Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

6 Design of Constant Dia RCC Chimney and Foundation 23052014

Caricato da

Ahmad Badsha QuadriCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

6 Design of Constant Dia RCC Chimney and Foundation 23052014

Caricato da

Ahmad Badsha QuadriCopyright:

Formati disponibili

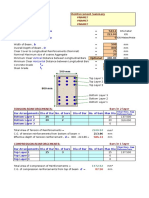

1)

15 20 25 30 35 40

0.25 0.22 0.22 0.23 0.23 0.23 0.23

0.50 0.29 0.30 0.31 0.31 0.31 0.32

0.75 0.34 0.35 0.36 0.37 0.37 0.38

1.00 0.37 0.39 0.40 0.41 0.42 0.42

1.25 0.40 0.42 0.44 0.45 0.45 0.46

1.50 0.42 0.45 0.46 0.48 0.49 0.49

= *( + + )) * 1.75 0.44 0.47 0.49 0.50 0.52 0.52

* * 2.00 0.44 0.49 0.51 0.53 0.54 0.55

2.25 0.44 0.51 0.53 0.55 0.56 0.57

= N 2.50 0.44 0.51 0.55 0.57 0.58 0.60

2.75 0.44 0.51 0.56 0.58 0.60 0.62

3.00 0.44 0.51 0.57 0.60 0.62 0.63

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

0.1 1.00 19000

20295

P T O

-4.40

Weight of Lining per meter height =

4.50 - 2 ( 0.4 0.1 0.05

Allowable tebsile stress (Direct) N/mm2 -2.00 -2.80 -3.20 -3.60 -4.00

10.00

Allowable compressive stress (Bending) N/mm2 5.00 7.00 8.50 10.00 11.50 13.00

Allowable compressive stress (Direct) N/mm2 4.00 5.00 6.00 8.00 9.00

35 40

modular ratio m 18.67 13.33 10.98 9.33 8.11 7.18

Shape Factor 0.70

100As

bd

Permissible Shear Stress in Concrete Tc

N/mm2 for grade of concrete

Grade of conc (N/mm2) 15 20 25 30

Grade of Steel (N/mm2) 250 415

Allowable tebsile stress

N/mm2

140 230

Constant wind pressure intensity at middle

portion

1600

N/m2

Constant wind pressure intensity at bottom

portion

1400

N/m2

Lining Support Distance @ every 6.00 m

Constant wind pressure intensity at top portion

1800

N/m2

Thickness of chimney shell at bottom portion

of Chimney

400

mm

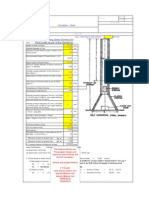

Cross-Section of Chimney Cross-Section of Chimney Cross-Section of Chimney Cross-Section of Chimney

Height of balance bottom portion of Chimney 22.00 m

300

mm

100

Height of middle portion of Chimney 25.00 m fig 1

400

Thickness of chimney shell at top portion 200

mm

1

4

0

0

n

/

m

2

2

2

.

0

0

m

Height of top portion of Chimney 25.00 m

Thickness of chimney shell at middle portion

of Chimney

Grade Concrete Mix M25 25 N/mm2

Modulus of Elasticity of Concrete Ec = 2.85E+04 N/mm2

Allowable tensile stress in steel 140 N/mm2

Modulus of Elasticity of steel Es = 2.05E+05 N/mm2

C

2

5

.

0

0

m

Coefficient of expansion of concrete and

Steel

1.1E-05

per deg C

Grade of Steel fy = ( 250 or 415) 250 N/mm2

Height of Fire Brick Lining above Ground

Level

48.00

m

1

6

0

0

3.90 m

300

The temperature of gases above

surrounding air

200

Unit weight of Fire Brick Lining 19000 N/m3 100

lining

thickness

Fire Brick Lining 100 mm thk

Air Gap Between Wall & Fire Brick Lining (min) 100 mm

4.10 m

Height of Chimney 72.00 m

2

5

.

0

0

m

External Diameter of Chimney 4.50 m

1800

4.50 m

Dimensions of Chimney and Forces 200

Ref Calculation Output

Design of RCC Chimney :- Design of RCC Chimney :- Design of RCC Chimney :- Design of RCC Chimney :-

Note : Input data in yellow cells only and ensure all check boxes are displaying "ok" or "safe".

Prepared by : Date :

Job no :

Sheet No :

cont'd :

Project :

Subject : Description : 4

Verified by : Date :

Revision note :

Calculation Sheet Calculation Sheet Calculation Sheet Calculation Sheet

Visit Abqconsultants.com

This program Designs and

Optimises RCC Chimney and

Foundation.

Written and programmed

by

:-

A B Quadri

www.abqconsultants.com

abquadri@yahoo.com

abquadri@gmail.com

Page 1 of 16

For shell, w = [ - ] * * *

= N / m

For shell, w = [ - ] * * *

= N / m

For shell, w = [ - ] * * *

= N / m

2)

Let the vertical reinforcement be % of the concrete area

place at a cover of

As = 1 * * ( ^2 - ^2 ) *

4

=

Nos of bars = =

Hence provide bars of 16mm suitably placed along the circumference

Actual As =

Equivalent thickness of steel ring placed at the centre of the shell

thickness ( R = - = m ) is

Ts = =

Horizontal steel (hoops) may be provided @ % of sectional area

Area of steel per metre height of chimney = * * =

Hence pitch s of mm bar hoops = * =

Provide these at mm centre

W = * = N

P1 = * ( * ) = N acting at

.: M = * =

.: Eccentricity e = M = = m =

W

For M concrete , m =

.: Eqivalent area = A = /4 * ( ^2 - ^2 ) * +

( - 1 )*

=

Eqivalent moment of inertia = I = ( / 64) ( D

4

-d

4

)+(m-1) R ts (R)

2

= * ( ^ 4 - ^ 4 ) * ^ 4 +

( - 1 ) * * * * ^ 2

=

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

64

10.98 2150 2.08 2150

6.9073E+12 mm

4

10.98 28149

2982693 mm2

4.50 4.10 1000

1688606

25 10.98

4.50 4.10 1000000

m below top

141750 12.5 1771875 N . m

1771875 1.049 1049 mm

0.7 1800 4.50 25.0 141750 12.5

400

250 ok

25.00 67544 1688606

100

12 1000 113 282.5 mm

2R

0.2 ok

0.2 200 1000 400 mm2

2.25 0.1 2.15

28149 2.08 mm

201

140 ok

28149 mm2 > 27018 mm2 ok

27018 mm2

16 mm

27018 135

4.50 4.10 1000000

100

128805

Stress at Section 25.00 m below top

1.00 ok

50 mm ok

1.00 25000

98960

400 mm thk 4.50 0.40 0.40 1.00 25000

67544

300 mm thk 4.50 0.30 0.30

Weight of Concrete per meter height

200 mm thk 4.50 0.20 0.20 1.00 25000

abquadri@gmail.com

9959010210

9959010211

Page 2 of 16

For no tension to develop, allowable eccentricity = 2 I = 2 *

AD *

=

The actual eccentricity is mm. Hence some tension will be developed in the leeward side.

