Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bayfield PDF

Caricato da

ruribev2000Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bayfield PDF

Caricato da

ruribev2000Copyright:

Formati disponibili

Report to:

BAYFIELD VENTURES CORP.

BURNS BLOCK NATIONAL

INSTRUMENT 43-101 COMPLIANT

TECHNICAL REPORT

JANUARY 2014

Prepared by

Cliff Duke P. Eng.

Date January 14, 2014

RiverbendGeologicalServicesInc.

Box 15 Group 310 RR#3, Beausejour, Manitoba R0E 0C0

Phone: 204-265-3338

RiverbendGeologicalServicesInc.

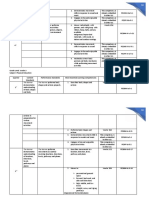

R E V I S I O N H I S T O R Y

REV.

NO

ISSUE DATE PREPARED BY

AND DATE

REVIEWED BY

AND DATE

APPROVED BY

AND DATE

DESCRIPTION OF REVISION

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. i

Burns Block NI 43-101 Compliant Technical Report January 2014

T A B L E O F C O N T E N T S

1.0 SUMMARY .......................................................................................................................... 8

2.0 INTRODUCTION AND TERMS OF REFERENCE ............................................................ 10

2.1 INTRODUCTION ................................................................................................................... 10

2.2 TERMS OF REFERENCE ....................................................................................................... 10

2.3 SOURCES OF INFORMATION ................................................................................................. 10

2.4 SITE VISIT ........................................................................................................................... 11

2.5 UNITS & CURRENCY ............................................................................................................ 11

3.0 RELIANCE ON OTHER EXPERTS ................................................................................... 12

4.0 PROPERTY DESCRIPTION AND LOCATION ................................................................. 13

4.1 LOCATION ........................................................................................................................... 13

4.2 MINERAL DISPOSITIONS ...................................................................................................... 15

4.3 TENURE RIGHTS ................................................................................................................. 15

4.4 RESOURCES, RESERVES, DEVELOPMENT AND INFRASTRUCTURE .......................................... 16

4.5 LEGAL SURVEY ................................................................................................................... 16

4.6 ENVIRONMENTAL LIABILITIES ............................................................................................... 16

4.7 PERMITS ............................................................................................................................. 16

5.0 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND

PHYSIOGRAPHY .............................................................................................................. 17

5.1 ACCESS .............................................................................................................................. 17

5.2 LOCAL RESOURCES ............................................................................................................ 17

5.3 CLIMATE ............................................................................................................................. 17

5.4 PHYSIOGRAPHY .................................................................................................................. 17

6.0 HISTORY ........................................................................................................................... 19

7.0 GEOLOGICAL SETTING & MINERALIZATION ............................................................... 21

7.1 REGIONAL GEOLOGY........................................................................................................... 21

7.2 LOCAL GEOLOGY ................................................................................................................ 22

7.3 PROPERTY GEOLOGY .......................................................................................................... 24

7.3.1 PROPERTY ROCK UNITS ...................................................................................................... 24

7.3.2 ALTERATION OF ROCK UNITS ............................................................................................... 28

7.3.3 VEINS AND VEINLETS ........................................................................................................... 30

7.4 MINERALIZATION ................................................................................................................. 31

8.0 DEPOSIT TYPE................................................................................................................. 33

9.0 EXPLORATION ................................................................................................................. 34

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. ii

Burns Block NI 43-101 Compliant Technical Report January 2014

9.1 AIRBORNE GEOPHYSICS ...................................................................................................... 34

9.2 DIAMOND DRILLING ............................................................................................................. 38

10.0 DRILLING .......................................................................................................................... 39

10.1 RAINY RIVER RESOURCES ................................................................................................... 39

10.2 BAYFIELD VENTURES .......................................................................................................... 39

11.0 SAMPLE PREPARATION, ANALYSIS & SECURITY ...................................................... 40

11.1 SAMPLE PREPARATION AND ASSAYING ................................................................................ 40

11.2 QUALITY ASSURANCE & QUALITY CONTROL ......................................................................... 41

11.2.1 RAINY RIVER RESOURCES ................................................................................................... 41

11.2.2 BAYFIELD ............................................................................................................................ 43

