Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ags531446-01 LD

Caricato da

mariomatoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ags531446-01 LD

Caricato da

mariomatoCopyright:

Formati disponibili

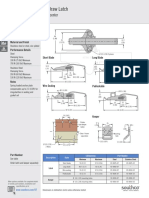

Medium-voltage switchgear

No. AGS 531 446-01

Edition 12/2011

www.schneider-electric.com

GHA

Gas-insulated switchgear 40.5 kV ( 40 kA)

for single and double busbar panels

Assembly Instructions

Manufacturer:

Schneider Electric Sachsenwerk GmbH

Rathenaustrasse 2

D-93055 Regensburg

Germany

( +49 (0) 9 41 46 20-0

7 +49 (0) 9 41 46 20-418

Service:

Schneider Electric Sachsenwerk GmbH

Rathenaustrasse 2

D-93055 Regensburg

Germany

( +49 (0) 9 41 46 20-777

7 +49 (0) 9 41 46 20-418

GHA

3 AGS 531 446-01 | Edition 12/2011

Contents

Remarks on this manual ............................................................................. 5

Purpose and target group ........................................................................................... 5

Reference documents ................................................................................................ 5

Terms and symbols used ............................................................................................ 6

Abbreviations used ..................................................................................................... 6

Any questions or suggestions?................................................................................... 6

1 Safety provisions .............................................................................. 7

2 Design, description, variants ........................................................... 8

2.1 Switchgear panels with single busbar ............................................................. 8

2.2 Panels with double busbar .............................................................................11

2.3 Dimensions and weights ............................................................................... 13

2.4 Applicable standards ..................................................................................... 17

2.5 Environmental and operating conditions ....................................................... 17

2.6 Intended use ................................................................................................. 18

2.7 Disposal after the end of service life ............................................................. 18

3 Packaging, transport, storage........................................................ 19

3.1 Shipping units ................................................................................................ 19

3.2 Transport ....................................................................................................... 19

3.3 Storage .......................................................................................................... 20

4 Assembly ......................................................................................... 21

4.1 Safety provisions ........................................................................................... 21

4.2 Important instructions for assembly .............................................................. 21

4.3 Requirements regarding the switchgear room .............................................. 22

4.4 Transporting the panels on the construction site........................................... 25

4.4.1 Transport of panel by means of a crane ................................................... 25

4.4.2 Transport using the transport frame ......................................................... 26

4.4.3 Transporting the panels onto the base frame ........................................... 27

4.5 Attachment of pressure relief duct ................................................................ 28

4.6 Remove cable compartment cover and shutters ........................................... 29

4.6.1 Cable compartment interlock (optional) .................................................... 29

4.6.2 Remove cable compartment cover and shutters ...................................... 30

4.7 Installation of panels ..................................................................................... 32

4.7.1 Installation of the frst switchgear panel .................................................... 32

4.7.2 Removal of transport securing device ...................................................... 32

4.7.3 Pre-coat the high-quality electrical joints of the busbar link ...................... 33

4.7.4 Preassembling the clamping contacts ...................................................... 34

4.7.5 Screw-fastening the panels to one another .............................................. 35

4.8 Compensating shutters for the panel front .................................................... 36

4.9 Busbar link: B link .......................................................................................... 38

4.9.1 Connecting the busbar (fasten preassembled clamping contacts) ........... 40

4.9.2 Contact resistance measurement of busbar screw fastening ................... 41

4.9.3 Fasten silicone sleeve to adjacent panel .................................................. 42

4.9.4 Cover of busbar link in case of panels without pressure relief duct .......... 43

4.10 Reinforcement ............................................................................................... 46

4.11 Screw-fastening the panel to the base frame ................................................ 47

4.12 Mounting the earth bus ................................................................................. 48

5 Busbar attachments ........................................................................ 49

5.1 Safety provisions ........................................................................................... 49

5.2 Assembly of surge arresters ......................................................................... 49

5.3 Assembly of voltage transformers ................................................................. 50

6 Low-voltage cabinet ........................................................................ 52

6.1 Assembly ....................................................................................................... 52

6.2 Connecting the control lines .......................................................................... 53

GHA

4 AGS 531 446-01 | Edition 12/2011 4

Contents

7 Switchgear termination................................................................... 55

7.1 Attachment of the protective tank to the left-hand / right-hand end

of the busbar ................................................................................................. 55

7.2 Switchgear without pressure relief duct ........................................................ 56

7.2.1 Overview ................................................................................................... 56

7.2.2 Attachment of the right-hand or left-hand side wall .................................. 56

7.2.3 Extension of side wall in double busbar switchgear ................................. 58

7.2.4 Gap covers ............................................................................................... 59

7.3 Attachment of fan .......................................................................................... 61

8 Switchgear with pressure relief device ......................................... 63

8.1 Overview ....................................................................................................... 63

8.2 Cover plate ................................................................................................... 65

8.3 Attachment of pressure relief duct ................................................................ 66

8.4 Attachment of side walls for pressure relief from the switchgear room ......... 67

8.5 Attachment of side walls for pressure relief into the switchgear room .......... 68

9 High-voltage connection ................................................................ 69

9.1 Cable compartment with base plates (optional) ............................................ 69

9.2 Outer cone-type bushing ............................................................................... 70

9.3 Inner cone-type socket .................................................................................. 73

10 Replacement of transformer .......................................................... 76

10.1 Current transformer for outer cone-type connection ..................................... 76

10.2 Voltage transformer ....................................................................................... 77

11 Commissioning ............................................................................... 78

11.1 Final steps ..................................................................................................... 78

11.1.1 Attachment of the tool board .................................................................... 78

11.1.2 Cleaning and checking assembly ............................................................. 78

11.1.3 Remount covers ....................................................................................... 79

11.1.4 Damaged paint ......................................................................................... 79

11.1.5 Inspection ................................................................................................. 79

11.2 Commissioning .............................................................................................. 79

12 Optional high-voltage test on commissioning ............................. 80

12.1 Power frequency withstand test of the busbar .............................................. 80

12.2 Cable testing ................................................................................................. 82

12.3 Cable jacket test ............................................................................................ 85

13 Annex ............................................................................................... 86

13.1 Auxiliary products .......................................................................................... 86

13.2 Required tools (not included in the scope of supplies) .................................. 86

13.3 Coating the contact surfaces ......................................................................... 88

13.4 Screw locking compound .............................................................................. 88

13.5 Specifcations for screw connections ............................................................ 89

GHA

5 AGS 531 446-01 | Edition 12/2011

For information which is not included in this manual and the assembly drawings sup-

plied with the equipment, please contact the manufacturer.

As our products are subject to continuous further development, we reserve the right

to make changes regarding the standards, illustrations and technical data.

All dimensions specifed in this manual are in millimeters.

Purpose and target group

This Technical Manual describes assembly and commissioning of gas-insulated

medium-voltage switchgear units of the GHA series.

It is an integral part of the product and must be stored so that it is readily accessible

at all times for and can be used by persons who are to work on the switchgear. If the

switchgear is sold to new owners, they must receive this document along with the

switchgear.

This Technical Manual is exclusively intended for specialist electricians who

have been certifed for the GHA series (training certifcate).

This Technical Manual cannot describe every imaginable individual case or every

customer-specifc version of the product. Thus, only the basic assembly procedure is

described. The detailed assembly work for the switchgear model in question is illus-

trated for each operation required in the assembly drawings provided to this effect.

Reference documents

Purchase agreement with the stipulations regarding the switchgear-specifc

equipment and the legal details

The appropriate switchgear-specifc circuit diagrams / documentation

GHA Operating Manual

The Operating Manuals of the devices installed in the switchgear:

Voltage detection systems, e. g. IVIS (no. AGS 531751-01)

Insulating gas monitoring system IDIS (no. AGS 531691-01)

System for the detection of internal arcs ILIS (optional)

(no. AGS 531761-01)

Devices in the low-voltage cabinet.