The maximum and minimum stresses are given by = W MD

A 2I

= * *

2 *

=

Compressive stress = N/mm2

N/mm2

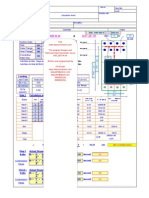

2)

Let the vertical reinforcement be % of the concrete area

place at a cover of

As = 1 * * ( ^2 - ^2 ) *

4

=

Nos of bars = =

Hence provide bars of 20mm suitably placed along the circumference

Actual As =

Equivalent thickness of steel ring placed at the centre of the shell

thickness ( R = - = m ) is

Ts = =

Horizontal steel (hoops) may be provided @ % of sectional area

Area of steel per metre height of chimney = * * =

Hence pitch s of mm bar hoops = * =

Provide these at mm centre

W = * + * +

* = N

P1 = * ( * ) + * ( * )

= + = N

.: M = * + * =

.: Eccentricity e = M = = m =

W

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

6890625 1.476 1476 mm

4669977

141750 37.5 126000 12.5 6890625 N . m

0.7 1600 4.50 25.0

141750 126000.00 267750.00

25.00 98960 4669977

0.7 1800 4.50 25.0

600

180 ok

25.00 67544 25.00 20295

100

12 1000 113 188.0 mm

2R

0.2 ok

0.2 300 1000 600 mm2

2.25 0.15 2.10

40841 3.10 mm

126

314

130 ok

40841 mm2 > 39584 mm2 ok

100

39584 mm2

20 mm

39584

50 mm ok

4.50 3.90 1000000

Stress at Section 50.00 m below top

Thickness of shell = 300 mm

1.00 ok

N/mm2 allowable (Safe)

Tensile stress = -0.011 < -0.8 N/mm2 allowable (Safe)

0.566 0.577

1.143 < 8.5

1049

1688606 1771875 1000 4500

2982693 6.9073E+12

6.9073E+12

2982693 4500

1029.2 mm

Page 3 of 16

For M concrete , m =

.: Eqivalent area = A = /4 * ( ^2 - ^2 ) * +

( - 1 )*

=

Eqivalent moment of inertia = I = ( /64 ) ( D

4

-d

4

) + ( m-1 ) R ts (R)

2

= * ( ^ 4 - ^ 4 ) * ^ 4 +

( - 1 ) * * * * ^ 2

=

For no tension to develop, allowable eccentricity = 2 I = 2 *

AD *

=

The actual eccentricity is mm. Hence some tension will be developed in the leeward side.

The maximum and minimum stresses are given by = W MD

A 2I

= * *

2 *

=

Compressive stress = N/mm2

N/mm2

3)

Let the vertical reinforcement be % of the concrete area

place at a cover of

As = 1 * * ( ^2 - ^2 ) *

4

=

Nos of bars = =

Hence provide bars of 25mm suitably placed along the circumference

Actual As =

Equivalent thickness of steel ring placed at the centre of the shell

thickness ( R = - = m ) is

Ts = =

Horizontal steel (hoops) may be provided @ % of sectional area

Area of steel per metre height of chimney = * * =

Hence pitch s of mm bar hoops = * =

Provide these at mm centre

800

140 ok

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

100

12 1000 113 141.0 mm

2R

0.2 ok

0.2 400 1000 800 mm2

ok

2.25 0.15 2.10

58905 4.46 mm

105 nos

491

120 ok

58905 mm2 > 51522 mm2

100

51522 mm2

25 mm

51522

50 mm ok

4.50 3.70 1000000

Stress at Section 72.00 m below top

Thickness of shell = 400 mm

1.00 ok

N/mm2 allowable (Safe)

Tensile stress = -0.533 < -0.8 N/mm2 allowable (Safe)

1.070 1.603

2.673 < 8.5

4669977 6890625 1000 4500

4365997 9.6716E+12

9.6716E+12

4365997 4500

984.5 mm

1476

64

10.98 2100 3.10 2100

9.6716E+12 mm

4

10.98 40841

4365997 mm2

4.50 3.90 1000

25 10.98

4.50 3.90 1000000

Page 4 of 16

W = * + * + * +

* + * = N

P1 = * ( * ) + * ( * )

* ( * )

= + + = N

.: M = * + * + *

=

.: Eccentricity e = M = = m =

W

For M concrete , m =

.: Eqivalent area = A = /4 * ( ^2 - ^2 ) * +

( - 1 )*

=

Eqivalent moment of inertia = I = ( /64 ) ( D

4

-d

4

) + ( m-1 ) R ts (R)

2

= * ( ^ 4 - ^ 4 ) * ^ 4 +

( - 1 ) * * * * ^ 2

=

For no tension to develop, allowable eccentricity = 2 I = 2 *

AD *

=

The actual eccentricity is mm. Hence some tension will be developed in the leeward side.

The maximum and minimum stresses are given by = W MD

A 2I

= * *

2 *

=

Compressive stress = N/mm2

N/mm2

The eccentricity is quite high. Due to this, tensile stresses in

the windward side are expected to be greather than 0.8 N/mm

2

resultingin cracking of concrete. Hence it is assumed that only

steel will take the tensile stresses and concrete in the tensile

zone will be ignored. Thus, the method of analysis used at

m and m will not be applicable.

We shall analyse the section for stresses by method

discussed in 8.3.