11.3 SECURITY ........................................................................................................................... 52

12.0 DATA VERIFICATION ...................................................................................................... 53

13.0 MINERAL PROCESSING & METALURGICAL TESTING ................................................ 55

14.0 MINERAL RESOURCE ESTIMATES ................................................................................ 56

14.1 DEFINITIONS ....................................................................................................................... 56

14.2 EXPLORATORY DATA ANALYSIS ........................................................................................... 57

14.2.1 ASSAYS .............................................................................................................................. 58

14.3 BULK DENSITY .................................................................................................................... 61

14.4 GEOLOGICAL INTERPRETATION ............................................................................................ 61

14.5 SPATIAL ANALYSIS .............................................................................................................. 62

14.5.1 CAPPING ............................................................................................................................. 62

14.5.2 COMPOSITES....................................................................................................................... 63

14.5.3 VARIOGRAPHY ..................................................................................................................... 66

14.6 RESOURCE BLOCK MODEL .................................................................................................. 67

14.7 INTERPOLATION PLAN .......................................................................................................... 68

14.8 MINERAL RESOURCE TABULATION ....................................................................................... 69

14.9 BLOCK MODEL VALIDATION ................................................................................................. 70

15.0 MINERAL RESERVE ESTIMATES ................................................................................... 73

16.0 MINING METHODS ........................................................................................................... 74

17.0 RECOVERY METHODS .................................................................................................... 75

18.0 PROJECT INFRASTRUCTURE ........................................................................................ 76

19.0 MARKET STUDIES & CONTRATCS ................................................................................ 77

20.0 ENVIRONMENTAL STUDIES, PERMITS, & SOCIAL OR COMMUNITY IMPACTS ........ 78

21.0 CAPITAL & OPERATING COSTS .................................................................................... 79

22.0 ECONOMIC ANALYSIS .................................................................................................... 80

23.0 ADJACENT PROPERTIES ............................................................................................... 81

24.0 OTHER RELEVANT DATA & INFORMATION ................................................................. 82

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. iii

Burns Block NI 43-101 Compliant Technical Report January 2014

25.0 INTERPRETATION & CONCLUSIONS ............................................................................ 83

26.0 RECOMMENDATIONS ..................................................................................................... 84

27.0 DATE & SIGNATURE PAGE ............................................................................................ 86

CERTIFICATE ................................................................................................................................ 87

REFERENCES ............................................................................................................................... 89

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. iv

Burns Block NI 43-101 Compliant Technical Report January 2014

L I S T O F T A B L E S

Table 14-1 Resource estimate search ellipse parameters ......................................................... 68

Table 14-2 Mineral resource estimate tabulation ...................................................................... 69

Table 14-3 Resource estimate comparison between OK and ID .............................................. 70

Table 26-1 Proposed diamond drill program ............................................................................ 84

L I S T O F F I G U R E S

Figure 4-1 Property location ...................................................................................................... 14

Figure 4-2 Map of patented claim location (from OGSEarth) ..................................................... 15

Figure 5-1 Burns Block Physiography ...................................................................................... 18

Figure 7-1 Regional geology ..................................................................................................... 22

Figure 7-2 Idealized lithologic sequence ................................................................................... 24

Figure 7-3 Property geology ...................................................................................................... 26

Figure 7-4 Typical mineralization, sulfides in sericitized dacite, local quartz carbonate veining.

.................................................................................................................................................. 32

Figure 9-1 VTEM B-Field Z component profiles........................................................................ 36

Figure 9-2 VTEM B-Field Z component channel 38 ................................................................... 37

Figure 11-1 Repeat assay correlation of Rainy River drill core ................................................. 42

Figure 11-2 Bayfield laboratory repeat assays .......................................................................... 43

Figure 11-3 Bayfield duplicate sample program results ............................................................ 44

Figure 11-4 Standard OREAS 2Pb performance ....................................................................... 45

Figure 11-5 Standard OREAS 4Pb performance ....................................................................... 45

Figure 11-6 Standard OREAS 5Pb performance ...................................................................... 46

Figure 11-7 Standard OREAS 6Pc performance ...................................................................... 46

Figure 11-8 Standard OREAS 15d performance ...................................................................... 47

