Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Applied Energy: Jemaa Brahmi, Lotfi Krichen, Abderrazak Ouali

Caricato da

Dhinesh BaluDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Applied Energy: Jemaa Brahmi, Lotfi Krichen, Abderrazak Ouali

Caricato da

Dhinesh BaluCopyright:

Formati disponibili

A comparative study between three sensorless control strategies

for PMSG in wind energy conversion system

Jemaa Brahmi, Lot Krichen

*

, Abderrazak Ouali

Advanced Control and Energy Management Research Unit ENIS, Department of Electrical Engineering, University of Sfax, 3038 Sfax, Tunisia

a r t i c l e i n f o

Article history:

Received 25 June 2008

Received in revised form 14 October 2008

Accepted 9 November 2008

Available online 30 December 2008

Keywords:

Sensorless

WECS

MPPT

Sliding mode observer

Articial neural network observer

Model reference adaptive observer

a b s t r a c t

This paper presents a comparative study of sliding mode, articial neural network and model reference

adaptive speed observers for a speed sensorless permanent magnet synchronous generator (PMSG) in

wind energy conversion system (WECS). Wind velocity and position sensorless operating methods for

wind generation system using observer are proposed only by measuring phase voltages and currents.

Maximum wind energy extraction is achieved by running the wind turbine generator in variable-speed

mode. In addition the three speed observers are compared to verify the robustness against parameter

variations.

2008 Elsevier Ltd. All rights reserved.

1. Introduction

Due to the drawbacks associated with the use of rotor position

sensors in permanent-magnet synchronous generator (PMSG)

drives, there has been signicant interest in the so-called rotor po-

sition sensorless drive. Rotor position sensorless control of the

PMSG typically requires knowledge of the PMSG structure and

parameters, which in some situations are not readily available or

may be difcult to obtain. Moreover the amount of energy ob-

tained from a wind energy conversion system (WECS) depends

not only on the characteristics of the wind regime at the site, but

also on the control strategy used for the WECS.

In the literature, many techniques have been developed for

sensorless control of induction machines [14] and for PMSG appli-

cations [57]. In [3], a sensorless vector-control strategy for an

induction generator in a variable-speed WECS using a MRAS obser-

ver to estimate the rotational speed of the induction generator is

studied. In [8], the neural network is applied for wind speed esti-

mation and robust control of maximum wind power extraction.

The work in [9] studies the rotor speed sensorless control of the

PMSG using the reduced order observer. In [10], a rotor position

sensorless control of the PMSM using a diagonally recurrent neural

network is implemented.

In this study, we propose the sensorless maximum power point

tracking of wind generation system. A speed observer based on the

MRAS theory for a speed sensorless permanent magnet synchro-

nous generator (PMSG) drive in wind energy conversion system

(WECS) is rst proposed. Next, the speed observer based on the

neural network is derived, and then a speed observer based on

the sliding mode control theory is done. The maximum power

point is based on the knowledge of the characteristic curve of the

wind turbine aerofoil. For high wind speeds, the pitch control ad-

justs the pitch angle to limit the aerodynamic power of the WECS,

which supplies a load or a grid through an inverter. This converter

allows the reactive power management by the regulation of the DC

voltage bus and the control of the reactive power. In addition, the

observers are compared, in order to test the robustness of the

observers against parameter variations of the PMSG.

Some simulation results are provided to demonstrate the effec-

tiveness of the sliding mode speed observer in wind energy conver-

sion system under decrease or increase of stator resistance.

2. Modeling of the WECS

2.1. Modeling of the wind turbine

The wind power acting on the swept area of the blade s is a

function of the air density q (kg m

3

) and the wind speed

v

w

m s

1

. The transmitted power P (W) is generally deduced

from the wind power using the power coefcient C

p

, as

0306-2619/$ - see front matter 2008 Elsevier Ltd. All rights reserved.

doi:10.1016/j.apenergy.2008.11.010

* Corresponding author.

E-mail addresses: brahmi_jemaa@yahoo.fr (J. Brahmi), lot.krichen@enis.rnu.tn

(L. Krichen), abderrazak.ouali@enis.rnu.tn (A. Ouali).

Applied Energy 86 (2009) 15651573

Contents lists available at ScienceDirect

Applied Energy

j our nal homepage: www. el sevi er . com/ l ocat e/ apener gy

P

1

2

C

P

qSv

3

w

1

The power coefcient is a non-linear function of the tip speed-ratio

k, which depends on the wind velocity and the rotation speed of the

shaft X

t

(rpm).

k

RX

t

v

w

2

where R represents the blade radius (m).

As both mechanical shafts are linked by the gearbox, there is

only one state variable. The mechanical equation is given by

dX

dt

1

J

C

m

C

em

f X 3

where C

m

is the mechanical torque (N m), C

em

is the electromagnetic

torque (N m), X is the mechanical speed of the rotor (rad s

1

), J is

the moment of inertia (kg m

2

) and f is the coefcient of viscous fric-

tion (N m s rad

1

).

2.2. Modeling of the PMSG

The model generally used of the PMSG is the Park model. By

considering only the fundamental harmonic of the ux distribution

in the air-gap of the machine and by neglecting the homopolar

component, the theory of the space vector gives the dynamic equa-

tions of the stator voltages as follows:

V

sd

R

s

I

sd

du

sd

dt

xu

sq

V

sq

R

s

I

sq

du

sq

dt

xu

sd

_

4

The stator uxes are given by

u

sd

LI

sd

/

m

u

sq

LI

sq

_

5

where R

s

is the phase resistance of the stator winding (X), L stator

inductance (H), u

m

is the ux of the permanent magnetic (Wb), V

sd

and V

sq

are the dq components of the stator voltages (V), respec-

tively, I

sd

and I

sq

are the dq components of the stator currents

(A), respectively, x is the rotor electric speed (rad s

1

) and p is

the number of pairs poles.

With arrangement of Eqs. (4)and (5) we obtain:

V

sd

R

s

I

sd

L

dI

sd

dt

xLI

sq

V

sq

R

s

I

sq

L

dIsq

dt

xLI

sd

x/

m

_

6

The electromagnetic torque is given by

C

em

p/

m

I

sq

7

A block diagram of the drive investigated for assessment of

quality of the proposed estimator of the rotor and position speed

by taking into account of the stator resistance variation is shown

in Fig. 1. The bloc of speed and position observer can be the MRAS,

the neural network or the sliding mode observer which are ex-

plained and detailed in the following sections. The wind generator

consists of a wind turbine driving a multi-pole permanent magnet

synchronous generator (PMSG) and of the AC/DC rectier to con-

nect this wind generator to the DC bus. The converter controls

the output voltages of the PMSG and indirectly the operating point

of the wind turbine and consequently its generated power.