Tc = R = - = m

Ts = eccentricity e =

m =

In order to find the position of N.A., use equation 8.3 :

m Ts

2

{ + } m Ts

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

(Tc-Ts) sin (-) cos cos

]

}

+

]

fig 2

e =

R

4 2

[

[

(Tc-Ts)

{

sin2

+

-

2.05

4.46 mm 1.742 m

10.98

25.00 50.00

400 mm 2.25 0.20

N/mm

2

allowable (Safe)

Tensile stress = -1.164 >= -0.8 N/mm

2

allowable Check further

1.385 2.549

3.934 < 8.5

7950177 13848345 1000 4500

5740082 1.2225E+13

1.2225E+13

5740082 4500

946.6 mm

1742

64

10.98 2100 4.46 2100

1.2225E+13 mm

4

10.98 58905

5740082 mm2

4.50 3.70 1000

7950177

25 10.98

4.50 3.70 1000000

13848345 N . m

13848345 1.742 1742 mm

141750 126000 97020 364770

141750 59.5 126000 34.5 97020 11.0

4.50 25.0

0.7 1400 4.50 22.00

0.7 1800 4.50 25.0 0.7 1600

98960

22.00 20295 22.00 128805 7950177

25.00 67544 25.00 20295 25.00

Page 5 of 16

*

m

Assume = =

.: e = + =

+

= m

.: consider =

The maximum stress c1 in concrete is found from Eq.8.1

.: 2 * *

1 +

c1

.:

Tensile stress in Steel, assuming concrete to be fully cracked.

1 - cos

1 + cos

Horizontal steel (hoops) may be provided @ % of sectional area

Area of steel per metre height of chimney = * * =

Hence pitch s of = * =

Provide these at mm centre

As = in pitch s = mm centre, if the cover is then

D1 = - =

p * s *

2 * As * D1 2 * *

N/mm

2

allowable

Safe

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

140

= 51.079 N/mm

2

< 140

4420

4500 80 4420 mm

.: t1 = =

364770

113

800

140 ok

113.1 mm

2

140 40 mm

12 mm bar hoops 1000 113 141.0 mm

0.2 400 1000 800 mm

2

100

140

N/mm

2

safe

(b) Stress in horizontal reinforcement

0.2 ok

[ ]

= 43.96 N/mm

2

< t1 = m * c1 *

N/mm

2

< 8.5

N/mm

2

safe

in Concrete 1726917

Compressive stress

c1 =

7950177

= 4.6037

4.46 * 0.0698

]

=

1726917

}

+ 10.98 * *

{

0.9976 + 1.6406 * 0.0698

400 - 4.46 ) *

0.06976

Ts cos

]

1+cos

7950177 =

2050 c1

[

(

+ (-) cos

}

+ m W =

2Rc1

[

(Tc-Ts)

{

sin

not ok which is slightly more than the actual value

86.00 C 1.5010 radians

6922.40 1578.44

]

Now adjust the value of angle in such a way that the value of eccentricity e is >= 1.742

}

+ 10.98 * * *

{

sin + (-) cos

0.00 C

]

4 2 2

[

( 40.00 - 0.45 )

-

}

+

10.98

*

0.45

0.45 ) *

{

sin2

+

0.45 * cos

8500.84

43.98 1.074 45.058

1.887

e = 205 *

[

( 40.00 -

Page 6 of 16

(c) Stress on leeward side due to temperature gradient

.: = - = mm

a = =

c1 =

Es = Ec = =

p = = =

= per C

Temperature difference =

Let us assume that % of temperature drops through the lining and shell.

Drop in temperature = * =

Asssuming that drop in lining is times more than that in shell, per unit thickness,

the drop of temperature through concrete is given by,

T = =

+ *

To locate -neutral axis in the shell thickness, use Eq. 8.10

= * T * Ec

* k

2

- m * p * (a - k)

.: *

[

1 + ( - 1 ) * )

]

= * *

* k

2

- * * ( - k )

or =

k

2

+ * k -

k

2

+ * k - = 0

solving for k k = 0.8419

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

10.2329 14.6043

0.24509 0.21445

0.245 0.915

71.11

0.5 10.98 0.01116 0.875 1.867E+04

0.5

4.6037 10.98 0.01116 1.1E-05

- 1 ) * p

]

c1

[

1 + ( m

5 ok

160

*

400 71.11 C

400 5 100

200 C ok

80 ok

200 0.8 160 C

N/mm

2

10.98

Ts 4.46 0.01116 1.10E-05

Concrete

Temperature

Co-efficient

Tc 400

4.6037

N/mm

2

400

2.05E+05

N/mm

2

2.05E+05 1.867E+04

350

Cover to vertical steel = 50 mm

350 0.875

Thickness of steel Ts = 4.46 mm

aTc 400 50

Thickness of shell Tc = 400 mm Thickness of lining Tl = 100 mm

fig 3

fig 4

Page 7 of 16

.: a * * T * Ec

Stress in Concrete a - k

= * * *

=

4

Stress in Concrete 3

The above analysis is based on the assumption that the tension caused by temperature variation

cannot be taken by concrete, and it is taken entirely by steel.

Stress in Steel = t = = * * ( - )

=

(d) Stresses on windward side, due to temperature gradient

p * t1 = * T * Ec

m * p * ( a - k ) - * k

2

where t1 = p = a = m =

= T = Ec =

.: * 0 = *

* * ( - k ) - * k

2

*

- k - * k

2

- k - * k

2

=

solving k =

.: c = * T * Ec * k =

Stress in Concrete

Tensile stress in Steel, assuming concrete to be fully cracked.

t = m c a - k = * * ( - )

k

=

(e) Stresses on the Neutral axis .(i.e. temperature effect alone)

where m = p = a =

= T = Ec =

or k

2

- * + 2 * * *

+ * * * 10.98 10.98 0.01116 0.01116

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

N/mm

2

=

10.98 0.01116 10.98 0.01116 0.875

0.01116 0.875

0.000011 71.11 C 18670

k

2

= -mp + 2mpa + m

2

p

2

10.98

95.36

N/mm

2

< 140

N/mm

2

( safe )

fig 5

10.98 4.0937 0.875 0.2803

0.2803

0.10723 0.12254 0.5 0.0336

0.2803

Compressive 4.0937

N/mm

2

or

0.490581772

=

14.604

0.107226563 0.122544643 0.5

0.01116 43.956 0.000011 71.11

10.98 0.01116 0.875 0.5 18670

43.956

N/mm

2

0.01116071 0.875 10.98

0.000011 71.11 C 18670

N/mm

2

0.842

k 0.842

5.308

N/mm

2

0.5

11.33 N/mm

2

Thus the compressive stress more than the permissible--not ok

m c a - k 10.98 12.295 0.875

Since wind stresses are taken into account,

Permissible

= * 8.5 =

0.842 1.1E-05 71.11 1.867E+04

12.295

N/mm

2

* T * Ec

1 +

k

Compressive

c = = k *

Page 8 of 16

k

2

=

.: c

2

=

* T * Ec *

k

2

=

Stress in Concrete

Tensile stress in concrete, assuming concrete to be fully cracked.

t

2 =

m c

2

a - k

2

= * * ( - )

k

2

=

(b) Stress in horizontal reinforcement due to temperature :

p' = = =

S T

c

*

a' = =

From Eq. 8.13.

or k' - * + 2 * * *

+ * * *

k' =

.: c' = * T * Ec * k' =

Stress in Concrete

Tensile stress in concrete, assuming concrete to be fully cracked.

t

2 =

m c' a' - k'

= * * ( - )

k'

=

These stresses are due to temperature effect alone. To this we must add the stresses due to wind.

