Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

522541

Caricato da

AmirAmiriCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

522541

Caricato da

AmirAmiriCopyright:

Formati disponibili

DIN US

D

IN

DIN US

D

IN

cyan yellow magenta key

U

S

U

S

w

w

w

.

a

r

b

u

r

g

.

c

o

m

Tie bar distances: 370 x 370 mm, 420 x 420 mm

Clamping forces: 600, 800, 1000 kN

Injection units (according to EUROMAP): 100, 250, 350

A S GOLDEN EDITION V T C

Technical data ALLROUNDER 370/420 C

DIN US

D

IN

DIN US

D

IN

cyan yellow magenta key

U

S

U

S

370/420 C Machine dimensions

1) Dimensions are valid for injection unit 100

2) Dimensions are valid for injection unit 250

3) Dimensions are valid for injection unit 350

4) Dimension only valid in conjunction with conveyor belt

m

i

n

.

2

1

0

m

a

x

.

3

8

5

cooling water connections

electrical connection

cooling water supply line DN 25

max. 25C min. 4 bar

cooling water return line DN 25

electrical connection

max. 3805

1)

4235

2)

4320

3)

4300

8

0

5

3

3

0

1

2

5

0

1

7

6

5

1

2

0

740 900

3560

2

1

5

/

4

4

0

4

)

2

0

7

0

1

)

2

0

8

0

2

)

2

0

9

0

3

)

2

5

5

500

800

9

8

5

1

3

7

0

R

3

9

0

1

6

3

5

1200 625

7

8

5

1

5

9

5

2

DIN US

D

IN

DIN US

D

IN

cyan yellow magenta key

U

S

U

S

370/420 C Technical data

Machine model

EUROMAP size indication

1)

Clamping unit

Clamping force max. kN

Closing force max. kN

Opening force / increased max. kN

Opening stroke max. mm

Mould height min. mm

Daylight max. mm

Distance between tie bars mm

Platen size (hor. x vert.) mm

Weight of mov. mould half max. kg

Ejector force max. kN

Ejector stroke max. mm

Hydraulics, drive, general

Drive power of the hydraulic pump kW

Dry cycle time for opening stroke

3)

s-mm

Total connected load

2)

kW

Colour: plastic coated, structure light grey / mint green / canary yellow

Control cabinet

Safety standard according to

Socket combination (1 single phase, 1 three-phase)

Injection unit

Screw diameter mm

Effective screw length L/D

Screw stroke max. mm

Calculated injection volume max. cm

3

Shot capacity max. g PS

Material throughput

6)

max. kg/h PS

max. kg/h PA 6.6

Injection pressure

5)

max. bar

Injection ow

5)

max. cm

3

/s

Injection ow with accumulator max. cm

3

/s

Back pressure positive / negative max. bar

Circumferential screw speed max. m/min

Screw torque max. Nm

Nozzle contact force max. kN

Nozzle retraction stroke max. mm

Installed cylinder heating power / heating zones kW

Installed nozzle heating power kW

Material hopper capacity l

Horizontal injection position

4)

max. mm

Machine dimensions and weights of the basic machine

Oil capacity l

Net weight kg

Electrical connection (pre-fused)

2)

A

1) 1st gure: clamping force (kN), 2nd gure: max. dosage volume (cm

3

) x max. injection pressure (kbar)

2) Values refer to 400 V/50 Hz. The load is symmetrically distributed on three phases. The specied value applies to the basic machine.

The connection value can be increased by additional options which may make 2 separate supply lines necessary (motor + controller/heating)

3) According to EUROMAP for the basic machine. Values shown in parentheses apply for dual-pump technology.

4) Measurement in brackets valid in connection with MULTILIFT H

5) A combination of max. injection pressure and max injection ow (max. injection capacity) can be mutually exclusive, depending on the equipment-related motor output

6) Deviations are possible depending upon process settings and material type

These technical data specications refer to the state at the time of printing. We reserve the right to modify specications in the interest of a continuous program of further development.

370 C

600-100

600

50

35 / 250

500

250

750

370 x 370

570 x 570

600

40

175

11

1,8 (1,6)-259

18,4

DIN EN 60204

1 x 16 A

100

20 / 25 / 30

25 / 20 / 16,7

100

31 / 49 / 71

29 / 45 / 65

5,5 / 8 / 9,5

2,8 / 4 / 4,9

2500 / 2240 / 1550

80 / 124 / 180

160 / 250 / 362

350 / 200

42 / 52 / 63

120 / 150 / 180

50

180

4,3 / 4

0,6

50

170 (120)

235

3370

63

370 C

600-250

600

50

35 / 250

500

250

750

370 x 370

570 x 570

600

40

175

15

1,8 (1,6)-259

23,9

DIN EN 60204

1 x 16 A

250

30 / 35 / 40

23,3 / 20 / 17,5

150

106 / 144 / 188

97 / 132 / 172

17 / 20,5 / 24,5

8,5 / 10,5 / 12,5

2470 / 1820 / 1390

112 / 154 / 202

350 / 476 / 622

350 / 140

49 / 57 / 66

320 / 380 / 430

60

240

5,8 / 4

0,6

50

170 (120)