2.3. Modeling of the converters

The modelling of the converters is made by using the concept of

instantaneous average value [11]. The converter is equivalent to a

matrix topology composed of three legs of which its two ideal

switches are in complementary states (Fig. 2). A switching function

f

ij

is dened for each power switch [12]. It represents the ideal

commutation orders and takes the value 1 when the switch is

closed (on) and 0 when it is opened (off):

f

ij

2 f0; 1g with

i 2 f1; 2; 3g no of the leg

j 2 f1; 2; g no of the switch in the leg

_

8

As ideal power switches are considered:

f

i1

f

i2

1; i 2 f1; 2; 3g 9

For both three-phase converters, rectier rec and inverter inv

of Fig. 1, modulation functions can be dened from the switching

functions:

m

rec

m

rec13

m

rec23

_ _

1 0 1

0 1 1

_ _ f

11

f

21

f

31

_

_

_

_

rec

m

inv

m

inv13

m

inv23

_ _

1 0 1

0 1 1

_ _ f

11

f

21

f

31

_

_

_

_

inv

10

The rectier provides the voltages V

sdq

V

sd

V

sq

T

from the

capacitor voltage U and the modulated current I

rec

:

Fig. 1. Block diagrams of speed sensorless PMSM drive in WECS.

1566 J. Brahmi et al. / Applied Energy 86 (2009) 15651573

V

sdq

m

rec

U

I

rec

m

T

rec

I

sdq

_

11

The three-phase inverter is modelled in the same way. It yields

the inverter voltages V

invdq

V

invd

V

invq

T

from the capacitor volt-

age and the inverter modulated current I

inv

from the line currents

I

ldq

I

ld

I

lq

T

:

V

invdq

m

inv

U

I

inv

m

T

inv

I

ldq

_

12

3. Optimal control strategy of the WECS

In this study, the search of the maximum power point is based

on the knowledge of the characteristic curve of the wind turbine

aerofoil. Fig. 3 represents the aerodynamic power according to

the PMSG speed for various values of the wind speed. The summits

of these curves give the maximumextractable power P

opt

and thus

the optimal point. This point is characterized by the optimal speed

X

opt

and the maximum power coefcient C

p,opt

. Fig. 4 represents

the power coefcient according to the specic speed k. For this

wind turbine the optimal specic speed is k

opt

= 8.1.

For the powers lower than the nominal output of the turbine

P

n

= 3.6 kW, the aerodynamic torque which gives the optimum

power according to the optimal PMSG speed is approximated by

the following polynomial function:

C

mopt

6:2491 10

7

X

3

opt

0:0021X

2

opt

0:0232X

opt

1:1834 13

Beyond the nominal output of the turbine, the pitch control is

activated and the PMSG works at constant power. For strong

speeds, the aerodynamic brake is operated.

Taking into account the relative difculty of the speed control of

a high inertial turbine, a torque control of the generator is applied.

This way of controlling the system requires an adaptation of the

device that ensures the maximum point of power MPPT.

4. Model reference adaptive speed observer

Speed estimation methods using MRAS have been described in

the literature for eld-oriented IM drives. Schauder [13] uses the

rotor ux as the output value for the model to estimate the rotor

speed, [14] propose a new MRAC method that uses the stator cur-

rents as the state variables for estimating the speed of induction

motor. In [15], the rotor speed is estimated by the full order adap-

tive observer.

In Fig. 5 the MRAS estimator uses two models to calculate a sta-

tor ux of the PMSG. One model is a reference model and the other

one is an adaptive model.

Eq. (5) represents the reference model which depends only on

stator currents and the adaptive model which considers the rotor

speed as the adjustable parameter, is shown in Eq. (14).

^

/

sd

_

V

sd

^ xL

^

I

sq

R

s

^

I

sd

dt /

m

^

/

sq

_

V

sq

^

xL

^

I

sd

R

s

^

I

sq

^

x/

m

dt

_

14

The outputs of these two models are compared in an adaptation

mechanism to estimate the adjustable parameter that tunes the

adaptive model in order to drive the output error between these

models to zero. The error between the two models is fed back to a

proportionalintegral (PI) controller in which an adaptation algo-

rithmis used to tune the speed ^ x, so that the error e = 0. The conver-

gence of the adaptation diagram is assured if the adaptive

mechanism in such manner is suitably chosen that one guarantees

the asymptotic stability of the error e. The error indq coordinates is

e e

1

; e

2

T

^

/

sd

/

sd

;

^

/

sq

/

sq

T

15

Let us suppose that e

1

^

/

sd

/

sd

, the state error equation is

written as follows:

i

c

f

11

f

12

f

13

i

t1

U u

m13

c u

m23

i

t3

f

21

f

22

f

23

Fig. 2. Diagram of ideal switches equivalent to the converter.

Fig. 3. Aerodynamic power versus PMSG speed.

Fig. 4. Power coefcient versus specic speed. Fig. 5. Block diagram for MRAS control.

J. Brahmi et al. / Applied Energy 86 (2009) 15651573 1567

de

1

dt

R

s

L

^

/

sd

^

x

^

/

sq

R

s

L

/

m

V

sd

L

dI

sd

dt

16

we obtain:

e

1

s

R

s

L

_ _

We

1

; t f t 17

where

f t

R

s

L

/

sd

R

s

L

/

m

V

sd

L

dI

sd

dt

and We

1

; t ^ xe

1

; t

^

/

sq

Eq. (17) describes a system with feedback explained in Fig. 6,

having a linear transfer function as Hs

1

sRs=L

_ _

, and a non-linear

function in the feedback chain where the input is e

1

and the output

is W(e

1

, t).

The synthesis of the stability conditions of a system composed

of two subsystems, one linear and the other non-linear requires

that

The linear function Hs

1

sRs=L

_ _

is null, positive, so R

e

Hjw

Rs=L

w

2

Rs=L

2

is positive 8w > 0.

The adaptive mechanism included in the non-linear block must

satisfy the criterion of the hyperstability of Popov [13].