Hence total stress in steel

= + =

Since wind is also acting, permissible

t = 4 * =

allowable tensile stress in steel 3

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

O.k

115.64 51.079 166.72

N/mm

2

140 186.67

N/mm

2

Safe

10.98 2.6118 0.900 0.17884

0.17884

115.64

N/mm

2

< 140

N/mm

2

10.98 10.98 0.00202 0.00202

0.17883981

Compressive 2.6118

N/mm

2

=

10.98 0.00202 10.98 0.00202 0.900

360 0.900

400

k' = -mp' + 2mp'a + m

2

p'

2

( safe )

A

113.10 0.00202

140 400

0.35649

83.15

N/mm

2

< 140

N/mm

2

0.35648596

Compressive 5.2062

N/mm

2

10.98 5.2062 0.875 0.35649

Page 9 of 16

5. Flue Opening :

Provide a flue opening m wide and

m high at bottom.

The boundary of the opening is thickened and

reinforced as shown in Fig A. The vertical

steel bars are bent on either side of the

opening as shown

P P = N

M = N . M m

V M V = N

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

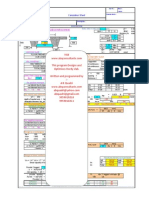

6. Force acting at 0.00 level for Foundation Design :

7950177

13848345

364770

0.00 level

P T O

1.5

2.0 ok

fig 6

Page 10 of 16

P

e

Data FFL

H

FGL

Soil filling inside

Axial load at the base of footing

=

= P + Weight of Chimney Wall + Soil Filling inside

of wall + Weight of soil + Self weight of footing

= + ( ^2 - ^2 )

4

* ( + ) *

+ ( ^2 ) *

4

+ ( ^2 - ^2 ) * *

4

+ ( ^2 ) * *

4

= + + + +

= kn

= + H * ( D + T + A )

= + * ( + + )

=

.: e' = = = < = m

Axx = * Ixx = * =

4

=

Zxx = * =

32

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

64

153.94 m

2

OD

3

m

3

269.39157

]

P' 21391.43 8

Ok

OD

2

OD

4

m

4

1885.74099

0.2

15380.38 Kn . M

M' 15380.38 0.7190

[

OD 1.75

M' 13848.345

13848.345 364.77 2.30 1.70

7950.18 128.33 237.65 4223.83 8851.44

21391.43

14.00 4.50 18 1.70

14.00 2.30 25

1.70 0.2 25

4.10 18

fig 7

1

4

0

0

0

O

D

7950.18

P'

7950.18 4.50 4.10

Footing Reinforcement dia = 32 25 mm 14000

Reinforcement cover c = 75 mm OD

Depth of Soil D = 1700 mm 4500

Depth of Footing T = 2300 mm d

T

Dia of Footing OD = 14.00 m

A = 200 mm

Level of footing below ground Totd = 4000 mm

4.50 m

Thickness of chimney wall t = 400 mm

2

3

0

0

Kn . M

4

0

0

0

eccentricity e = M/P = 1.742 m

T

o

t

d

Horizontal load H = 364.77 Kn

Outer dia of chimney d =

1

7

0

0

D

Density of soil Ws = 18 Kn/m3

Axial Load P = 7950.18 Kn

Moment M = 13848.345

Steel Grade fy = 415 N/mm2

S.B.C of Soil Qs = 200 Kn/m2

7. Design of Cirrcullar Chimney Foundation :

7950.18

364.77 1742

Concrete Grade fc' = 25 N/mm2

2

0

0

A

Page 11 of 16

The maximum and minimum base pressures are given by = P'

A

=

=

=

=

Factor of Safety against overturning = = P' * OD

2

= *

=

Assume initially of mm bars nos spaced radially along the

+ mm bars = mm2 circumferance

= = radians

= = mm

= = mm

= mm Length of segment 'PQ'

= mm Length of segment 'RS'

=

CG of Segment 'PQRS'

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

= 2.782 m

from 'PQ'

fig 9

P T O

Pressure due to

= 18.4 Kn / m2

Moment at 'PQ'

Area of Segment 'PQRS' 1.15028 m2

Uniform pressure

= 139.0 Kn / m2

under area 'PQRS'

Pressure due to

= 57.1 Kn / m2

Moment at 'RS'

Radius of Foundation fro 7000

Bar Spacing at ro 118

Bar Spacing at fro 367

1295

3.00 0.0524

Radius of Chimney ro 2250

1 Layer 32 120

25 As

15380.38

9.74 > 1.5 safe

Design of Footing slab

Stabilising Moment

Overturning Moment

M'

21391.43 14.00

2

Ok

min 81.87 Kn / m2 > 0 Kn / m2 allowable Ok

max 196.05 Kn / m2 < 200 Kn / m2 allowable

21391.43 15380.38

153.94 269.39

8

1

.

8

7

1

9

6

.