235

3450

80

370 C / 420 C

800-250

800

50

35 / 250

500

250

750

370 x 370 / 420 x 420

570 x 570

600

40

175

15

1,8 (1,7)-259 | 1,9 (1,8)-294

23,9

DIN EN 60204

1 x 16 A

250

30 / 35 / 40

23,3 / 20 / 17,5

150

106 / 144 / 188

97 / 132 / 172

17 / 20,5 / 24,5

8,5 / 10,5 / 12,5

2470 / 1820 / 1390

112 / 154 / 202

350 / 476 / 622

350 / 140

49 / 57 / 66

320 / 380 / 430

60

240

5,8 / 4

0,6

50

170 (120)

235

3450

80

420 C

1000-250

1000

50

35 / 250

500

250

750

420 x 420

570 x 570

600

40

175

18,5

2,0 (1,7)-294

27,4

DIN EN 60204

1 x 16 A

250

30 / 35 / 40

23,3 / 20 / 17,5

150

106 / 144 / 188

97 / 132 / 172

17 / 20,5 / 24,5

8,5 / 10,5 / 12,5

2470 / 1820 / 1390

144 / 196 / 256

350 / 476 / 622

350 / 140

49 / 58 / 66

320 / 380 / 430

60

240

5,8 / 4

0,6

50

170 (120)

235

3460

100

420 C

1000-350

1000

50

35 / 250

500

250

750

420 x 420

570 x 570

600

40

175

22

2,0 (1,6)-294

33,9

DIN EN 60204

1 x 16 A

350

35 / 40 / 45

23 / 20 / 18

145

139 / 182 / 230

127 / 166 / 210

25 / 29 / 35

12,5 / 15 / 17,5

2500 / 2120 / 1670

128 / 168 / 212

492 / 642 / 814

350 / 160

47 / 53 / 60

480 / 550 / 610

60

300

8,8 / 4

0,6

50

170 (120)

235

3700

100

3

DIN US

D

IN

DIN US

D

IN

cyan yellow magenta key

U

S

U

S

370/420 C Equipment

Control system and control

cabinet

SELOGICA control system (modu-

lar, graphic multi-processor sys-

tem)

Available in different language

versions

j Language change

Cycle sequence programming

with symbols

Cycle step display in sequence

diagram

j Cycle time diagram

Swivelling monitor unit, central

on the operators side, with col-

our monitor

Process graphics for injection

speed, screw stroke and injection

pressure

Quality assurance program with

fault evaluation and monitoring

chart

Optimisation and user help, fol-

low-up functions at program

end, for freely programmable

parameter pages, selectable units

Modular control cabinet design

with self-recognition of plug in

circuit board system

Operating modes:

- Set up

- Freely programmed test run

- Reconguration

- Automatic purging and dosing

j Equipment for switch-over to

holding pressure via injection

pressure, material pressure with

different pressure transducers, or

via external switch over signal

Data set administration via dis-

kette

Visual warning signal (warning

lamp)

j Visual / audible warning signal

(ashing light / siren)

Serial printer interface for hard

copy, data record and quality

protocol

j Interfaces for: PC keyboard, plot-

ter, robotic system according to

EUROMAP 12 or 67, part weigh-

ing scale, optical barrier, host

processor, AQC, ALLROUNDER@

web, colouring unit, LSR dos-

ing system, INJESTER, container

change, wiper unit (brush), THER-

MOLIFT, hot runner control unit

and temperature control units for

moulds and cylinder

Socket combination 1 CEE,

1 Schuko 230 V

j Socket combination 1 CEE,

1 Schuko or 3 CEE, 3 Schuko

230 V with external supply line

j 1 additional heating regulation

circuit for the nozzle

j Electric heating regulation circuits

for moulds (adaptive) (3, 6, 9, 12,

15, 18); mould heating fused at

10 A

j Fuses for mould heating 16 A

j 4 or 8 freely programmable in-

puts / outputs

j Core pull programs in many ver-

sions integrated in the SELOGICA

control system

j Special processes such as injection

coining, mould venting, variot-

herm temperature control, intrud-

ing, marbling

j Monitoring: Freely-programmable

position monitoring

j Many individual options for spe-

cial processes

Machine base and hydraulic

system

Free standing machine base on

anti-vibration pads

Ergonomic protection cover with

free access to mould and nozzle

Space for peripheral devices

within oor space

The hydraulic system operates

with an energy-saving variable

displacement pump and a servo

valve for pressure and speed

regulation

j Expansion to up to 2 hydraulic

control circuits

j Expansion to up to 3 hydraulic

control circuits

j ARBURG energy saving system

AES (rpm changeable for hydrau-

lic pump drive)

