora

- New SSPC Visual Standard for Abrasive Blast CleaningDocumento4 pagineNew SSPC Visual Standard for Abrasive Blast CleaningOscar López Lemos100% (1)

- Copper Alloys - Compositions, Applications and PropertiesDocumento18 pagineCopper Alloys - Compositions, Applications and PropertiesKristin Andrews100% (2)

- Iso 8502-06Documento18 pagineIso 8502-06Alex OliveiraNessuna valutazione finora

- Inspect Flash RustDocumento113 pagineInspect Flash RustMario Jorge Pereira100% (1)

- SSPC Products CatalogDocumento20 pagineSSPC Products CatalogAnbalagan Ravichandran100% (2)

- Ficha Tecnica Mangueras Hidraulicas DaycoDocumento41 pagineFicha Tecnica Mangueras Hidraulicas DaycoDIEGO A. TOVAR CHIA100% (1)

- The Coating Inspectors HandbookR3.1Documento64 pagineThe Coating Inspectors HandbookR3.1Akhter Khan100% (11)

- Determination of Maximum Span Between Pipe Support Using Bending Stress TheoryDocumento4 pagineDetermination of Maximum Span Between Pipe Support Using Bending Stress TheoryMannattil Krishna KumarNessuna valutazione finora

- SSPC sp1-sp12Documento5 pagineSSPC sp1-sp12RAJA GOPALNessuna valutazione finora

- Replica Tape Unlocking Hidden InformationDocumento17 pagineReplica Tape Unlocking Hidden InformationTrịnh Minh KhoaNessuna valutazione finora

- Surface PreparationDocumento9 pagineSurface PreparationIsabelo AbaoNessuna valutazione finora

- Painting Inspector: Passbooks Study GuideDa EverandPainting Inspector: Passbooks Study GuideNessuna valutazione finora

- Webinar-Coating Girth Welds FINAL REV PDFDocumento59 pagineWebinar-Coating Girth Welds FINAL REV PDFdakidofdaboomNessuna valutazione finora

- When Is SPC-SP3 Power Tool Cleaning Used?Documento2 pagineWhen Is SPC-SP3 Power Tool Cleaning Used?HennieNessuna valutazione finora

- SSPC - Surface Preparation Standards: NotesDocumento2 pagineSSPC - Surface Preparation Standards: NotesvsnaiduqcNessuna valutazione finora

- Wab - Reduced SSPCDocumento33 pagineWab - Reduced SSPCMOHAMAD NIZAMUDINNessuna valutazione finora

- Surface Preparation StandardsDocumento3 pagineSurface Preparation StandardsReyhand SaveroNessuna valutazione finora

- Vis stds02Documento9 pagineVis stds02Hector Aldair Valle RiveraNessuna valutazione finora

- 1 Pig Gauge (Model OG204) / Elcometer 121: St2/St3 St2/St3Documento19 pagine1 Pig Gauge (Model OG204) / Elcometer 121: St2/St3 St2/St3Akansha SharmaNessuna valutazione finora

- Especificaciones SSPC y Definiciones SP1-SPX PDFDocumento32 pagineEspecificaciones SSPC y Definiciones SP1-SPX PDFjorgelunaNessuna valutazione finora

- Steel Fabrication Surface Preparation StandardsDocumento5 pagineSteel Fabrication Surface Preparation Standardssam NgaboNessuna valutazione finora

- Painting Procedure Chugoku PaintDocumento129 paginePainting Procedure Chugoku PaintKarthik SNessuna valutazione finora

- Surface Preparation Standards - ComparasionDocumento4 pagineSurface Preparation Standards - ComparasiontaiNessuna valutazione finora

- Surface Preparation StandardsDocumento7 pagineSurface Preparation Standardsazhar enggNessuna valutazione finora

- 5 - Surface Prep - Ferrous and Non-Ferrous MetalDocumento5 pagine5 - Surface Prep - Ferrous and Non-Ferrous Metalkiran vargheseNessuna valutazione finora

- Removing Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncDocumento46 pagineRemoving Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncMilagros MorantesNessuna valutazione finora

- SSPC Surface Preparation StandardsDocumento7 pagineSSPC Surface Preparation StandardsAshish GuptaNessuna valutazione finora

- Surface Preparation StandardDocumento5 pagineSurface Preparation StandardKarthikeyan ShanmugavelNessuna valutazione finora

- Pregatirea Suprafetelor Pentru VopsireDocumento4 paginePregatirea Suprafetelor Pentru VopsireValentin GalbenNessuna valutazione finora

- Surface Cleaning MethodsDocumento4 pagineSurface Cleaning MethodsMAHESH CHANDNessuna valutazione finora

- 510 Closed Book Blank TestDocumento70 pagine510 Closed Book Blank TestJake SparrowNessuna valutazione finora

- Construction code pressure vesselsDocumento24 pagineConstruction code pressure vesselshugo.dutillet6002100% (1)

- 510 Bay Tech Closed BookDocumento70 pagine510 Bay Tech Closed BookJake Sparrow100% (1)

- Professional Resume v2Documento1 paginaProfessional Resume v2Jake SparrowNessuna valutazione finora

- Anodes in Cooling Water Heat Exchangers - GuidelinesDocumento12 pagineAnodes in Cooling Water Heat Exchangers - GuidelinesJake SparrowNessuna valutazione finora