Figure 11-9 Standard OREAS 15g performance ...................................................................... 47

Figure 11-10 Standard OREAS 15h performance .................................................................... 48

Figure 11-11 Standard OREAS 15f performance ..................................................................... 48

Figure 11-12 Standard OREAS 16a performance .................................................................... 49

Figure 11-13 Standard OREAS 52Pb performance .................................................................. 49

Figure 11-14 Standard OREAS 53Pb performance .................................................................. 50

Figure 11-15 Standard OREAS 60b performance .................................................................... 50

Figure 11-16 Standard OREAS 61d performance .................................................................... 51

Figure 11-17 Standard OREAS H3 performance ...................................................................... 51

Figure 12-1 Duplicate core samples collected by Riverbend vs. original assays ...................... 54

Figure 14-1 Sample Au assay population descriptive statistics ................................................ 59

Figure 14-2 Sample Ag assay population descriptive statistics ................................................ 60

Figure 14-3 Core density measurement descriptive statistics .................................................. 61

Figure 14-4 Core sample lengths ............................................................................................. 64

Figure 14-5 Comparison of composite grades with sample grades inside the wireframe ......... 65

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. v

Burns Block NI 43-101 Compliant Technical Report January 2014

Figure 14-6 Correlogram parameters used for resource estimation ......................................... 66

Figure 14-7 Resource fence plot by level ................................................................................. 71

Figure 14-8 Resource fence plot by column ............................................................................. 72

Figure 14-9 Resource fence plot by row ................................................................................... 72

Figure 23-1 New Gold's land position in relation to the Burns Block ......................................... 81

Figure 24-1 Burns Block location relative to New Gold's proposed development of the Rainy

River deposit.............................................................................................................................. 82

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. vi

Burns Block NI 43-101 Compliant Technical Report January 2014

L I S T O F A P P E N D I C E S

APPENDIX A STATISTICAL ANALYSIS

APPENDIX B PROPOSED DIAMOND DRILL PROGRAM

APPENIDX C SITE VISIT

APPENDIX D LABORATORY CERTIFICATES

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. vii

Burns Block NI 43-101 Compliant Technical Report January 2014

G L O S S A R Y

UNI TS OF MEASURE

Centimetre ....................................................................................................................................... cm

Cubic centimetre .............................................................................................................................. cm

3

Degrees Celsius ............................................................................................................................... C

Dollar (American) ............................................................................................................................. US$

Dollar (Canadian) ............................................................................................................................. Cdn$

Formazin Turbidity Unit .................................................................................................................... FTU

Gram ................................................................................................................................................ g

Grams per Cubic Centimetre ........................................................................................................... g/cm

3

Hectare (10,000 m

2

) ......................................................................................................................... ha

Kilometre .......................................................................................................................................... km

Kilovolt ............................................................................................................................................. kV

Metre ................................................................................................................................................ m

Millimetre .......................................................................................................................................... mm

Million tonnes ................................................................................................................................... Mt

Percent............................................................................................................................................. %

Specific gravity ................................................................................................................................. SG

Tonne (1,000 kg) .............................................................................................................................. t

ACRONYMS AND ABBREVI ATI ONS

Quarry Lease ................................................................................................................................... QL

Mineral Lease .................................................................................................................................. ML

North ................................................................................................................................................ N

East .................................................................................................................................................. E

South ............................................................................................................................................... S

West ................................................................................................................................................. W

Silica ................................................................................................................................................ SiO

2

Gold ................................................................................................................................................. Au

Silver ................................................................................................................................................ Ag

Copper ............................................................................................................................................. Cu

Lead ................................................................................................................................................. Pb

Ordinary Kriging ............................................................................................................................... OK

Nearest Neighbor ............................................................................................................................. NN

Inverse Distance .............................................................................................................................. ID

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 8

Burns Block NI 43-101 Compliant Technical Report January 2014

1 . 0 S U M M A R Y

Bayfield Ventures Inc. ("Bayfield") asked Riverbend Geological Services Inc.

("Riverbend") to model the deposit, and estimate the Mineral Resource on the Burns

Block, as outlined by their extensive recent diamond drill programs.