The Assembly Instructions of the manufacturer

of the cable connection systems to be connected to the switchgear

of the voltage transformers.

The assembly drawings supplied with the equipment

The following additional

documents must be complied

with:

Remarks on this manual

GHA

6 AGS 531 446-01 | Edition 12/2011 6

Remarks on this manual

Terms and symbols used

This Technical Manual uses certain terms and symbols. They warn about dangers or

provide important information which must be complied with in order to avoid danger

to persons and damage to equipment:

"Danger!"

This danger symbol warns about dangerous electrical voltage.

Contact with voltage may result in fatal injury!

"Warning!"

This danger symbol warns about the risk of injury. Please comply

with all the provisions identifed by this symbol in order to avoid

death or serious injury.

"Warning!"

This danger symbol warns about the risk of falling.

"Important:"

This instruction symbol is used for information which is important to

avoid material damage.

Abbreviations used

For reasons of simplifcation, the following abbreviations are used in this manual:

ESS = Single busbar

DSS = Double busbar

SS1 = Busbar 1

SS2 = Busbar 2

SS-StW = Busbar current transformer

TrSS = Disconnector in the busbar run

U

r

= Rated voltage

I

r

= Rated normal current (feeder panel)

Any questions or suggestions?

Do you have any questions or suggestions regarding this manual, or do you require

further information?

We always strive to provide you with the best-possible information for optimum, safe

use of our products. Thus, do not hesitate to contact us if you have any recommen-

dations, amendments or proposals for improvement.

GHA

7 AGS 531 446-01 | Edition 12/2011

1 Safety provisions

The work described in this manual may only be performed by specialist electricians

with proven experience in conjunction with the GHA series and the applicable safety

provisions.

Please read the whole manual carefully before working on the switchgear.

Metal-enclosed AC switchgear for rated voltages > 1 kV up to including 52 kV:

IEC 62271-200

Use and handling of sulphur hexafuoride (SF

6

) in high-voltage switchgear: IEC

62271-303

The locally applicable accident prevention, operating and work instructions

must be complied with.

Installation: IEC 61936-1/EN 61936-1

1

Operation of electrical equipment: EN 50110-1

1

1

The national standards applicable in the country where the equipment is to be

installed must be complied with.

Before performing work on the panels, it is essential that you comply with the follow-

ing instructions:

Danger!

Risk of fatalities due to high voltage. Isolation from high voltage

and earthing must always be ensured before performing assembly

or maintenance work.

Danger!

Risk of fatalities due to supply voltage. Isolation from supply

voltage must always be ensured before performing assembly or

maintenance work.

Warning!

Risk of injury due to movable parts in mechanical drives. For

maintenance work,

isolate the system from the supply voltage

release the circuit-breakers energy storing device by OFF-

ON-OFF operation and make-proof earthing switches by the

appropriate ON-operation.

Warning!

After removing covers from a switchgear unit, operator safety

may be reduced regarding internal arcs unless the switchgear is

isolated from the power supply. Optimum operator safety is only

ensured if the switchgear is completely disconnected from the

power supply and grounded during assembly.

For the case of an internal fault, the GHA switchgear features pressure relief ports

which prevent the panels and the switchgear from bursting.

This Technical Manual does not include information regarding the safety of buildings

in case of internal faults (pressure load of the switchgear room and necessary pres-

sure relief ports). Pressure calculations for switchgear rooms incl. recommendations

regarding pressure relief ports can be provided on request against a fee. For further

details, please contact the manufacturer.

In case of fre or of internal faults, toxic and caustic decomposition products may be

produced. Comply with the locally applicable accident and safety provisions.

In case of personal injury, take frst-aid measures or cause them to be taken.

Applicable standards

and regulations:

Behaviour in case of incidents or

accidents

GHA

8 AGS 531 446-01 | Edition 12/2011

2 Design, description, variants

2.1 Switchgear panels with single busbar

1

2

3

4

5

6a

7

8

9

10

12

13

14

15

16

17

1 Busbar tank with three-position

switch

2 Jack rings

3 Busbar link

4 Circuit-breaker tank with vacuum

interrupter chambers

5 Toroidal-core current transformer

6a Outer cone-type bushing

6b Inner cone-type socket

7 Voltage transformer (optional)

8 Cable support

9 Cable compartment cover

10 Disconnecting device for voltage

transformer (optional)

11 Test sockets for cable test

12 Capacitive voltage testing system

13 IDIS indicator for insulating gas

monitoring

14 Hinged front frame

15 Manual operator interface

16 Low-voltage cabinet

17 IDIS gas density switch

Fig. 1

Circuit-breaker panel with outer cone-type bushing

1

2

3

4

5

7

11

16

17

18

10

6b

8

9

11

6b

8

7

5

10

Fig. 2

Circuit-breaker panel with inner cone-type socket

GHA

9 AGS 531 446-01 | Edition 12/2011 9

2 Design, description, variants

1 2 3

4

5

6

9

12

10

11

8

7

13

14

1 Right-hand busbar tank with three-

position switch

2 Left-hand busbar tank with three-

position switch

3 Jack rings

4 Busbar link

5 Circuit-breaker tank with vacuum

interrupter chambers

6 Toroidal-core current transformer

(optional)

7 Voltage transformer (optional)

8 Cable compartment cover

9 Test sockets (optional)

10 IDIS indicator for insulating gas

monitoring

11 Hinged front frame

12 Manual operator interface

13 Low-voltage cabinet

14 IDIS gas density switch

Fig. 3

Bus section coupler, shown for rated current I

r

2000 A

6

8

Fig. 4

Bus section coupler, shown for rated current I

r

2500 A

L R

L R

GHA

10 AGS 531 446-01 | Edition 12/2011 10

2 Design, description, variants

Busbar attachments

Fig. 5

Busbar voltage transformers (2 variants available)

Fig. 6

Busbar surge arresters (2 variants available)

Fig. 7

Busbar earthing switch

GHA

11 AGS 531 446-01 | Edition 12/2011 11

2 Design, description, variants

2.2 Panels with double busbar

1

2

7

3

4a

5

6

17 18 19 16

8

9

10

12

13

14

15

11

1 Gas density switch of the IDIS sys-

tem for busbar 1 (rear busbar)

2 Busbar link SS1

3 Circuit-breaker tank with vacuum

interrupter chambers

4a Outer cone-type bushing

4b Inner cone-type socket

5 Toroidal-core current transformer

6 Voltage transformer (optional)

7 Cable support

8 Cable compartment cover

9 Disconnecting device for voltage

transformer (optional)

10 Capacitive voltage testing system

11 IDIS indicator for insulating gas

monitoring

12 Hinged front frame

13 Manual operator interface

14 Low-voltage cabinet

15 Gas density switch of the IDIS sys-

tem for busbar 2 (upper busbar)

16 Busbar link SS2

17 Tank, busbar 2 (upper busbar) with

three-position switch

18 Jack rings

19 Tank, busbar 1 (rear busbar) with

disconnector

20 Test sockets for cable test

Fig. 8

Circuit-breaker panel with outer cone-type bushing

1

2

3

4

5

7

20

16

17

18

10

6b

8 9

5

11

10

7

8

6b

Fig. 9

Circuit-breaker panel with inner cone-type socket

1

2

1

2

GHA

12 AGS 531 446-01 | Edition 12/2011 12

2 Design, description, variants

Fig. 10

Bus section coupler, busbar 2 (busbar 1 analogous)

Fig. 11

Bus coupler

Fig. 12

Metering panel with busbar voltage transformer or with bus-

bar surge arrester (not shown)

Fig. 13

Bus section coupler, busbar 2 (busbar 1 analogous)

1

2

1

2

1

2 1

2

GHA

13 AGS 531 446-01 | Edition 12/2011 13

2 Design, description, variants

2.3 Dimensions and weights

Switchgear panels with single busbar (see Fig. 14, page 15)

