Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

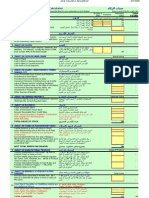

Pumping en Print REV3 ABB

Caricato da

Dheen Meeran0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

35 visualizzazioni8 pagineAbb Catalog

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoAbb Catalog

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

35 visualizzazioni8 paginePumping en Print REV3 ABB

Caricato da

Dheen MeeranAbb Catalog

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 8

Water Industry Sector

Products and solutions for pumping stations

Enhanced plant performance, efficiency

and reliability

2 Products and solutions for pumping stations

Moving Water Everywhere

A global challenge

Nearly twenty percent of the worlds energy is employed for

pumping and a majority of that is used for water pumping, a

key process in the water lifecycle.

Pumping stations are used for reliable and efficient transport

and distribution of fresh water to guarantee the availability

of this precious resource for human consumption, and

for industrial and agricultural production, for waste water

discharge or for seawater intake at desalination plants.

The challenges for creating new infrastructures as well

as modernization of existing ones are not only limited to

ensure the basic availability of water but also to guarantee a

sustainable development considering important factors like

energy efficiency, productivity, reliability and life cycle cost.

Technology and process know-how

The ABB portfolio includes products and solutions covering

the entire electrical and automation scope for pumping station

projects: drives and motors, soft-starters, low, medium and

high-voltage switchgears and components, transformers,

instrumentation, control products and PLCs (Programmable

Logic Controllers), DCS (Distributed Control Systems), and

optimization and asset management tools.

Moreover ABB provides engineered packages as well as

turnkey pumping stations, including electrical and mechanical

BoP (Balance of Plant).

- Complete and reliable portfolio

- System integration and optimization

- A presence in over 100 countries

Products and solutions for pumping stations 3

From Products to Turnkey Projects

A leader for integrated solutions

ABB combines in-house technology with process know-how

to develop complete and integrated solution. We serve end

users, EPC contractors, and pump OEMs, delivering turnkey

pumping stations, integrated systems, power and automation

products.

ABB is the ideal partner for large water transfer projects and

can take the responsibility for building complete solutions,

including pumping stations, electrical substations, pipeline

control systems, and communication networks. By serving as

a single interface for the project, we reduce costs significantly.

Electrical balance of plant

ABB offers integrated electrical balance of plant solutions

for pumping stations. We have the knowledge to assess the

degree of customization required, and we have the electrical

products and services to create a fully integrated solution.

Electrical balance of plant covers electrical equipment and

systems from pump level up to grid connection, ensuring

that the pumping station runs efficiently, safely, and reliably.

ABB (eBoP) solutions include the following equipment and

systems: high-voltage substations, grid connections, medium-

voltage systems, low-voltage systems, emergency systems,

and facility management. ABB is a single source for design,

engineering, supply, installation, commissioning, testing, and

maintenance, reducing the cost of ownership.

- Design

- Engineering

- Procurement

- Installation

- Commissioning

- Service & Maintenance

4 Products and solutions for pumping stations

Power and Automation

Instrumentation and Control

ABBs programmable logic controller (PLC) and supervisory

control and data acquisition (SCADA) platforms as well as our

distributed control system (DCS) provide an innovative,

consistent and flexible control solution for small to large size

pumping stations. The solution handles all plant operations

as well as information management (historian functions,

archiving, reporting, performance calculations) and optional

added-value applications, such as Pump Efficiency Monitoring

System (PEMS), simulation and leakage detection.

ABBs instrumentation portfolio includes flow, pressure, and

level measurement, quality analyzers and recorders.

Field devices, instrumentation, and control systems can

be easily integrated to deliver complete plant automation

solutions.

- Measurement, monitoring, and control

- Energy management

- Performance optimization

- Longer asset life

Motor and drives: a choice to increase efficiency

Motors and drives play a significant role in pumping

stations and can drastically affect the long-term operational

management of pumping stations.

ABB motors and drives which can be used for regulating

a variety of pumps, bring many benefits, including efficiency

improvements, energy savings, and reduced wear and tear on

moving equipment.

ABB is a world leading supplier of highly energy efficient

motors. We deliver a full range of high efficiency and a

broad range of premium efficiency as well as super premium

efficiency motors. Using our motors will substantially

contribute to make your operation more energy efficient.

ABB variable speed drives (VSDs) are used to control the

motor speed of pumps with a typical 30 to 60 percent savings

in energy consumption. The use of drives also reduces

mechanical and electrical stress on pumps and aeration

equipment components.

VSDs in combination with high efficiency motors does not

only make water processes in all parts of the water cycle

more efficient, but also help reduce maintenance costs.

Products and solutions for pumping stations 5

Added-Value Applications

An easy way to plant optimization

The ABB portfolio includes a suite of dedicated software

applications for pumping stations. The Pump Efficiency

Monitoring System (PEMS) provides rapid and detailed

real-time information on pump efficiency. Based on a

thermodynamic measuring method using ABB patented

components, this solution calculates pump efficiency by

processing water temperatures, pressures, and the motor

power associated with each pump. Customers are able to

monitor the status of their assets and improve maintenance

activities.

Less stress means cost savings

The ideal solution to reduce pressure surges and mechanical

stress is a gradual startup and shutdown of the pumps, using

(for instance) a soft-starter with torque control. This approach

prevents damage to pipelines, less wear and tear on pumps

and guarantees better management of water networks.

ABB products and automation solutions reduce stress on the

pumps and allow more flexible management, slowing down

the ageing process of key components.

From single plant to water networks

A single pumping station is often part of a complex water

network. To manage cascaded pumping stations and complex

transmission and distribution schemes, ABB developed

advanced solutions for on-line monitoring and control,

network management, simulation and leakage detection.

- Simulation

- Water management

- Pump efciency

- Leakage detection

6 Products and solutions for pumping stations

From Challenge to Projects

Abu Dhabi: long-range power and control

ABB supported Abu Dhabi Water & Electricity Authority

(ADWEA) by delivering the complete electrical, control, and

instrumentation system for the Shuweihat Water Transmission

Scheme, one of the most important projects ensuring

adequate supplies of water in the United Arab Emirates. Water

is transferred from the Mirfa Pumping Station to the Mussafah

Pumping Station and further on to the Unit IV Pumping Station

and Distribution Network in Abu Dhabi.

The system includes a parallel double pipeline 1.600 mm in

diameter. Each pipeline is 250 km in length, with a transfer

capacity of 375.000 m

3

/day. ABBs solution (including

engineering, installation, and commissioning services)

integrates a wide range of ABB products: medium and

low-voltage switchgears, power, distribution and phase

shift transformers, motors, variable speed drives, DC/UPS

systems, automation system, and field instrumentation all

under the control of a SCADA and telemetry system that

allows centralized management of the plants.

Mubarak: the worlds largest pumping station

Collecting water from Lake Nasser is one of the basic

irrigation aims of the Egyptian government. Water transfers to

the irrigation area via the Sheikh Zayed canal system through

the Mubarak Pumping station in Toshka. This gigantic plant,

which is located at the intake basin, uses 24 variable speed

pumps with a total capacity of 288 MW (24x12 MW) and a

total discharge of 350 m

3

/s (21x16.7 m

3

/s).

Project development and execution were headed by

the Ministry of Public and Water Resources, Egypt. As

subcontractor for electrical works, ABB delivered a complete

solution, including equipment (220 kV substation, medium

and low-voltage switchgears, busducts, variable speed drives,

and transformers) as well as engineering, installation and

commissioning services.

Products and solutions for pumping stations 7

From Challenge to Projects

Singapore: PUBs Changi Water Reclamation Plant

Singapores national water agency, PUBs Changi Water

Reclamation Plant is the cornerstone of the first phase of

the Deep Tunnel Sewerage System project. The Deep Tunnel

Sewerage System is an efficient and cost-effective solution to

meet Singapores long-term needs for used water collection,

treatment and disposal. The first phase of the project features

a state-of-the-art, compact and covered used water treatment

plant designed to handle 800.000 m

3

/day of used water per

day, expandable to an ultimate 2.400.000 m

3

/day. The plant

will provide a high standard of treatment to used water before

it is discharged through the deep sea outfalls.

ABB was selected for the complete range of high quality

products as well as our ability to deliver the equipment as

turnkey solution, coupled with a strong local service and

support team, which is our key differentiating factor. The

complete portfolio meant one single contact point, quicker

response time and more efficient service, essential for a

project so critical for the future of Singapore.

Both the influent and the effluent pumping stations have

ABB medium voltage motors and drives, providing energy

efficiency and reliable power to the connected pumps. Power

is supplied via two ABB 66kV high voltage switchgears with

full redundancy. Various ABB medium voltage and low voltage

systems, including transformers, distribute power to the plant

equipment, such as ABB instrumentation which monitor key

process parameters.

Istanbul: Melen and Cumhuriyet pumping stations

The main aim of the Melen Project is to secure drinking water

supply of the 15 million population city of Istanbul up to the

year 2040. River water from Melen near the Black Sea is

pumped 200 km via a pipeline and two pumping stations at a

rate of max.

720.000 m

3

/day into the water treatment plant in Cumhuriyet.

Treated water is then pumped through an undersea tunnel

below the Straits of Bosporus to Istanbul. ABB was part

of a consortium, which is responsible for civil, mechanical

and electrical works (turnkey) of the two pumping stations.

The client is the Directorate of State Hydraulic Works (DSI),

Ankara Turkey. ABB solution, for both Melen and Cumhuriyet

pumping stations, includes equipment (Centrifugal Pumps,

Medium Voltage Motors, Power Factor Correction System,

DC and UPS System, Distribution Transformers, MV and LV

Switchgears, Instrumentation and Control System, Ventilation

System, Surge Vessels, Weir and Header Tank) as well as

engineering, installation and commissioning services.

Contact us

P

u

m

p

i

n

g

-

R

e

v

.

3

-

0

6

/

2

0

1

2

www.abb.com/water

water.team@it.abb.com

Scan this QR code with your SmartPhone

for a direct link to the ABB Water portal.

Potrebbero piacerti anche

- Low Voltage Distribution Fuse Boards (Feeder Pillars)Documento22 pagineLow Voltage Distribution Fuse Boards (Feeder Pillars)Dheen Meeran0% (1)

- BOQ Procedure - SJF 1995Documento5 pagineBOQ Procedure - SJF 1995Dheen MeeranNessuna valutazione finora

- Quantity Take OffDocumento26 pagineQuantity Take OffTien Ngo Minh100% (1)

- CDM Worked ExampleDocumento211 pagineCDM Worked ExampleDheen MeeranNessuna valutazione finora

- Thrustream-Installation Operation & MaintenanceDocumento29 pagineThrustream-Installation Operation & MaintenanceDheen MeeranNessuna valutazione finora

- برنامج حساب زكاه المالDocumento3 pagineبرنامج حساب زكاه المالnewlife4me100% (10)

- Manual SPP Bomba Horizontal InglesDocumento23 pagineManual SPP Bomba Horizontal InglesDheen Meeran100% (1)

- Computer safety tipsDocumento27 pagineComputer safety tipsDheen MeeranNessuna valutazione finora

- AREVA Relay - ListDocumento8 pagineAREVA Relay - ListDheen MeeranNessuna valutazione finora

- Bukhari Tamil FullDocumento2.497 pagineBukhari Tamil Fullapi-370288191% (44)

- Emergency Floodlighting Unit GuideDocumento1 paginaEmergency Floodlighting Unit GuideDheen MeeranNessuna valutazione finora

- Who Moved My CheeseDocumento32 pagineWho Moved My CheeseDheen MeeranNessuna valutazione finora

- Pilot Wire ProtectionDocumento18 paginePilot Wire ProtectionDheen Meeran100% (3)

- VD4 Manual-En BA 460-07 EDocumento55 pagineVD4 Manual-En BA 460-07 EDheen MeeranNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Decoding The Teenage Brain (In 3 Charts) - Edutopia PDFDocumento6 pagineDecoding The Teenage Brain (In 3 Charts) - Edutopia PDFVirgínia Chaves de LimaNessuna valutazione finora

- Garrison's Model Improves Student Self-ConceptDocumento10 pagineGarrison's Model Improves Student Self-ConceptNurul Ain Mohd FauziNessuna valutazione finora

- Kareem Shagar Formation An Oil Field Located in Ras Gharib DevelopmentDocumento53 pagineKareem Shagar Formation An Oil Field Located in Ras Gharib Developmentwisam alkhooryNessuna valutazione finora

- Ans To Exercises Stice Chap 1 and Hall Chap 1234 5 11 All ProblemsDocumento188 pagineAns To Exercises Stice Chap 1 and Hall Chap 1234 5 11 All ProblemsLouise GazaNessuna valutazione finora

- Waste Classification Using Convolutional Neural Network On Edge DevicesDocumento5 pagineWaste Classification Using Convolutional Neural Network On Edge DevicesInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Metabolic AdaptationDocumento17 pagineMetabolic AdaptationMozil Fadzil KamarudinNessuna valutazione finora

- Thesis Paper Final Report PDFDocumento3 pagineThesis Paper Final Report PDFFiraol NegasiNessuna valutazione finora

- Machine Learning - Problem Setup, Conditional Probability, MLEDocumento6 pagineMachine Learning - Problem Setup, Conditional Probability, MLEtarun guptaNessuna valutazione finora

- Mizpah Community Christian Academe Inc.: 3rd Periodical Test Understanding CultureDocumento4 pagineMizpah Community Christian Academe Inc.: 3rd Periodical Test Understanding CultureGabriel YuNessuna valutazione finora

- A Smart Building Automation System: International Journal of Smart Home September 2016Documento9 pagineA Smart Building Automation System: International Journal of Smart Home September 2016mohammed imran pashaNessuna valutazione finora

- GS1 Global Traceability StandardDocumento58 pagineGS1 Global Traceability StandardmindtrussNessuna valutazione finora

- Teamwork and Team BuildingDocumento25 pagineTeamwork and Team Buildingalizman100% (2)

- Correlated Subqueries With AliasesDocumento5 pagineCorrelated Subqueries With AliasesPretty BellaNessuna valutazione finora

- Schedule A Deliverables For GPDS 3 0Documento80 pagineSchedule A Deliverables For GPDS 3 0MAYTE1085Nessuna valutazione finora

- Modul Push 15A enDocumento6 pagineModul Push 15A enUPOTERMNessuna valutazione finora

- Compare and Contrast RubricDocumento1 paginaCompare and Contrast RubricBrian BorkowskiNessuna valutazione finora

- Workplace Etiquettes UneditedDocumento23 pagineWorkplace Etiquettes UneditedNikitaNessuna valutazione finora

- Beechtree ISCDocumento6 pagineBeechtree ISCWinterNessuna valutazione finora

- 06.07 Review and Critical ThinkingDocumento2 pagine06.07 Review and Critical ThinkingmarielaNessuna valutazione finora

- Bulk Storage SilosDocumento5 pagineBulk Storage SilosMiran VidovićNessuna valutazione finora

- Cast StudyDocumento5 pagineCast StudyFrancisco Rodriguez0% (3)

- Introduction To: Information RetrievalDocumento42 pagineIntroduction To: Information Retrievalanon_284938973Nessuna valutazione finora

- Action Paper g2 Final OutputDocumento67 pagineAction Paper g2 Final Outputjay diazNessuna valutazione finora

- Subject Centered - Correlational DesignDocumento13 pagineSubject Centered - Correlational DesignWarrenBualoySayagoNessuna valutazione finora

- CDMA Telephone TroubleshootingDocumento30 pagineCDMA Telephone Troubleshootingsaboor ashraf100% (1)

- Week 17 PDFDocumento23 pagineWeek 17 PDFGerlie V. ArribaNessuna valutazione finora

- Bus Conductor Design and ApplicationsDocumento70 pagineBus Conductor Design and ApplicationsJithinNessuna valutazione finora

- Assignment 1 - ProsperDocumento9 pagineAssignment 1 - ProsperMuhammad Amirullah SanadiNessuna valutazione finora

- TO: Belverd E. Needles, JR., PH.D., CPA, CMA From: Melanie Patton Date: May 9, 2013 SUBJECT: Evaluation of Comptronix CorporationDocumento6 pagineTO: Belverd E. Needles, JR., PH.D., CPA, CMA From: Melanie Patton Date: May 9, 2013 SUBJECT: Evaluation of Comptronix CorporationjasminekalraNessuna valutazione finora

- News Lessons SnakebiteDocumento5 pagineNews Lessons SnakebiteGuilherme SalvadoriNessuna valutazione finora