Drilling on the Burns Block property has confirmed the presence of gold and silver.

Both shallow and deeper (below potential open pit parameters) intercepts reported by

Bayfield Ventures along the strike extension of New Gold's Rainy River deposit

clearly shows that high grade gold and silver mineralization cross the claim boundary

onto the Burns Block. New Gold is at the feasibility study stage in developing its

Rainy River deposit.

Mineralization on the Burns Block is contained within a package of south dipping,

strongly foliated, sheared and locally folded dacitic volcanic rock. Pervasive sericite-

silica alteration is characteristic of the zone. The foliation is near coincident with the

strike and dip of the lithologies. Gold and silver grade appears to be strongly

influenced by proximity to the margins of strong sericitic alteration within the shear

system. The zones strike at 120 degrees and dip at around 60 degrees to the

southwest on the Burns Block property.

The higher grade mineralization is always accompanied by sulfide mineralization,

predominantly dark brown sphalerite, chalcopyrite, pyrite, galena and arsenopyrite.

Gold and silver mineralization are invariably found together.

Riverbend used the diamond drill hole database for the Burns Block to estimate that

the Burns Block contains an indicated resource of 1.3 million tonnes grading

1.4 g/t Au, and 16.0 g/t Ag. An additional 3.0 million tonnes of inferred resources

grading 1.6 g/t Au and 16.3 g/t Ag have also been identified. Resources have been

classified as amenable to open pit mining if they lie within 500m of the surface, while

those at greater depths will require an underground mining method.

The Ag content adds significant value to the Burns Block. In order to include this

value, RIverbend has added the Ag value to the Au value using the formula:

AuEQ = Au grade + (Ag grade / 60)

The lower cutoff grades for the deposit have been determined from the AuEQ (Au

equivalent) grade.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 9

Burns Block NI 43-101 Compliant Technical Report January 2014

Indicated Resources

Cutoff Tonnes Au grade Ag Grade Au Ag

AuEQ (g/t) T x 1000 g/t g/t oz oz

Pit 0.35 1,253 1.0 14.7 39,928 591,954

UG 2.5 79 7.9 37.0 20,029 93,716

Total Indicated 1,332 1.4 16.0 59,957 685,670

Inferred Resources

Cutoff Tonnes Au grade Ag Grade Au Ag

AuEQ (g/t) T x 1000 g/t g/t oz oz

Pit 0.35 2,788 1.2 14.4 104,121 1,293,763

UG 2.5 195 7.4 43.0 46,475 269,708

Total Inferred 2,983 1.6 16.3 150,596 1,563,470

Riverbend recommends that an additional diamond drill program be conducted on

the property to further evaluate the potential mineralization in the central part of the

Burns Block. This would best be accomplished by drilling 6 diamond drill holes

targeting the area about 450m below surface, on a 50m horizontal spacing. This

would require 2,970m of drilling and is expected to cost $445,500.

A second series of 4 holes has also been proposed near section 427000E to test

possibility that the high grade Intrepid zone extends toward the surface, to the west.

This part of the program would require 2,070m of drilling and is expected to cost

$310,500.

Riverbend has also proposed 4 additional holes at depth in the western part of the

claim. These holes would help fill in large holes in the model that have not been

assigned a grade, due to a lack of data. This part of the program would require

2,220m of drilling and is expected to cost $333,000

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 10

Burns Block NI 43-101 Compliant Technical Report January 2014

2 . 0 I N T R O D U C T I O N A N D T E R M S O F

R E F E R E N C E

2.1 I NT RODUCT I ON

Riverbend Geological Services Inc. ("Riverbend") was retained by Bayfield Ventures

Corp. ("Bayfield") to define a National Instrument 43-101 ("NI 43-101") compliant

Mineral Resource estimate and NI 43-101 Technical Report for their Burns Block

property near Rainy River, Ontario, Canada. The estimate and report are in

compliance with the standards of the Canadian Securities Administrators' NI 43-101

and the definitions of the Council of the Canadian Institute of Mining, Metallurgy and

Petroleum ("CIM").

2.2 TERMS OF REF ERENCE

Riverbend understands that Bayfield have completed about 103,044 m of surface

drilling on the Burns Block property, located near Rainy River, Ontario. The drill

program was directed at defining the extent and tenor of the gold-silver resource on

the property.