Minimum oil volume, oil change

interval every 20,000 hours

Monitoring of oil level, oil temper-

ature and oil lter contamination

Fine mesh oil lter in the return

line

Mechanical regulation of hydrau-

lic oil temperature

j Electronic regulation of hydraulic

oil temperature. Display and

monitoring via screen

Hydraulic oil preheating program

to reduce start-up time

j Separate, continuous oil circula-

tion for additional cooling and

ltration

Manually adjustable, machine-re-

lated cooling water circuits with

4 free mould connections

j 6 or 8 free cooling water circuits,

manually adjustable

j Programmable, machine and

mould-related cooling water cir-

cuits

j 1 or 2 central switch-off valves

for cooling water

j Conveyor belt (electrically driven),

height-adjustable in 3 steps, can

be integrated into the machine

base with or without sorter unit

j Crane with electric hoist to fa-

cilitate mould installation and to

swivel or shift the injection unit

Clamping unit

Centrally applied, fully-hydraulic

clamping system with 4 individu-

ally-removable tie bars

Vertical support of the movable

mould platens

Movement profiles for the mould

clamping unit are programmable

and regulated. They are serially

driven using energy-saving one-

circuit pump technology (Tech-

nology stage 1)

j Movement profiles for the mould

clamping unit are programmable

and regulated. They are driven

using two-circuit pump technol-

ogy (Technology stage 2 - servo-

regulated). The closing pressure

is regulated. Simultaneous move-

ment of nozzle and ejector is

possible

j Hydraulic system with 3 regulat-

ing pumps for extended simulta-

neous movements (T3)

Closing and opening profiles are

2-stage programmable (4-stage

with Technology stage 2)

j Intermediate stop possible when

closing and opening (standard

with T2)

Regulated hydraulic mould pro-

tection with monitoring of mould

protection time. Follow-up func-

tions: Open or stop after 1 or 2

activations of mould protection

j Extended mould protection (e.g.

for spring loaded moulds). Freely-

programmable start and end

Automatic ramp control during

switch-over to a lower speed and

during stopping of a movement

function

Hydraulic ejector with quick re-

lease coupling is integrated into

the clamping system

Hydraulic ejector: Forces and

speeds, multiple stroke (up to 10)

and ejector advanced at program

end are programmable

j Hydraulic ejector for simultane-

ous movements regulated with

servo valve

Mould monitoring via ejector

platen safety switch

j Electro-mechanical servo drive for

ejector system, position control-

led for simultaneous drive move-

ments

j Hydraulic core pulls with rapid

connect coupling on the movable

mould platen

j Hydraulic core pull movement

profiles programmable and regu-

lated

j Core holding pressure manually

adjustable

j Pressure hold programmable

j Hydraulic core pull, simultaneous

movements regulated

j Controlled hydraulic unscrewing

units for threaded cores in one

or two directions of rotation for

mounting on xed or movable

clamping platen. Restricted ejec-

tor stroke

4

DIN US

D

IN

DIN US

D

IN

cyan yellow magenta key

U

S

U

S

370/420 C Equipment

j Unscrewing unit with electro-

mechanical servo drive for

2-direction threaded cores for

installation on the movable

clamping platen for ultra-precise

positioning and reproducibility.

Restricted ejector stroke

Attachment option for robotic

handling device

j Mechanical rapid clamping

system with mould support to

facilitate mould installation

j Power-operated safety gate,

programmable opening time

j Mould blow unit with pressure

relief valve

j Sorter unit (SELECTRON)

j Mechanical mould closing

protection

Injection unit

Central injection unit, can be

re-positioned and swivelled as a

complete assembly

j Horizontally displaceable injec-

tion unit (VARIO principle)

j Adapter for parting line injection

Plasticising module with univer-

sal screw, central coupling and

adaptive temperature regulation,

available in different diameters

Thermoplastic cylinder with

universal screw in wear resistant

execution

j Thermoplastic cylinder complete

with very high wear resistant

equipment

j Plasticising module for processing

thermoset, elastomer and silicone

materials

j Thermoplast screws for special

applications, e.g. self-dyeing

(mixing section), PVC (shear-sen-

sitive), POM, PA (semi-crystalline)

Programmable nozzle speeds

(advance 2, retract 1 stage) and

advance and retract delay

Monitored nozzle contact

Continuous nozzle contact dur-

ing the complete cycle

Programmable nozzle contact

force

j Regulated nozzle contact force

Regulated injection speed prole,

2 steps programmable with injec-

tion delay

j Pressure accumulator for very fast

injection

j Position-regulated screw (forced

movement of injection axis)