The proportional and integral law adaptation is written

xe

1

; t

_

t

0

w

1

dt w

2

18

We pose

x

i

e

1

; t

_

t

0

w

1

dt and x

p

e

1

; t w

2

19

The non-linear block veries the inequality of Popov dened by

I

_

e

1

Wdt I

1

I

2

> g

2

20

where I

1

_

e

1

^

/

sq

_

t

0

w

1

e

1

; t dt dt and I

2

_

e

1

^

/

sq

w

2

dt

The solution of I

1

is given by the integral law adaptation

x

i

e

1

; t k

1

_

t

0

e

1

^

/

sq

dt x0 and the solution of I

2

is given by

the proportional law adaptation, x

p

e

1

; t k

2

e

1

^

/

sq

; k

1

and k

2

are

positive constants.

xe

1

; t k

2

e

1

^

/

sq

k

1

_

t

0

e

1

^

/

sq

dt x0

_ _

For e

2

^

/

sq

/

sq

and in the same way as e

1

, we determine

x(e

2

, t) which can be expressed as

xe

2

; t k

0

1

e

2

^

/

sd

k

0

2

_

t

0

e

2

^

/

sd

dt x0

_ _

The estimated speed is nally given by

^ x xe

1

; t xe

2

; t

k

p

e

1

^

/

sq

e

2

^

/

sd

k

i

_

e

1

^

/

sq

e

2

^

/

sd

dt x0 21

where e

1

^

/

sq

e

2

^

/

sd

/

sq

^

/

sd

/

sd

^

/

sq

.

5. Articial neural network

The structure of the proposed feedforward neural network used

for estimation is indicated in Fig. 7. The network has three layers,

i.e., input layer, hidden layer, and output layer. The circles in the

network represent the neurons. The input and output layers have

neurons equal to the respective number of signals, whereas the

hidden layer in the present design has ve neurons. The basic ele-

ment of the ANN is the neuron which has four main parts: inputs,

weights and biases, activation function and outputs as illustrated

in Fig. 7. A training algorithm adjusts the weights and the biases.

The data set is formed by the current components (I

a

, I

b

,

I

a

(k 1), I

b

(k 1)) and the voltage ones (V

a

, V

b

). Thus, we have

six neurons in the input layer and one neuron as an output which

represents the estimated speed.

Supervised neural networks applied to the speed observer were

trained to produce the desired output correction to the estimated

speed. Implementation of these supervised networks was carried

out in two steps.

In the rst step, the groups of inputdesired output training

data were obtained from simulation of the complete drive system.

The network inputs and the desired output were normalized. To

improve the learning process, the input data to the ANN were

the subject of polynomial interpolation. This operation is repeated

for the entire next learning data considering that each new learn-

ing starts from the weights, which were determined in the previ-

ous learning process.

The next step is for testing. The last stage of checking the perfor-

mance of the speed observer was testing using data that are differ-

ent than the learning ones.

The data vector set is:

E

n

= [i

a

, i

b

, i

a

(k 1), i

b

(k 1), v

a

, v

b

],

W

ci

: input weight i = (1:6),

W

sj

: output weight j = (1.5),

W

c

= [W

c1

W

c2

W

c3

W

c4

W

c5

W

c6

]

W

s

= [W

s1

W

s2

W

s3

W

s4

W

s5

]

with b

e

: input bias and b

s

: output bias.

The output of the hidden layer is given by the following

expression:

S

c

f W

c

E

n

b

e

The estimated speed is expressed by

W f W

s

S

c

b

s

where S

c

is the output of the hidden layer and the function f is a tan-

gent sigmoid function.

6. Sliding mode observer

In the stationary reference frame, the (a, b) model for the PMSG

without saliency is characterized by Fig. 6. Equivalent diagram of MRAS.

Input

layer

hidden

layer

Output

layer

I

I

I

I

V

V

b

b

W W

W

(k-1)

(k-1)

ci sj

s

s

31

^

Fig. 7. Neural network structure.

1568 J. Brahmi et al. / Applied Energy 86 (2009) 15651573

di

s

dt

Ai

s

Bm

s

Be

s

22

where

i

s

= (i

a

, i

b

)

T

: stator a- and b-axes currents,

v

s

= (v

a

, v

b

)

T

: stator a- and b-axes voltages,

e

s

= (ea, eb)

T

: induced voltage,

e

a

= k

e

x sinh; k

e

back emf constant,

e

b

= k

e

x cosh.

A

R

s

L

I; B

1

L

I; I

1 0

0 1

_ _

The sliding mode observer (SMO) is depicted in Fig. 8 which

consists of the three parts, current observer, continuous control

function and rotor position and speed calculator.

From Eq. (22) the SMO is made as the following structure:

d^i

s

dt

A

^

i

s

Bv

s

B^e

s

23

where the equivalent controls of conventional sliding mode obser-

ver can be obtained in Eq. (24)

^e

a

k

1

sign

^

i

a

i

a

k

e

^ xsin

^

h

^e

b

k

1

sign

^

i

b

i

b

k

e

^

xcos

^

h

_

24

The superscript ^ represents the estimated quantities, k

1

is

the constant current observer gain, (^i

a

i

a

) and (^i

b

i

b

) are the er-

ror between estimated current and actual one in the a- and b-axis,

respectively.

The sliding mode surface is dened as

S

n

s

a

s

b

T

25

where S

a

^i

a

i

a

i

a

and S

b

^i

b

i

b

i

b

.

To avoid the chattering phenomena, the sign function is re-

placed by the sigmoid function dened by [16]

Hi

a

2

1 expai

a

_ _

1; i

a

i

a

i

a

Hi

b

2

1 expai

b

_ _

1; i

b

i

b

i

b

a is a positive number.

When the estimation error trajectories reach the sliding surface

(s

n

= 0), it is obvious that the observed current will converge to the

actual ones, i.e., ^i

a

i

a

and ^i

b

i

b

.

Lets design the Lyapunov function to nd such condition of

sliding mode existence.

V

1

2

s

T

n

_ s

n

^ xx

2

2

26

Under the assumption that the rotor speed is constant within

one estimation period, derivative of Lyapunov function becomes

_

V s

T

n

_ s

n

^

_ xDx where Dx ^ xx 27

_ s

n

_ s

a

_ s

b

A

^

i

s

i

s

Be

s

k 28

The sliding mode exists when

_

V < 0

Substituting Eq. (28) into Eq. (27), the following equation is

obtained:

_

V s

T

n

A

^

i

s

i

s

B^e

s

e

s

k

^

_

x Dx < 0 29

According to the Lyapuvovs stability theory, V must be obeyed

to guarantee that the observer is stable. In order to drive the sys-

tem to be convergent, we have these conditions:

s

T

n

A^i

s

i

s

k < 0 30a

s

T

n

Be

s

^

_ xD x 0 30b

From Eq. (30b), the speed estimator may be derived as

^

_ x

k

L

s

a

sin

^

h s

b

cos

^

h 31

Also, from Eq. (24) and with sin

^

h ! sinh; cos

^

h ! cos h the rotor

position is determined as follows:

^

h tan

1

e

a

e

b

_ _

32

7. Comparative study of speed estimators and simulation

results

To make a concrete comparison between the three methods, we

have proceeded by a steady state simulation. By applying a step

signal of a wind ranging between 7 and 9 m/s at time t = 30 s,

and by increasing the stator resistance of 20% at time t = 70 s, the

, i i

Current

observer

Speed and

position

calculator

Sigmoid

function (H)

v v

,

^ ^

^

^

e k sign_(i -i )

1

^ ^

i i

,

=

e k sign_(i -i ) 1

^ ^

=

Fig. 8. Sliding mode observer.