This NI 43-101 Technical Report is copyright protected, the copyright is vested in

Riverbend, and this report or any part thereof may not be reproduced in any form or

by any means whatsoever without the written permission of Riverbend.

Notwithstanding the foregoing, Riverbend hereby permits Bayfield to file this report

with securities regulators to support public disclosure of the Mineral Resource

estimate and for filing on SEDAR. Furthermore, Riverbend permits the report to be

used for a basis for project financings and in the preparation of a Preliminary

Assessment, should one be undertaken, and that part or all of the report may be

produced by Bayfield in any subsequent reports, with prior consent of Riverbend.

Riverbend was originally authorized to complete the Mineral Resource estimate and

NI 43-101 Technical Report by Mr. Don Huston, President, Bayfield Ventures Corp..

2.3 SOURCES OF I NF ORMAT I ON

To prepare this report, Riverbend relied on technical reports in government files,

publicly available filings on SEDAR, and additional material provided by Bayfield

Ventures Corp. These included information from Rainy River Resources Feasibility

study, and its technical associated reports. Riverbend has also referenced Bayfield's

Annual information Form ("AIF"). Riverbend was also provided with additional written

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 11

Burns Block NI 43-101 Compliant Technical Report January 2014

(in the form of reports and memos) and verbal data by Bayfield, as well as drill hole,

geology and assay data in digital format.

2.4 SI T E VI SI T

Mr. Cliff Duke, P.Eng., President or Riverbend Geological Services Inc. visited the

Property on 13th of June, 2013 to review logging and sampling procedures, review

core from numerous drill holes from the drill campaign, and collect independent

samples and other pertinent data from site personnel.

2.5 UNI T S & CURRENCY

Throughout this report, measurements are in metric units, unless the historic context

dictates the use of Imperial units is appropriate. Tonnages are shown as tonnes ("t",

being 1,000 kg), linear measurements as centimetres ("cm"), cubic centimetres

("cm

3

"), millimetres ("mm"), metres ("m"), or kilometres ("km"), and precious metal

values as grams ("g"), grams per tonne gold ("g Au/t"), and million tonnes ("Mt").

Currency amounts are quoted in Canadian dollars unless otherwise noted.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 12

Burns Block NI 43-101 Compliant Technical Report January 2014

3 . 0 R E L I A N C E O N O T H E R E X P E R T S

Riverbend prepared this study using the resource materials, reports and documents

as noted in the text and "References" at the end of this report.

Riverbend has relied upon Mr. Robert Marvin P. Geo. and VP Exploration for

Bayfield, for the detailed geology description of the Burns Block.

For this report Riverbend has relied upon the ownership information provided by

Bayfield. Riverbend has verified the claim documentation in the Province of Ontario

Claims Registry, but Riverbend has not researched the property title of the patented

claims.

Riverbend has relied on statements made by Rainy River Resources and New Gold

on their websites and public reports for the description of their Rainy River property

and its proposed development.

Riverbend has relied on Bayfields representation that there are no current needs for

First Nations community consultation or agreements and that no environmental

permits or compliance requirements are in default or that will be required to continue

exploration of the property as recommended herein.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 13

Burns Block NI 43-101 Compliant Technical Report January 2014

4 . 0 P R O P E R T Y D E S C R I P T I O N A N D

L O C A T I O N

4.1 LOCAT I ON

The Burns Block is located around 48.83N 94.00W, about 48 kilometres north-west

of the town of Fort Frances, 34 kilometers south of Nestor Falls, and 45 kilometres

north-east of the town of Rainy River, Ontario. The Property lies entirely within

Richardson Township, west of highway 101. The Property is accessed off of

highway 71 by Teeple Road, a municipal gravel road.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 14

Burns Block NI 43-101 Compliant Technical Report January 2014

Figure 4-1 Property location

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 15

Burns Block NI 43-101 Compliant Technical Report January 2014

4.2 MI NERAL DI SPOSI T I ONS

The Burns Block consists of a single patented claim. The claim lies in surveyed

territory and is described as the north half of Lot 4 Concession 1 of Richardson

Township, Rainy River District of Ontario. The claim is about 32.4 ha in size, and is

subject to a 2% NSR.