j Injection process control with

external sensor

Measurement, display and

monitoring of the injection time,

switchover volume and switcho-

ver pressure

Switch over to holding pressure

as a volume or time dependent

function

Material cushion monitoring

Holding pressure prole regulat-

ed via polygon with 4 base points

Programmable delay times for all

movements

Screw circumferential speed dis-

play

Positively and negatively pro-

grammable back pressure

Dosage time display with

programmable dosage time

monitoring

Dosage possible before or after

nozzle retraction

Material decompression with pro-

grammable decompression speed

j Dosage with electro-mechanical

servo drive, energy-saving

Open nozzle with screw-in tip

j Needle type shut off nozzle,

spring force actuated

j Needle type shut off nozzle,

hydraulically actuated

Zone-dependent monitoring of

heating circuits for continuity,

short circuit and defective sensors

Temperature monitoring with re-

lease tolerance range and zone-

dependent monitoring tolerance

j Automatic temperature sink can

be selected on error or after au-

tomatic switch off

50 litre corrosion proof stainless

steel material hopper movable to

a blocking and emptying position

j Granulate feed zone, program-

mable and regulated with moni-

toring

Extended functions

j Extended monitoring of the me-

chanical sequence of mould and

machine for complex applications

j Extended drive movements: In-

crease in number of movement

stages, intermediate stop func-

tions and extended locking force

program

j Production control with nomi-

nal temperature value control,

programmable alarm cycles, pro-

grammable switch-on / switch-off

sequences as well as time-con-

trolled automatic switch-on/off

in second programming level for

follow-up batch

Regulated parameters

Control cabinet temperature

Hydraulic oil temperature

Plasticising cylinder temperature

(adaptive)

Screw rotation speed

Injection ow or injection speed

Holding pressure

Movements and force of mould,

nozzle and ejector

Ramp control sequence for

mould, ejector and nozzle end

position

Back pressure

j Electrical mould heating circuits

(adaptive)

j Mould cooling circuits

j Internal cavity pressure or

screw chamber pressure (external

sensor)

j Nozzle contact force

j Screw position

j Granulate feed zone temperature

j Ejector

ARBURG robotic systems

j INTEGRALPICKER H: sprue picker

operating horizontally from the

rear of the machine under the

protection cover; pneumatic drive

j INTEGRALPICKER V: vertical sprue

picker operating from above,

pneumatic drive

j MULTILIFT H: robotic system op-

erating horizontally from the rear

of the machine with pneumatic

drives (Z-axis optional with servo-

electric drive)

j MULTILIFT V: robotic system oper-

ating vertically from above (longi-

tudinal and transverse installation

possible) with 3 servo-electric

axes

Basic machine

j Options

5

DIN US

D

IN

DIN US

D

IN

cyan yellow magenta key

U

S

U

S

370/420 C Mould and platen layout

innitely adjustable max. 175

cylinder platen

coupling

1) Dimensions are valid for thermoset moulds for injection units 100 and 250

2) Dimensions apply for 420 C 1000-350

Refer to separate dimension sheet for parting line unit (on request)

stroke

max. 500

max. 750

40 / 20

1)

50

2)

nozzle in advanced end position

mould height

View C-D View E

thread M16-31 deep

in cylinder platen

for mech. ejector

thread M8-16 deep for

robotic handling device

thread M16-30 deep for

robotic handling device

min. 250

Dimensions only apply for 420 C 1000-350

counter bore in the mould

required only for short sprue

dimensions for thermoset moulds

ejector bolt

273-1

X

C

3

0

5

Y

D

E

85

400

327

1245

Y

5

0

8

9

5

4

X

115

3

1

1

1

532.5

35

1

0

0

97.5

105

B A

6

0

20

290

2

9

5

3

6

9

0

6

5

1

1

0

20 9

20.5

1

2

5

H

7

2

8

0

4

9

0

12-0.1

19

3

2

-

0

.

1

2

4

3

2

50

3

0

3

6

DIN US

D

IN

DIN US

D

IN

cyan yellow magenta key

U

S

U

S

370/420 C

( ) Dimensions apply for 420 C

Mould and platen layout

thread M12-24 deep

Bores for ARBURG mechanical

mould quick-clamping system

thread M8-16 deep for

robotic handling device

thread M10 for

unscrewing unit

Useable mounting surface with tie bars removed

Fixed platen

Movable platen

View A / for horizontally displaceable injection unit View A / for central injection unit

View B

1

1

0

1

2

5

H

7

3

5

0

2

8

0

2

1

0

1

4

0

7

0

350

280

210

140

70

420

1

8

9

1

2

6

22

68

2

9

3

.

5

85

6

0

0

4

3

0

(

4

8

0

)

6

0

3

7

0

(

4

2

0

)

5

8

0

4

6

0

6

5

5

3

5

0

580

170

100

370 (420)

430 (480)

880

5

4

8

(

6

1

8

)

800

4

9

0

1

2

5

H

7

170

2

5

4

2

0

490

7

DIN US

D

IN

DIN US

D

IN

cyan yellow magenta key

U

S

U

S

370/420 C Maximum shot weights

Maximum theoretical shot weights for the most important injection moulding materials (in grams)

Injection units according to EUROMAP

Screw diameter mm

Polystyrene PS

Styrene heteropolymerizates SB

SAN, ABS

1)

Cellulose acetate CA

1)

Celluloseacetobutyrate CAB

1)

Polymethyl methacrylate PMMA

Polyphenylene ether, mod. PPE

Polycarbonate PC

Polysulphone PSU

Polyamides PA 6.6, PA 6

1)

PA 6.10, PA 11

1)

Polyoximethylene (Polyacetal) POM

Polyethylene terephthalate PET

Polyethylene PE-LD

PE-HD

Polypropylene PP

Fluorpolymerides FEP, PFA, PCTFE

1)

ETFE

Polyvinyl chloride PVC-U

PVC-P

1)