0 10 20 30 40 50 60 70 80 90 100

70

75

80

85

90

95

100

105

110

115

120

Time (s)

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

real

estimated

Fig. 9. Actual and estimated rotor speeds (MRAS).

70

75

80

85

90

95

100

105

110

real

estimated

0 10 20 30 40 50 60 70 80 90 100

Time (s)

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

Fig. 10. Actual and estimated rotor speeds (ANN).

J. Brahmi et al. / Applied Energy 86 (2009) 15651573 1569

simulation results of the MRAS, the ANN and the SMO observers

are depicted in Figs. 911, respectively.

For SMO and ANN observers, we note good results when the

stator resistance variation appears and chattering phenomenon is

observed with SMO. The stator resistance perturbation causes a

static error in the case of MRAS observer.

In the following, we have considered a real wind speed ranging

between 6 and 12 m/s with an average value of 9 m/s where two

simulations with and without resistance variation are investigated.

The wind speed sequence is obtained by adding a turbulent com-

ponent to a slowly varying signal.

Figs. 1217 present the simulation results without stator varia-

tion. The estimated and actual rotor speeds at the nominal condi-

tion are shown in Fig. 12. The simulation result of wind velocity

estimation is shown in Fig. 13. When the wind speed is high, i.e.,

greater than 10 m/s, the pitch control adjusts the pitch angle de-

real

estimated

0 10 20 30 40 50 60 70 80 90 100

70

75

80

85

90

95

100

105

110

115

120

Time (s)

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

Fig. 11. Actual and estimated rotor speeds (SMO).

0 10 20 30 40 50 60 70 80 90 100

40

50

60

70

80

90

100

110

120

130

140

Time (s)

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

0 10 20 30 40 50 60 70 80 90 100

40

50

60

70

80

90

100

110

120

130

140

0 10 20 30 40 50 60 70 80 90 100

40

50

60

70

80

90

100

110

120

130

140

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

Time (s) Time (s)

a

b

c

Fig. 12. Actual and estimated rotor speeds at nominal condition. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer. - - - -: Estimated value and : real

value.

0 10 20 30 40 50 60 70 80 90 100

0

2

4

6

8

10

12

14

w

i

n

d

s

p

e

e

d

(

m

/

s

)

0 10 20 30 40 50 60 70 80 90 100

0

2

4

6

8

10

12

14

0 10 20 30 40 50 60 70 80 90 100

0

2

4

6

8

10

12

14

w

i

n

d

s

p

e

e

d

(

m

/

s

)

w

i

n

d

s

p

e

e

d

(

m

/

s

)

Time (s) Time (s) Time (s)

a

b

c

Fig. 13. Actual and estimated wind speeds at nominal condition. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer. - - - -: Estimated value and : real

value.

0 10 20 30 40 50 60 70 80 90 100

0

1

2

3

4

5

6

P

i

t

c

h

a

n

g

l

e

(

d

e

g

)

0 10 20 30 40 50 60 70 80 90 100

0

1

2

3

4

5

6

0 10 20 30 40 50 60 70 80 90 100

0

1

2

3

4

5

6

P

i

t

c

h

a

n

g

l

e

(

d

e

g

)

P

i

t

c

h

a

n

g

l

e

(

d

e

g

)

Time (s) Time (s) Time (s)

a b

c

Fig. 14. Pitch angle. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer.

1570 J. Brahmi et al. / Applied Energy 86 (2009) 15651573

0 10 20 30 40 50 60 70 80 90 100

0

500

1000

1500

2000

2500

3000

3500

4000

0 10 20 30 40 50 60 70 80 90 100

0

500

1000

1500

2000

2500

3000

3500

4000

0 10 20 30 40 50 60 70 80 90 100

0

500

1000

1500

2000

2500

3000

3500

4000

A

e

r

o

d

y

n

a

m

i

c

p

o

w

e

r

(

W

)

A

e

r

o

d

y

n

a

m

i

c

p

o

w

e

r

(

W

)

A

e

r

o

d

y

n

a

m

i

c

p

o

w

e

r

(

W

)

Time (s) Time (s) Time (s)

a

b

c

Fig. 15. Aerodynamic power. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer.

0 10 20 30 40 50 60 70 80 90 100

0

5

10

15

20

25

30

35

40

T

o

r

q

u

e

(

N

m

)

0 10 20 30 40 50 60 70 80 90 100

0

5

10

15

20

25

30

35

40

0 10 20 30 40 50 60 70 80 90 100

0

5

10

15

20

25

30

35

40

T

o

r

q

u

e

(

N

m

)

T

o

r

q

u

e

(

N

m

)

Time (s) Time (s) Time (s)

a

b

c

Fig. 16. Actual and estimated output torque. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer. - - - -: Estimated value and : real value.

0 0.05 0.1 0.15 0.2 0.25

0

1

2

3

4

5

6

7

8

0 0.05 0.1 0.15 0.2 0.25

0

1

2

3

4

5

6

7

8

0 0.005 0.01 0.015 0.02 0.025

0

1

2

3

4

5

6

7

8

R

o

t

o

r

p

o

s

i

t

i

o

n

(

r

a

d

/

s

)

R

o

t

o

r

p

o

s

i

t

i

o

n

(

r

a

d

/

s

)

R

o

t

o

r

p

o

s

i

t

i

o

n

(

r

a

d

/

s

)

Time (s) Time (s) Time (s)

a

b

c

Fig. 17. Rotor position. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer.

0 10 20 30 40 50 60 70 80 90 100

40

50

60

70

80

90

100

110

120

130

140

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

0 10 20 30 40 50 60 70 80 90 100

40

50

60

70

80

90

100

110

120

130

140

0 10 20 30 40 50 60 70 80 90 100

40

50

60

70

80

90

100

110

120

130

140

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

Time (s) Time (s) Time (s)

a

b

c

Fig. 18. Actual and estimated rotor speeds considering the variation of stator resistance: 20% decrease. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer. -

- - -: Estimated value and : real value.

J. Brahmi et al. / Applied Energy 86 (2009) 15651573 1571

picted in Fig. 14 to limit the aerodynamic power plotted in Fig. 15 to

the nominal value of the PMSG. The wind turbine output torque is

represented in Fig. 16. Fig. 17 depicts the angle position of the rotor.