Panel type

Rated current I

r

1

[A]

Panel width A

[mm]

Depth

2

[mm]

Depth

3

[mm]

Approx.

weight

[kg]

4

Feeder panel

1250 600

1330

2400/2780

(Height of low-voltage

cabinet:

800/1200)

700

1600

600/800

5

800

2000 1380/1330

5

900

2500 900 1330 1100

L R

Bus section

coupler

1250

800

1330 900

1600/2000 1380 1100

2500 1000 1330 1300

Bus sectionalizer

with disconnector

2500 600 1330 300

Busbar measure-

ment with current

transformer

2500 600 1330

2600/2780

(Height of low-voltage

cabinet:

800/1200)

300

Attached busbar earthing switch +70

Disconnecting device attached to the busbar (for voltage transformer or

surge arrester) (panel height depending on the attachment design, see

Chapter 2.1, page 10)

2400

6

/2500

7

+70

Voltage transformer for outgoing feeder cable / busbar

+120

(3 x 40)

1

In the case of feeder panels, the rated current I

r

refers to the feeder (max. busbar nominal current: 2500 A)

2

The values listed in the Tables are referred to a panel depth without pressure relief duct on the rear.

Depth of panels with rear pressure relief duct: 1595 mm

3

Damping resistor (for optional voltage transformer) on the low-voltage cabinet: specifed height +150

Height of pressure relief duct: 2400

Height of pressure relief duct with fan: 2600

4

including the low-voltage cabinet, without voltage transformer and for feeder panels with outer cone-type bushing

feeder panels with inner cone-type socket: max. + 200 kg

Panels with rear pressure relief duct: max. + 100 kg

5

The dimensions depend on the cable connection system; inner cone-type socket / outer cone-type bushing system

6

Voltage transformer on the busbar can be removed by pulling it laterally (see Fig. 5, page 10)

7

Voltage transformer on the busbar can be removed by pulling it upwards (see Fig. 5, page 10

GHA

14 AGS 531 446-01 | Edition 12/2011 14

2 Design, description, variants

Switchgear panels with double busbar (see Fig. 15, page 16)

Panel type

Rated current I

r

1

[A]

Panel width

A

[mm]

Depth

2

[mm]

Depth

3

[mm]

Approx.

weight

[kg]

4

1

2

Feeder panel

1250 600

1700

2400/2780

(Height of low-voltage

cabinet:

800/1200)

900

1600

600/800

5

900

2000

1860

1200

2500 900 1400

1

2

Bus section coupler

1250/1600

800

1700 1100

2000 1980 1400

2500 1000 2030 1300

1

2

Bus section coupler

1250/1600

800 1700

1100

2000 1400

2500 1000 1850 1300

1

2

Bus coupler

1250/1600

600

1700 900

2000

1860

1100

2500 900 1600

1

2

Bus sectionalizer with

disconnector

1600

2500

600

600

1700

1970

400

450

1

2 Busbar measurement

with current trans-

former

2500 600 1700 2600/2780 600

1

In the case of feeder panels, the rated current I

r

refers to the feeder (max. busbar nominal current: 2500 A).

2

The values listed in the Tables are referred to a panel depth without pressure relief duct on the rear.

Technical details and the design for the rear pressure relief duct must be clarifed with the manufacturer as required.

3

Damping resistor (for optional voltage transformer) on the low-voltage cabinet: specifed height +150

Height of pressure relief duct: 2400

Height of pressure relief duct with fan: 2600

4

The specifed weights apply including the low-voltage cabinet and without the voltage transformer; they refer to feeder panels

with outer cone-type bushing.

- Feeder panels with inner cone-type socket: max. + 200 kg

Panels with rear pressure relief duct: max. + 150 kg

5

The dimensions depend on the cable connection system; inner cone-type socket / outer cone-type bushing

GHA

15 AGS 531 446-01 | Edition 12/2011 15

2 Design, description, variants

Panel type

Rated current I

r

1

[A]

Panel width

A

[mm]

Depth

2

[mm]

Depth

3

[mm]

Approx.

weight

[kg]

4

1

2

Metering panel for volt-

age transformer

2500 600 1700 2400

6

/2500

7

400

1

2

attached busbar earth-

ing switch

2500 600 1700 2400/2780 400

attached voltage transformer for outgoing feeder cable / busbar

+ 120

(3 x 40)

1

In the case of feeder panels, the rated current I

r

refers to the feeder (max. busbar nominal current: 2500 A).

2

The values listed in the Tables are referred to a panel depth without pressure relief duct on the rear.

Technical details and the design for the rear pressure relief duct must be clarifed with the manufacturer as required.

3

Damping resistor (for optional voltage transformer) on the low-voltage cabinet: specifed height +150

Height of pressure relief duct: 2400

Height of pressure relief duct with fan: 2600

4

The specifed weights apply including the low-voltage cabinet and without the voltage transformer; they refer to feeder pan-

els with outer cone-type bushing.

- Feeder panels with inner cone-type socket: max. + 200 kg

Panels with rear pressure relief duct: max. + 150 kg

5

The dimensions depend on the cable connection system; inner cone-type socket / outer cone-type bushing

6

Voltage transformer can be removed by pulling it laterally (see Fig. 12, page 12)

7

Voltage transformer can be removed by pulling it upwards

1340/1380

3

1595

4

2

3

8

0

/

2

7

8

0

1

2

4

0

0

A

2

1

0

0

-

2

3

0

0

+150 +200

5 6

1 with low-voltage cabinet 800/1200

mm

2 Height depends on the busbar

cooler attachments

3 Panel depth depending on rated

current I

r

of the panel (without/with

cooler, see Table)

4 Depth of panel with pressure relief

duct

5 Damping resistor

6 Fan attachment

Fig. 14

Dimensions of a series GHA single busbar panel

GHA

16 AGS 531 446-01 | Edition 12/2011 16

2 Design, description, variants

2

1

0

0

-

2

3

0

0

2

3

8

0

/

2

7

8

0

1

1700/1960

1990

6

/2210

7

A

2

4

0

0

+150 +200

5 4

1 with low-voltage cabinet 800/1200

mm

2 Height depends on the busbar

cooler attachments

3 Panel depth depending on rated

current Ir of the panel (see Table)

4 Damping resistor

5 Fan attachment

6 Depth of panel with pressure relief

duct

7 Depth of panel with pressure relief

duct and bus section coupler of

the rear busbars

(I

r

= 2500 A)

Fig. 15

Dimensions of a series GHA double busbar panel

GHA

17 AGS 531 446-01 | Edition 12/2011 17

2 Design, description, variants

2.4 Applicable standards

metal-enclosed

SF

6

-insulated

type-tested and prefabricated

tested for internal faults (qualifcation IAC)

dimensioned for indoor installation

Designation IEC standard EN standard

Switchgear

IEC 62271-1

IEC 62271-200

EN 62271-200

Circuit-breaker IEC 62271-100 EN 62271-100

Earthing switch IEC 62271-102 EN 62271-102

Disconnector IEC 62271-102 EN 62271-102

Current transformer IEC 60044-1 EN 60044-1

Voltage transformer IEC 60044-2 EN 60044-2

Voltage detection systems IEC 61243-5 EN 61243-5

Protection against accidental con-

tact, foreign bodies and water

IEC 60529 EN 60529

Installation IEC 61936-1 EN 61936-1

1

Operation of electrical equipment EN 50110-1

1

Insulating gas sulphur hexafuoride

SF

6

IEC 60376 EN 60376

Use and handling of sulphur hexa-

fuoride (SF

6

)

IEC 62271-303

1

The national standards applicable in the country where the equipment is to be

installed must be complied with.