1) average value

100

20 25 30

29 45 65

28 44 63

27 43 62

32 50 73

30 47 68

30 46 67

27 42 60

30 47 68

31 49 70

28 44 64

26 41 60

35 55 80

34 53 77

22 34 49

22 35 50

23 36 51

46 72 103

40 63 91

35 54 78

32 50 72

250

30 35 40

97 132 172

95 129 168

93 126 165

109 148 194

101 138 180

100 136 178

90 122 160

102 139 181

105 143 187

96 131 171

90 122 160

120 163 213

115 157 205

73 100 130

76 103 134

77 105 137

155 211 276

136 185 242

117 159 208

108 147 192

350

35 40 45

127 166 210

124 162 205

122 160 202

143 187 237

133 174 220

132 172 218

118 154 195

134 175 221

138 181 229

127 165 209

118 154 195

157 205 260

152 198 251

96 126 159

99 130 164

101 133 168

204 266 337

178 232 294

154 201 254

142 186 235

5

2

2

5

4

1

_

E

N

_

G

B

_

0

3

2

0

0

8

S

u

b

j

e

c

t

t

o

a

l

t

e

r

a

t

i

o

n

s

P

r

i

n

t

e

d

i

n

G

e

r

m

a

n

y

ARBURG GmbH + Co KG Quality:

DIN EN ISO 9001 + 14001 certied

ARBURG GmbH + Co KG

Postfach 11 09 72286 Lossburg Tel.: +49(0)7446 33-0 Fax: +49(0)7446 33-3365 www.arburg.com e-mail: contact@arburg.com

With locations in | Europe: Germany, Belgium, Denmark, France, United Kingdom, Italy, Netherlands, Austria, Poland, Switzerland, Slovakia,

Spain, Czech Republic, Turkey, Hungary | Asia: Peoples Republic of China, Indonesia, Malaysia, Singapore, Thailand | America: Brazil, Mexico, USA

For more information, please go to www.arburg.com.

2008 ARBURG GmbH + Co KG

The brochure is protected by copyright. Any utilisation, which is not expressly permitted under copyright legislation, requires the previous approval of ARBURG.

All data and technical information have been compiled with great care. However, we are unable to guarantee its correctness. Individual illustrations and information may deviate from the actual

delivery condition of the machine. The relevant valid operating instructions are applicable for the installation and operation of the machine.

Potrebbero piacerti anche

- Operation Manual: Mist CollectorDocumento40 pagineOperation Manual: Mist CollectorYing Kei ChanNessuna valutazione finora

- Anglamar Company ProfileDocumento19 pagineAnglamar Company ProfileKayeAnGeeNessuna valutazione finora

- BSPT Thread Sizes & TypesDocumento3 pagineBSPT Thread Sizes & TypesuttampokharkarNessuna valutazione finora

- Process Capability & SQCDocumento37 pagineProcess Capability & SQCNirav Solanki0% (1)

- Unigraphics Interview Question A IreDocumento5 pagineUnigraphics Interview Question A Ireyuvarajtalele100% (2)

- Tap Drill ChartDocumento1 paginaTap Drill ChartITLHAPNNessuna valutazione finora

- 02.DesignForAssembly109 (NXPowerLite)Documento109 pagine02.DesignForAssembly109 (NXPowerLite)maddy_scribdNessuna valutazione finora

- How To Install NX 7.5 in Window 7Documento2 pagineHow To Install NX 7.5 in Window 7priyankar00750% (2)

- Curriculum Vitae Sample From NTTFDocumento2 pagineCurriculum Vitae Sample From NTTFshaileswor100% (1)

- CorelDraw Training For Laser Cutting Machines With Many Examples Learn and Master Many Example You Can Do With Coreldraw.... (Kaşoğlu, Abdulkadir Kaşoğlu, Abdulkadir)Documento59 pagineCorelDraw Training For Laser Cutting Machines With Many Examples Learn and Master Many Example You Can Do With Coreldraw.... (Kaşoğlu, Abdulkadir Kaşoğlu, Abdulkadir)MirelaMilanNessuna valutazione finora

- CATIA V5 Fundamentals PDFDocumento3 pagineCATIA V5 Fundamentals PDFHarshitNessuna valutazione finora

- DEWALT D55270 TYPE 2 Owners ManualDocumento26 pagineDEWALT D55270 TYPE 2 Owners ManualITLHAPNNessuna valutazione finora

- Asistente de Preparacion Al Mecanizado PrismaticoDocumento25 pagineAsistente de Preparacion Al Mecanizado PrismaticoJuanGómezNessuna valutazione finora

- Rubber Molding Methods and Material Selection GuideDocumento9 pagineRubber Molding Methods and Material Selection GuideStefan VladNessuna valutazione finora

- Limits Fits TolerancesDocumento77 pagineLimits Fits Tolerancessunil_gundNessuna valutazione finora

- Parx Plastics Successfully Adds Antimicrobial Property To BASF Terluran® GP-35 ABS Copolymer - Modern Plastics & PolymersDocumento1 paginaParx Plastics Successfully Adds Antimicrobial Property To BASF Terluran® GP-35 ABS Copolymer - Modern Plastics & PolymersParas PatelNessuna valutazione finora