Figs. 1821 show simulation results with increase or decrease

of stator resistance in order to analyze the performances of the

three observers relative to parameter variations. In this study, an

increase or a decrease of 20% of the stator resistance is applied at

time t = 50 s. Figs. 18 and 19 represent rotor and wind speeds

respectively in the case of a decrease of the stator resistance.

Whereas, Figs. 20 and 21 represent rotor and wind speeds respec-

tively in the case of an increase of the stator resistance. Figs. 18a,b

and 20a,b, where the variation of the stator resistance occurs, show

a static error between the estimated and the real rotor speed for

ANN and MRAS observers.

According to these simulations, we note a good behavior of the

three algorithms especially at the nominal condition under both

transient and steady-state conditions. The disagreement between

the estimated speed and the real one is accented especially with

the MRAS, where it can be seen that a 20% variation of stator resis-

tance can produce an important estimation error. The ANN is more

insensitive against the stator resistance and wind speed variations

than the MRAS observer. Moreover, the robustness of the proposed

sliding mode speed observer against the variation of stator resis-

tance can be observed from these simulation results.

0 10 20 30 40 50 60 70 80 90 100

0

2

4

6

8

10

12

14

0 10 20 30 40 50 60 70 80 90 100

0

2

4

6

8

10

12

14

0 10 20 30 40 50 60 70 80 90 100

0

2

4

6

8

10

12

14

W

i

n

d

s

p

e

e

d

(

m

/

s

)

W

i

n

d

s

p

e

e

d

(

m

/

s

)

W

i

n

d

s

p

e

e

d

(

m

/

s

)

Time (s)

Time (s)

Time (s)

a

b

c

Fig. 19. Actual and estimated wind speeds considering the variation of stator resistance: 20% decrease. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer. -

- - -: Estimated value and : real value.

0 10 20 30 40 50 60 70 80 90 100

40

50

60

70

80

90

100

110

120

130

140

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

0 10 20 30 40 50 60 70 80 90 100

40

50

60

70

80

90

100

110

120

130

140

0 10 20 30 40 50 60 70 80 90 100

40

50

60

70

80

90

100

110

120

130

140

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

P

M

S

G

s

p

e

e

d

(

r

a

d

/

s

)

Time (s) Time (s) Time (s)

a

b

c

Fig. 20. Actual and estimated rotor speeds considering the variation of stator resistance: 20% increase. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer. - -

- -: Estimated value and : real value.

0 10 20 30 40 50 60 70 80 90 100

0

2

4

6

8

10

12

14

0 10 20 30 40 50 60 70 80 90 100

0

2

4

6

8

10

12

14

0 10 20 30 40 50 60 70 80 90 100

0

2

4

6

8

10

12

14

W

i

n

d

s

p

e

e

d

(

m

/

s

)

W

i

n

d

s

p

e

e

d

(

m

/

s

)

W

i

n

d

s

p

e

e

d

(

m

/

s

)

Time (s)

Time (s)

Time (s)

a

b

c

Fig. 21. Actual and estimated wind speeds considering the variation of stator resistance: 20% increase. Legend: (a) MRAS, (b) neural network and (c) sliding mode observer. - -

- -: Estimated value and : real value.

1572 J. Brahmi et al. / Applied Energy 86 (2009) 15651573

8. Conclusion

In this paper, we have presented a comparative study between

three sensorless direct torque control strategies of PMSG used in

WECS. Speed observers based on MRAS algorithm, neural networks

and a sliding mode are investigated. Simulation results have con-

rmed the validity of the algorithms related to the three ap-

proaches. In term of robustness against parameters variation, the

sliding mode observer is the best one. In addition, the MPPT based

on the characteristic curve of the wind turbine was ensured. Taking

into account the relative difculty of the speed control of a high

inertial turbine, a torque control of the generator was applied. When

the wind speed is high, the pitch control adjusts the pitch angle to

limit the aerodynamic power to the nominal value of the PMSG.

Appendix A. Wind turbine

The power coefcient of the simulated turbine is given by [17]

C

p

k; b 0:53

151

k

i

0:58b 0:002b

2:14

13:2

_ _

exp

18:4

k

i

_ _

with : k

i

1

1

k0:02b

0:003

b

3

1

The blade radius of the simulated wind turbine is 2 m.

Appendix B. Permanent magnetic synchronous generator:

PMSG

Number of pole pairs: p = 3;

Stator resistance: R

s

= 0.895 X;

Stator inductance: L = 12.16 mH;

Permanent magnetic ux: u

m

= 0.3 Wb

Inertia: j = 0.2 kg m

2

;

Friction coefcient: f = 0.001 N m s rad

1

.

Appendix C. DC bus and line

Capacitance: C = 2200 lF;

Maximal voltage: U

max

= 800 V

Line inductance: L

f

= 3 mH;

Line resistance: R

f

= 0.1 X.

References

[1] Lascu Cristian, Andreescu Gheorghe-Daniel. Sliding-mode observer and

improved integrator with dc-offset compensation for ux estimation in

sensorless-controlled induction motors. IEEE Trans Ind Electron

2006;53(3):16.

[2] Wlas Miroslaw, Krzemin ski Zbigniew, Guzin ski Jarosaw, Abu-Rub Haithem,

Toliyat Hamid A. Articial-neural-network-based sensorless nonlinear control

of induction motors. IEEE Trans Energy Convers 2005;20(3):5208.

[3] Crdenas Roberto, Pea Rubn. Sensorless vector control of induction

machines for variable-speed wind energy applications. IEEE Trans Energy

Convers 2004;19(1):169205.

[4] Beguenane R et al. A new scheme for sensorless induction motor control drives

operating in low speed region. Math Comput Simulat 2006;71:10920.

[5] Senjyu T, Tamakia S, Muhandoa E, Urasaki N, Kinjo H, Funabashib T, et al. Wind

velocity and rotor position sensorless maximum power point tracking control

for wind generation system. Renew Energy 2006;31:176475.

[6] Batzel T, Lee KY. Slotless permanent magnet synchronous motor operation

without a high resolution rotor angle sensor. IEEE Trans Energy Convers

2000;15(4):36671.

[7] Tan Kelvin, Islam Syed. Optimum control strategies in energy conversion of

PMSG wind turbine system without mechanical sensors. IEEE Trans Energy

Convers 2004;19(2):3929.

[8] Li Hui, Shi KL, McLaren PG. Neural-network-based sensorless maximum wind

energy capture with compensated power coefcient. IEEE Trans Ind Appl

2005;41(6):154856.

[9] Krichen L, Ouali A. Sensorless optimal control strategy of PMSG in wind energy

conversion system. Int Rev Electr Eng (IREE) 2007;2(4):6128.