Degrees of protection against accidental contact and foreign objects accord-

ing to IEC 60529

Main electric circuits IP65

Drive mechanisms IP2X

1

Low-voltage cabinet IP3X

1

Cable compartment IP3X

1

1

optional IP5X

2.5 Environmental and operating conditions

GHA is an indoor switchgear and may only be operated under normal conditions

in acc. with IEC 62271-1. Operation under conditions deviating from these is only

admissible subject to consultation with and written approval from the manufacturer.

Ambient conditions (in accordance with IEC 62271-1)

Temperature class "Minus 5 indoors

Min./max. ambient temperature C 5

1

/+40

1

Average value over 24 hours C 35

1

mean rel. air humidity: 24 hour/1 month % 95/ 90

Installation altitude above sea-level m 1000

1

1

other values available on request

Type GHA switchgear units are:

GHA switchgear units meet

the following standards and

regulations:

Degree of protection against

accidental contact and foreign

objects:

GHA

18 AGS 531 446-01 | Edition 12/2011 18

2 Design, description, variants

2.6 Intended use

Gas-insulated GHA medium-voltage switchgear units are exclusively intended for

switching and distributing electrical energies. They may only be used in the scope of

the specifed standards and the switchgear-specifc technical data. Any other utiliza-

tion constitutes improper use and may result in dangers and damage.

The manufacturer shall not be held responsible for damage which occurs if

instructions in this Technical Manual are not complied with;

the switchgear is not operated according to its intended use (see above);

the switchgear is assembled, connected or operated improperly;

accessories or spare parts are used which have not been approved by the

manufacturer;

the switchgear is converted without the manufacturers approval, or if inadmis-

sible parts are added.

No liability is accepted for parts provided by customers, e.g. current transformers.

2.7 Disposal after the end of service life

The operating equipment contains the fuorinated greenhouse gas SF

6

covered by

the Kyoto Protocol with a global warming potential (GWP) of 22 200.

SF

6

must be recovered and must not be released into the atmosphere. When trans-

porting and handling SF

6

, the specifcations in IEC 62271 High-Voltage Switchgear

and Controlgear Part 303 Use and Handling of Sulphur Hexafuoride (SF

6

), must

be complied with.

A material and recycling data sheet can be provided on request for the disposal of

series GHA switchgear units at the end of their service life.

Disposal is performed as a service by the manufacturers Service Center and is

subject to a fee.

Liability Disclaimers

GHA

19 AGS 531 446-01 | Edition 12/2011

3 Packaging, transport, storage

3.1 Shipping units

Delivery is effected in terms of prefabricated single switchgear panels. One transport

unit consists of max. 2 individual switchgear panels which are fastened to the pallet.

The busbar compartment with three-position switch, the circuit-breaker compart-

ment, the drive mechanisms and the supporting structures are mounted ready for

connection and routine-tested. The individual busbar links are mounted on site.

The low-voltage cabinets are assembled in the factory or supplied as accessories,

depending on the customers wishes.

If packed exclusively for truck transport, the panels are delivered on a pallet

with PE protective flm.

For sea transport, the units are packed in sealed aluminium foil with desiccant

and in a closed wooden case with tightly closed wooden base (also for con-

tainer transport).

In case of air transport, the panels are packaged in wooden crates with a

protective PE flm hood (dust protection) or in wooden crates, also with closed

wooden bases, however without protective hoods (dust protection).

Important:

The weight of the entire transport unit is indicated on the packaging.

3.2 Transport

Warning!

Danger due to tipping

load.

Transport units must be

protected suffciently

against slipping and tip-

ping during transport.

Warning!

Suffcient stability and evenness of the supporting area (foor)

must be ensured.

Handle shipping units carefully when unloading and unpacking them

Shipping units must be checked upon receipt. Any damage which may have

occurred in transit must be recorded and reported to the manufacturer immedi-

ately.

The consignment must be checked for completeness based on the shipping

documents.

The supplier must be notifed in writing without delay about any possible devia-

tions.

Packaging

Abb. 16

Do not tip the transport units

Transport using a forklift truck

GHA

20 AGS 531 446-01 | Edition 12/2011 20

3 Packaging, transport, storage

The panel may only be transported on a pallet. The entire length of the forks must be

placed under the transport unit (Fig. 17).

Fig. 17

Transport with forklift truck

3.3 Storage

Warning!

Suffcient stability and evenness of the supporting area (foor)

must be ensured.

If the panels are not installed immediately after delivery, they can be stored under

the following conditions:

Panels must be stored in vertical position, and must not be stacked.

Storage only admissible indoors

Panels and accessories must be packed in a wooden crate with a dessicant

and sealed in aluminium foil (storage period max. 2 years after date of packag-

ing).

5 C

+ 40 C

Fig. 18

Diagram showing the storage conditions

Transport using a forklift truck

GHA

21 AGS 531 446-01 | Edition 12/2011

4 Assembly

4.1 Safety provisions

The switchgear panels may only be installed and assembled by the manufacturers

staff or by persons who have been certifed for this work.

The GHA series switchgear panels are delivered with the circuit-breaker set to

OFF, the energy storing device released and the disconnector and earthing switch

set to OFF.

Warning!

Risk of injury due to movable parts in the mechanical drive. The

energy storing device of the circuit-breakers and the earthing

switches must not be charged during assembly.

Warning!

Risk of accidents! Watch out for foor openings in the switchgear

room.

Danger!

Danger due to insuffcient dielectric strength of high-voltage con-

nections in case of assembly under aggravated ambient condi-

tions. During assembly of the busbar link and the high-voltage

connections, it is essential to avoid condensation, dirt and dust

deposits. At the time of installation, the ambient temperature must

amount to 10 C.

Warning!

The top sides of the panels are not meant to be walked on. Per-

sons may fall through them, get injured or may damage the panel.

When work has to be performed on the panel top - e.g. assembly

of defectors, fans or pressure relief ducts - temporarily position a

solid mounting rack to step on.

Warning!

Risk of injury due to non-respect of the safety provisions in Chap-

ter 1, on page 7.

4.2 Important instructions for assembly

Important:

Switchgear with pressure relief duct (see Chapter 8, as of page

63): The pressure relief duct must be mounted before the panel is

positioned on the base frame.

Condensation, dirt and dust should be avoided during assembly

on all accounts, in order to prevent damage to the panels.

For assembly, observe the assembly drawings supplied with the

equipment. Read them before you commence assembly work.

The drawing numbers are specifed in this manual under the de-

scription of the assembly work in question.

For all screw connections, refer to the tightening torques specifed

in the Annex.

The transport securing device on the busbars must not be re-

moved before assembly of the busbar link acc. to Chapter 4.7 on

page 32.

GHA

22 AGS 531 446-01 | Edition 12/2011 22

4 Assembly

4.3 Requirements regarding the switchgear room

Important:

Before installing the switchgear panels, make sure that the switchgear

room is checked according to the customer-specifc switchgear docu-

mentation.

Observe the minimum distance between the switchgear and the wall of the

building.

The load-bearing capacity of the fastening areas must correspond to the weight

of the switchgear (perform a stress analysis of the building).

Check base frame for dimensions and tolerances in position.

Check position of foor openings for high-voltage and low-voltage cables.

Before the switchgear is positioned at its site of installation, check that the base

frame dimensions are precisely correct.

