Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vacuum Treatment of Melts With Charge Weights Up To 30 Tons: Vacuum Induction Degassing VID 400 - VID 3000

Caricato da

sureshkumar908Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vacuum Treatment of Melts With Charge Weights Up To 30 Tons: Vacuum Induction Degassing VID 400 - VID 3000

Caricato da

sureshkumar908Copyright:

Formati disponibili

Vacuum Tr eat ment of Mel t s

wi t h Char ge Wei ght s up t o 30 t ons

VI D

Vac uum I nduc t i on Degassi ng

VI D 400 VI D 3000

Mg

Ti

Cr

Mn

Mo

Fe

Co

Ni

Cu

Al

H

N

S

O

C

Product Application and Quality Improvement in Different Processes

2

VI D Vacuum I nduct i on Degassi ng

VI D

The Vacuum Induction Degassing (VID)

furnace concept has been developed for

special applications in the ferrous and

non-ferrous metals industry for charge

weights up to 30 tons. Whenever pouring

under vacuum is not specified or not

required for metallurgical reasons, this

bell type furnace with open-air teeming is

recommended for its favourable economics.

Smaller steel shops and foundries will be

able to produce with the VID furnace, within

one step, high quality vacuum treated steels,

whereas larger shops have to realize these

qualities employing a conventional LF/VD/VOD

production line. The temperature losses during

degassing treatment are compensated by

induction heating.

The opt i mal l i nk bet ween c onvent i onal St eel Degassi ng

( Sec ondar y Met al l ur gy) and Vac uum I nduc t i on Mel t i ng ( VI M)

Basic design [1]

Vacuum tight, tiltable, charge weights up to 30 tons

Melting under vacuum [2]

Vacuum degassing/Deoxidation

Precise temperature adjustment

Decarburization/Desulphurization

Alloying and Pouring

Pouring

VID: Pouring at air [3]

VID-Pro: Pouring under protective gas [4]

VID-Oxy: Decarburization with dissolved

oxygen [5]

1 2

VD LF/VD VOD VODC VID VIM

Low carbon steels

High carbon steels

Tool and die steels

Stainless steels

Fe-Ni-Alloys

Superalloys

Non ferrous alloys

Hydrogen removal

Nitrogen removal

Decarburization

Vacuum carbon deoxidation

Desulphurization

Inclusion removal

Extra low carbon

Fine trimming

Temperature control

+ + o o +

+ + + + +

+ + +

+

+

+ +

+ + + +

+ + + + + +

+ + +

+

+

+ +

+ +

+ +

+ + + + +

+ +

+

+ +

+

+ + +

+ +

+ +

+ +

+ +

+

good not suitable secondary effect o

+ + +

o

+ +

+

+

+

Basic design Melting under vacuum

o o

3

VI D

All important secondary metallurgy treatment

steps melting under vacuum, refining such as

decar burization, desulphurization, deoxidation,

removal of undesired gases like hydrogen

and nitrogen, exact adjustment of chemical

analysis, cleaning, alloying, heating are done

in one single unit. The melt will be cast at air.

VI D- Pr o

The modified VID-Pro furnace allows not

only meltdown and vacuum-refining, but also

pouring under protective inert gas. The vacuum

lid stays in closed position during melting,

refining and casting. Gas-pick-up during

tapping can be minimized.

3 4 5

VI D- Oxy

The VID-Oxy furnace is dedicated to economical

production of high-chromium steel grades,

accomplished by using low-cost raw materials.

Soft oxygen top blowing by means of a gas

lance allows additional removal of carbon.

With the VID-Oxy furnace concept it is possible

to carry out metallurgical work such as

degassing, deoxidation, desulphurization and

removal of oxide-inclusions with a reactive

basic slag and chemistry adjustment under

vacuum. The results are very low carbon and

nitrogen contents and high chromium yield.

The VID-Oxy furnace is the ideal alternative to

conventional steel degassing with EAF/VD/VOD

at charge weights up to 30 tons.