[10] Batzel TD, Lee KY. An approach to sensorless operation of the permanent-

magnet synchronous motor using diagonally recurrent neural networks. IEEE

Trans Energy Convers 2003;18(1):1006.

[11] Robyns B, Pankow Y, Leclercq L, Franois B. Equivalent continuous dynamic

model of reneweble energy systems. In: 7th International conference on

modelling and simulation of electric machines, converters and systems:

electrimacs 2002, CD, 1821 Aout 2002, Montreal, Canada.

[12] Bouscayrol A, Delarue Ph, Guillaud X. Power strategies for maximum control

structure of a wind energy conversion system with a synchronous machine.

Renew Energy 2005;30:227388.

[13] Schauder C. Adaptive speed identication for vector control of induction

motors without rotational transducers. IEEE Trans Ind Appl

1992;28(5):105461.

[14] Park Chul-Woo, Kwon Woo-Hyen. Simple and robust speed sensorless vector

control of induction motor using stator current based MRAC. Electr Power Syst

Res 2004;71:25766.

[15] Yang Geng, Chin Tung-Hai. Adaptive-speed identication scheme for a vector-

controlled speed sensorless inverter-induction motor drive. IEEE Trans Ind

Appl 1993;29(4):8205.

[16] Paponpen Kittithuch, Konghirun Mongkol. Speed sensorless control of PMSM

using an improved sliding mode observer with sigmoid function. ECTI Trans

Electr Eng Electron Commun 2007;5(1):515.

[17] Slootweg JG, de Haan SWH, Polinder H, Kling WL. General model for

representing variable speed wind turbines in power system dynamics

simulations. IEEE Trans Power Syst 2003;18(1):14451.

J. Brahmi et al. / Applied Energy 86 (2009) 15651573 1573

Potrebbero piacerti anche

- PMSG ModelingDocumento6 paginePMSG Modelingوليد ابو شاكرNessuna valutazione finora

- Power Maximization Control of Small Wind System Using Permanent Magnet Synchronous GeneratorDocumento13 paginePower Maximization Control of Small Wind System Using Permanent Magnet Synchronous GeneratorhassenbbNessuna valutazione finora

- Sliding Mode Controls of Active and Reactive Power of A DFIG With MPPT For Variable Speed Wind Energy ConversionDocumento13 pagineSliding Mode Controls of Active and Reactive Power of A DFIG With MPPT For Variable Speed Wind Energy ConversionelecnaimelecNessuna valutazione finora

- Wind Speed and Rotor Position Sensorless Control For Direct-Drive PMG Wind TurbinesDocumento9 pagineWind Speed and Rotor Position Sensorless Control For Direct-Drive PMG Wind TurbinesRaj KumarNessuna valutazione finora

- A Fuzzy-Logic Based MPPT Method For Stand-Alone Wind Turbine SystemDocumento8 pagineA Fuzzy-Logic Based MPPT Method For Stand-Alone Wind Turbine SystemAJER JOURNALNessuna valutazione finora

- New Control Strategies of A Small Size Wind Generation System For Battery ChargingDocumento6 pagineNew Control Strategies of A Small Size Wind Generation System For Battery ChargingZellagui EnergyNessuna valutazione finora

- Simulation and Analysis of PMSG-based Wind Energy Conversion System Using Different Coverter ModelsDocumento5 pagineSimulation and Analysis of PMSG-based Wind Energy Conversion System Using Different Coverter ModelsHamza MahmoodNessuna valutazione finora

- Particle Swarm Optimization Based Sliding Mode Control of Variable Speed Wind Energy Conversion SystemDocumento11 pagineParticle Swarm Optimization Based Sliding Mode Control of Variable Speed Wind Energy Conversion SystemBukan Syahrul Yasin LimpoNessuna valutazione finora

- Simulation of Low Voltage Ride Through Capability of Wind Turbines With Doubly Fed Induction GeneratorDocumento9 pagineSimulation of Low Voltage Ride Through Capability of Wind Turbines With Doubly Fed Induction GeneratorDanny LiNessuna valutazione finora

- Jjmie: Modeling and Optimization of Wind Turbine Driving Permanent Magnet Synchronous GeneratorDocumento6 pagineJjmie: Modeling and Optimization of Wind Turbine Driving Permanent Magnet Synchronous GeneratorhassenbbNessuna valutazione finora

- Watts 3 w AU p ρC 2 1 m PDocumento7 pagineWatts 3 w AU p ρC 2 1 m PAbhishek SinghNessuna valutazione finora

- A Novel Control Strategy of Power Converter Used To Direct Driven Permanent Magnet Wind Power Generation SystemDocumento4 pagineA Novel Control Strategy of Power Converter Used To Direct Driven Permanent Magnet Wind Power Generation Systemjamal64722111Nessuna valutazione finora

- Modelling and Controlof A Wind Turbine Using PermaDocumento8 pagineModelling and Controlof A Wind Turbine Using PermaALEJANDRO JOSE VARGAS OPORTONessuna valutazione finora

- Modeling and Control of Direct Drive Variable Speed Stand-Alone Wind Energy Conversion SystemsDocumento6 pagineModeling and Control of Direct Drive Variable Speed Stand-Alone Wind Energy Conversion SystemsSamundra GurungNessuna valutazione finora

- Steady State Analysis of PMSG PDFDocumento16 pagineSteady State Analysis of PMSG PDF1balamanianNessuna valutazione finora

- Volume (8) Issue (4) 493-507Documento15 pagineVolume (8) Issue (4) 493-507Seid BegovicNessuna valutazione finora

- Introdução VariaçãoDocumento6 pagineIntrodução VariaçãoTravis GrayNessuna valutazione finora

- Study and Control of A Variable-Speed Wind-Energy System Connected To The GridDocumento9 pagineStudy and Control of A Variable-Speed Wind-Energy System Connected To The GridhassenbbNessuna valutazione finora

- An Improved Efficiency of Fuzzy Sliding Mode Cont PDFDocumento5 pagineAn Improved Efficiency of Fuzzy Sliding Mode Cont PDFNoureddine BounaslaNessuna valutazione finora

- SVC ModeloDocumento4 pagineSVC ModeloLuc JeanNessuna valutazione finora

- A Direct Torque Control Method For CSC Based PMSG Wind Energy Conversion SystemsDocumento7 pagineA Direct Torque Control Method For CSC Based PMSG Wind Energy Conversion SystemsLê Xuân ThăngNessuna valutazione finora

- Performance Enhancement of Grid Connected Wind Energy Conversion SystemsDocumento6 paginePerformance Enhancement of Grid Connected Wind Energy Conversion Systemskanda71Nessuna valutazione finora