Bayfield optioned the Burns Block on September 26, 2007. The agreement allowed

Bayfield to earn a 100% interest the patented mineral rights (totaling 80 acres)

located in Richardson Township, Ontario, known as Parcel #15916. As

consideration, Bayfield was required to make cash payments of $145,000 and issue

340,000 shares over a four year period. The property is subject to a 2% NSR of

which Bayfield may purchase one-half (1%) of for the sum of $1,000,000. Bayfield

completed its payments for the option on the property by April 2011.

Figure 4-2 Map of patented claim location (from OGSEarth)

4.3 TENURE RI GHT S

Surface rights to the property are owned by New Gold Inc. This does not inhibit

exploration, but work must be completed in compliance with New Gold's health and

safety guidelines.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 16

Burns Block NI 43-101 Compliant Technical Report January 2014

4.4 RESOURCES, RESERVES, DEVEL OPMENT AND I NF RAST RUCT URE

The property is surrounded on all sides by the Rainy River gold project, owned by

New Gold Inc. (TSX:NGD). At the time of this report, New Gold had recently

purchased the gold project from Rainy River Resources Ltd.. Rainy River Resources

has published a Feasibility Study for the project that indicated that project

development can proceed under present economic conditions. Rainy River claimed

"a NI43-101 compliant gold resource of 1.2 Moz Measured, 5.0 Moz indicated

and 2.3 Moz inferred. Our April 2013 Feasibility Study envisions average annual

production of 326,000 of gold and 494,000 ounces of silver over the first 10 years of

a combined open pit and underground mining operation. Cash costs average

US$486 per ounce in this period, with mill head grades averaging 1.46 g/t."

The property is readily accessed by municipal gravel roads that connect to highways

11 and 71. The towns of Fort Frances, Rainy River, and Nestor Falls are the nearest

communities.

4.5 LEGAL SURVEY

The patented claim that comprises the Burns Block has been surveyed.

4.6 ENVI RONMENT AL LI ABI L I T I ES

The Burns Block lies in a "green fields" exploration camp, and there has been no

historical mining on the property.

4.7 PERMI T S

No additional permits are required at this time to complete the proposed exploration

program.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 17

Burns Block NI 43-101 Compliant Technical Report January 2014

5 . 0 A C C E S S I B I L I T Y , C L I M A T E , L O C A L

R E S O U R C E S , I N F R A S T R U C T U R E A N D

P H Y S I O G R A P H Y

5.1 ACCESS

The town of Fort Frances is located on highway 11, about 290 km west of Thunder

Bay, Ontario, and 295 km south east of Winnipeg, Manitoba. Highway 71 leads

north from Fort Frances to Kenora on the Trans-Canada highway. The property is

accessed off of highway 71 on Teeple Road, a municipal gravel road. The site has

year round access.

5.2 LOCAL RESOURCES

The town of Fort Frances has a population of 7,952 (2011 census). Three smaller

towns, Emo (pop. 1,252 - 2011 census), Rainy River (pop. 842 - 2011 census)and

Nestor Falls (pop. 290 - 2006 census) are also within 50km of the site. There is a

rich mining heritage in the area going back to the 1895, when a gold mine opened on

Regina Bay near Nestor Falls. Iron mining in Atikokan stopped in 1980, leaving

behind much of the infrastructure necessary to support a mining operation, including

power lines, railways. Osisko is currently developing it's Hammond Reef deposit

near Atikokan.

Hydro-electricity is produced at several sites thru out north-western Ontario, and the

provincial electrical power grid runs near the property. A thermal-electric power plant

east of Fort Frances is also available to supply the area. Forestry is the major

industry in the area, and local service for heavy equipment is readily available.

5.3 CL I MAT E

Climate data for Fort Frances, as recorded by Environment Canada, has been used

for this report. Temperatures are highest in July, averaging 19.6C, and lowest in

January, averaging -16.2C. Total annual precipitation averages 580 mm, with 150

mm falling as snow between October and May.