0

5

138.961 57.093

M'

Zxx

fig 8

ro

fro

MainReinforcement

Area covered by

one unit of Main

Reinforcement

Critical Section

for Moment

Footing

Outer Dia

Chimney

Outer Dia

A

A

P

R

S

Q

Line of Punching Shear

Line of Shear

S

a1

a2

b2

b1

rs

rp

Page 12 of 16

r

16 top radial reinforcement

1

Shear Stirrups (if required)

Main Radial reinforcement Circullar reinf

nos 16 @ c/c

cover

Section A - A

.: = + =

fy = .: fyall = m =

fc' = .: fc'all =

.: k = * =

* +

j = 1 - k = 1 - =

3

R = 1 j k = 1 * * *

2 2

=

Hence d = = * = mm

* R *

.: adopt T = cover = d = -

.: d = effective depth

As = = =

Fyall * j * d * *

.: + = * ( + )

4

=

@ c/c = * = %

*

0.494

distribution steel 118 2225

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

> 1241 mm

2

ok

Provide 16 200 p% 1295 100

1 dia bars.

layer of Main radial reinforcement 1295 mm

2

mm

2

230 0.90378 2225

Provide 32 25 A 32 25

2225 mm ok

M 573887856 1241

2096.08

1000 118 1.109

2300 mm 75 mm 2300 75

0.289

1.109

Mf

573.89 1000000

0.289 0.90378

3

fc'all 8.5 0.904

10.98 8.5 0.289

10.98 8.5 230

415 N/mm2 230 N/mm2 10.98

25 N/mm2 8.5 N/mm2

fig 10

Moment at 'PQ' Mf 503.33 70.56 573.89 Kn .m

1112.5 75

critical punching shear section

2225 critical shear Section

7000

1.61

c/L of Foundation

2

3

0

0

9

0

0

32 120 200

2250 2500 2250

Straight portion Sloping portion

C / L of foundation

C / L

Page 13 of 16

r = d = r + d =

2 2

= = radians

= = mm

= = mm

= mm

= mm

=

.: F = + =

= = * =

.: Depth required for punching shear do = =

* *

= < mm provided

Check shear at r + d from the c/L, End of Straight portion,

and at three points at sloping portion.

32 + 25 32 + 25 32 + 25 32 + 16 32 + 16 32 + 0

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

ok ok ok not ok ok ok

1 1

.: Provided spacing = mm 175 175

Minimum shear s = 2.5Asvfy/b mm 341 169 1 1

1

spacing mm 349 2638 245 193 142 91

1 1

Shear - MS bar dia fyall 140 12 12 1 1 1

Shear - Vs per main bar Kn 101 13 1 1

49 0

Shear Reinf Reqd Reqd Not Reqd Not Reqd Not Reqd Not Reqd

Shear actual Kn 181 133 123 90

0.23 0.23

Shear allowable Kn 80 120 127 116 97 69

Shear Stress tc N/mm2 0.31 0.23 0.23 0.23

ok ok

p% for Shear 0.50 0.25 0.25 0.25 0.25 0.25

ok ok ok ok

19 0

M allowable / bar Kn.m 599 599 599 367 270 138

M actual / bar Kn.m 575 194 157 73

0.260 0.000

CG of Segment 'PQxx' m 2.79 1.36 1.20 0.78 0.38 0.00

Area of Segment 'PQxx' m2 1.150 0.759 0.692 0.491

57.1 57.1

Pressure due to moment at section kn/m2 18.35 36.50 38.74 44.86 50.98 57.09

Pressure due to moment @ rs kn/m2 57.1 57.1 57.1 57.1

ok ok

Uniform pressure kn/m2 139.0 139.0 139.0 139.0 139.0 139.0

ok ok ok not ok

1005 804

p% 0.5018 0.2488 0.2347 0.1999 0.2387 0.2664

1292 825

Bar dia mm

As mm

2

1295 1295 1295 1005

Effective depth mm 2225 2225 2225 1758

6250 7000

Reinforcement Spacing mm 116 234 248 286 326 366

1270 2225 OK

Shear :

distance from c/L mm 2250 4475 4750 5500

0.16

fck 176 0.8 176

25 0.8 N/mm2

F 178831

Punching Shear at 'a1a2' 164.19 14.64 178.83 Kn

Allowable Punching Shear stress 0.16

fck 0.16

Kn / m2

from 'a1a2'

Moment at 'RS'

Pressure due to

= 27.4 Kn / m2

Moment at 'PQ'

0.98682 m2

under area 'PQRS' CG of Segment 'PQa1a2'

= 2.032 m

Pressure due to

= 57.1

Bar Spacing at fro 367 Length of segment 'RS'

Uniform pressure

= 139.0 Kn / m2

Area of Segment 'PQa1a2'

Radius of Foundation fro 7000

Bar Spacing at rps 176 Length of segment 'a1a2'

3363 mm

3.00 0.0524

Radius of Punching shear rps 3363

Punching Shear : Check Punching shear at ro + d/2 from the c/L

2250 mm 1112.5 mm

Page 14 of 16

Data :

Height of Top portion of Chimney =

Wind intensity of top portion of Chimney = N/m2

Concrete Area of Top Portion of chimney = mm2

Moment of Inertia of Top portion of Chimney = mm4

Wind Moment at the base of Top Portion = N.m

Modulus of Elasticity of Concrete = N/mm2

M / Ei = 1/mm

Area of M / Ei of top portion =

C.g of Area of M / Ei of top portion = mm

Moment of Area of M / Ei from top portion =

Partial Deflection of Top Portion top = mm

Ratio L / = L / L /

Height of Middle portion of Chimney =

Wind intensity of Middle portion of Chimney = N/m2

Area of Middle Portion of chimney = mm2

Moment of Inertia of Middle portion of Chimney = mm4

Wind Moment at the base of Middle Portion = N.m

Modulus of Elasticity of Concrete = N/mm2

M / Ei = 1/mm

Area of M / Ei of Middle portion =

C.g of Area of M / Ei of Middle portion from top = mm

Moment of Area of M / Ei of Middle portion =

Partial Deflection of Top Portion top = mm

Ratio L / = L / L /

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

17.812

wrt bottom of middle portion

2807 < 200

ok

2.8500E+04

2.4999E-08

4.2499E-04

3.7500E+04

1.7812E+01 (2)

25.00 m

1600

4365997

9.6716E+12

6.8906E+06

13332 > 200

ok

Middle Portion :

1.1251E-04

1.6667E+04

1.8752E+00 (1)

1.875

wrt bottom of top portion

1800

2982693

6.9073E+12

1.7719E+06

2.8500E+04

9.0008E-09

Check Deflection of Chimney :

Top Portion :

25.00 m

Page 15 of 16

Height of Bottom portion of Chimney =

Wind intensity of Bottom portion of Chimney = N/m2

Area of Bottom Portion of chimney = mm2

Moment of Inertia of Bottom portion of Chimney = mm4

Wind Moment at the base of Bottom Portion = N.m

Modulus of Elasticity of Concrete = N/mm2

M / Ei = 1/mm

Area of M / Ei of Bottom portion =

C.g of Area of M / Ei of Bottom portion from top = mm

Moment of Area of M / Ei of Bottom portion =

Total Deflection of Top Portion top = mm

Ratio L / = L / L /

ok

P T O

Prep By : A B Quadri- Abq Consultants - 9959010210 - em-abquadri@yahoo.com-12-2-826/2 Royal Residency, Besides Amba talkies, Mehdipatnam , Hyderabad-500028-www.abqconsultants.com