- Plastic Bottle PDFDocumento21 paginePlastic Bottle PDFnasyahrahNessuna valutazione finora

- G. G. Automotive Gears Ltd. ProfileDocumento7 pagineG. G. Automotive Gears Ltd. Profileca_pksandcoNessuna valutazione finora

- Kinematics Particle Straight LineDocumento51 pagineKinematics Particle Straight LineisamalhassanNessuna valutazione finora

- Vericut Brochure 70Documento16 pagineVericut Brochure 70sivakumarsambandamNessuna valutazione finora

- Speed Up Your Outputs by Using These ShortcutsDocumento8 pagineSpeed Up Your Outputs by Using These Shortcutsychaudhry2006Nessuna valutazione finora

- Tangent ContinuityDocumento4 pagineTangent ContinuityGM59476Nessuna valutazione finora

- Ascending Triangle Guide - How to Identify & Trade This Bullish PatternDocumento8 pagineAscending Triangle Guide - How to Identify & Trade This Bullish PatternSurya NayakNessuna valutazione finora

- Training Exercises for SAP Business Intelligence Characteristic InfoObjectsDocumento54 pagineTraining Exercises for SAP Business Intelligence Characteristic InfoObjectsNEX4REU50% (2)

- Tolerancing in PlasticsDocumento5 pagineTolerancing in PlasticsNarasimha ReddyNessuna valutazione finora

- SIEMENS - Ingenieria Mecanica 2012 08 - CENITEC 1Documento141 pagineSIEMENS - Ingenieria Mecanica 2012 08 - CENITEC 1Nestor IglesiasNessuna valutazione finora

- Inch Thread PlugDocumento10 pagineInch Thread PlugAizen SousukeNessuna valutazione finora

- Injection MouldingDocumento16 pagineInjection Mouldingramesh.rao3192Nessuna valutazione finora

- Trade of Tool MakingDocumento14 pagineTrade of Tool MakingabdurazakNessuna valutazione finora

- 2000 09 JIMT Cost Estimation Injection MoldingDocumento11 pagine2000 09 JIMT Cost Estimation Injection MoldingVictor Villouta LunaNessuna valutazione finora

- Introduction to 3D Scanning TechniquesDocumento18 pagineIntroduction to 3D Scanning TechniquesMoiz AamirNessuna valutazione finora

- Training Programme For Managers and Supervisors: What Makes A Good Supervisor?Documento20 pagineTraining Programme For Managers and Supervisors: What Makes A Good Supervisor?Prateek AgarwalNessuna valutazione finora

- Shrinkage TableDocumento6 pagineShrinkage TableMahesh Deivasiga Mani DNessuna valutazione finora

- 2d Curve DigitizingDocumento2 pagine2d Curve DigitizingMark Hauser100% (1)

- Cddvdportal - Cad Cam Cae CFD Software CdsDocumento5 pagineCddvdportal - Cad Cam Cae CFD Software CdscddvdportalNessuna valutazione finora

- m1 U5 Assembly & DowelingDocumento14 paginem1 U5 Assembly & DowelingViệt Đặng XuânNessuna valutazione finora

- MoldFlow Simulation Optimizes Injection MoldingDocumento47 pagineMoldFlow Simulation Optimizes Injection MoldingpraveenmanturNessuna valutazione finora

- NX Modeling, Assembly and Drafting GuideDocumento38 pagineNX Modeling, Assembly and Drafting GuidePradeepvenugopalNessuna valutazione finora

- Catia ModulesDocumento4 pagineCatia ModulesYaswanthNessuna valutazione finora

- 1488644012final Bending - Forming, DrawingDocumento31 pagine1488644012final Bending - Forming, DrawingasifNessuna valutazione finora

- m1 - U3 - Drilling, Counterboring & CountersinkingDocumento15 paginem1 - U3 - Drilling, Counterboring & CountersinkingViệt Đặng XuânNessuna valutazione finora

- Edu Cat e MTD FX v5r8Documento20 pagineEdu Cat e MTD FX v5r8Lup DanielNessuna valutazione finora

- MicroSurvey CAD Fundamentals Online CourseDocumento1 paginaMicroSurvey CAD Fundamentals Online CoursetopogcarlosNessuna valutazione finora

- ~تلرانس هاي هندسي-محمد رضا عباسی 1386 PDFDocumento480 pagine~تلرانس هاي هندسي-محمد رضا عباسی 1386 PDFdavoodsalimiNessuna valutazione finora

- Bracket DrawingDocumento1 paginaBracket DrawingdhareeshNessuna valutazione finora

- Designn of Tranmission SystemDocumento4 pagineDesignn of Tranmission Systemsathiskumar411Nessuna valutazione finora

- Nettur Technical Training Foundation Diploma in Tool and Die Making-Cp 01 Press Tool TechnologyDocumento25 pagineNettur Technical Training Foundation Diploma in Tool and Die Making-Cp 01 Press Tool Technologynidhin mathewNessuna valutazione finora

- Mold Material: H13 P20 Mirror Polish Texture H13 P20Documento1 paginaMold Material: H13 P20 Mirror Polish Texture H13 P20Jyoti KaleNessuna valutazione finora

