Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Section 16110 Raceways, Boxes and Fittings

Caricato da

eng_asayed0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

30 visualizzazioni13 pagineSECTION 16110 Division 16

RACEWAYS, BOXES AND FITTINGS

Titolo originale

SECTION 16110

RACEWAYS, BOXES AND FITTINGS

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSECTION 16110 Division 16

RACEWAYS, BOXES AND FITTINGS

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

30 visualizzazioni13 pagineSection 16110 Raceways, Boxes and Fittings

Caricato da

eng_asayedSECTION 16110 Division 16

RACEWAYS, BOXES AND FITTINGS

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 13

SECTION 16110

RACEWAYS, BOXES AND FITTINGS

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of Contract, including General and special Conditions and Division-1

(General Requirements) appl to wor! of t"is section.

#. General $rovisions for %lectrical &or! 'ection 1()1).

C. *"e requirements of t"is section appl to racewas specified elsew"ere in t"is specification.

D. 'pecification 'ection 1++,-. /ounting and 0solation of /ec"anical and %lectrical 'stems and related

contract drawings, appl to t"is section of t"e wor!.

1.2 DESCRIPTION OF WORK

A. &or! includes providing completel coordinated grounded racewa sstems complete wit" 1o2es,

fittings, supports, anc"ors, sleeves, "angers, clamps, straps, seals, fle2i1le connections to vi1rating

equipment and accessories, as specified and as required for a complete sstem. Conduit or tu1ing

si3es referred to in t"e specifications and on t"e Drawings are nominal internal diameters. Racewa is

required for all wiring unless specificall indicated or specified ot"erwise.

1.3 QUALITY ASSURANCE

A. /anufacturers. 4irms regularl engaged in manufacture of racewa sstems, 1o2es and fittings of

tpes and si3es required, w"ose products "ave 1een in satisfactor use in similar service for not less

t"an + ears and s"all 1e of one manufacturer, approved 1 t"e !a"ramaa, and conform to t"e

requirements set fort" in t"is specification.

#. 'tandards Compliance. Compl wit" requirements of applica1le local codes, !a"ramaa regulations

latest edition, 5D%6D07, 0%C, #', 7%C, 89 and 7%/A 'tandards pertaining to racewas, 1o2es and

fittings. $rovide racewas, 1o2es and components w"ic" "ave 1een 89 listed and la1elled.

C. 0n case of conflict among t"e referenced standards and codes, t"e more stringent provision will govern.

1. SUBMITTALS

A. $roduct Data. 'u1mit manufacturer:s tec"nical product data, including specifications and installation

instructions, for eac" tpe of racewa sstem and 1o2 required. 0nclude data su1stantiating t"at

materials compl wit" requirements.

#. 'amples. 'u1mit 1+cm lengt" of e2posed tpe surface racewas wit" required finis", in accordance

wit" requirements of Division 1.

$age 1 of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

C. '"op Drawings. su1mit dimensioned laout drawings on arc"itectural 1ac!grounds of racewas, 1o2es

and fitting including, 1ut not limited to si3e of racewas, 1o2es and fittings elevations, tpe and

reference no.

PART 2 - PRODUCTS

2.1 RACEWAYS

A. Rigid 'teel Conduit (R'C). 4ull weig"t steel pipe "ot dipped galvani3ed inside and outside, t"readed,

minimum <)mm, unless ot"erwise noted= minimum 1+mm for switc" legs.

#. 0ntermediate /etal Conduit (0/C). Rigid intermediate grade, "ot dipped galvani3ed outside, t"readed,

minimum <)mm, unless ot"erwise noted= minimum 1+mm for switc" legs.

C. %lectrical /etallic *u1ing (%/*). *"in wall steel, galvani3ed, t"readless, minimum <)mm, unless

ot"erwise noted= minimum 1+mm for switc" legs.

D. 4le2i1le 'teel Conduit. Continuous lengt" of speciall wound interloc!ed, galvani3ed strip steel,

minimum <)mm.

%. 9iquid *ig"t 4le2i1le /etal Conduit. Continuous lengt" of fle2i1le interloc!ed, galvani3ed inside and

outside steel tu1ing, wit" a continuous copper 1onding conductor wound speciall 1etween t"e

convolution, coated wit" a liquid tig"t >ac!et of fle2i1le polvinl c"loride ($5C), minimum <)mm

4. $olvinl C"loride Conduit

1. 'elf-e2tinguis"ing and "eav gauge conduits and conduit fittings to meet #' ,()-, #' ()?? and

#'-(-1 wiring regulations.

<. 4or concrete encasement.

;. 4or direct 1urial, 'c"edule ,) conduit.