6.1000E+04

6.1256E+01 (3)

61.256

wrt bottom of bottom portion

1175 < 200

5740082

1.2225E+13

1.3848E+07

2.8500E+04

3.9746E-08

7.1219E-04

Bottom Portion :

22.00 m

1400

Page 16 of 16

Potrebbero piacerti anche

- Design of Const Dia RCC ChimneyDocumento16 pagineDesign of Const Dia RCC ChimneyVadirajNHalgeri100% (3)

- RCC Chimney DesignDocumento13 pagineRCC Chimney DesignJaydip PatelNessuna valutazione finora

- Analysis of RCC ChimneyDocumento26 pagineAnalysis of RCC ChimneynaveenaeeNessuna valutazione finora

- CH Design-R1 PDFDocumento12 pagineCH Design-R1 PDFmazumdar_satyajitNessuna valutazione finora

- Draft Code for Design of Reinforced Concrete ChimneysDocumento54 pagineDraft Code for Design of Reinforced Concrete Chimneysakshay chauhan67% (3)

- ChimneyDocumento42 pagineChimneyAnand SwamiNessuna valutazione finora

- ART20161236 Design Chimney ThisesDocumento5 pagineART20161236 Design Chimney ThisesAnand.5Nessuna valutazione finora

- Design of PileDocumento6 pagineDesign of Pilemahantesh_82Nessuna valutazione finora

- Chimney Design UnlineDocumento9 pagineChimney Design Unlinemsn sastryNessuna valutazione finora

- CODE OF PRACrrICE FOR DESIGN AND CONSTRUCTION OF MACHINE FOUNDATIONS PART II FOUNDATIONS FOR IMPACT TYPE MACHINES (HAMMER FOUNDATIONS)Documento21 pagineCODE OF PRACrrICE FOR DESIGN AND CONSTRUCTION OF MACHINE FOUNDATIONS PART II FOUNDATIONS FOR IMPACT TYPE MACHINES (HAMMER FOUNDATIONS)Mohamed MamdohNessuna valutazione finora

- Design of Circular ChimneyDocumento15 pagineDesign of Circular ChimneyPatel TosifNessuna valutazione finora

- Load Calculation for Pipe Conveyor Junction Tower Side RunnersDocumento2 pagineLoad Calculation for Pipe Conveyor Junction Tower Side RunnersMuhammad HasanNessuna valutazione finora

- Wind Load IS875Documento30 pagineWind Load IS875Pranjal Pareek100% (2)

- Chimney DesignDocumento8 pagineChimney DesignTroy HooperNessuna valutazione finora

- 09 bs8007 CrackwidthDocumento11 pagine09 bs8007 CrackwidthMUTHUKKUMARAMNessuna valutazione finora

- Splices & ConnectionsDocumento37 pagineSplices & Connectionsprabhu81Nessuna valutazione finora

- IS 4998 - 1 RCC ChimneyDocumento16 pagineIS 4998 - 1 RCC ChimneyDevang BhavsarNessuna valutazione finora

- RC WALLS & Base Raft Design-R2Documento96 pagineRC WALLS & Base Raft Design-R2Moideen Sunaif Mustafa100% (1)

- Design of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)Documento30 pagineDesign of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)raman212Nessuna valutazione finora

- Gantry Girder DesignDocumento6 pagineGantry Girder DesignpandianNessuna valutazione finora

- Design of ChimneyDocumento13 pagineDesign of Chimneyjay_p_shahNessuna valutazione finora

- ChimneyDocumento41 pagineChimneyhemantkle2u100% (2)

- Design of RCC Chimney in HyderabadDocumento84 pagineDesign of RCC Chimney in Hyderabadhemantkle2u100% (1)

- A Solar Chimney Power Plant TULJAPURDocumento16 pagineA Solar Chimney Power Plant TULJAPURDIPAK VINAYAK SHIRBHATE100% (3)

- NEO Steel Chimney DesignDocumento8 pagineNEO Steel Chimney DesignAnil Pradeep100% (1)

- Design of ChimneyDocumento39 pagineDesign of ChimneyVenkatesha Hebbar100% (2)

- Chimney DesignDocumento12 pagineChimney DesignVivek PremjiNessuna valutazione finora

- Chimney DesignDocumento6 pagineChimney Designneel0% (1)

- Approximate Methods for Structural AnalysisDocumento22 pagineApproximate Methods for Structural AnalysisRAJA SEKHARNessuna valutazione finora

- Ultimate Load Capacity of Circular Hollow Sections Filled With HiDocumento266 pagineUltimate Load Capacity of Circular Hollow Sections Filled With Hipatricklim1982Nessuna valutazione finora

- Material Data:: Foundation For Pipe SupportDocumento8 pagineMaterial Data:: Foundation For Pipe SupportAleksandar Obradovic100% (1)

- Design of Steel Chimney and RCC Foundation As Per Indian Code 22052014Documento12 pagineDesign of Steel Chimney and RCC Foundation As Per Indian Code 22052014Ahmad Badsha Quadri58% (19)

- Structural Calculations for Pad FoundationDocumento2 pagineStructural Calculations for Pad Foundationnazeer_mohdNessuna valutazione finora

- Here: Mat Foundation Design Spreadsheet PDFDocumento2 pagineHere: Mat Foundation Design Spreadsheet PDFbiniamNessuna valutazione finora

- S 101 Sodium Chloride Silo Specification Sheet and DesignDocumento8 pagineS 101 Sodium Chloride Silo Specification Sheet and DesignBenedick Jayson MartiNessuna valutazione finora

- Single Cell Box CulvertDocumento9 pagineSingle Cell Box CulvertAfiq SyahmiNessuna valutazione finora

- Truss Design ReportDocumento5 pagineTruss Design Reportapi-302388419Nessuna valutazione finora

- Calculation PDFDocumento126 pagineCalculation PDFmohammed almahrooqiNessuna valutazione finora

- Chimney/ring Fdn. DesignDocumento3 pagineChimney/ring Fdn. Designmasum91032Nessuna valutazione finora