Flatness: 1 mm/meter

Straightness: 1 mm/meter

Parallelism: 1 mm/meter

Height difference over the entire length of the switchgear: 2 mm

Design data of GHA switchgear: Examples for various switchgear panel variants

5

0

0

1

1

9

4

4

1

180 600/800 600/800

5

0

5

0

7

2

50

6

8

1

4

2 3

50

900

800

900

800

100

460/660 660

1

7

5

35

5

Fig. 19

Location of base frame and ceiling ducts (example: double busbar switchgear)

1 Rear gap cover

2 Steel base frame

3 Ceiling duct for high-voltage connections

4 Wall of building

5 Possible cross-bracings

6 Cooler attachments

7 Side wall

8 Side wall extension for double busbar switchgear

GHA

23 AGS 531 446-01 | Edition 12/2011 23

4 Assembly

100

1700

1

0

0

0

1340

2

4

0

0

/

2

7

8

0

Fig. 20

Example of panels with single busbar in the switchgear room

500 2100

1

0

0

0

2

3

8

0

/

2

7

8

0

1700

Fig. 21

Example of panels with double busbar in the switchgear room

GHA

24 AGS 531 446-01 | Edition 12/2011 24

4 Assembly

500

1

1700 1595

1

0

0

0

2

4

0

0

Fig. 22

Example of panels with single busbar and pressure relief duct in the switchgear room

1

Switchgear accessible from the rear: 800

500

1

2100 1990

1

0

0

0

2

4

0

0

Fig. 23

Example of panels with double busbar and pressure relief duct in the switchgear room

1

Switchgear accessible from the rear: 800

GHA

25 AGS 531 446-01 | Edition 12/2011 25

4 Assembly

4.4 Transporting the panels on the construction site

Warning!

Make sure the rope or chain is strong enough to bear the weight

of the panel and the trucks. Comply with the relevant provisions

for hoisting equipment.

Warning!

On lowering the panels, make sure that the supporting platform is

suffciently stable and even.

Warning!

Risk of tipping over. During transport, pay attention to the weight

distribution. The center of gravity is at gas tank level in the upper

part of the switchgear panel. Never move panels without using

transport aids.

Warning!

Risk of accidents. Pay attention to foor openings!

4.4.1 Transport of panel by means of a crane

1. Remove transport packaging (protective flms).

2. Attach rope/chains to the jack rings located on the busbar tank (Fig. 24).

Important:

The ropes must have the following minimum lengths: L 900 mm

3. Release transport fastening device of the panel from the transport pallet (Fig.

24, item 1).

4. Lift the panel carefully with the crane.

5. If necessary, mount transport rollers (Fig. 26). Description of assembly, see

following page.

6. Lower the panel slowly to the foor at its place of destination.

1

L

9

0

0

Fig. 24

When lifting, make sure that at least the

minimum rope length L is used.

1 Transport fastening

1

Fig. 25

Panels with cooler and busbar attach-

ments

1 Use an additional frame for crane

transport.

Fig. 26

Mounting the transport rollers (see

Chap. 4.4.2, page 26)

GHA

26 AGS 531 446-01 | Edition 12/2011 26

4 Assembly

4.4.2 Transport using the transport frame

For transport on the foor, a frame must be mounted to the left and right of the

switchgear panel (not included in scope of supplies).

1. Insert locating pins of transport frame into the lateral bore-holes in the support-

ing structure of the switchgear panel, and secure them by means of the two

knurled screws (Fig. 27, item 2).

2. Actuate front toggle lever (3) to its stop in the direction of the arrow. Press the

button on the rear lifting device (4) and actuate lever to its stop in the direction

of the arrow till it reaches its stop.

3. The panel is lifted.

1 2

3 4

5

Fig. 27

Mounting the transport rollers

1 Transport frame

2 Knurled screws

3 Front toggle lever

4 Rear lifting device with push-button

5 Switchgear panel

These panels are delivered from the factory with additional supporting profles

mounted. The supporting profles must not be removed during assembly.

For transport on the foor, the transport rollers must be secured to the supporting

profles to the left and right of the supports provided to this effect (Fig. 28).

Remove a supporting profle before screw-fastening the panel to an adjacent panel.

A supporting profle - left-hand or right-hand - must always be left mounted to the

panel as long as the panel is not screw-fastened to the adjacent panel. Remove sup-

porting profle after having screw-fastened the panels.

Fig. 28

Panel with pre-assembled supporting profles and attached transport rollers

Assembly

Panels with center of gravity

located in the rear part (e. g.

single busbar panel with bus

section coupler on the rear

busbar)

GHA

27 AGS 531 446-01 | Edition 12/2011 27

4 Assembly

4.4.3 Transporting the panels onto the base frame

1. Place two U profles (not included in scope of supplies) on the base frame as

traversing aid and block them by (lower) stops against slipping in the base

frame (Fig. 29, item 1).

2. Adjust the distance between the two U profles in accordance with the panel

width. When positioning the panels, make sure that the transport rollers are

located in the U profles.

3. Move panel onto the base frame, align front edge (see space assignment plan)

and lower the panel.

4. Remove transport rollers and U profles.

1

2 3

Fig. 29

Moving the panel on the base frame

1 U profles with stop edges as traversing aid

2 Transport frame

3 Switchgear panel

GHA

28 AGS 531 446-01 | Edition 12/2011 28

4 Assembly

4.5 Attachment of pressure relief duct

Switchgear units are provided with pressure relief duct, if the following is required:

Accessibility in acc. with IEC 62271-200: Qualifcation IAC AFLR (accessibility

from all sides) and/or

Qualifcation IAC AFL(R) internal arc 40 kA/1 s

Important:

The pre-assembled pressure relief duct supplied with the equipment

must be mounted before the panel is positioned on the base frame.

After installation of the panels, mounting may no longer be possible in

part.

L 2 L 3

Fig. 30

Switchgear panel with single busbar

and pressure relief duct

Fig. 31

Switchgear panel with double busbar

and pressure relief duct

The attachment of the pressure relief duct is described in the assembly drawing in

question:

Panel width

[mm]

Busbar

system

Pressure

relief from the

switchgear

room with

customized

duct

Pressure relief

into the switchgear room

for fan attach-

ment

TrSS

SS-

Stw

600 800 900 1000

Sin-

gle

bus-

bar

Dou-

ble

bus-

bar

Internal arc

qualifcation

IAC AFLR,

25 kA/1 s

Internal arc

qualifcation

IAC AFLR,

40 kA/1 s

AGS002105-02 AGS003379-01

2

AGS002105-04 AGS002105-04

AGS002105-06 AGS002105-06 AGS002105-15

1

AGS002105-07 AGS002105-07 AGS002105-16

1

AGS003216-01 AGS003216-01

AGS002105-08 AGS003379-08

AGS002105-10 AGS002105-10

AGS002105-12 AGS002105-12

AGS002105-14 AGS002105-14

AGS003216-02 AGS003216-02

AGS002105-08 AGS002105-08 AGS002105-18

3

1

Optional fan attachment

2

only to be used for panels without busbar top structure, in this case AGS002105-02

3

only in case of I

r

= 2500 A

GHA

29 AGS 531 446-01 | Edition 12/2011 29

4 Assembly

4.6 Remove cable compartment cover and shutters

4.6.1 Cable compartment interlock (optional)

An additional interlock prevents the cable compartment cover from being removed if

the earthing switch is not switched ON.

1. Charge spring mechanism of the circuit-breaker (Fig. 32, item 3). Earth the

outgoing feeder cable (see Operating Manual).

2. Push interlocking slide of cable compartment cover (2) upwards.

At the same time, the cable compartment cover is unlocked and actuation of the

earthing switch (1) interrupted mechanically and electrically.

Important:

After removing the cable compartment cover, it is impossible to push

the slide (Fig. 32, item 2) down. The earthing switch remains locked.

1

2

3

00346

Fig. 32

Unlock/lock cable compartment cover

1 Insertion opening for manual actuation of the earthing switch

2 Slide for locking/unlocking the cable compartment cover

3 Charge the spring mechanism of the circuit-breaker drive manually (as long no

supply voltage is applied).

Interlocking matrix Earthing switch

Cable compartment

cover

Cable compart-

ment cover

screw-fastened unlocked

removed locked

Earthing switch

ON unlocked

OFF locked

After assembly of the cable compartment cover, press interlocking slide (Fig. 32,

item 2) down.

The earthing switch (1) can be switched off mechanically and electrically.

Unlocking the cable

compartment cover

Locking the cable compartment

cover

GHA

30 AGS 531 446-01 | Edition 12/2011 30

4 Assembly

4.6.2 Remove cable compartment cover and shutters

Important:

Store screws, bolts and shutters carefully for subsequent reuse.