5.4 PHYSI OGRAPHY

The Burns Block is located on the margin of the Canadian Shield, at an elevation of

about 381 m above sea level ("ASL"). The terrain is gently hilly, and the claim largely

covers one of the local bedrock outcrops, between a large swamp to the west, and

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 18

Burns Block NI 43-101 Compliant Technical Report January 2014

farmland to the east. The bedrock is generally covered with glacial till, silt and clay.

The property is forested predominantly with pine, birch and poplar.

Figure 5-1 Burns Block Physiography

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 19

Burns Block NI 43-101 Compliant Technical Report January 2014

6 . 0 H I S T O R Y

Gold mining in the area dates back to 1894, when the Regina Mining Company set

out to explore the Nestor Falls area. Other exploration in the area by individual

prospectors dates back to the 1930's, but the documented exploration in the Ministry

of Natural Resources assessment files only dates back to1967. Exploration programs

are known to have taken place on private land, however a record of assessment was

not filed.

In 1967 copper was reported in a water well hole drilled on the western shore of Off

Lake. Noranda Exploration Company staked claims around the discovery and

conducted some mapping, geophysics, and diamond drilling. The claims were

subsequently allowed to lapse.

In 1971 International Nickel Company of Canada Limited conducted regional airborne

and follow-up ground geophysics. There is no record of this work, but INCO filed a

report on two diamond drill holes in Richardson Township in 1973. One of these

holes encountered anomalous gold values, but the exact location of this hole is not

known.

In 1972 Hudson's Bay Exploration and Development carried out airborne geophysical

surveys, followed by claim staking and ground geophysics programs. In 1973, 54

diamond drill holes were bored to test 42 E.M. conductors. Base metals were likely

the target of this exploration but none of the work was filed for assessment purposes.

Considerable interest was generated in the area west of Finland following the release

of the O.G.S. publication "Gold Grains in Rotosonic Drill Core and Surface Samples

(1987-1988), Map No. P.3140. The following year, 1989, Mingold Resources Inc.

staked 85 claims and optioned property from 12 landowners in three separate blocks

in Richardson, Tait, Pattullo, and Sifton townships. From 1989 to 1990 Mingold

carried out a geological mapping, ground geophysics, and sampling program of the

glacial drift.

In 1992 Nuinsco optioned patented lands centred on Richardson Township and the

Menary Township gold occurrences of Kings Bay Gold Corporation from Western

Troy Resources. This ultimately led to the discovery of the "17 Zone" in 1994. In

2005, Rainy River acquired a 100% interest in the project from Nuinsco.

The first drilling on the Burns Block was by Rainy River Resources (RR) in 2008

when they drilled 10 holes that were either collared on the Burns or drilled through

portions of the property. Hole NR08283 was one of the holes collared 100 meters S

of the SW corner of the Burns Block and drilled north onto the Burns Block. This hole

intersected strong gold mineralization from 501.5 to 507.5 meters down hole, on the

Burns. The 6 meter interval returned 5.76 g/t Au and 6.0 g/t Ag. This hole is

considered the discovery hole on the Burns Block.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 20

Burns Block NI 43-101 Compliant Technical Report January 2014

The drilling by RR was done under an option agreement between Bayfield Ventures

and RR. Bayfield had come to agreement for the purchase of the mineral rights for

the Burns Block in 2007 directly from the Burns brothers and then optioned the

ground to RR. RR failed to complete the required expenditures under the agreement

and the property was "returned" to Bayfield.

In December 2010, Geotech Ltd. carried out a helicopter-borne geophysical survey

over the Burns Block and surrounding areas.

Following a brief reconnaissance drill program in Jan and March 2010, Bayfield

began an aggressive drilling program in May 2010. The property was extensively

drilled till November 2013.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 21

Burns Block NI 43-101 Compliant Technical Report January 2014

7 . 0 G E O L O G I C A L S E T T I N G &

M I N E R A L I Z A T I O N

7.1 REGI ONAL GEOL OGY

The Burns Block lies near the southern margin of the Wabigoon Sub province, of the

Superior province. The Wabigoon sub province is composed of meta-volcanic and

meta-sedimentary rocks ranging from 3 to 2.71 billion years old. These units have

been intruded by 3 to 2.69 billion year old granitic batholiths, gabbroic sills and

stocks. Greenstone belts of the Wabigoon province are mostly low metamorphic

grade. Geochemical and geochronological evidence suggests that the large,

elliptical, internal batholiths are penecontemporaneous and consanguineous with the

surrounding greenstones. Post-tectonic stocks cut the granitic areas and greenstone

belts.