- Cdo CalcDocumento3 pagineCdo CalcJeric FarinNessuna valutazione finora

- Admin.. Water TankDocumento10 pagineAdmin.. Water TankGanesh ChavanNessuna valutazione finora

- Design of Water Tank On The Ground According To Bs 8007:1987Documento109 pagineDesign of Water Tank On The Ground According To Bs 8007:1987minov minovitchNessuna valutazione finora

- Steel BeamDocumento12 pagineSteel BeamV.m. RajanNessuna valutazione finora

- Analysis of Self-Supported Steel Chimney With The Effects of Geometrical ParametersDocumento6 pagineAnalysis of Self-Supported Steel Chimney With The Effects of Geometrical Parametersvikram413Nessuna valutazione finora

- Dynamic Analysis of Self Supported Steel Chimney As Per Indian StandardDocumento81 pagineDynamic Analysis of Self Supported Steel Chimney As Per Indian Standardmoganna73Nessuna valutazione finora

- Eccentric FootingDocumento13 pagineEccentric FootingMegatech Engineering Consultants100% (1)

- Bolt Load Design CalculationDocumento2 pagineBolt Load Design CalculationDamanpreet SinghNessuna valutazione finora

- OHSRDocumento48 pagineOHSRsachingadage100% (2)

- DG Consulting Engineers: Job NoDocumento52 pagineDG Consulting Engineers: Job NosthakshyNessuna valutazione finora

- T Beam Roof SlabDocumento22 pagineT Beam Roof SlabRohit Khandelwal100% (1)

- DESIGN OF CANTILEVER BEAM AND LINTEL SUNSHADEDocumento31 pagineDESIGN OF CANTILEVER BEAM AND LINTEL SUNSHADENirina ArimananaNessuna valutazione finora

- Structural design and analysis of a low-rise buildingDocumento42 pagineStructural design and analysis of a low-rise buildingMohammed SumerNessuna valutazione finora

- Aci BeamDocumento6 pagineAci BeamkumsbamaNessuna valutazione finora

- Design of Rectangular Water Tank with L/B Ratio Greater than 2Documento5 pagineDesign of Rectangular Water Tank with L/B Ratio Greater than 2Hareesh RameshNessuna valutazione finora

- Staircase Design 1Documento365 pagineStaircase Design 1Vanu VamalaiNessuna valutazione finora

- RCC DESIGN CASE STUDYDocumento25 pagineRCC DESIGN CASE STUDYWHATS APP STATUSNessuna valutazione finora

- Design SectionDocumento19 pagineDesign SectionKrishna KumarNessuna valutazione finora

- Design ChimneyDocumento30 pagineDesign ChimneyMeera R. JadhavNessuna valutazione finora

- Ba Culvertf TestDocumento16 pagineBa Culvertf TestsanjuktaacharyyaNessuna valutazione finora

- Moment Connection - Flush End Plate-19.01.06Documento48 pagineMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- 28-1 Design of Anchored Sheet Pile Wall in Granular Soil-2 23052014Documento2 pagine28-1 Design of Anchored Sheet Pile Wall in Granular Soil-2 23052014Ahmad Badsha Quadri100% (1)

- Analysis and Design of R.C.C CIRCULLAR TANK As Per IS 3370: Calculation SheetDocumento3 pagineAnalysis and Design of R.C.C CIRCULLAR TANK As Per IS 3370: Calculation SheetAhmad Badsha QuadriNessuna valutazione finora

- 31 Design of RCC Beams For Biaxial Moment Shear Torsion and Axial Loads As Per Is 456 2000 23052014Documento2 pagine31 Design of RCC Beams For Biaxial Moment Shear Torsion and Axial Loads As Per Is 456 2000 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Documento3 pagine28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 26 Design of Singly Reinforced Continous RCC Beam As Per Is456-2000 23052014Documento1 pagina26 Design of Singly Reinforced Continous RCC Beam As Per Is456-2000 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 21 AISC Check of Steel I Sections For PEB 23052014Documento4 pagine21 AISC Check of Steel I Sections For PEB 23052014Ahmad Badsha QuadriNessuna valutazione finora

- Analysis and Design of R.C.C CIRCULLAR TANK As Per IS 3370: Calculation SheetDocumento3 pagineAnalysis and Design of R.C.C CIRCULLAR TANK As Per IS 3370: Calculation SheetAhmad Badsha QuadriNessuna valutazione finora

- 24-Optimised Design For Built Up Steel Beams For Mezzanine For PEB As Per AISC 23052014Documento5 pagine24-Optimised Design For Built Up Steel Beams For Mezzanine For PEB As Per AISC 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Documento3 pagine28 Design of Anchored Sheet Pile Wall in Granular Soil-1 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 19 Design of Fixed Steel Base Plate 23052014Documento1 pagina19 Design of Fixed Steel Base Plate 23052014Ahmad Badsha QuadriNessuna valutazione finora

- Design of Steel Chimney and RCC Foundation As Per Indian Code 22052014Documento12 pagineDesign of Steel Chimney and RCC Foundation As Per Indian Code 22052014Ahmad Badsha Quadri58% (19)

- 22 Analysis and Design of RCC Beam For Bi-Axial Moment Shear Torsion and Axial Load 23052014Documento3 pagine22 Analysis and Design of RCC Beam For Bi-Axial Moment Shear Torsion and Axial Load 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 11 Steel Connection Design As Per AISC 23052014Documento2 pagine11 Steel Connection Design As Per AISC 23052014Ahmad Badsha Quadri50% (2)

- 18 Preliminary Design of Concrete Shear Wall For Tall Buildings 23052014 1Documento1 pagina18 Preliminary Design of Concrete Shear Wall For Tall Buildings 23052014 1Ahmad Badsha QuadriNessuna valutazione finora

- 14 Design of RCC Combined Footing 23052014Documento2 pagine14 Design of RCC Combined Footing 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 13 Design of RCC Footing 23052014Documento3 pagine13 Design of RCC Footing 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 20 Design of RCC Retaining Wall 23052014Documento2 pagine20 Design of RCC Retaining Wall 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 14 Design of RCC Combined Footing 23052014Documento2 pagine14 Design of RCC Combined Footing 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 16 Selection of Concrete Filled Steel Pipe Columns 23052014Documento1 pagina16 Selection of Concrete Filled Steel Pipe Columns 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 15 Design of RCC Dome 23052014Documento3 pagine15 Design of RCC Dome 23052014Ahmad Badsha Quadri50% (2)