[3] VID: Pouring at air [4] VID-Pro: Pouring under protective gas [5] VID-Oxy: Oxygen blowing and slag

treatment

Pouring at air Pouring under protective gas Slag treatment

V I D S y s t e ms a n d Re f e r e n c e s

4

1

2

[4] VI D- Pr o

VI D- Pr o 400 3 t

Vacuumschmelze Hanau, Germany

Pouring of Fe-base alloys under protective

inert gas atmosphere

[3] VI D- Pr o

VI D- Pr o 2000 16 t

KM- Kabel met al l , Osnabr c k, Ger many

Pouring of copper alloys under protective inert

gas atmosphere into slab caster

[1+2] VI D

VI D 1000 5 t

Kind & Co, Germany

Producer of tool-steels

Pouring at air

3

5

[5] VI D- Oxy

VI D- Oxy 6 t

Shagang, China

Decarburization by oxygen blowing

Production of special steels and low carbon steels

4

5

6

[6] VI D

VI D 2000 14 t

Bhler Edelstahl, Kapfenberg, Austria

Production of special steels

Typi cal syst em conf i gur at i on

7

H

L

W

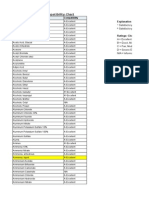

Space Requirement (in m)

Furnace Size

(metric ton)

Type L W H

1 - 3 VID 400 10 10 8.5

4 - 8 VID 1000 12 10 9.5

9 - 16 VID 2000 14 14 10

17 - 30 VID 3000 25 16 12

VID Melt and Pouring Station

Melting

Power

Supply

Furnace Platform +2.6 Vacuum Pumping Room

Power Supply

VID Furnace

Ladle

Power Cables

Filter

Dust

Catcher

Dust

Filter

VID Furnace Tilted

Transformer

Trafo

Technical Data

Characteristic Units VID VID VID VID

400 1000 2000 3000

Crucible size (metric tons) 1 - 3 4 - 8 9 - 16 17 - 30

Capacity

(based on Ni)

Typical cycle times

Fe-Cr base alloy/

Fe-Ni base alloys/

special steels (h) 3 - 6 3 - 6 3 - 6 3 - 6

Typical

operating pressure

with mechanical pump set (mbar) 0.5 - 5 0.5 - 5 0.5 - 5 0.5 - 5

Electrical layout

Output, melting power supply (kW) 600 - 1,500 1,500 - 2,500 2,500 - 3,500 3,500 - 5,000

Connected power vacuum

pump set and auxiliary

equipment

(depending on scope of supply) (kVA) 80 100 130 150

Cooling water

Total consumption (m

3

x h

-1

) 80 100 150 200

(t=10 C)

Floor area length (L) x width (W) L x W (m) 10 x 10 12 x 10 14 x 14 25 x 16

Height (m) 8.5 9.5 10 12

Recommended

Crane Capacity (metric tons) 15 30 50 70

ALD Vacuum Technologies GmbH

Wilhelm-Rohn-Strasse 35

D-63450 Hanau, Germany

Phone: +49 (0) 6181- 307-0

Fax: +49 (0) 6181- 307-3290

e-mail: info@ald-vt.de

Internet: www.ald-vt.de

M

e

t

a

C

o

m

/

V

I

D

/

0

5

.

1

1

/

/

5

0

0

/

S

c

h

Great Britain

ALD Vacuum Technologies Ltd.

First Floor

276 High Street

Guildford, Surrey GU 1 3JL, UK

Phone +44 (1483) 45 44 34

e-mail: info@aldvactech.co.uk

Russia

ALD Vacuumyje Technologii OOO

ul. Bolschaja Ordynka 40, str. 2

109017 Moskau, Russia

Phone +7 (495) 787 6733

e-mail: ald@metallurg.com.ru

China

ALD Liaison Ofce

c/o C&K Development Co., Ltd.

Rm. 1102, South Ofce Tower

Hong Kong Plaza

283 Huai Hai Zhong Rd.

Shanghai, 200021, China

Phone +86 (21) 63 85 - 55 00

e-mail: ald@ald-vt.cn

Far East

ALD Thermo Technologies Far East Co., Ltd.