1. Open front frame:

Operating shutter without inspection glass:

Release the two securing bolts (Fig. 33, item 1).

Operating shutter with inspection glass:

Open interlocking mechanism using the double-bit key (Fig. 34, item 2).

Then, open the front frame by swinging it to the left.

2. Unscrew the two securing bolts from the cable compartment cover (3).

3. First pull the cable compartment cover up, then forwards to remove it.

1

1

3

4

Fig. 33

Operating shutter without inspection

glass

1 Securing bolts of the front panel

3 Securing bolts of cable compart-

ment cover

4 Hinged front frame

3

4

2

Fig. 34

Operating shutter with inspection glass

2 Lock and double-bit key

3 Securing bolts of cable compart-

ment cover

4 Hinged front frame

Removing cable compartment

cover

GHA

31 AGS 531 446-01 | Edition 12/2011 31

4 Assembly

Important:

Identify panel in accordance with the nameplate on the operating shut-

ter to avoid confusion.

1. Release screw connection of the operating shutter (Fig. 35, item 5) from the

4 fastening points and remove shutter

2. Release the fastening of the two lateral covers (4) of the right-hand cable tray

and remove covers.

1

2

3

4

5

Fig. 35

Removal of shutters

1 Hinged front frame

2 Operating shutter

3 Cable compartment cover

4 Cable tray cover

5 Screw connection of operating shutter (4 x)

Unscrewing the shutters

GHA

32 AGS 531 446-01 | Edition 12/2011 32

4 Assembly

4.7 Installation of panels

4.7.1 Installation of the frst switchgear panel

Important:

The position of the frst panel is decisive for placement of the subse-

quent panels, thus it is essential that measuring is effected with the

utmost precision!

1. Place the panel on the base frame according to the switchgear-specifc space

assignment plan (see Chapter 4.4.3, page 27).

2. Align panel. Check the panel front for correct horizontal and vertical position. If

applicable, lift the panel and place shims in the direct vicinity of the fastening

areas, until the horizontal position has been reached.

3. Position the following panel on the base frame next to the frst panel according

to the switchgear-specifc space assignment plan.

4. Remove shutters from the panels as described in Chapter 4.6 as of page 29.

4.7.2 Removal of transport securing device

Remove transport securing device above the high-quality electrical joints of the

busbar link.

Remove plastic cover from the busbar bushing (Fig. 36).

The plastic hood above the silicone sleeve is attached laterally and on top of

the retaining clip (Fig. 37). Remove plastic hood carefully applying little force

only.

Fig. 36

Plastic cover on the busbar bushing

Fig. 37

Plastic hood above the silicone sleeve

GHA

33 AGS 531 446-01 | Edition 12/2011 33

4 Assembly

4.7.3 Pre-coat the high-quality electrical joints of the busbar link

Important:

Make sure the high-quality electrical joints are absolutely clean.

Special grease (art. no. AGS 003371-01) and the sponge element

(art. no. S 065969) are either included in the scope of supplies

or must be purchased separately, depending on the agreement

concluded.

In case of doubt, please contact the manufacturer as required.

1. Clean the high-quality electrical joints of the busbar link (Fig. 40) using white

spirit (art. no. S 009 002) and a lint-free cloth (also micro-fbre cloths).

2. For each side of a high-quality electrical joint, press a length of approx. 10 mm

substance out of the tube and apply it using the sponge element (Fig. 40). In

the beginning, apply slightly more (approx. 15 mm), as the sponge also absorbs

grease.

One tube (90 g) is suffcient for approx. 36 complete high-quality electrical joints

(72 high-quality joint surfaces).

Abb. 38

Special grease (art. no. AGS 003371-

01)

Abb. 39

Sponge element (art. no. S 065969)

10-15

1

Fig. 40

High-quality electrical joint at the bus-

bar bushing

1 Make sure that the inner diameter

is greased thoroughly!

10-15

1

Fig. 41

High-quality electrical joint on the sili-

cone sleeve

1 Make sure the electrode ring is

clean!

3. Use the sponge element to spread a uniform thin flm of the the special grease

over the entire surface. Blank spots not covered by grease should be avoided

on all accounts. Once treated, do not touch the surfaces of the high-quality

electrical joints any longer.

Apply special grease and spread

it uniformly by means of the

sponge element.

GHA

34 AGS 531 446-01 | Edition 12/2011 34

4 Assembly

Important:

Busbar bushing (Fig. 40): Check especially the inner diameter

of the high-quality electrical joint for non-greased areas and, if

necessary, re-coat.

Check the electrode ring in the silicone sleeve (Fig. 41, item 1) for

cleanness and the absence of grease and, if necessary, clean.

4.7.4 Preassembling the clamping contacts

4. The following factory setting of the clamping contacts (Fig. 42) must be checked

prior to assembly:

Turn the two screws until the two clamping contacts are in loose contact, then

turn the screws back by a half turn of the thread.

5. Clean and grease busbar contact surfaces and contact points on the clamping

contact (see Chapter 13.3, page 88).

6. Carefully slip the clamping contacts into the busbar tubes of the left-hand panel.

3 2

1

Fig. 42

1 Check the clamping contact screws.

2 Clean and grease the contact surfaces

3 Insert the contact tips

GHA

35 AGS 531 446-01 | Edition 12/2011 35

4 Assembly

4.7.5 Screw-fastening the panels to one another

1. Push panels carefully together. Clearance between busbar tanks: 153 2 mm

(Fig. 43, item 1).

2. Connect panels to one another

(assembly drawing AGS 000913-01):

front panel screw connection:

9 x self-locking screw M8 to its stop (Fig. 43, item 3).

Panels with a width of 900 or 1000 mm are screw-fastened using compen-

sating shutters (see Chapter 4.8, page 36).

rear panel screw connection:

Screw-fasten connecting link to the jack ring plate

2 x self-locking screw connection M8 (Fig. 43, item 2).

Panel types Pressure relief duct Mat. no.

without with

All panel variants, except busbar

current transformers

AGS000913-03

AGS000913-01

Busbar current transformer

AGS000913-02

AGS000913-05

3

2

1

9x

1532

2

Fig. 43

Screw-fastening the panels to one another

1 Check setting 153 2; measuring location: Edge shown on the busbar tank

2 Rear panel screw connection: fasten connecting link

3 Screw-fasten panels on the front.

GHA

36 AGS 531 446-01 | Edition 12/2011 36

4 Assembly

4.8 Compensating shutters for the panel front

Compensating shutters are only required for panels with a width of 900/1000 mm

(see also switchgear-specifc documentation), panels with a width of 600/800 mm do

not require compensating shutters in-between each other. The shutters are always

supplied in preassembled condition as accessories. The compensating shutter vari-

ants are subdivided in accordance with the following dependencies:

Height of low-voltage cabinet 800 mm or 1200 mm

Nominal width of compensating shutter 50 mm or 100 mm, depending on panel

arrangement (see Table)

Panel with

panel width [mm]

Panel width, adjacent panel

(left-hand or right-hand)

[mm]

Rated width, compensating

shutter (left-hand or right-

hand)

[mm]

900/1000

600/800 50

900/1000 100

A

1

2

3

4

5

50 100

4 4 1/2 3/5

900/1000

A

Fig. 44

Compensating shutters in the panel front

1 Upper compensating shutter, width

100 mm

2 Lower compensating shutter, width

100 mm

3 Lower compensating shutter, width

50 mm

4 Screw connection M8 (12 x per

shutter)

5 Upper compensating shutter, width

50 mm

Required nominal width of the

compensating shutter depending

on the panel arrangement:

GHA

37 AGS 531 446-01 | Edition 12/2011 37

4 Assembly

In-line panel, left-

hand

Panel width

LV cabinet height End panel, left-

hand

600/800 mm

In-line panel,

right-hand

Panel width

800 1200

not required 600/800

AGS003372-01

900/1000

AGS003372-02

In-line panel, left-

hand

Panel width

LV cabinet height End panel, left-

hand

900/1000 mm

In-line panel,

right-hand

Panel width

800 1200

AGS003372-01

600/800/900/1000

AGS003372-02

In-line panel, left-

hand

Panel width

LV cabinet height Center panel

600/800 mm

In-line panel,

right-hand

Panel width

800 1200

600/800

not required 600/800

AGS003372-01

900/1000

AGS003372-02

900/1000

AGS003374-01

600/800

AGS003374-02

AGS003372-01

+AGS003374-01

900/1000

AGS003372-02

+AGS003374-02

In-line panel, left-

hand

Panel width

LV cabinet height Center panel

900/1000 mm

In-line panel,

right-hand

Panel width

800 1200

600/800/900/1000

AGS003372-01

+AGS003374-01

600/800/900/1000

AGS003372-02

+AGS003374-02

In-line panel, left-

hand

Panel width

LV cabinet height End panel, right-

hand

600/800 mm

In-line panel,

right-hand

Panel width

800 1200

600/800 not required

900/1000

AGS003374-01

AGS003374-02

In-line panel, left-

hand

Panel width

LV cabinet height End panel, right-

hand 900/1000

mm

In-line panel,

right-hand

Panel width

800 1200

600/800/900/1000

AGS003374-01

AGS003374-02

In-line panel, left-

hand

Panel width

LV cabinet height End panel, left-

hand

900 mm

In-line panel,

right-hand

Panel width

800 1200

AGS002596-01

600/800

AGS002596-02

AGS002597-01

900/1000

AGS002597-02

Front compensating shutter,

attachment to panel

GHA

38 AGS 531 446-01 | Edition 12/2011 38

4 Assembly

In-line panel, left-

hand

Panel width

LV cabinet height Center panel

900/1000 mm

In-line panel,

right-hand

Panel width

800 1200

600/800

AGS002598-01

600/800

AGS002598-02

AGS002599-01

900/1000

AGS002599-02

900/1000

AGS002596-01

600/800

AGS002596-02

AGS002597-01

900/1000

AGS002597-02

In-line panel, left-

hand

Panel width

LV cabinet height End panel, right-

hand 900 mm

In-line panel,

right-hand

Panel width

800 1200

600/800

AGS002600-01

AGS002600-02

900/1000 not required

4.9 Busbar link: B link

L1

L2

L3

L1

L2

L3

SS1

SS2

Fig. 45

Overview of designations for busbars and phase angle

Upper busbar = SS2 Rear busbar = SS1

Front compensating shutter,

attachment to panel

GHA

39 AGS 531 446-01 | Edition 12/2011 39

4 Assembly

1 2 3 4 5 6

7

Fig. 46

Overview of busbar link

1 Busbar support with high-quality

electrical joint

2 Busbar

3 Spacer pin

4 Retaining clip

5 Busbar clamping contacts

6 Silicone sleeve with securing

half-shells

Fig. 47

Tool for compressing

the silicone sleeve - fork

Fig. 48

Tool for compressing the silicone

sleeve (alternative) - claw fastener

To get access to the pre-assembled clamping contacts and to complete the busbar

link, it is necessary to press the silicone sleeve back.

To this effect, only the auxiliary equipment approved by the manufacturer may be

used, e.g. the fork Fig. 47 and the claw fastener Fig. 48.

Position the tool according to the illustration and press the silicone sleeve back.

Relieve the silicone sleeve. To do so, slowly release the silicone sleeve using the

tool being used, and remove the tool.

Detail drawing of a

B-link

Tool for pressing the silicone

sleeve back (see also Annex,

Chapter 13.2, page 85)

GHA

40 AGS 531 446-01 | Edition 12/2011 40

4 Assembly

4.9.1 Connecting the busbar (fasten preassembled clamping

contacts)

Important:

The two lugs of the upper clamping contact must be located between

the busbar tubes.

Assembly drawing for single and double busbar: AGS 002 268-01

1. Position the preassembled clamping contacts (see Chapter 4.7.4, page 34) acc.

to Fig. 49, item 2. The two lugs of the upper clamping contact must be located

between the busbar tubes (see Fig. 49, item 4).

2. Tighten the clamped connection with a torque of 8 1 Nm.

3. After tightening the clamped connection applying the specifed torque, remove

the red flm from the sandwich label (5). A green stripe appears which indicates

that the busbar link has been established correctly.

1

8 1 Nm

0-3 mm

2

3

4

5

4

Fig. 49

Busbar link

1 Tool

2 Clamping contacts

3 Busbar

4 Locating lugs

5 Sandwich label

GHA

41 AGS 531 446-01 | Edition 12/2011 41

4 Assembly

4.9.2 Contact resistance measurement of busbar screw fastening

Important:

Comply with the manufacturers specifcations regarding the contact

resistance measuring unit.

1. Set the feeder panel for resistance measurement in testing position (A)

(Fig. 50): Switch disconnector and circuit-breaker ON, refer also to operating

manual.

2. Connect the clip-on ammeter probes of the contact resistance measuring unit to

the high-voltage cable connection in the right-hand panel (B).

Illustrated: Outer cone-type bushing. Use suitable current probes for the inner

cone-type bushing.

3. On the lined-up panel, connect clip-on ammeter probes of the contact resis-

tance measuring unit to the busbar tube by means of inner cone-type current

probes (C).

4. Apply test current 100 A DC (D).

5. Measure contact resistance R between the busbar tube and the lug of the

clamping contact (E). Set value R: 5 .

If the measured value exceeds the specifed value:

Undo busbar screw fastening.

Clean contact surfaces carefully and repeat the mounting and measuring

procedure.

In this way, check the contact resistance of all phases between all panels.

100 A DC

00243

C

D

E

A

B

R 5

Fig. 50

Contact resistance measurement

GHA

42 AGS 531 446-01 | Edition 12/2011 42

4 Assembly

4.9.3 Fasten silicone sleeve to adjacent panel

Important:

Check pre-coated high-quality electrical joints again for absolute clean-

ness.

The surfaces of the high-quality electrical joint must be coated com-

pletely and uniformly with a thin layer of special grease.

Check high-quality electrical joints for non-greased areas and, if neces-

sary, coat again, see Chapter 4.7.3, page 33.

6. Relieve the silicone sleeve. To do so, slowly release the silicone sleeve using

the tool being used, and remove the tool.

7. Clean spacer pins (accessories, Fig. 46, item 3) and welding studs and coat

them with a screw locking compound (see Chapter 13.3, page 87). Screw-

fasten spacer pin onto the welding studs.

8. Slip retaining clip onto the two pins. The sides of the retaining clip must butt

against the retaining lugs of the securing half-shells.

Subsequently, position the cage with the cup springs and fasten retaining clip

by means of a M8 self-locking nut. The surfaces of the high-quality electrical

joint must be compressed by the retaining clip.

1

(121,5 Nm)

2

3

4

(121,5 Nm)

Fig. 51

Fastening the silicone sleeve to the adjacent panel

1 Spacer pin

2 Retaining clip

3 Cup spring package

4 Nut

Checking high-quality electrical

joints

Mounting the retaining clips

GHA

43 AGS 531 446-01 | Edition 12/2011 43

4 Assembly

4.9.4 Cover of busbar link in case of panels without pressure relief

duct

Panel width, adja-

cent panel, left-hand

[mm]

Panel width

[mm]

Assembly drawing

Single busbar Double busbar

600/800 600 AGS003202-01 AGS003202-02

600/800 800 AGS003202-01 AGS003203-02

900/1000 600/800 AGS003204-01 AGS003204-02

600/800 900 AGS003205-01 AGS003205-02

900/1000 900 AGS003206-01 AGS003206-02

600/800 1000 AGS002609-02 AGS003205-02

900/1000 1000 AGS002610-02 AGS003206-02

SS-StW 600/800 AGS003215-03 AGS003215-07

SS-StW 900 AGS003215-04 AGS003215-08

600/800 SS-StW AGS003215-01 AGS003215-05

900 SS-StW AGS003215-02 AGS003215-06

1

2

Fig. 52

Cover of busbar link

1 Cover of upper busbar link

2 Cover of rear busbar link

GHA

44 AGS 531 446-01 | Edition 12/2011 44

4 Assembly

Cover of busbar link in case of panels with pressure relief duct

Fig. 53

Cover of busbar link in case of panels with pressure relief duct

Panel width

[mm]

adjacent panel, right-hand

Panel width

[mm]

Busbar sys-

tem

Mat. no.