- 12 Design of Hordy Slab 23052014Documento1 pagina12 Design of Hordy Slab 23052014Ahmad Badsha QuadriNessuna valutazione finora

- 10 Design of Cantilever RCC Beam 23052014 2Documento1 pagina10 Design of Cantilever RCC Beam 23052014 2Ahmad Badsha QuadriNessuna valutazione finora

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 4Documento3 pagine9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 4Ahmad Badsha QuadriNessuna valutazione finora

- 1 Design of RCC Corbels-23052014Documento9 pagine1 Design of RCC Corbels-23052014Ahmad Badsha QuadriNessuna valutazione finora

- 10 Design of Cantilever RCC Beam 23052014 1Documento1 pagina10 Design of Cantilever RCC Beam 23052014 1Ahmad Badsha QuadriNessuna valutazione finora

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 3Documento2 pagine9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 3Ahmad Badsha Quadri100% (1)

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Documento2 pagine9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 2Ahmad Badsha QuadriNessuna valutazione finora

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Documento2 pagine9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 5Ahmad Badsha QuadriNessuna valutazione finora

- 9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 1Documento9 pagine9 Design of Flat Slab Column Connections As Per Aci 352-4-R89 23052014 1Ahmad Badsha QuadriNessuna valutazione finora

- 8 Design of Simply Supported RCC Beams 23052014-2Documento1 pagina8 Design of Simply Supported RCC Beams 23052014-2Ahmad Badsha QuadriNessuna valutazione finora

- Bond Strength of Electrical Insulating Varnishes by The Twisted-Coil TestDocumento3 pagineBond Strength of Electrical Insulating Varnishes by The Twisted-Coil TestAmer AmeryNessuna valutazione finora

- Workout TrackerDocumento3 pagineWorkout TrackerGuriNessuna valutazione finora

- 5-7T Ic ForkliftDocumento68 pagine5-7T Ic ForkliftalexNessuna valutazione finora

- C++ Classes and Data Structures Jeffrey S. Childs Chapter 1 Structs and ClassesDocumento63 pagineC++ Classes and Data Structures Jeffrey S. Childs Chapter 1 Structs and Classessamba684Nessuna valutazione finora

- IO2654 - F11 - 2013 - WDM Management PDFDocumento23 pagineIO2654 - F11 - 2013 - WDM Management PDFKlaudio MarkoNessuna valutazione finora

- ITAF Companion Performance Guidelines 2208Documento20 pagineITAF Companion Performance Guidelines 2208ReferatScoalaNessuna valutazione finora

- Siemens Landis QRA2 Detector Llama UltravioletaDocumento14 pagineSiemens Landis QRA2 Detector Llama UltravioletaPabloAlvNessuna valutazione finora

- Cemented Sand B E C MIX 23-9Documento7 pagineCemented Sand B E C MIX 23-9Mohammed Ghareib NasrNessuna valutazione finora

- Chapter 6 Interest Rates and Bond ValuationDocumento14 pagineChapter 6 Interest Rates and Bond ValuationPatricia CorpuzNessuna valutazione finora

- Check If A Given Binary Tree Is Height Balanced Like A Red-Black Tree - GeeksforGeeksDocumento5 pagineCheck If A Given Binary Tree Is Height Balanced Like A Red-Black Tree - GeeksforGeeksAtul GargNessuna valutazione finora

- Reporting Student LearningDocumento6 pagineReporting Student LearningKip PygmanNessuna valutazione finora

- Ratio and Proportion, RaviDocumento85 pagineRatio and Proportion, RaviShrishailamalikarjunNessuna valutazione finora

- CHP574 - NSD570 Teleprotection EquipmentDocumento2 pagineCHP574 - NSD570 Teleprotection EquipmentMichael Parohinog GregasNessuna valutazione finora

- Measure Front & Back Pants PatternDocumento8 pagineMeasure Front & Back Pants PatternAlicia MyersNessuna valutazione finora

- Design and Fluid Structural Interface Analysis of Marine PropellerDocumento67 pagineDesign and Fluid Structural Interface Analysis of Marine PropellerPavaniNessuna valutazione finora

- Vacon Theoretical Harmonic Simulation ReportDocumento4 pagineVacon Theoretical Harmonic Simulation Reportbriamserna91Nessuna valutazione finora

- Chapter 3Documento46 pagineChapter 3AnilKarwankarNessuna valutazione finora

- A Current Carrying Coil Behave Like A MagnetDocumento3 pagineA Current Carrying Coil Behave Like A MagnetAdlin SeedonNessuna valutazione finora

- Oscillating Universe TheoryDocumento1 paginaOscillating Universe TheoryArabella BasilioNessuna valutazione finora

- 3 - Trig Graph Vocabulary - MathBitsNotebook (A2 - CCSS Math)Documento4 pagine3 - Trig Graph Vocabulary - MathBitsNotebook (A2 - CCSS Math)kamal arabNessuna valutazione finora

- P6Documento33 pagineP6adaptive4u4527Nessuna valutazione finora

- Automatizando Consolidated SoDocumento23 pagineAutomatizando Consolidated SoCHRISTIAN STEVEN HUANATICO CHOMBONessuna valutazione finora

- Solution 3.11 Problem Statement: F I J I JDocumento5 pagineSolution 3.11 Problem Statement: F I J I JPandji Arie NugrahaNessuna valutazione finora

- TIRODA THERMAL DESIGN REPORTDocumento38 pagineTIRODA THERMAL DESIGN REPORTmithun46100% (2)

- Melissa StyrochemDocumento40 pagineMelissa StyrochemAjayMaurya100% (1)

- MCTRL300 Independent Controller Specifications V2.3 1Documento11 pagineMCTRL300 Independent Controller Specifications V2.3 1jerome larinNessuna valutazione finora

- Fanuc Hardware Connection MNL, GFZ 036867291Documento560 pagineFanuc Hardware Connection MNL, GFZ 036867291zcadNessuna valutazione finora

- Math For Real LifeDocumento213 pagineMath For Real LifezagarzusemNessuna valutazione finora

- REHEAT-REGENERATIVE RANKINE CYCLE CalculatorDocumento86 pagineREHEAT-REGENERATIVE RANKINE CYCLE CalculatorJustine SomentacNessuna valutazione finora

- Capital Budgeting Techniques and NPV AnalysisDocumento38 pagineCapital Budgeting Techniques and NPV AnalysisKushNessuna valutazione finora