10F. Shinjuku Nomura Bldg.

1-26-2 Nishi-Shinjuku, Shinjuku-Ku

Tokyo 163-0558, Japan

Phone +81 (3) 33 40 37 26

e-mail: Peter.Lang@ald-vt.de

USA / Canada

ALD Vacuum Technologies, Inc.

18, Thompson Road

East Windsor, CT 06088, USA

Phone +1 (860) 386 72 - 27

e-mail: info@ald-usa.com

Potrebbero piacerti anche

- 3D & 5D Pipe Bend For PipelineDocumento6 pagine3D & 5D Pipe Bend For PipelinemohammadazraiNessuna valutazione finora

- Odisha Power Transmission Corporation LTD.: PACKAGE: 25/2019-20Documento25 pagineOdisha Power Transmission Corporation LTD.: PACKAGE: 25/2019-20VenkatNessuna valutazione finora

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDa EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNessuna valutazione finora

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsDa EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsValutazione: 5 su 5 stelle5/5 (1)

- CH 12Documento99 pagineCH 12Kathy Yella100% (2)

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicDa EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNessuna valutazione finora

- Brochure Roll Bonded Clad Plates EDocumento36 pagineBrochure Roll Bonded Clad Plates EAries MarteNessuna valutazione finora

- Weldwell Catalogue 2015Documento8 pagineWeldwell Catalogue 2015jaganelrNessuna valutazione finora

- Selected Welding Application in Offshore IndustryDocumento38 pagineSelected Welding Application in Offshore IndustryzuudeeNessuna valutazione finora

- Specialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Documento3 pagineSpecialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Jarbas MoraesNessuna valutazione finora

- Astm e 415 - 2015Documento11 pagineAstm e 415 - 2015singaravelan narayanasamy83% (6)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Industeel Tableau Nuances Special Carbon and Low AlloyDocumento1 paginaIndusteel Tableau Nuances Special Carbon and Low AlloyPravin VisputeNessuna valutazione finora

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldDa EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldValutazione: 3 su 5 stelle3/5 (2)

- Linde Air HeaterDocumento24 pagineLinde Air HeaterjmsmechNessuna valutazione finora

- Exam - 2Documento12 pagineExam - 2Stanley Alex100% (3)

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesDa EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNessuna valutazione finora

- Almatis - Andus Buhr - TrendsRefractoriesCleanSteelTechnology - LitcorrectionDocumento15 pagineAlmatis - Andus Buhr - TrendsRefractoriesCleanSteelTechnology - LitcorrectionSaptarshi SenguptaNessuna valutazione finora

- IGCSE Chemistry Section 1 Lesson 3Documento66 pagineIGCSE Chemistry Section 1 Lesson 3Akbar TorayevNessuna valutazione finora

- Ventilatoren Zement enDocumento49 pagineVentilatoren Zement enFran Jimenez100% (1)

- Sponge Iron ManufacturingDocumento14 pagineSponge Iron Manufacturingapi-2604165367% (3)

- Elektror ProduktoversigtDocumento16 pagineElektror ProduktoversigtjonalserNessuna valutazione finora

- Cutting Materials, Tools and CoolantsDocumento63 pagineCutting Materials, Tools and CoolantsLeonardo BarabasNessuna valutazione finora

- Vacuum Challenges and Solutions: August 2009Documento2 pagineVacuum Challenges and Solutions: August 2009mrkkrmNessuna valutazione finora

- Vim Eng 06Documento12 pagineVim Eng 06Vijay Kadam100% (1)

- BengtssonDocumento19 pagineBengtssonpuisneNessuna valutazione finora

- Bulk GasesDocumento2 pagineBulk GasesfarzanefrhNessuna valutazione finora

- Bycast Folder 1106 LRDocumento20 pagineBycast Folder 1106 LRmarloplenNessuna valutazione finora

- Elektror Product CatalogDocumento16 pagineElektror Product Catalogjewan ramlalNessuna valutazione finora

- Gas NitridingDocumento4 pagineGas NitridingPaul Joseph MonsaludNessuna valutazione finora

- Hot RolledDocumento16 pagineHot Rolledlbo33Nessuna valutazione finora

- Vacuum Treatment of Molten Steel, RH (Rurhstahl Heraeus) Versus VTD (Vacuum Tank Degasser)Documento11 pagineVacuum Treatment of Molten Steel, RH (Rurhstahl Heraeus) Versus VTD (Vacuum Tank Degasser)Al M JamilNessuna valutazione finora

- 6.1.3. Dillimax Tech InfoDocumento52 pagine6.1.3. Dillimax Tech Infosohanlal29Nessuna valutazione finora

- 421 - Domex 700 MCDocumento2 pagine421 - Domex 700 MClalamed21Nessuna valutazione finora

- Duplex Stainless Steels by ArcelorMittal - 930koDocumento11 pagineDuplex Stainless Steels by ArcelorMittal - 930koSampath Kumar YerraNessuna valutazione finora

- GEA PHE Fullywelded Phe en 1Documento12 pagineGEA PHE Fullywelded Phe en 1gemagdyNessuna valutazione finora

- Alfa Laval Alfa-V VDD: Industrial Dry Coolers V-TypeDocumento2 pagineAlfa Laval Alfa-V VDD: Industrial Dry Coolers V-TypemoghanmogaNessuna valutazione finora

- WARod Brochure v10211Documento3 pagineWARod Brochure v10211gazwang478Nessuna valutazione finora

- Vac Heat Treatment MonoTherm 2009 Engl (Kompatibilitätsmodus)Documento33 pagineVac Heat Treatment MonoTherm 2009 Engl (Kompatibilitätsmodus)AmitNessuna valutazione finora

- Top With VapourDocumento2 pagineTop With VapourThanida ChampolNessuna valutazione finora

- Secondary Steelmaking PaperDocumento10 pagineSecondary Steelmaking Paperdebjit123Nessuna valutazione finora

- High Temp Resistant SteelDocumento14 pagineHigh Temp Resistant SteelrajivashishNessuna valutazione finora

- Industeel DuplexDocumento2 pagineIndusteel DuplexClaudio SampaioNessuna valutazione finora

- URB25Documento4 pagineURB25malika_00Nessuna valutazione finora

- ASC BeamsDocumento114 pagineASC BeamsRadu StratilaNessuna valutazione finora

- IMU Basic Knowledge English Final 11-03-14Documento102 pagineIMU Basic Knowledge English Final 11-03-14ramchandra rao deshpandeNessuna valutazione finora

- Current ASTM A897 ADA Specifications: Stage 1Documento5 pagineCurrent ASTM A897 ADA Specifications: Stage 1bronx_ldNessuna valutazione finora

- Sintering Stainless SteelDocumento42 pagineSintering Stainless SteelSteve GreenNessuna valutazione finora

- Silicon Mulitcore Cable, Flexible, Halogen-Free, Meter MarkingDocumento1 paginaSilicon Mulitcore Cable, Flexible, Halogen-Free, Meter Markingbaguspermana7Nessuna valutazione finora

- UR45 NPlusDocumento4 pagineUR45 NPlusMaiara Lima PereiraNessuna valutazione finora

- WP I FCAW Sept 2010Documento99 pagineWP I FCAW Sept 2010jhas988Nessuna valutazione finora

- Manufactured and Tested To ANSI/UL StandardsDocumento1 paginaManufactured and Tested To ANSI/UL StandardsfatraskyNessuna valutazione finora

- Application For Oil IndustryDocumento23 pagineApplication For Oil IndustryzuudeeNessuna valutazione finora

- Chainflex Data CablesDocumento9 pagineChainflex Data CablesigusukNessuna valutazione finora

- Heating Centre CatalogDocumento157 pagineHeating Centre Catalogwaynepowell21Nessuna valutazione finora

- Sirius 314: A 25% CR - 1.8 % Si Heat Resistant Stainless SteelDocumento4 pagineSirius 314: A 25% CR - 1.8 % Si Heat Resistant Stainless SteelVíctor SandovskyNessuna valutazione finora