- Accounting Entries Under GSTDocumento9 pagineAccounting Entries Under GSTLovaraju RajuNessuna valutazione finora

- Mat mt11050 GDocumento362 pagineMat mt11050 Gandreeaoana45Nessuna valutazione finora

- CADSYS INDIA Limited Annual Report 2017 18 04 09 2018 Interactive PDFDocumento123 pagineCADSYS INDIA Limited Annual Report 2017 18 04 09 2018 Interactive PDFRajuNessuna valutazione finora

- NX NF TipsUndTricksDocumento12 pagineNX NF TipsUndTricksThilo Breitsprecher100% (1)

- Nettur Technical Training Foundation: Programmable Logic Controller Lab W /CP15 /7516Documento101 pagineNettur Technical Training Foundation: Programmable Logic Controller Lab W /CP15 /7516Aaron DmcNessuna valutazione finora

- Taking A Geometric Dimensioning and Tolerancing CourseDocumento2 pagineTaking A Geometric Dimensioning and Tolerancing CourseJames D. Meadows & Associates, Inc.Nessuna valutazione finora

- PDFDocumento8 paginePDFomarNessuna valutazione finora

- Arburg370&420C PDFDocumento8 pagineArburg370&420C PDFMatoa PapedaNessuna valutazione finora

- Woojin Plaimm Injection Molding MachineDocumento10 pagineWoojin Plaimm Injection Molding MachineFauzi IskandarNessuna valutazione finora

- Moldeadora PDFDocumento12 pagineMoldeadora PDFAmirAmiriNessuna valutazione finora

- Guidelines: Injection Mold DesignDocumento4 pagineGuidelines: Injection Mold DesignAmirAmiriNessuna valutazione finora

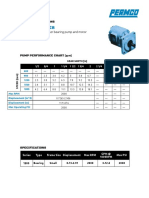

- Technical specifications and performance charts for 1500 series small displacement roller bearing pumpsDocumento2 pagineTechnical specifications and performance charts for 1500 series small displacement roller bearing pumpsAmirAmiriNessuna valutazione finora

- 1320 HP Zr2440w MonitorDocumento2 pagine1320 HP Zr2440w MonitorAmirAmiriNessuna valutazione finora

- Aluminium Alloy 1100 Data SheetDocumento1 paginaAluminium Alloy 1100 Data SheetKhaja NawasNessuna valutazione finora

- 1511 04990Documento20 pagine1511 04990AmirAmiriNessuna valutazione finora

- Project Report FinalDocumento52 pagineProject Report FinalAmirAmiri0% (1)

- D 004663 PDFDocumento96 pagineD 004663 PDFAmirAmiriNessuna valutazione finora

- Te TramerDocumento8 pagineTe TramerAmirAmiriNessuna valutazione finora

- Engineering Plastics..Documento55 pagineEngineering Plastics..AmirAmiriNessuna valutazione finora

- Forging 140519005802 Phpapp02Documento38 pagineForging 140519005802 Phpapp02AmirAmiriNessuna valutazione finora

- Fatigue Testing MachineDocumento3 pagineFatigue Testing MachineAmirAmiriNessuna valutazione finora

- Interface: Giving People A VoiceDocumento3 pagineInterface: Giving People A VoiceAmirAmiriNessuna valutazione finora

- Injection Molding Lecture 09-04-08Documento20 pagineInjection Molding Lecture 09-04-08viswaforuNessuna valutazione finora

- Injection Moulding: CD Catalogue Online CatalogueDocumento1 paginaInjection Moulding: CD Catalogue Online CatalogueAmirAmiriNessuna valutazione finora

- PDM PLMDocumento7 paginePDM PLMAmirAmiriNessuna valutazione finora

- Honeywell Ekoflush - Airco SpoelenDocumento4 pagineHoneywell Ekoflush - Airco SpoelenAmirAmiriNessuna valutazione finora

- Ground Spur Gears Module 0.5 ISO Class 5 8mm Face 20Documento2 pagineGround Spur Gears Module 0.5 ISO Class 5 8mm Face 20AmirAmiriNessuna valutazione finora

- Eastman Polymers - Processing and Mold Design GuidelinesDocumento44 pagineEastman Polymers - Processing and Mold Design GuidelinesnimonhNessuna valutazione finora

- Scoring Short Ipaq April04Documento9 pagineScoring Short Ipaq April04AmirAmiriNessuna valutazione finora

- Injection Moulding: CD Catalogue Online CatalogueDocumento1 paginaInjection Moulding: CD Catalogue Online CatalogueAmirAmiriNessuna valutazione finora

- Plate Design For Husky Manifold SystemsDocumento14 paginePlate Design For Husky Manifold SystemsAmirAmiriNessuna valutazione finora

- Injection MoldingDocumento8 pagineInjection MoldingDebasmiti MishraNessuna valutazione finora

- Dmls Design GuidelinesDocumento8 pagineDmls Design GuidelinesAmirAmiriNessuna valutazione finora

- PrefDocumento3 paginePrefAmirAmiriNessuna valutazione finora

- Training Documents - SolidWorks ComposerDocumento2 pagineTraining Documents - SolidWorks ComposerAmirAmiriNessuna valutazione finora

- Appendix Nve: RsionsDocumento7 pagineAppendix Nve: RsionsAmirAmiriNessuna valutazione finora

- Tool CRMDocumento36 pagineTool CRMAmirAmiriNessuna valutazione finora

- Harmonic Motion of A Maxwell Model: Trigonometric NotationDocumento4 pagineHarmonic Motion of A Maxwell Model: Trigonometric NotationAmirAmiriNessuna valutazione finora

- USB GPW CB03 MT02 - EngDocumento21 pagineUSB GPW CB03 MT02 - EngRafael BispoNessuna valutazione finora

- Scramjet EngineDocumento2 pagineScramjet EngineSãröj ShâhNessuna valutazione finora

- Proper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFDocumento12 pagineProper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFAnonymous bHh1L1Nessuna valutazione finora

- FOT - CG Limitation A320neo - Web ConferenceDocumento7 pagineFOT - CG Limitation A320neo - Web Conferencerohan sinha100% (2)

- SIEMENS-7SA522 Setting CalculationDocumento20 pagineSIEMENS-7SA522 Setting Calculationnaran19794735Nessuna valutazione finora

- Answer Key Grade 6 - 2023Documento7 pagineAnswer Key Grade 6 - 2023ALKHANSAA ELOBEIDYNessuna valutazione finora

- Tech Note 14Documento2 pagineTech Note 14meteohrNessuna valutazione finora

- Hydrogen and Its Compound.1Documento10 pagineHydrogen and Its Compound.1abhishekNessuna valutazione finora

- SERVICE MANUAL CRAWLER EXCAVATOR R210LC-7Documento1 paginaSERVICE MANUAL CRAWLER EXCAVATOR R210LC-7DmitryNessuna valutazione finora

- Answers To Chemistry Homework 5.1 From Particles To Solutions P. 178 # 8,9,10Documento6 pagineAnswers To Chemistry Homework 5.1 From Particles To Solutions P. 178 # 8,9,10fantasy373Nessuna valutazione finora

- MITRES 6 002S08 Chapter2Documento87 pagineMITRES 6 002S08 Chapter2shalvinNessuna valutazione finora

- Employee performance factors analysis electronic companyDocumento10 pagineEmployee performance factors analysis electronic companyAmrithaNessuna valutazione finora

- 2010 MaxxForce DT-9-10 DiagnosticDocumento1.329 pagine2010 MaxxForce DT-9-10 Diagnosticbullfly100% (8)

- Haidarali-MR-2011-PhD-Thesis 01 PDFDocumento378 pagineHaidarali-MR-2011-PhD-Thesis 01 PDFIbrahim KhanNessuna valutazione finora

- SUBstation Equipmens TLDocumento12 pagineSUBstation Equipmens TLJecer Casipong NuruddinNessuna valutazione finora

- Ey-H3l Yh1576Documento44 pagineEy-H3l Yh1576jorgeNessuna valutazione finora

- Wsat200 RamsaDocumento12 pagineWsat200 RamsaAndy ColeNessuna valutazione finora

- TIM Fungsi 1Documento40 pagineTIM Fungsi 1lilikNessuna valutazione finora

- Bilstein SZ SL Sls 2010Documento16 pagineBilstein SZ SL Sls 2010Wimin HungNessuna valutazione finora

- Verify scope acceptance of project deliverablesDocumento5 pagineVerify scope acceptance of project deliverablesmypmpbooksNessuna valutazione finora

- DasibiOzoneMonitorManual 1008Documento183 pagineDasibiOzoneMonitorManual 1008api-26966403100% (2)

- Measurements/ Specifications: Torque Wrench Selection GuideDocumento5 pagineMeasurements/ Specifications: Torque Wrench Selection GuideSylvester RakgateNessuna valutazione finora

- Introducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionDocumento9 pagineIntroducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionJhónatan CarranzaNessuna valutazione finora

- Climate Change: The Fork at The End of NowDocumento28 pagineClimate Change: The Fork at The End of NowMomentum Press100% (1)

- Meeting 5: Data Warehouses and SQL Query OptimizationDocumento4 pagineMeeting 5: Data Warehouses and SQL Query Optimizationzvipev1050% (2)

- Ms-Dos Device Drivers: Device Drivers Are The That in File atDocumento13 pagineMs-Dos Device Drivers: Device Drivers Are The That in File atJass GillNessuna valutazione finora

- WPS Office 2016Documento22 pagineWPS Office 2016Muhammad Aliff SyukriNessuna valutazione finora

- Regeln Map 2Documento2 pagineRegeln Map 2bruno.wetzelNessuna valutazione finora

- ANSYS ACT Developers GuideDocumento506 pagineANSYS ACT Developers GuideEDIZONNessuna valutazione finora

- PDS - GulfSea Hydraulic AW Series-1Documento2 paginePDS - GulfSea Hydraulic AW Series-1Zaini YaakubNessuna valutazione finora