,. /inimum <) mm for lig"ting and power wiring, minimum 1( mm for telep"one installation.

G. &ire was. 'teel, minimum 1.+mm t"ic!ness, wit" screw-on covers, racewa !noc!out, el1ow fittings,

"angers, wire retainers, and ca1inet adapter= si3e as noted or required.

<.< 40**07G' A7D ACC%''@R0%'

$age < of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

A. GENERAL

1. Accessories as required including, 1ut not limited to, 1us"ings, !noc!out closures, loc!nuts,

mounting 1rac!ets, device 1o2 e2tensions, switc" 1o2 supports, plaster ears, and plaster1oard

e2panda1le grip fasteners, w"ic" are compati1le wit" device 1o2es 1eing utili3ed to fulfill installation

requirements for individual wiring situation.

<. Die-cast fittings not permitted.

;. %art"ing (grounding) #us"ings. &it" lug suita1le for t"e si3e and tpe of eart"ing (grounding)

conductor to 1e terminated.

$age ; of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

B. RIGID STEEL AND INTERMEDIATE METAL CONDUIT FITTINGS

1. 'teel or mallea1le iron, standard t"readed couplings, loc!nuts, 1us"ings, and el1ows.

<. Conductive tpe t"read compounds to insure low resistance ground continuit t"roug" conduit.

&atertig"t couplings and connections in concrete.

;. 9oc!nuts of t"e 1onding tpe wit" s"arp edges for digging into t"e metal wall of t"e enclosure.

,. #us"ings of t"e metallic insulating tpe, consisting of an insulating insert molded or loc!ed into

t"e metallic 1od of t"e fitting.

+. Corrosion resistant metallic conduit fittings.

(. 'ealing fittings of t"e t"readed cast iron tpe. &"ere sealing fittings are used to prevent

passage of water vapor, utili3e t"e continuous drain tpe.

C. %lectrical /etallic *u1ing 4ittings. 'teel or mallea1le iron concrete tig"t couplings and connectors of

t"e gland and ring compression tpe= set screw tpe connectors are permitted for interior dr locations

onl, indent tpe connectors are not permitted.

D. 4le2i1le /etal Conduit 4ittings. 'teel or mallea1le iron, insulated t"roat angle wedge tpe.

%. 'urface /etal Racewa 4ittings. As recommended 1 manufacturer to matc" integrit of racewa

sstem.

4. $olvinl C"loride Conduit 4ittings. As recommended 1 t"e manufacturer to matc" integrit of eac"

tpe of racewa sstem.

G. %A$A7'0@7 A7D D%49%C*0@7 C@8$907G'

1. Compl wit" approved applica1le standards.

<. Accommodate 1.? cm deflection, e2pansion and contraction in an direction.

;. Allow ;) degree angular deflection.

,. 0nclude internal fle2i1le metal 1raid si3ed to guarantee conduit ground continuit and fault

currents.

+. &atertig"t, seismicall qualified corrosion resistant t"readed and compati1le wit" associated

conduit.

(. Bac!et. 4le2i1le, corrosion resistant, watertig"t, moisture and "eat resistant molded ru11er

material wit" stainless steel >ac!et clamps.

-. SUPPORTS

1. Cinc coated or equivalent.

<. Conduit "angers, designed for t"e purpose and "ave pre-assem1led closure 1olt and nut and

provision for receiving "anger rod.

;. /ultiple conduit (trape3e) "angers not less t"an ;Dcm 2 ;Dcm, <,-mm t"ic!ness steel, cold

formed, dipped clamps. Eanger rods not less t"an ).?+ cm diameter steel.

$age , of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

,. Anc"ors of tpes, si3es and materials designed for t"e purpose.

2.3 OUTLET BOXES

A. @8*9%* #@A%'

1. $5C "eav gauge for concealed wor!, and galvani3ed cast iron or aluminum wit" t"readed

"u1s for e2posed wor!= 1o2es of s"apes, cu1ic inc" capacit, and si3es as required, suita1le for

installation at respective location.

<. &it" mounting "oles and wit" ca1le and conduit si3e !noc!out openings.

;. &it" t"readed screw "oles, wit" corrosion resistant ridged cover and grounding screws for

fastening surface and device tpe 1o2 covers, and for equipment grounding.

,. 4or concealed wor!, utili3e 1)cm square or octagon outlet 1o2es, e2cept as ot"erwise

required 1 construction devices or wiring and as follows.

a. A1ove ceiling. ;.Dcm deep.

1. 0n ceiling or sla1. -.(cm deep.

c. 0n wall for fi2tures. -cm deep.

d. 0n wall for receptacles and switc"es. ;.Dcm deep.

e. &it" raised covers and fi2ture studs w"ere required.

f. Ganga1le tpe 1o2es are not permitted.

g. 4or installation of more t"an two devices in a common outlet 1o2, utili3e 1o2es and

device rings manufactured specificall for t"is purpose.

". @utlet 1o2 device rings used to 1e of sufficient dept" so as to ma!e t"e use of

e2tension 1o2es and rings unnecessar.

+. 4or e2posed wor! utili3e 1)cm round 2 +cm deep for mounting on ceilings and 1)cm square 2

+cm deep for mounting on walls, e2cept as ot"erwise required 1 construction, devices, or

wiring.

(. $rovide 1lan! covers for outlet 1o2es wit"out devices. Covers to matc" ad>acent plates.

2. WIRING TROUG-S, .UNCTION AND PULL BOXES

A. Eeav gauge $5C, galvani3ed s"eet steel wit" screw-on covers for interior wor!, and galvani3ed cast

iron and6or <.-mm t"ic!ness stainless steel wit" t"readed "u1s, gas!ets for outdoors and damp

locations= 1o2es of s"apes, cu1ic cm capacit, and si3es as required, suita1le for installation at

respecta1le location.

#. 0nsulated ca1le supports.

2./ ACCEPTABLE MANUFACTURER

R!0!# T& +1! 2S*1!34%! &0 P#!0!##!3 E%!*+#(*$% M$"40$*+4#!#) 5 S466%(!#)2.

$age + of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

PART 3 - EXECUTION

3.1 INSPECTION

A. %2amine conditions under w"ic" racewas, 1o2es, accessories, and fittings are to 1e installed and

su1strate w"ic" will support racewas. 7otif Arc"itect in writing of conditions detrimental to proper

completion of t"e wor!. Do not proceed wit" wor! until unsatisfactor conditions "ave 1een corrected.

3.2 INSTALLATION

A. GENERAL

1. 0nstall racewas, 1o2es, accessories, and fittings as indicated, in accordance wit"

manufacturerFs written installation instructions, requirements of applica1le standards, and in

accordance wit" recogni3ed industr practices to ensure t"at installation complies wit"

requirements and serves intended function.

<. Coordinate as necessar to interface installation of electrical racewas, 1o2es, and components

wit" ot"er wor!. Run racewas concealed, e2cept as noted.

;. /ec"anicall fasten toget"er metal conduits, enclosures, and racewas for conductors to form

continuous electrical conductor. Connect to electrical 1o2es, fittings and ca1inets to provide

electrical continuit and firm mec"anical assem1l. /aintain grounding continuit of interrupted

metallic racewas wit" ground conductor.

,. Avoid use of dissimilar metals t"roug"out sstem to eliminate possi1ilit of electrolsis. &"ere

dissimilar metals are in contact, coat surfaces wit" corrosion in"i1iting compound 1efore

assem1ling.

+. 'upport racewas 1 means of ceiling trape3e, strap "angers, wall 1rac!ets wit" 1ac! spacer,

structural steel angles or c"annels. 'upport riser racewas at eac" floor. 'ecure racewas to

supports wit" pipe straps or 8-1olts. 'pace supports as per applica1le electrical code and per

manufacturer:s recommendations, unless ot"erwise indicated.

(. /ount supports to structure wit" toggle 1olts on "ollow masonr, e2pansion s"ields or inserts

on concrete and 1ric!, mac"ine screws on metal, wood screws on wood. 7ails, raw plugs,

wood, and6or plastic plugs are not permitted.

-. Geep racewas clear of motor foundations. Also, do not o1struct "eadroom, doorwas, or

wal!was, wit" racewa.

D. 0nstall miscellaneous fittings suc" as reducers, c"ase nipples, ;-piece unions, split couplings,

and plugs t"at "ave 1een specificall designed and manufactured for t"eir particular application.

?. 8se roug"ing-in dimensions of electricall operated equipment furnis"ed 1 equipment supplier.

'et conduit and 1o2es for connection to equipment onl after receiving dimensioned drawings

from equipment installer and after c"ec!ing location wit" ot"er trades.

1). *est conduits required to 1e installed, 1ut left empt, wit" 1all mandrel. Clear an conduit w"ic"

re>ects 1all mandrel.

$age ( of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

11. $rovide long radius 1ends for empt racewa sstems w"ere required to satisf t"e sstem

ca1ling requirements.

1<. 0nstall complete racewa runs 1efore pulling in wire or ca1le. 0nstall racewas so t"at required

conductors ma 1e drawn in wit"out in>ur or e2cessive strain to racewa or ca1le. &"ere

racewa si3e is not indicated, follow applica1le code.

1;. Geep end of racewas plugged or capped during construction.

1,. 4or empt racewas over ;m long, provide fis" or pull wire. 4or ;.Dm and larger pull wire to

consist of steel core nlon rope and terminal 1all.

1+. Remove damaged or deformed racewas.

$age - of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

1(. Do not support 1ranc" circuit conduits 1 t"e suspended ceiling or its supporting mem1ers,

lig"ting fi2tures, mec"anical piping, or air conditioning ducts.

1-. Conduits are not to cross pipe s"afts or ventilating duct openings. Avoid present and future

openings in floor, wall or ceiling construction, w"en so indicated on drawings.

1D. Geep conduits a minimum distance of ,+cm from parallel runs of fuels or similar and 1+cm from

"ot water pipes or ot"er sources of "eat. &"erever possi1le, install "ori3ontal racewa runs

a1ove water and steam piping. $rovide t"ermal insulation w"ere t"ese separations cannot 1e

maintained.

1?. 'upport riser conduit at eac" floor level wit" clamp "angers.

<). 8se of running t"reads at conduit >oints and terminations is pro"i1ited. &"ere required, use

;-piece union or split coupling.

<1. $rovide !noc!out closures to cap unused !noc!out "oles w"ere 1lan!s "ave 1een removed.

<<. 0nstall electrical 1o2es in t"ose locations w"ic" ensure read accessi1ilit to enclosed electrical

wiring.

<;. Do not install 1o2es 1ac!-to-1ac! in walls. $rovide not less t"an 1+) mm separation.

<,. Do not install aluminum products in concrete. $lug and seal conduit interconnections.

<+. $osition recessed outlet 1o2es accuratel to allow for surface finis" t"ic!ness.

<(. 4asten electrical 1o2es firml and rigidl to su1strates or structural surfaces to w"ic" attac"ed

or solidl em1ed electrical 1o2es in concrete or masonr.

<-. 'u1sequent to installation of 1o2es, protect 1o2es from construction de1ris and damage.

<D. 'et 1o2es square and true wit" t"e 1uilding finis". 'ecure 1o2es to t"e 1uilding structure and

adequatel support all 1o2es during construction to prevent movement.

<?. 5erif outlet locations in finis"ed spaces wit" Arc"itectural Drawings or 0nterior Design

drawings, details and finis"es. *a!e caution in locating outlet to allow for over"ead pipes, ducts,

and variations in arrangement, t"ic!ness in finis", window trim and ot"er Arc"itectural

Construction Details.

;). Correct an inaccurac in locating outlets wit"out additional e2pense to t"e @wner. Refer to

Arc"itect an condition t"at would place an outlet 1o2 in an unsuita1le location, suc" as a

molding, 1rea! glass in wall finis", or 1e"ind a "eating enclosure.

;1. /ount outlet 1o2es for similar equipment at uniform "eig"t wit"in same or similar areas. &"ere

mounting "eig"t or location of outlets is not s"own or specified, mount outlet as 1est suited for

equipment connected t"ereto, or as directed.

;<. $rovide 1arriers 1etween switc"es connected to different p"ases.

;;. %2cept w"ere special outlets are required, provide 1)cm square wall outlets wit" single gang

raised cover and 1us"ed plate for signaling sstems.

;,. 0n cold rooms, wal!-in refrigeration 1o2es, etc., w"en applica1le weat"erproof racewa

installations and use sealing fittings and compounds as entries.

$age D of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

;+. 4or conduit or ca1le tra runs e2posed inside t"e 1uilding, mar! (stencil ; / on centers,

including in "ung ceiling, wit" t"e notation, HDanger, 5olts,H indicating t"e actual voltage (i.e.

HDanger 11,))) 5olts,H HDanger,1+5oltsH).

;(. 0nstall conduits located underground 1eond t"e 1uilding as follows.

a. &it" a minimum of () cm top cover, a1ove t"e conduits, and sloped awa from t"e

1uilding.

1. $laced over well tamped trenc" 1ottom and on concrete 1loc! 1.+ / on center.

Anc"or conduits to prevent t"eir movement. 'tagger conduit >oints a minimum of 1+

cm apart. /a!e all >oints watertig"t.

c. &it" a minimum clear separation 1etween t"e electric and telep"one conduits of ;)

cm of well tamped eart" or 1+ cm of concrete.

;-. 4or conduits and direct 1urial ca1le entering t"e 1uilding w"en applica1le perform t"e following.

a. $lug all empt racewas.

1. %nter t"roug" floor or wall entrance fittings. 4or t"e entrance fittings utili3e a gland

assem1l ca1le of provide seal around t"e conduit or ca1le to wit"stand 1+/ "ead

of water wit"out lea!age.

c. 'lope awa from 1uilding.

d. 0n lieu of wall entrance fittings t"roug" floor or wall, <.+ mm metal plates ma 1e

utili3ed su1>ect to t"e following.

1) $late e2tends a minimum of 1))mm from racewa in ever direction.

<) $late is welded to racewas forming a watertig"t seal.

;) Racewas are not damaged.

;D. &or! wit" e2treme care near e2isting ducts, conduits, ca1les and ot"er utilities to avoid

damaging t"em.

;?. $rovide weat"er-tig"t outlets for interior and e2terior locations e2posed to weat"er or moisture.

,). 'et floor 1o2es level and flus" wit" finis" flooring material. Coordinate trim wit" tpe of finis",

i.e., tile, carpet, etc.

#. 4or all vi1rating equipment ad>acent or a1ove acousticall treated areas, provide t"e following.

$age ? of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

1. 4le2i1le conduit at t"e entries, e2its, and outlets.

<. 'ealing fittings wit" compound at t"e entries and e2its.

;. 'upports of ru11er-in-s"ear ceiling "angers.

,. %2pansion fittings at isolating sla1 >oints.

+. Ru11er gas!eted recessed outlets.

(. #ac! plaster recessed outlets.

-. 4ree-standing equipment wit" vi1ration isolators.

C. RIGID STEEL CONDUIT

1. 8se rigid steel conduit for underground installation, in wet or damp locations, for e2posed runs

on t"e e2terior of t"e 1uilding, in concrete sla1s, for all feeder conduits, in mec"anical

equipment spaces, and as noted.

<. &"ere conduit is directl 1uried, provide two coats of poluret"ane. Dr t"oroug"l 1etween

coats and 1efore 1ac!filling.

;. &"ere located under t"e 1uilding, encase conduit for all runs a1ove +mm wit" concrete

envelope wit" walls not less t"an Dcm t"ic!.

D. INTERMEDIATE METAL CONDUIT

1. 8se intermediate metal conduit in lieu of rigid steel conduit w"ere permitted 1 applica1le

electrical codes.

<. &"ere located under t"e 1uilding, encase conduit for all runs a1ove +cm wit" concrete

envelope not less t"an Dcm t"ic!.

E. ELECTRIC METALLIC TUBING 7EMT8

1. 8se electrical metallic tu1ing for 1ranc" circuits onl, in dr locations ("ung ceilings, "ollow

1loc! walls and furred spaces) and for fire alarm, smo!e and fire detection sstem w"ere in

accordance wit" all applica1le codes, aut"orities, etc.

<. %/* is not permitted to 1e used in mec"anical equipment spaces and w"ere su1>ect to

moisture, dampness, and mec"anical damage.

F. FLEXIBLE STEEL CONDUIT

1. 8se fle2i1le steel conduit wit" an internal eart" (ground) connection for s"ort connections w"ere

rigid conduit or tu1ing is impractica1le and for final connections to vi1rating equipment.

<. $rovide a minimum lengt" of ,(cm wit" slac!. Connect t"e eart" (ground) conductor to t"e

enclosure or racewa at eac" end.

G. LIQUID TIG-T FLEXIBLE METAL CONDUIT

1. 4or damp and wet conditions and in all plenums.

$age 1) of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

<. 8se liquid tig"t fle2i1le metal conduit for final connections to motor terminal 1o2es, transformers

and ot"er vi1rating equipment.

;. $rovide a minimum lengt" of ,+cm wit" slac!. Connect t"e ground conductor to t"e enclosure

or racewa at eac" end.

-. POLY9INYL C-LORIDE CONDUIT 7P9C8

1. 8se in or 1elow sla1s for service entrance conductors (sleeves) for lig"ting sstem, telep"one

service, lig"tning protection down conductors and onl as ot"erwise indicated. $rovide

separate eart"ing (ground) wire.

<. Cut ends square, ream smoot", wipe clean, appl approved solvent cement and quarter turn as

drawing up tig"t in accordance wit" recommendations of manufacturer.

;. Convert to steel conduit using adapters w"en entering t"e 1uilding from underground locations.

,. /aintain a 1/ minimum clearance of $5C conduits from "ot water and steam lines, w"ere

applica1le.

+. &"ere located under 1uilding, par!ing lot, and roadwas, concrete encase conduit for all runs

a1ove +)mm, w"ere applica1le.

(. Conduit, fittings and accessories s"all 1e of t"e same manufacture to provide a consistent

sstem wit" compati1le appearance. *"e use of alternative designs and different

manufacturer:s products will not 1e permitted.

-. All conduit >oints s"all 1e made in accordance wit" t"e manufacture:s installation

recommendations using a solvent ad"esive recommended 1 t"e ma!er of t"e conduit. All suc"

>oints s"all 1e watertig"t.

*"e same conditions s"all appl to >oints 1etween conduit, fittings and accessories. *"e dipping

of conduit or fittings into solvent ad"esives is e2pressl for1idden. #efore >oints are made,

conduit ends s"all 1e cut square and all 1urrs and s"arp edges s"all 1e removed. Care s"ould

1e ta!en to remove all damp, grease, cement dust and oil from all faces of conduits and

accessories prior to >ointing. Conduits s"all 1e entered full into 1o2 spouts and 1utted into

couplers, ot"er t"an e2pansion couplers, for >ointing purposes.

D. 'crewed $5C conduit s"all not 1e used unless specificall called for on t"e drawings or w"en

t"e $5C conduit is to 1e connected to metal equipment, conduit and fittings wit" screwed

entries. &"ere suc" entries are not availa1le, non-screwed male 1us"es and couplers s"all 1e

used.

$age 11 of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

?. &"ere conduit crosses 1uilding e2pansion >oints or w"ere t"ere are c"anges of temperature in

e2cess of <+ C, fle2i1ilit of t"e conduit to cope wit" t"e associated movement s"all 1e

ac"ieved 1 a met"od approved 1 t"e manufacturer of t"e conduit.

1). All 1ends s"all 1e made using t"e correct si3e spring. Conduit si3es of <+ mm and 1elow ma

1e set cold 1ut all larger si3es s"all 1e set "ot. A pipe vice s"all not 1e used during t"is or an

ot"er operation. *"e radius of an conduit 1end s"all not 1e less t"an , time t"e outside

diameter of t"e conduit. 7a!ed flames s"all not 1e used directl to "eat conduit for 1ending

purposes. *"e use of conduit 1ends "aving factures and conduits wit" an wrin!les on formed

1ends is not permitted.

11. Concealed conduit and accessories s"all 1e securel fi2ed 1efore an operations involving

casting, concrete pouring, screed laing and plastering. 4i2ing s"all 1e 1 means purpose

made clips w"ic" s"all not cause deformation of t"e conduit. 4i2ings s"all 1e used at regular

intervals not e2ceeding 1.+ meters and t"e distance of clips on eac" side of 1ends or

accessories s"all not e2ceed 1+) mm.

1<. A protective conductor of not less t"an <.+ mm

<

wit" green and ellow insulation s"all 1e

installed t"roug"out, sufficientl long to allow looping in and of fittings and accessories. &"ere

e2pansion couplers are used allowance s"all 1e made in t"e lengt" of t"e protective conductor

to accommodate an e2pansion.

1;. &"ere luminaries are to 1e connected to a ceiling conduit sstem, metal conduit 1o2es s"all

1e used. 4ittings ma not 1e "ung from t"e $5C conduit sstem and full details of t"e means of

support s"all 1e s"own on t"e Co-ordination and s"op Drawings.

1,. &"ere a num1er of conduits converge, large adapta1le $5C 1o2es s"all 1e emploed to avoid

t"e conduits crossing. Conduits s"all 1e connected to t"e 1o2es 1 means of male 1us"ees and

couplers.

1+. Different coloures s"all 1e applied for conduits of different sstems.

0. $rovide e2pansion-deflection fittings at e2pansion >oints and on lengt" of runs in accordance wit"

manufacturer:s recommendations. 8tili3e e2pansion-deflection fittings of si3e as required complete

wit" 1onding >umper.

B. 4or Ea3ardous 9ocations w"ere applica1le

1. 8tili3e rigid steel onl, unless ot"erwise noted.

<. 0nstall approved sealing fittings to prevent passage of e2plosive vapors as required 1 t"e

applica1le electrical codes.

G. 4or &et, Damp, or /oist 9ocations w"ere applica1le

1. $rovide sealing fittings to prevent passage of water vapor, w"ere conduits pass from warm to

cold locations, suc" as refrigerated spaces, air conditioned spaces, or similar spaces.

$age 1< of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

3.3 FIELD QUALITY CONTROL

9. 8pon completion of installation of racewas, perform continuit tests 1 testing t"e resistance of all

feeder conduits from t"e service to t"e point of t"eir final distri1ution using 1 conductor return. 9imit

t"e ma2imum resistance to <+ o"ms. &"en possi1le, field-correct malfunctioning equipment, t"en

retest to demonstrate compliance. Replace equipment w"ic" cannot 1e satisfactoril corrected, at no

additional cost to t"e @wner.

END OF SECTION 16110

$age 1; of 1;

G!"!#$% P#&'()(&") F&# E%!*+#(*$% W&#,

'ection 1()1)

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Enneagram Couples IntroDocumento28 pagineEnneagram Couples IntroEnrique Rojas100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Vansco VMM Diagnostics Rev 6 - CUBEXDocumento27 pagineVansco VMM Diagnostics Rev 6 - CUBEXHector Sepulveda Orellana100% (3)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Enneagram Test Arabic عربي انياجرامDocumento49 pagineEnneagram Test Arabic عربي انياجرامeng_asayed100% (3)

- Analysis and Design of Transmission TowersDocumento50 pagineAnalysis and Design of Transmission Towersadnan-651358Nessuna valutazione finora

- Electrical Vendors ListDocumento20 pagineElectrical Vendors Listeng_asayedNessuna valutazione finora

- Electricty Wiring Code 2016Documento92 pagineElectricty Wiring Code 2016waelroustom50% (2)

- UAE Construction Costs Update May 2018Documento4 pagineUAE Construction Costs Update May 2018eng_asayedNessuna valutazione finora

- Ecad Chapter 1 Jun2020Documento18 pagineEcad Chapter 1 Jun2020Azlan AzizNessuna valutazione finora

- Full Tender Document For Design 1Documento49 pagineFull Tender Document For Design 1eng_asayedNessuna valutazione finora

- Dps-01-Rev 01 - Dec 2011Documento42 pagineDps-01-Rev 01 - Dec 2011Sonia Mathur0% (1)

- Eltek Flatpack 2 User ManualDocumento101 pagineEltek Flatpack 2 User Manualproximohitman100% (9)

- 323-1851-545.r1.2 - OME6500 Module Replacement ProcedureDocumento114 pagine323-1851-545.r1.2 - OME6500 Module Replacement ProcedureJonatn SilvaNessuna valutazione finora

- Qtel RegulationDocumento81 pagineQtel RegulationAbraham JyothimonNessuna valutazione finora

- Dual Band Outdoor Panel Antenna Technical Data SheetDocumento2 pagineDual Band Outdoor Panel Antenna Technical Data SheetBie BieNessuna valutazione finora

- Construction Cost Index: Tower Buildings ProjectsDocumento15 pagineConstruction Cost Index: Tower Buildings Projectseng_asayedNessuna valutazione finora

- Firex 2015 Price List - PART 1 - GENERALDocumento51 pagineFirex 2015 Price List - PART 1 - GENERALeng_asayedNessuna valutazione finora

- Cable Price QATARDocumento1 paginaCable Price QATAReng_asayedNessuna valutazione finora

- QCD - Sample Inspection CommentsDocumento17 pagineQCD - Sample Inspection Commentseng_asayed100% (1)

- Enneagram Mbti: Type 1 Type 2 Type 3Documento3 pagineEnneagram Mbti: Type 1 Type 2 Type 3eng_asayedNessuna valutazione finora

- QCD CommentsDocumento6 pagineQCD Commentseng_asayedNessuna valutazione finora

- KM Substation Civil Details-CompressedDocumento1 paginaKM Substation Civil Details-Compressedeng_asayedNessuna valutazione finora

- 00-Rmu FSW Oil TX Bolt On 4 Way Feeder Pillar Up To 2nos 210kwDocumento1 pagina00-Rmu FSW Oil TX Bolt On 4 Way Feeder Pillar Up To 2nos 210kweng_asayedNessuna valutazione finora

- Energy conservation checklistDocumento2 pagineEnergy conservation checklisteng_asayedNessuna valutazione finora

- Advanced Metering Infrastructure Code 2016Documento7 pagineAdvanced Metering Infrastructure Code 2016eng_asayedNessuna valutazione finora

- Fire Alarm Battery CalculationDocumento10 pagineFire Alarm Battery Calculationeng_asayedNessuna valutazione finora

- Elevator Handover Certtificate SampleDocumento2 pagineElevator Handover Certtificate Sampleeng_asayed100% (1)

- Fire Fighting System Cover Sheet: Area StatementDocumento11 pagineFire Fighting System Cover Sheet: Area Statementeng_asayedNessuna valutazione finora

- Channels Compliance Sheet As Per QCSDocumento6 pagineChannels Compliance Sheet As Per QCSeng_asayedNessuna valutazione finora

- Application For Water ConnectionDocumento1 paginaApplication For Water Connectioneng_asayedNessuna valutazione finora

- Hydrostatic Test ReportDocumento1 paginaHydrostatic Test Reporteng_asayedNessuna valutazione finora

- b1 Fa System Record of CompletionDocumento6 pagineb1 Fa System Record of Completioneng_asayedNessuna valutazione finora

- ElevationDocumento2 pagineElevationeng_asayedNessuna valutazione finora

- 2015 NewEP DP C1 Issue 4Documento17 pagine2015 NewEP DP C1 Issue 4eng_asayedNessuna valutazione finora

- Acmv PlansDocumento1 paginaAcmv Planseng_asayedNessuna valutazione finora

- Mew-R-1 2009Documento110 pagineMew-R-1 2009eng_asayedNessuna valutazione finora

- Cell Planning ProcessDocumento4 pagineCell Planning Processeng_asayedNessuna valutazione finora

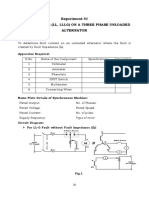

- 6.fault Analysis (LL, LLLG) On A Three Phase Unloaded AlternatorDocumento4 pagine6.fault Analysis (LL, LLLG) On A Three Phase Unloaded Alternatorarjuna4306Nessuna valutazione finora

- List of Prequalified Manufacturers/Suppliers For Main Distribution Networks Materials - Till 04 September 2013Documento60 pagineList of Prequalified Manufacturers/Suppliers For Main Distribution Networks Materials - Till 04 September 2013Eng-Ahmad Abo-AledousNessuna valutazione finora

- ESAB ARC 400iDocumento15 pagineESAB ARC 400ipm-kcpNessuna valutazione finora

- Synchronization and Reactive Current Support of PMSG Based Wind Farm During Severe Grid FaultDocumento4 pagineSynchronization and Reactive Current Support of PMSG Based Wind Farm During Severe Grid FaultBrightworld ProjectsNessuna valutazione finora

- Ee2355 LPDocumento6 pagineEe2355 LPanuj1166Nessuna valutazione finora

- Lennox CHA 16 - 261 To 653Documento101 pagineLennox CHA 16 - 261 To 653Mike ZellerNessuna valutazione finora

- Military Searchlights (1912)Documento83 pagineMilitary Searchlights (1912)CAP History LibraryNessuna valutazione finora

- K3ma-J Dsheet Csm255Documento16 pagineK3ma-J Dsheet Csm255tatasrbaNessuna valutazione finora

- V5 wiring devices series for electrical installationsDocumento2 pagineV5 wiring devices series for electrical installationsmroys mroysNessuna valutazione finora

- L-132XYD (Ver 17B)Documento5 pagineL-132XYD (Ver 17B)yafix34669Nessuna valutazione finora

- Subminiature High Power Relay Features Under 40 CharactersDocumento2 pagineSubminiature High Power Relay Features Under 40 CharactersRoberto MendesNessuna valutazione finora

- 02 ESP Operation and MaintenanceDocumento38 pagine02 ESP Operation and MaintenancerandyNessuna valutazione finora

- Electrical Safety Plan: Plan Last Updated: (Date)Documento24 pagineElectrical Safety Plan: Plan Last Updated: (Date)beratcansuNessuna valutazione finora

- Daiwa CN-465M VHF SWR & Power MeterDocumento5 pagineDaiwa CN-465M VHF SWR & Power MeterEmilio EscalanteNessuna valutazione finora

- STAMFORD, HCM534F - Technical Data Sheet (Power Generators)Documento11 pagineSTAMFORD, HCM534F - Technical Data Sheet (Power Generators)eduardo ayalaNessuna valutazione finora

- Line Reactance, Zero Sequence Reactance and Mutual Zero Sequence ReactanceDocumento39 pagineLine Reactance, Zero Sequence Reactance and Mutual Zero Sequence ReactanceHanh-Trang DangNessuna valutazione finora

- 55W - 14601 - 0 TDR Z MeasurementsDocumento16 pagine55W - 14601 - 0 TDR Z MeasurementsgiaonkNessuna valutazione finora

- Symmetrical Fault Calculations ExplainedDocumento27 pagineSymmetrical Fault Calculations ExplainedAsanka SamaranayakeNessuna valutazione finora

- Untitled - SA1S Interrupting Duty CompleteDocumento1 paginaUntitled - SA1S Interrupting Duty CompleteFredy AlemánNessuna valutazione finora

- Tps 54240Documento48 pagineTps 54240Maria KhanNessuna valutazione finora

- Electric ChargeDocumento14 pagineElectric Chargefrancis solivenNessuna valutazione finora

- Technical Standard - Ts-108: For Distribution Equipment and Transformer RoomsDocumento32 pagineTechnical Standard - Ts-108: For Distribution Equipment and Transformer RoomsEijnuj PitzNessuna valutazione finora

- Control Techniques for Four-Leg VSIs in MicrogridsDocumento19 pagineControl Techniques for Four-Leg VSIs in MicrogridsAshraf AyasrahNessuna valutazione finora

- of Eddy Current Braking System NNNNDocumento17 pagineof Eddy Current Braking System NNNNKaramjeet Singh MalhotraNessuna valutazione finora