- 06-Klitzke Sidwell Jensen Presentation Part 123Documento89 pagine06-Klitzke Sidwell Jensen Presentation Part 123Nguyễn Thanh TùngNessuna valutazione finora

- Catalogue General enDocumento31 pagineCatalogue General enzhyhhNessuna valutazione finora

- 1973 BACKER Shaped Heat 20111009Documento50 pagine1973 BACKER Shaped Heat 20111009Hank MarvinNessuna valutazione finora

- Marcegaglia Forli Plant en SlideDocumento19 pagineMarcegaglia Forli Plant en SlidelucidbaseNessuna valutazione finora

- Scientific American, Vol. XXXIX.—No. 24. [New Series.], December 14, 1878 A Weekly Journal Of Practical Information, Art, Science, Mechanics, Chemistry, And ManufacturesDa EverandScientific American, Vol. XXXIX.—No. 24. [New Series.], December 14, 1878 A Weekly Journal Of Practical Information, Art, Science, Mechanics, Chemistry, And ManufacturesNessuna valutazione finora

- Bio 0757419 PP 0 PK 6Documento2 pagineBio 0757419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 058 R 419 PP 0 PK 6Documento2 pagineBio 058 R 419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 057419 PP 0 PK 6Documento2 pagineBio 057419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 0567419 PP 0 PK 6Documento2 pagineBio 0567419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 0 y 57419 PP 0 PK 6Documento2 pagineBio 0 y 57419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 0587419 PP 0 PK 6Documento2 pagineBio 0587419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 79419 PP 0 PK 6Documento2 pagineBio 79419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 0749419 PP 0 PK 6Documento2 pagineBio 0749419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 0797419 PP 0 PK 6Documento2 pagineBio 0797419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 079419 PP 0 PK 6Documento2 pagineBio 079419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 0744419 PP 0 PK 6Documento2 pagineBio 0744419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7909 PPP 0 PK 6Documento2 pagineBio 7909 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 0799419 PP 0 PK 6Documento2 pagineBio 0799419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 179419 PP 0 PK 6Documento2 pagineBio 179419 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7 W 71 PPP 0 PK 6Documento2 pagineBio 7 W 71 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7 y 719 PP 0 PK 6Documento2 pagineBio 7 y 719 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 79719 PP 0 PK 6Documento2 pagineBio 79719 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7 R 719 PP 0 PK 6Documento2 pagineBio 7 R 719 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7 R 619 PP 0 PK 6Documento2 pagineBio 7 R 619 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7 y 619 PP 0 PK 6Documento2 pagineBio 7 y 619 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7 W 79 PPP 0 PK 6Documento2 pagineBio 7 W 79 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7 W 09 PPP 0 PK 6Documento2 pagineBio 7 W 09 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7609 PPP 0 PK 6Documento2 pagineBio 7609 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7 y 919 PP 0 PK 6Documento2 pagineBio 7 y 919 PP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 7 R 71 PPP 0 PK 6Documento2 pagineBio 7 R 71 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 909 PPP 0 PK 6Documento2 pagineBio 909 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 909 PPP 0 PK 6Documento2 pagineBio 909 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 849 PPP 0 PK 6Documento2 pagineBio 849 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 909 PPP 0 PK 6Documento2 pagineBio 909 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Bio 949 PPP 0 PK 6Documento2 pagineBio 949 PPP 0 PK 6sureshkumar908Nessuna valutazione finora

- Ultramet 2507: Stainless Steel Electrodes Product Data SheetDocumento1 paginaUltramet 2507: Stainless Steel Electrodes Product Data Sheetshaan1001gbNessuna valutazione finora

- Atomic Structure For Grade 10Documento4 pagineAtomic Structure For Grade 10Aja AndersonNessuna valutazione finora

- Diamondspark 54 MC: Seamless Cored WireDocumento2 pagineDiamondspark 54 MC: Seamless Cored WireDavid RodriguesNessuna valutazione finora

- Percent Water in A Hydrate LabDocumento7 paginePercent Water in A Hydrate LabCreselle MoralesNessuna valutazione finora

- Aashto T0048 PDFDocumento4 pagineAashto T0048 PDFram6265790Nessuna valutazione finora

- PijDocumento149 paginePijAduchelab AdamsonuniversityNessuna valutazione finora

- 50 Ways To Name Your Compound: Assignment: Write The Corresponding Name or Formula For Each of The FollowingDocumento1 pagina50 Ways To Name Your Compound: Assignment: Write The Corresponding Name or Formula For Each of The FollowingRavenia Ghani PutriNessuna valutazione finora

- Applications of Coordination CompoundsDocumento6 pagineApplications of Coordination CompoundsFizsNessuna valutazione finora

- TCVN 5945-2010 Industrial Waste Water - Discharge StandardsDocumento9 pagineTCVN 5945-2010 Industrial Waste Water - Discharge StandardsDoThanhTungNessuna valutazione finora

- Lonestar College - Kingwood General Chemistry 1411 Naming Compounds and ReactionsDocumento3 pagineLonestar College - Kingwood General Chemistry 1411 Naming Compounds and ReactionsHân BảoNessuna valutazione finora

- Covalent and Metallic BondingDocumento53 pagineCovalent and Metallic BondingAaditya MKNessuna valutazione finora

- Construction Materials Ii: 1.1 Ferrous MetalDocumento6 pagineConstruction Materials Ii: 1.1 Ferrous MetalQila HusinNessuna valutazione finora

- November 2016 (v1) QP - Paper 4 CIE Chemistry IGCSEDocumento17 pagineNovember 2016 (v1) QP - Paper 4 CIE Chemistry IGCSEJohanna Martin LipioNessuna valutazione finora

- Caustic EmbrittlementDocumento2 pagineCaustic Embrittlementrao9990Nessuna valutazione finora

- Potash Alum FinalDocumento13 paginePotash Alum FinalAnonymous yX4s4KHeEuNessuna valutazione finora

- Index of Mining LiteratureDocumento38 pagineIndex of Mining LiteratureRichard BalaisNessuna valutazione finora

- Solutions To CHEM 1123 Unit 2 Sample ProblemsDocumento3 pagineSolutions To CHEM 1123 Unit 2 Sample ProblemsLeena LapenaNessuna valutazione finora

- Sorelmetal: 111 Advances in Welding Ductile Iron To SteelDocumento2 pagineSorelmetal: 111 Advances in Welding Ductile Iron To Steelhrk100Nessuna valutazione finora

- Hse Plustwo Chemistry Svolumetric Analysis Anil HssliveDocumento4 pagineHse Plustwo Chemistry Svolumetric Analysis Anil HssliveAryan ThakurNessuna valutazione finora

- Annexure 2 - Virgin PTFE Compatibility ChartDocumento26 pagineAnnexure 2 - Virgin PTFE Compatibility ChartsachinumaryeNessuna valutazione finora

- The Corrosion Behaviour of Aisi 304 Stainless Steel in Methanol H2SO4 MixturesDocumento11 pagineThe Corrosion Behaviour of Aisi 304 Stainless Steel in Methanol H2SO4 MixturesnicusebpNessuna valutazione finora

- 5 Sedimentary, ExogenicDocumento70 pagine5 Sedimentary, ExogenicRaúl Tovar ContrerasNessuna valutazione finora

- Appendix A Analysis by The BlowpipeDocumento38 pagineAppendix A Analysis by The BlowpipeArsalan BalochNessuna valutazione finora

- Aalco Copper Brass Bronze TubingDocumento26 pagineAalco Copper Brass Bronze Tubingjoe bloggsNessuna valutazione finora

- Metals 1 PDFDocumento17 pagineMetals 1 PDFhareshNessuna valutazione finora

![Scientific American, Vol. XXXIX.—No. 24. [New Series.], December 14, 1878

A Weekly Journal Of Practical Information, Art, Science,

Mechanics, Chemistry, And Manufactures](https://imgv2-1-f.scribdassets.com/img/word_document/187374175/149x198/94bb94db93/1579716754?v=1)