- Ball ValveDocumento12 pagineBall ValvemohamedfirozNessuna valutazione finora

- Class 300 LWN, HB, CODocumento1 paginaClass 300 LWN, HB, COJake SparrowNessuna valutazione finora

- Ultrasonic Examination ProcedureDocumento10 pagineUltrasonic Examination ProcedureJake SparrowNessuna valutazione finora

- Ferrite Content Effect On Autenitic Ss Weld at Cryogenic TempDocumento12 pagineFerrite Content Effect On Autenitic Ss Weld at Cryogenic TemparunkumarNessuna valutazione finora

- Adobe Reader and Acrobat Cleaner Tool For 10.x and LaterDocumento4 pagineAdobe Reader and Acrobat Cleaner Tool For 10.x and LaterJake SparrowNessuna valutazione finora

- UT ExchangerDocumento1 paginaUT ExchangerJake SparrowNessuna valutazione finora

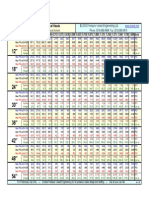

- ASME DesignCharts Charts Pipe103 18ksiDocumento3 pagineASME DesignCharts Charts Pipe103 18ksiJake SparrowNessuna valutazione finora

- 130-U.pdf Title Aplication TX StateDocumento2 pagine130-U.pdf Title Aplication TX StatehusanzNessuna valutazione finora

- API 578 Study MaterialDocumento12 pagineAPI 578 Study MaterialVimin Prakash100% (1)

- AWS - Welding SymbolsDocumento1 paginaAWS - Welding SymbolsAli Saifullizan IsmailNessuna valutazione finora

- ASME DesignCharts Charts HemisphericalHeads 20ksiDocumento4 pagineASME DesignCharts Charts HemisphericalHeads 20ksiJake SparrowNessuna valutazione finora

- API 578 Study MaterialDocumento12 pagineAPI 578 Study MaterialVimin Prakash100% (1)

- MSTS 2014 API and AWS certification training scheduleDocumento1 paginaMSTS 2014 API and AWS certification training scheduleJake SparrowNessuna valutazione finora

- Civil Disturbance OperationsDocumento256 pagineCivil Disturbance OperationsGrey WolfNessuna valutazione finora

- Ferrite Content Effect On Autenitic Ss Weld at Cryogenic TempDocumento12 pagineFerrite Content Effect On Autenitic Ss Weld at Cryogenic TemparunkumarNessuna valutazione finora

- PresentationDocumento36 paginePresentationsdNessuna valutazione finora

- Freilog (Pty) LTD - 2014Documento6 pagineFreilog (Pty) LTD - 2014FreilogNessuna valutazione finora

- Supply Chain Management SystemDocumento60 pagineSupply Chain Management SystemRohanNessuna valutazione finora

- Production Question Set 2Documento70 pagineProduction Question Set 2ErKRGautamNessuna valutazione finora

- Inorganic "Metallic" Finishes, Processes, and EquipmentDocumento29 pagineInorganic "Metallic" Finishes, Processes, and EquipmenthaisamdoNessuna valutazione finora

- MicrotheneDocumento3 pagineMicrotheneRodrigo GhiroNessuna valutazione finora

- Installation Handbook HardwoodDocumento20 pagineInstallation Handbook HardwoodYi LiuNessuna valutazione finora

- Micromachining - Seminar Reports - PPT - PDF - DOC - Presentation - Free Download For Mechanical EngineeringDocumento3 pagineMicromachining - Seminar Reports - PPT - PDF - DOC - Presentation - Free Download For Mechanical EngineeringAnup Patil100% (1)

- BEML Company Profile: India's Leading Manufacturer of Mining, Construction, Defense and Rail EquipmentDocumento56 pagineBEML Company Profile: India's Leading Manufacturer of Mining, Construction, Defense and Rail EquipmentJithun NaiduNessuna valutazione finora

- Программа Преквалификации в системе ВОЗDocumento27 pagineПрограмма Преквалификации в системе ВОЗAnton MymrikovNessuna valutazione finora

- Jadwal Monitoring PMC Dan PMUDocumento4 pagineJadwal Monitoring PMC Dan PMUFirmanSimeulueNessuna valutazione finora

- PVDC Coated BOPET Film DevelopmentDocumento28 paginePVDC Coated BOPET Film DevelopmentLucas Del PretteNessuna valutazione finora

- Electrofusion WeldingDocumento3 pagineElectrofusion Weldingmaheshmalaichamy007Nessuna valutazione finora

- Application of Teflon in Fabric ProtectionDocumento6 pagineApplication of Teflon in Fabric ProtectionMohammed Atiqul Hoque ChowdhuryNessuna valutazione finora

- Ironing Pressing FinishingDocumento5 pagineIroning Pressing FinishingAman DeepNessuna valutazione finora

- Composite Materials For Civil Engineering Structures US Army Corps of EngineersDocumento66 pagineComposite Materials For Civil Engineering Structures US Army Corps of EngineersRicardo AlfaroNessuna valutazione finora

- Dewan: Cement LimitedDocumento6 pagineDewan: Cement LimitedIrfan AhmedNessuna valutazione finora

- Ontario Aggregate Standard Specification GuideDocumento15 pagineOntario Aggregate Standard Specification GuideJonathan Enrique Canales SanchezNessuna valutazione finora

- Superblock PrintingDocumento5 pagineSuperblock PrintingVaidish SumariaNessuna valutazione finora