- APPLICATION OF MATRIX CONVERTER IN WIND PMSGDocumento8 pagineAPPLICATION OF MATRIX CONVERTER IN WIND PMSGChetan GhatageNessuna valutazione finora

- Modelling and Fuzzy Logic Control of DFIG Based Wind Energy Conversion SystemsDocumento6 pagineModelling and Fuzzy Logic Control of DFIG Based Wind Energy Conversion SystemsNa ChNessuna valutazione finora

- Voltage/Pitch Control For Maximization and Regulation of Active/Reactive Powers in Wind Turbines With UncertaintiesDocumento10 pagineVoltage/Pitch Control For Maximization and Regulation of Active/Reactive Powers in Wind Turbines With UncertaintiesKeyur PatelNessuna valutazione finora

- A Study of MPPT Schemes in PMSG Based Wind Turbine System: Joydeep Sarkar Prof. Shridhar S KhuleDocumento6 pagineA Study of MPPT Schemes in PMSG Based Wind Turbine System: Joydeep Sarkar Prof. Shridhar S KhuleKhiem NguyenNessuna valutazione finora

- EEE 1201 021 Doubly Fed Induction Wind Turbines PSCAD EMTDCDocumento6 pagineEEE 1201 021 Doubly Fed Induction Wind Turbines PSCAD EMTDCShruthi SaNessuna valutazione finora

- Modeling and Simulation of PMSG Based Wecs: Jamuna V Baskar M Senthoorselvam DDocumento5 pagineModeling and Simulation of PMSG Based Wecs: Jamuna V Baskar M Senthoorselvam DSundaraPandiyanNessuna valutazione finora

- Analysis of Detent Torque in Hybrid Stepping Motors: Jonathan U AgberDocumento7 pagineAnalysis of Detent Torque in Hybrid Stepping Motors: Jonathan U AgbertheijesNessuna valutazione finora

- Pan 2008Documento5 paginePan 2008raisaNessuna valutazione finora

- Control Strategy For HVDC Interconnected DC-based Offshore Wind FarmDocumento6 pagineControl Strategy For HVDC Interconnected DC-based Offshore Wind FarmTruong HoaNessuna valutazione finora

- Control The Flywheel Storage System by Fuzzy Logic Associated With The Wind GeneratorDocumento7 pagineControl The Flywheel Storage System by Fuzzy Logic Associated With The Wind GeneratorhassenbbNessuna valutazione finora

- Paper ID 105Documento6 paginePaper ID 105hassenbbNessuna valutazione finora

- PSCAD Based Dynamic ModelingDocumento7 paginePSCAD Based Dynamic ModelingLalith KrishnanNessuna valutazione finora

- Asma TounsiDocumento13 pagineAsma TounsiHAFEDH ABIDNessuna valutazione finora

- Intelligent Control A Class Wind Energy Conversion Systems: Chedid, F. Mrad, M. BasmaDocumento8 pagineIntelligent Control A Class Wind Energy Conversion Systems: Chedid, F. Mrad, M. Basmamusaad1Nessuna valutazione finora

- Steady State Analysis of Wind TurbineDocumento7 pagineSteady State Analysis of Wind TurbineKhy-khy PutraNessuna valutazione finora

- Modeling and Control of PMSG Based Variable Speed Wind Turbine 2010 Electric Power Systems ResearchDocumento7 pagineModeling and Control of PMSG Based Variable Speed Wind Turbine 2010 Electric Power Systems ResearchRAJESHNessuna valutazione finora

- Design and Analysis of PMSG Based Wind Power Generation: Ee Department, SRMGPC, Lucknow 1Documento10 pagineDesign and Analysis of PMSG Based Wind Power Generation: Ee Department, SRMGPC, Lucknow 1AMANNessuna valutazione finora

- Maximum Power Point Tracking of Variable Speed Wind Energy Conversion SystemDocumento9 pagineMaximum Power Point Tracking of Variable Speed Wind Energy Conversion SystemJoniNessuna valutazione finora

- MPPT of Multi-Signal Feedforward Doubly-Fed Asynchronous Wind TurbineDocumento6 pagineMPPT of Multi-Signal Feedforward Doubly-Fed Asynchronous Wind Turbineyasmin ElsayedNessuna valutazione finora

- Wind TurbineDocumento5 pagineWind TurbineAnthony WellsNessuna valutazione finora

- Performance and Analysis of STATCOM For Damping Power System Disturbances Using Fuzzy Logic ControllerDocumento11 paginePerformance and Analysis of STATCOM For Damping Power System Disturbances Using Fuzzy Logic ControllerBerhanu ZelalemNessuna valutazione finora

- Electrical Braking of Large Wind TurbinesDocumento11 pagineElectrical Braking of Large Wind Turbineslaaloo41Nessuna valutazione finora

- 5 Modeling and Control of Variable Speed Wind Turbine Drive System DynamicsDocumento11 pagine5 Modeling and Control of Variable Speed Wind Turbine Drive System DynamicsnguyenngocbanNessuna valutazione finora

- Application Research of Maximum Wind-Energy Tracing Controller Based Adaptive Control Strategy in WECSDocumento5 pagineApplication Research of Maximum Wind-Energy Tracing Controller Based Adaptive Control Strategy in WECSEngr Tahir Iqbal AwanNessuna valutazione finora

- Design and Analysis of Direct Power and Flux Control of Dual Stator Induction Generator Integrated in Wind Conversion System Connected To The GridDocumento6 pagineDesign and Analysis of Direct Power and Flux Control of Dual Stator Induction Generator Integrated in Wind Conversion System Connected To The Gridhamza mesaiNessuna valutazione finora

- Ann 3Documento4 pagineAnn 3chawlavishnuNessuna valutazione finora

- A New Method of Maximum Power Point Tracking For DFIG Based Wind TurbineDocumento7 pagineA New Method of Maximum Power Point Tracking For DFIG Based Wind Turbinebalaji06202Nessuna valutazione finora

- JESV5SI0109Documento5 pagineJESV5SI0109Kiran YaddanapudiNessuna valutazione finora

- A Combination of An OTC Based MPPT and Fuzzy Logic Current Control For A Wind Driven PMSG Under Variability of Wind SpeedDocumento24 pagineA Combination of An OTC Based MPPT and Fuzzy Logic Current Control For A Wind Driven PMSG Under Variability of Wind SpeedMahdi HERMASSINessuna valutazione finora

- DFIG-Based Wind Turbine Robust Control Using High-Order Sliding Modes and A High Gain ObserverDocumento8 pagineDFIG-Based Wind Turbine Robust Control Using High-Order Sliding Modes and A High Gain Observerabdeldjabbar14Nessuna valutazione finora