SS-Stw 600 800 900 1000 SS-Stw 600 800 900 1000

Single

bus-

bar

Dou-

ble

bus-

bar

AGS002115-05

AGS002115-03

AGS003217-01

AGS002115-04

AGS002115-06

AGS003217-02

AGS002115-06

AGS002115-02

AGS002115-07

AGS003217-05

AGS002115-08

AGS002115-09

AGS003217-06

AGS003217-03

AGS003217-04

AGS003217-07

AGS003217-08

AGS003217-09

AGS003217-10

AGS002115-10

AGS002115-11

H O AGS002115-14

O = Bus section coupler with upper busbar separation (SS2)

H = Bus section coupler with rear busbar separation (SS1)

GHA

45 AGS 531 446-01 | Edition 12/2011 45

4 Assembly

Panel width

[mm]

adjacent panel, right-

hand

Panel width

[mm]

Busbar

system

LV

cabinet

Height

[mm]

Cover

Pressure

relief device

Cover SS (to

the right-hand

adjacent

panel)

Cover

LV cabinet

S

S

-

S

t

w

6

0

0

8

0

0

9

0

0

1

0

0

0

S

S

-

S

t

w

6

0

0

8

0

0

9

0

0

1

0

0

0

S

i

n

g

l

e

b

u

s

b

a

r

D

o

u

b

l

e

b

u

s

b

a

r

8

0

0

1

2

0

0

AGS002113-01 AGS003386-03 -

AGS002113-03 AGS003386-01 AGS003416-02

AGS002113-03 AGS003386-01 AGS003416-04

- - -

AGS002113-03 AGS003386-02 AGS003416-02

AGS002113-03 AGS003386-02 AGS003416-04

AGS002113-04 AGS003386-05 AGS003416-03

AGS002113-04 AGS003386-05 AGS003416-05

- - AGS003416-02

- - AGS003416-04

AGS002113-04 AGS003386-05 AGS003416-03

AGS002113-04 AGS003386-05 AGS003416-05

AGS002113-02 AGS003386-03 -

AGS002113-05 AGS003386-01 AGS003416-02

AGS002113-05 AGS003386-01 AGS003416-04

AGS002113-05 AGS003386-02 AGS003416-02

AGS002113-05 AGS003386-02 AGS003416-04

AGS002113-06 AGS003386-05 AGS003416-03

AGS002113-06 AGS003386-05 AGS003416-05

- - -

- - AGS003416-02

- - AGS003416-04

- - AGS003416-02

- - AGS003416-04

- - AGS003416-02

- - AGS003416-04

- - AGS003416-03

- - AGS003416-05

GHA

46 AGS 531 446-01 | Edition 12/2011 46

4 Assembly

4.10 Reinforcement

Required in case of

internal arc strength acc. to IEC 62271-200, qualifcation IAC AFL(R), internal

arc 40 kA/1 s

Seismic design / vibration-resistance

Fan

attachment

Panel width

adjacent panel,

left-hand

Panel

width

Assembly drawing

with-

out

with Single busbar Double busbar

600/800 600 AGS003389-01 AGS003389-02

600/800 800 AGS003389-01 AGS003389-02

900/1000 600/800 AGS003389-03 AGS003389-04

600/800 900/1000 AGS003389-05 AGS003389-06

900 900 AGS003389-07 AGS003389-08

900 1000 AGS003389-09 AGS003389-10

1000 900 AGS003389-09 AGS003389-10

SS-StW 600/800 AGS003389-11 AGS003389-12

SS-StW 900 AGS003389-13 AGS003389-14

600/800 SS-StW AGS003389-15 AGS003389-16

900 SS-StW AGS003389-17 AGS003389-18

Fig. 54

Reinforcements

GHA

47 AGS 531 446-01 | Edition 12/2011 47

4 Assembly

4.11 Screw-fastening the panel to the base frame

Important:

The switchgear panels may not be screw-fastened to the base frame

before they have all been installed and adjusted.

Cut thread M8 in the base frame at the securing points provided to this effect

(Fig. 55). To this effect, drill initial holes of 6.8. Screw-fasten the panels 2 x each

on the front and rear.

1

1

4

2 3

Fig. 55

Fastening points in the base frame

If the rear fastening points are not

accessible, e. g. due to voltage trans-

formers, fastening links (Fig. 56) can be

mounted.

Screw-fasten both fastening links to the

panel's supporting structure.

Cut a thread M8 in the base frame on

the specifed fastening points. To this

effect, drill initial holes of 6.8.

Panel width

[mm]

Seismic design /

vibration-resistance

Mat. no.

600 800 900 1000 without with

AGS002206-01

AGS002206-02

AGS002206-03

AGS002206-04

The base frame must be designed in view of the seismic design. The panels are

fastened to the base frame by means of screws M12.

Additional securing points

(optional)

1

2

3

Fig. 56

Rear fastening links

1 Rear base frame

2 Fastening link

3 Screw connection

GHA

48 AGS 531 446-01 | Edition 12/2011 48

4 Assembly

4.12 Mounting the earth bus

Important:

Observe the specifc standards referring to earthing systems which ap-

ply in the country in question.

1. Clean all contact areas of the connecting bar and the appropriate earth bar in

the switchgear panels and coat them with lubricant (KL) (see Chapter 13.3,

page 88).

2. Slip the connecting bar into the adjacent panel's supporting structure through

the cutout in the panel.

3. Screw-fasten the connecting bar with the support brackets on both sides, to the

earth bar in question and screw-fasten the support brackets to the panel.

4. Mount the connecting piece for switchgear earthing (Fig. 57, item 6). Connect

the earth bus to the earthing system of the switchgear building. Connecting

lines and screw accessories are not included in the scope of supplies.

Connecting piece for switchgear earthing: AGS 000294-03

Panels with base plates: Observe Chapter 9.1, page 69.

The earth bus should be connected to the earth conductor of the building's earth

connection at least at the frst and at each tenth panel of the switchgear.

Panel width

[mm]

Panel width

Adjacent panel

[mm]

Assembly drawing

600 (also for end panel right-hand)

600/800

AGS 000294-01

800 (also for end panel right-hand) AGS 000294-02

600 900 AGS 000294-04

900 (also for end panel right-hand) 600/800 AGS 002510-01

900 900 AGS 002510-02

1000

600/800 AGS 002510-03

900 AGS 002510-04

1

2

3

4

5

6 ( 13 mm)

Fig. 57

Mounting the earth bar and connecting bar

1 Earth bar

2 Support brackets

3 Connecting bar

4 Screw-fastening the support brackets to the earth bar and the connecting bar

5 Screw-fastening the support brackets to the panel

6 External point of connection for the earth bus of the panel

The earth bars are screw-

fastened from panel to panel by

means of connecting bars (Fig.

57, item 3).

GHA

49 AGS 531 446-01 | Edition 12/2011

5 Busbar attachments

5.1 Safety provisions

Warning!

When performing assembly work on busbar attachments, the ap-

propriate disconnecting device must be in earthed position (see

Operating Manual).

Warning!

Please comply with the safety provisions in Chapter 1, page 7.

5.2 Assembly of surge arresters

Important: