Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

NEXTSTATION Turbo Color Capacitor Replacement

Caricato da

Piotr TwareckiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

NEXTSTATION Turbo Color Capacitor Replacement

Caricato da

Piotr TwareckiCopyright:

Formati disponibili

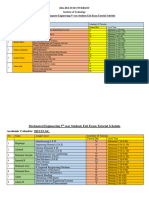

NEXTSTATION TURBO COLOR MAIN BOARD

PREPARED BY T-REXKY

N E X T C O M P U T E R S . O R G

El ectrol yti c Capaci tor Repl acement / Ref resh

Re vi s i on NC 2013- 12- 07

1. Background

I recently resurrected my Turbo Color station and spent a considerable amount of time and money restoring it into a

good operating condition. I bought RAM, SCSI hard disks, a true multi-sync capable LCD monitor and even a spare

"just in case" Turbo Color unit from Rob at BlackHole.

I nally got the station all set-up and was in the process of tidying up the "computer museum" room when I noticed

something quite alarming. The lighting was just right to show a stain around one of the electrolytic capacitors on the

"spare" motherboard. Upon closer inspection it became clear that all of the electrolytic capacitors have vented with 1

to 1.5 inch stains around them and even some evidence of leakage through the board vias to the opposite (lower)

side. The following photograph illustrates a partially wiped-off electrolyte stain around one of the capacitors:

I opened the second station and noticed that the capacitors started venting electrolyte as well, although not as badly.

It is not surprising that the capacitors are at the end of their life, considering that they are almost 20 years old. In ad-

dition, the early surface mount electrolytic capacitors are well known to have reliability issues - many expensive Tek-

tronix oscilloscopes from late 80s and early 90s have been damaged by leaking surface mount capacitor electrolyte.

I spent a number of hours cross-referencing various component suppliers and I ordered a full set of replacement elec-

trolytic capacitors for both of my stations, two sound boxes and also two power supplies. For anyone else wanting to

rework their NeXT machines, this document outlines the parts and the procedure that I used to rework my slab

motherboards. I focused this document primarily on the SMD capacitor replacement since the through-hole part

replacement is pretty straight forward. The power supplies are very challenging to rework due to their mechanical

design and I may cover them in a separate document some time in the future.

NEXTSTATI ON Tur bo Col or Ma i n Boa r d El e c t r ol yt i c Ca pa c i t or Re pl a c e me nt / Re f r e s h

1

2. Tools

1. A good quality, temperature controlled solder station with an appropriate tip is the only truly critical tool. I used

my Weller WTCPT Solder Station with a PTF7 Tip and it worked extremely well. I found that the at portion of

the conical tip worked well and that the size of the tip was a good compromise between its thermal capacity and

accessibility to component solder pads. I selected 700F tip temperature to prevent pad overheat while minimizing

the required solder time. I did not experience any issues with pads lifting off the boards that I reworked.

2. Sewing needle with maximum diameter slightly larger than the capacitor leads for clearing through hole solder. If

you are in a bind I also successfully used wooden toothpicks in the past.

3. Medium size tweezers to hold the replacement capacitors aligned in place while soldering them onto the board.

4. Bright task light.

5. A pint of good beer, or perhaps a few pints. Other liquids can also be substituted.

3. Consumables

1. CHIPQUIK no-clean rosin core solder (CHIPQUIK SMDSWLF.020 1OZ, DigiKey SMDSWLF.020 1OZ-ND). This

is a small diameter rosin core solder with mild ux, perfect for SMD work. This solder is available in various spool

sizes, so pick an appropriate part number. Note that this is lead free and the original solder is lead based but this

will not be an issue.

2. LOCTITE / Multicore 0.03 no clean desoldering wick (Multicore M291017, DigiKey 82-152-ND). Perfect for SMD

work. Will also work well with through hole devices, but you will use more of it. For extensive through hole re-

work, such as the slab power supply, I would recommend a wider wick, such as 0.06. Note that I tried several dif-

ferent wick brands and this one BY FAR works the best. Always buy the best wick if you want to avoid frustration

and component or board damage!

3. Kester 186 ux pen (Kester 83-1000-0186, DigiKey KE1803-ND). This ux is easy to apply and very easy to re-

move. It is also mild enough to be left on after the solder process and will not cause any damage or corrosion to the

components or to the board.

4. A can of electrical contact cleaner from your local hardware store. This will work better than alcohol for board

cleanup. Or you can use a proper ux cleaner.

5. A supply of Q-tips for electrolyte and ux cleanup.

4. Parts

1. Surface mount capacitors (Qty. 8 for Turbo Color Slab): 47"F 16V Panasonic FP series (Panasonic EEE-FP1C470AP,

DigiKey PCE4530CT-ND). The absolute best choice here would be polymer capacitors such as 47"F 20V Nichicon

CV series (Nichicon PCV1D470MCL1GS, DigiKey 493-4369-1-ND), but they are several times the price and

probably completely unnecessary. They may also destabilize the power supply due to their extremely low imped-

ance.

NEXTSTATI ON Tur bo Col or Ma i n Boa r d El e c t r ol yt i c Ca pa c i t or Re pl a c e me nt / Re f r e s h

2

2. Through hole capacitors (Qty. 3 for Turbo Color Slab): 220"F 35V Panasonic FC series (Panasonic EEU-FC1V221,

DigiKey P10297-ND). These are high temperature 3000 Hr low impedance capacitors (thats 3000 hour estimated

life at 105C. I selected 35V rated capacitors as they have the same can size as the originals, longer life and higher

ripple current. The Panasonic FM series and Nichicon PW series are also an excellent alternative. The polymer

option would be covered by 270"F 25V Nichicon LV series (Nichicon PLV1E271MDL1TD, DigiKey 493-3865-1-

ND). Look for 5mm lead spacing to t the motherboard through holes.

5. Procedure for SMD Capacitors

The right tools and patience are absolutely key to a successful rework! The most important aspect is to not overheat

the pads and the components! While desoldering or soldering, if things do not appear to work right, STOP and re-

think! My rule of thumb for good solder joints is application of heat for approximately three seconds. One should

never apply the heat for more than ve seconds, except under special circumstances. In addition, be careful how you

position the soldering iron in tight areas in order to avoid touching and damaging the surrounding components.

The overall work ow is pretty straight forward and in-line with the following sequence: (i) clean the area, (ii) desol-

der the component, (iii) prepare the pads, (iv) solder on a replacement component, (v) clean the residual ux. All of

this of course assumes that the board has been rst removed from the slab housing.

5.1 Clean and Prepare the Area

Using dry Q-tips rst thoroughly clean the area surrounding each capacitor. Then spray a Q-tip with electrical con-

tact cleaner or ux remover and clean the solder on the exposed part of the pads. This will help the heat transfer

from the soldering iron into the pads:

5.2 Desolder the Capacitor

I successfully used the alternating pad technique to desolder each surface mount capacitor without any damage to

the board. Another method involves cutting the old capacitor can with side cutters parallel to the board and desol-

NEXTSTATI ON Tur bo Col or Ma i n Boa r d El e c t r ol yt i c Ca pa c i t or Re pl a c e me nt / Re f r e s h

3

dering the leads individually. For anyone who has not done any SMD rework in the past I would highly recommend

reviewing various guides that are available online.

Apply the soldering iron tip to one of the solder pads ensuring a rm contact with the solder. Wait for one to two

seconds and then carefully lift the same side of the capacitor away from the board, but do not force it. Immediately

remove the tip of the soldering iron from the pad.

At this point one side of the capacitor should be slightly lifted, but the solder will likely still be holding it to the pad.

Repeat the same process on the opposite capacitor pad, and then repeat it again as required, until the capacitor is

detached from the board. Once done, you will be looking at empty solder pads like these:

NOTES:

(i) the initial movement of the capacitor may be a bit difcult because of adhesive used to afx the capacitor to the

board during original manufacturing

(ii)adding a small quantity of rosin core solder to the pad will help the heat transfer from the iron tip if you encounter

a stubborn pad

NEXTSTATI ON Tur bo Col or Ma i n Boa r d El e c t r ol yt i c Ca pa c i t or Re pl a c e me nt / Re f r e s h

4

5.3 Prepare the Solder Pads

Spray a Q-tip with electrical contact cleaner or ux remover and clean the solder pads and the surrounding area from

any remaining electrolyte, adhesive and old ux. Apply a small quantity of new ux to the pads with the ux pen.

Cut approximately 1mm long pieces of rosin core solder and place them on the pads:

Apply the soldering iron tip to the pad and solder pieces for approximately one second to form clean solder meniscus

on each pad. Once cool, reapply a small quantity of ux with the ux pen:

The pads are now ready to accept a new replacement capacitor.

5.4 Solder-on the Capacitor

This is actually by far the easiest part of the process. Begin by applying a small quantity of ux to the capacitor legs

with the ux pen:

NEXTSTATI ON Tur bo Col or Ma i n Boa r d El e c t r ol yt i c Ca pa c i t or Re pl a c e me nt / Re f r e s h

5

Then align the capacitor with the pads, maintaining the correct polarity. Hold the capacitor aligned using tweezers

while applying slight downward pressure:

Now apply the soldering iron tip to one of the solder pads ensuring a rm contact with the solder. The solder should

melt immediately and the capacitor will sink onto the pad surface. Wait for two to three seconds and then remove

the soldering iron away from the pad. Reposition the tweezers and repeat the solder process on the second solder

pad.

5.5 Clean the Residual Flux

Spray a Q-tip with electrical contact cleaner or ux remover and clean the surrounding area from any remaining ux.

The capacitor installation is now nished:

NEXTSTATI ON Tur bo Col or Ma i n Boa r d El e c t r ol yt i c Ca pa c i t or Re pl a c e me nt / Re f r e s h

6

6. Abbreviated Procedure for Through Hole Capacitors

I focused this document on the SMD capacitor replacement since through hole components are much easier to re-

place. The basic steps of the process are effectively the same: (i) clean the area, (ii) desolder the component, (iii) pre-

pare the pads, (iv) solder on a replacement component, (v) clean the residual ux. I normally use my Hakko 808

desoldering gun that leaves the through holes nice and clean. Without one, the best procedure would be to also use

either the alternating pad approach or to cut the capacitor can with side cutters and remove the pins individually.

Removing the capacitor without a desolder gun will require additional cleanup of the through holes to ensure that

the new component pins can easily slide through. Either a toothpick or a sawing needle work well to accomplish

this: rst heat the pad and the through hole with a soldering iron to melt the solder, then carefully push the toothpick

or sawing needle through the hole while the solder is melted. Push the tool in the same direction as the component

pins you will be inserting later.

7. Closing

I hope this document is useful to others who want to keep their NeXT equipment in top notch operating condition for

many more years to come.

If you have any additional questions, comments or suggestions please feel free to contact me through

nextcomputers.org forums under user name t-rexky. You can also check out a few additional photographs on my

ickr account at !!!"#$%&'("&)*+,-).)/+.0(12'3+

Happy retro-computing!

NEXTSTATI ON Tur bo Col or Ma i n Boa r d El e c t r ol yt i c Ca pa c i t or Re pl a c e me nt / Re f r e s h

7

Potrebbero piacerti anche

- Soldering electronic circuits: Beginner's guideDa EverandSoldering electronic circuits: Beginner's guideValutazione: 4.5 su 5 stelle4.5/5 (9)

- The Little Book of Vacuum Tube Pre-Amplifier ProjectsDa EverandThe Little Book of Vacuum Tube Pre-Amplifier ProjectsNessuna valutazione finora

- How To Replace C52 KefDocumento7 pagineHow To Replace C52 KefSheena CotterillNessuna valutazione finora

- SW20+ ManualDocumento17 pagineSW20+ ManualhackmanNessuna valutazione finora

- Replace Capacitors On EcuDocumento9 pagineReplace Capacitors On EcuHomar Mur100% (3)

- Land Rover Discovery II Fuse Box Integrated Relay RepairDocumento9 pagineLand Rover Discovery II Fuse Box Integrated Relay Repairbelewjo100% (3)

- Flex-Circuit Soldering and Assembly Tutorial and NotesDocumento18 pagineFlex-Circuit Soldering and Assembly Tutorial and NotescaptnskydiverNessuna valutazione finora

- KAT-KIT Deacy Amp Assembly and Test InstructionsDocumento22 pagineKAT-KIT Deacy Amp Assembly and Test InstructionsAntony Sebastián Villalobos CataldoNessuna valutazione finora

- C520 C528 C620 C628 Upgrade Kit V2.96 ManualDocumento11 pagineC520 C528 C620 C628 Upgrade Kit V2.96 ManualRogerNessuna valutazione finora

- How To Recap The Royal 500Documento4 pagineHow To Recap The Royal 500El Tio la VaraNessuna valutazione finora

- USING STANDARD x1 and x10 OSCILLOSCOPE PROBES WITH THE TEKTRONIX 222PS OSCILLOSCOPEDocumento13 pagineUSING STANDARD x1 and x10 OSCILLOSCOPE PROBES WITH THE TEKTRONIX 222PS OSCILLOSCOPEmarius virtosu65Nessuna valutazione finora

- BUILDING YOUR FROG GUITAR EFFECT PEDAL PCB - A General GuideDocumento7 pagineBUILDING YOUR FROG GUITAR EFFECT PEDAL PCB - A General GuideGladson GoesNessuna valutazione finora

- Quasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General DescriptionDocumento6 pagineQuasar Electronics Kit No. 1065 Inverter 12 VDC To 220 Vac: General Descriptionapi-3864578Nessuna valutazione finora

- rs232-db9 To TTL ConverterDocumento5 paginers232-db9 To TTL ConvertersolensiNessuna valutazione finora

- Diy Minipro DC/DC ConverterDocumento14 pagineDiy Minipro DC/DC Convertermrcinek01Nessuna valutazione finora

- Digital Clock CircuitDocumento40 pagineDigital Clock CircuitdatmawgabwoyNessuna valutazione finora

- Homelite HL-EH-LR Rebuild Kit Tech Bulletin Rev ADocumento8 pagineHomelite HL-EH-LR Rebuild Kit Tech Bulletin Rev AAMWATSON6754Nessuna valutazione finora

- RX RegenDocumento8 pagineRX RegenhgbarieroNessuna valutazione finora

- Casio PG380 Capacitor ReplacementDocumento4 pagineCasio PG380 Capacitor ReplacementsegurahNessuna valutazione finora

- Nintendo 64 Power Supply Capacitor Replacement KitDocumento12 pagineNintendo 64 Power Supply Capacitor Replacement KitlookeadorNessuna valutazione finora

- Relogio TranmanualDocumento61 pagineRelogio TranmanualJorge FarinhaNessuna valutazione finora

- PicoKeyer Plus 080501Documento10 paginePicoKeyer Plus 080501diney m e willemenNessuna valutazione finora

- Important Warranty Informationi Please ReadDocumento26 pagineImportant Warranty Informationi Please ReadAdam A. KhanNessuna valutazione finora

- AtsgDocumento7 pagineAtsgAtanas Janchev100% (1)

- Kit Manual IN14Documento19 pagineKit Manual IN14Caio VilarNessuna valutazione finora

- Important Warranty Information! Please ReadDocumento34 pagineImportant Warranty Information! Please Readyu3zaNessuna valutazione finora

- Aion Refractor Centaur DocumentationDocumento8 pagineAion Refractor Centaur Documentationpmacs10Nessuna valutazione finora

- Dentron MLA-2500 GI7B Modification Procedure 3Documento27 pagineDentron MLA-2500 GI7B Modification Procedure 3david bonilla pinoNessuna valutazione finora

- Novabrite RGB Full Color High Power Led Application Note: R&D CenterDocumento15 pagineNovabrite RGB Full Color High Power Led Application Note: R&D CenterVinu KumarNessuna valutazione finora

- Construction TipsDocumento2 pagineConstruction TipsANdreaNessuna valutazione finora

- Casio DM100 Sample ExpansionDocumento17 pagineCasio DM100 Sample ExpansionSesan del futuroNessuna valutazione finora

- Electronic Transistor Ignition For Cars Kit Manual PDFDocumento12 pagineElectronic Transistor Ignition For Cars Kit Manual PDFRaúl MartínNessuna valutazione finora

- Symasym - "The Sequel", Aak'S Rev - 1.4 PCB Assembly InstructionsDocumento8 pagineSymasym - "The Sequel", Aak'S Rev - 1.4 PCB Assembly InstructionsWojciechNessuna valutazione finora

- PWMcircuit 08Documento10 paginePWMcircuit 08kcarringNessuna valutazione finora

- Gold PicDocumento6 pagineGold PicBalbalaManiukNessuna valutazione finora

- ConcentricDocumento16 pagineConcentricsorinn1987100% (1)

- HIHAT - MANUAL - 1 Compressed Compressed 003Documento13 pagineHIHAT - MANUAL - 1 Compressed Compressed 003faj22017Nessuna valutazione finora

- Hendershot 1Documento6 pagineHendershot 1ajaskoalinkoNessuna valutazione finora

- The Zl2bmi DSB Transceiver Introduction 2Documento9 pagineThe Zl2bmi DSB Transceiver Introduction 2jlnlimaNessuna valutazione finora

- Kastle v1.5 Assembly GuideDocumento16 pagineKastle v1.5 Assembly GuideArto SillanpääNessuna valutazione finora

- Vec 1180 KDocumento35 pagineVec 1180 Kyu3zaNessuna valutazione finora

- Vec 1202 KDocumento34 pagineVec 1202 Kyu3za100% (1)

- TuringMachine Expanders 1.1Documento14 pagineTuringMachine Expanders 1.1Nico PinealNessuna valutazione finora

- How To Build pedalSHIELD UNO - 2018 02 26 - 3Documento7 pagineHow To Build pedalSHIELD UNO - 2018 02 26 - 3myahya89Nessuna valutazione finora

- ZX81 ServiceManualAndAssemblyInstructions PDFDocumento43 pagineZX81 ServiceManualAndAssemblyInstructions PDFViorel AldeaNessuna valutazione finora

- STM 800 BuildDocumento17 pagineSTM 800 BuildKevin Montañez Huaman0% (1)

- PowerLabs Flyback DriverDocumento8 paginePowerLabs Flyback DriverJayam SonaniNessuna valutazione finora

- SMD Component RemovalDocumento5 pagineSMD Component RemovalahimpliNessuna valutazione finora

- NOA Build ManualDocumento42 pagineNOA Build ManualJelly PinNessuna valutazione finora

- Qrpguys K8Tnd Regenerative Receiver: Please Read All The Instructions Before Starting To Assemble The ReceiverDocumento10 pagineQrpguys K8Tnd Regenerative Receiver: Please Read All The Instructions Before Starting To Assemble The ReceiverAltan KomanNessuna valutazione finora

- ADA MP-1 Noise-ModDocumento19 pagineADA MP-1 Noise-ModAndrei Popa100% (1)

- 7-Segmen Led Display Digital VoltmeterDocumento8 pagine7-Segmen Led Display Digital VoltmeterJoey TorresNessuna valutazione finora

- Digital VoltmeterDocumento7 pagineDigital VoltmeterKrishna KithuNessuna valutazione finora

- Service Manual SONY LCD klv32bx350Documento44 pagineService Manual SONY LCD klv32bx350elec104Nessuna valutazione finora

- Vec 830 KDocumento19 pagineVec 830 Kyu3zaNessuna valutazione finora

- Assembly and User Manual: 500 SeriesDocumento37 pagineAssembly and User Manual: 500 SeriesjacomartNessuna valutazione finora

- Illustrated Assembly Manual - Velleman K8042 Symmetric 1A Power SupplyDocumento12 pagineIllustrated Assembly Manual - Velleman K8042 Symmetric 1A Power Supplymr_sharkNessuna valutazione finora

- POWERLABS' High Voltage Solid State Flyback DriverDocumento11 paginePOWERLABS' High Voltage Solid State Flyback DriverArnab Acharya50% (2)

- International Islamic University Islamabad: Workshop Practice Lab (EE102L)Documento10 pagineInternational Islamic University Islamabad: Workshop Practice Lab (EE102L)Muhammad AnasNessuna valutazione finora

- GK Build Instructions v5-5Documento12 pagineGK Build Instructions v5-5Raghavendra RaoNessuna valutazione finora

- Xa Artix-7 Fpgas Data Sheet: Overview: General DescriptionDocumento10 pagineXa Artix-7 Fpgas Data Sheet: Overview: General DescriptionmpzachariaNessuna valutazione finora

- 2N5320 21Documento5 pagine2N5320 21crackintheshatNessuna valutazione finora

- pnc10 15Documento2 paginepnc10 15mtonellyNessuna valutazione finora

- 4-2 ECE R13 Syllabus TSSNDocumento21 pagine4-2 ECE R13 Syllabus TSSNnagaraniNessuna valutazione finora

- AN764 Debounce SwitchDocumento15 pagineAN764 Debounce Switchd.c.delatorre2200Nessuna valutazione finora

- Supratek Test ResultsDocumento2 pagineSupratek Test ResultsDimitris ZampelisNessuna valutazione finora

- RENR5042 C11 C13 TroubleshootingDocumento196 pagineRENR5042 C11 C13 TroubleshootingAndrei Bleoju100% (39)

- Citroen Xsara - Technical - Training PDFDocumento228 pagineCitroen Xsara - Technical - Training PDFFlorian LeordeanuNessuna valutazione finora

- Classes of Pole Based On Horizontal Loads Ansi 05Documento2 pagineClasses of Pole Based On Horizontal Loads Ansi 05JosePinosNessuna valutazione finora

- Coin Cell Batteries For LoRaWAN IoT Device - Murata QoitechDocumento9 pagineCoin Cell Batteries For LoRaWAN IoT Device - Murata QoitechAri LundenNessuna valutazione finora

- Bảng thông số sản phẩm: Micrologic 5.0 A - for Masterpact NT - drawoutDocumento2 pagineBảng thông số sản phẩm: Micrologic 5.0 A - for Masterpact NT - drawoutair VNessuna valutazione finora

- Alpha-I SVM AlarmCodesDocumento5 pagineAlpha-I SVM AlarmCodesSait Enrique Tellez RodriguezNessuna valutazione finora

- Power TriangleDocumento7 paginePower TriangleKrishna MurariNessuna valutazione finora

- Casio M300 Service ManualDocumento12 pagineCasio M300 Service ManualGiovanni OlmoNessuna valutazione finora

- Tempo2 - One-Shot/Test Timer: OverviewDocumento4 pagineTempo2 - One-Shot/Test Timer: OverviewLuis Enrique Antonio del AngelNessuna valutazione finora

- TroubleshootingGuide ACS 2k CTRLDocumento72 pagineTroubleshootingGuide ACS 2k CTRLadrianahouki100% (2)

- W 1 Weigh Scale User GuideDocumento108 pagineW 1 Weigh Scale User GuideCarlos F FerradaNessuna valutazione finora

- NOJA and Tavrida: Unique IntegrationDocumento1 paginaNOJA and Tavrida: Unique IntegrationTayyab ZubairNessuna valutazione finora

- Experiment 4Documento9 pagineExperiment 4mohammed_524176180Nessuna valutazione finora

- Electronics For Technician EngineersDocumento618 pagineElectronics For Technician EngineersIan Moree100% (12)

- Spiral CableDocumento2 pagineSpiral Cableanju vargheseNessuna valutazione finora

- FTTH Solutions BrochureDocumento3 pagineFTTH Solutions BrochureAli VaelizadehNessuna valutazione finora

- PanasonicGP31 ChassisDocumento16 paginePanasonicGP31 ChassisLuis RamirezNessuna valutazione finora

- QW 482 Suggested Format For Welding Procedure Specifications WPSDocumento3 pagineQW 482 Suggested Format For Welding Procedure Specifications WPSmohamedqcNessuna valutazione finora

- 42BYGH SeriesDocumento2 pagine42BYGH SeriesGedealdo TorresNessuna valutazione finora

- CI 8038 - CI 555 FinalDocumento10 pagineCI 8038 - CI 555 Finalmaria diazNessuna valutazione finora

- 125mbps 4400 Wireless AP 2Documento2 pagine125mbps 4400 Wireless AP 2FreeTheNetNessuna valutazione finora

- ps60 SmanualDocumento19 pagineps60 Smanualaknet99Nessuna valutazione finora

- Transmission Gate Characteristics: DS DSDocumento17 pagineTransmission Gate Characteristics: DS DSradeonleonNessuna valutazione finora

- IOT Exit Exam ScheduleDocumento6 pagineIOT Exit Exam ScheduleabdulazizNessuna valutazione finora