- Ref For ANFISDocumento21 pagineRef For ANFISTheodore Teddy JNessuna valutazione finora

- 1 PBDocumento10 pagine1 PBaasfklNessuna valutazione finora

- 510 TorresDocumento6 pagine510 TorresnavidelecNessuna valutazione finora

- Volume8Issue4493 507Documento16 pagineVolume8Issue4493 507Mark FordNessuna valutazione finora

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDa EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetValutazione: 2 su 5 stelle2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDa EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNessuna valutazione finora

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlDa EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlValutazione: 5 su 5 stelle5/5 (1)

- Study of a reluctance magnetic gearbox for energy storage system applicationDa EverandStudy of a reluctance magnetic gearbox for energy storage system applicationValutazione: 1 su 5 stelle1/5 (1)

- Microgrid Dynamic Performance Improvement Using A Doubly Fed Induction Wind GeneratorDocumento9 pagineMicrogrid Dynamic Performance Improvement Using A Doubly Fed Induction Wind GeneratorDhinesh BaluNessuna valutazione finora

- 2009 - IEEE - Comprehensive Approach To Modeling and Simulation of PV ArraysDocumento11 pagine2009 - IEEE - Comprehensive Approach To Modeling and Simulation of PV ArraysmvillabrNessuna valutazione finora

- 16-Characteristics of The Multiple-InputDC-DC ConverterDocumento7 pagine16-Characteristics of The Multiple-InputDC-DC ConverterDhinesh BaluNessuna valutazione finora

- Pune To Bangalore 31112Documento1 paginaPune To Bangalore 31112Dhinesh BaluNessuna valutazione finora

- SE Electronics and Engineering-2013-14Documento2 pagineSE Electronics and Engineering-2013-14Dhinesh BaluNessuna valutazione finora

- 4.3 Dynamic InteractionsDocumento1 pagina4.3 Dynamic InteractionsDhinesh BaluNessuna valutazione finora

- GDDocumento1 paginaGDDhinesh BaluNessuna valutazione finora

- Modeling and Simulation of Permanent Magnet Synchronous Motor Drive SystemDocumento106 pagineModeling and Simulation of Permanent Magnet Synchronous Motor Drive SystemSlimane SouagNessuna valutazione finora

- Lesson Exemplar Math 7Documento6 pagineLesson Exemplar Math 7Pablo Jimenea100% (2)

- Angle ModulationDocumento26 pagineAngle ModulationAtish RanjanNessuna valutazione finora

- 19 Uco 578Documento20 pagine19 Uco 578roshan jainNessuna valutazione finora

- Biosynthesis and Characterization of Silica Nanoparticles From RiceDocumento10 pagineBiosynthesis and Characterization of Silica Nanoparticles From Riceanon_432216275Nessuna valutazione finora

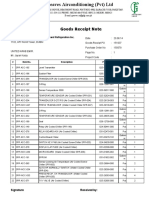

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento4 pagineGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNessuna valutazione finora

- Progressive Muscle Relaxation ExerciseDocumento2 pagineProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- تأثير العناصر الثقافية والبراغماتية الأسلوبية في ترجمة سورة الناس من القرآن الكريم إلى اللغة الإ PDFDocumento36 pagineتأثير العناصر الثقافية والبراغماتية الأسلوبية في ترجمة سورة الناس من القرآن الكريم إلى اللغة الإ PDFSofiane DouifiNessuna valutazione finora

- Turbine Start-Up SOPDocumento17 pagineTurbine Start-Up SOPCo-gen ManagerNessuna valutazione finora

- Lecture 5Documento20 pagineLecture 5Paylaşım KanalıNessuna valutazione finora

- Romano Uts Paragraph Writing (Sorry For The Late)Documento7 pagineRomano Uts Paragraph Writing (Sorry For The Late)ទី ទីNessuna valutazione finora

- Make Yeast StarterDocumento2 pagineMake Yeast StarterAlexandraNessuna valutazione finora

- Car Parking DesignDocumento6 pagineCar Parking Designcharler kinyuajNessuna valutazione finora

- Control System PPT DO1Documento11 pagineControl System PPT DO1Luis AndersonNessuna valutazione finora

- Summative Test in Foundation of Social StudiesDocumento2 pagineSummative Test in Foundation of Social StudiesJane FajelNessuna valutazione finora

- UntitledDocumento5 pagineUntitledapril montejoNessuna valutazione finora

- Ship Recognition Manual TOSDocumento138 pagineShip Recognition Manual TOSCody Lees94% (17)

- Chapter Two: General Design ConsiderationsDocumento27 pagineChapter Two: General Design ConsiderationsTeddy Ekubay GNessuna valutazione finora

- Analysis Chart - Julie Taymor-ArticleDocumento3 pagineAnalysis Chart - Julie Taymor-ArticlePATRICIO PALENCIANessuna valutazione finora

- OB Case Study Care by Volvo UK 2020Documento1 paginaOB Case Study Care by Volvo UK 2020Anima AgarwalNessuna valutazione finora

- Electronic Parts Catalog - Option Detail Option Group Graphic Film Card DateDocumento2 pagineElectronic Parts Catalog - Option Detail Option Group Graphic Film Card DatenurdinzaiNessuna valutazione finora

- ALTS150-12P Datasheet1Documento2 pagineALTS150-12P Datasheet1mamloveNessuna valutazione finora

- William Ury Power of A Positive No Bantam - 2007Documento227 pagineWilliam Ury Power of A Positive No Bantam - 2007Tam Jeopardy100% (1)

- Aicte Internship Approval Pending 1Documento7 pagineAicte Internship Approval Pending 1Anisha KumariNessuna valutazione finora

- Schmidt Hammer TestDocumento5 pagineSchmidt Hammer Testchrtrom100% (1)

- T54125ADocumento64 pagineT54125ARaúl FroddenNessuna valutazione finora

- JCPS School Safety PlanDocumento14 pagineJCPS School Safety PlanDebbie HarbsmeierNessuna valutazione finora

- Chapter 3 - Methods of Circuit Analysis and Circuit TheoremsDocumento125 pagineChapter 3 - Methods of Circuit Analysis and Circuit TheoremsNaim NizamNessuna valutazione finora

- Program of ActivitiesDocumento2 pagineProgram of ActivitiesVon Limuel LopezNessuna valutazione finora

- DTS 600 GDO Installation ManualDocumento12 pagineDTS 600 GDO Installation Manualpiesang007Nessuna valutazione finora

- Sop GC6890 MS5973Documento11 pagineSop GC6890 MS5973Felipe AndrinoNessuna valutazione finora