The Wabigoon sub province is divided into 3 parts. The Western Wabigoon area,

host to the Burns Block, is a series of interconnected greenstone belts surrounding

lobate granitoid batholiths. The greenstone belts are made up of 60-80% meta-

volcanic rocks. Volcanic sequences comprise of ultramafic and mafic, to felsic rocks

and can be grouped into 2 categories: 1) basal, laterally extensive, mafic

metavolcanic rocks; subordinate mafic metavolcanic units occupy stratigraphically

higher positions; and 2) less thick, laterally limited, diverse assemblages of

intermediate to felsic volcanic rocks that commonly overlie mafic metavolcanic

assemblages. Absolute age data and mapping have demonstrated the presence of

thrust-based duplication of strata.

Sedimentary units are typically clastic rocks of alluvial fan-fluvial, re-deposited

(turbidite) and rare platformal facies, with minor chemical metasedimentary rocks,

predominantly oxide facies iron formation.

Felsic to intermediate volcanism occurred between 2745 to 2711 Ma, coeval with the

early, marginal phases of the internal batholiths. The metavolcanic units are overlain

by synorogenic resedimented metasedimentary units or less commonly by alluvial

fan-fluvial metasedimentary rocks. Deformation and syntectonic to post tectonic

plutonism occurred in the interval 2711 to 2685 Ma.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 22

Burns Block NI 43-101 Compliant Technical Report January 2014

Figure 7-1 Regional geology

7.2 LOCAL GEOL OGY

A WNW-ESE trending belt of greenschist facies, supracrustal rocks forms the core of

the Rainy River Gold District. This belt is composed of metavolcanic rocks,

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 23

Burns Block NI 43-101 Compliant Technical Report January 2014

metamorphosed hypabassal intrusive rocks and metasedimentary units including

both clastic and chemical type packages. This discrict to regional scale scale rock

package dips steeply south at approximately 60

o

.The facing direction of the rock

metavolcanic and metasedimentary rock package has not been definitely determined

but no robust evidence of overturning has been documented.

This lithologically complex sequence is bounded to the north by an upper amphibolite

grade meta-igneous terrain and to the south by granulite facies igneous and

metasedimentary gneisses.

This belt of greenschist grade supracrustal rock is widely foliated, microfolded and

sheared. The WNW-ENE trending, south dipping sequence of subracrustal rocks in

known core of the Rainy River gold district is bent sharply to the NNE in a position

approximately 200 meters east of the eastern boundary of the Burns Block. The

NNE trend of the belt then passes into the Off Lake area to east of Highway 71. To

the west, the WNW trend is truncated along the Pinewood fault in position near

Deerlock.

Distinctive, cross cutting, felsic intrusions into the greenstone belt are known from

both OGS field mapping and from drill intercepts. Two, N-S elongate, granodorite

intrusions occur east of the Burns Block, the Black Hawk and Finland stocks (Figure

7.1). These stocks are likely the cause of Kspar-Magnetite alteration in 0.5 to 1

kilometer haloes in the surrounding greenstones.

At present, the cumulative exploration by Nunisco, Rainy River Resources and

Bayfield Ventures has resulted in the identification of numerous well gold-silver

mineralized positions along approximately 4.5 kilometers of the quite linear WNW-

ESE trending portion of the greenschist facies, supracrustal rock package.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 24

Burns Block NI 43-101 Compliant Technical Report January 2014

Figure 7-2 Idealized lithologic sequence

7.3 PROPERT Y GEOL OGY

The geology of the Burns Block has been determined largely from diamond drill

holes, regional field mapping and airborne geophysics. In particular, the data from

the detailed logging of core from drilling concentrated in the western and eastern

portions of the property is the exclusive source of the information on property rock

type, structure, alteration and veining contained in the following sections of this

report.

7. 3. 1 PROPERTY ROCK UNI TS

The Burns Block is dominantly covered by an felsic to intermediate hypabassal

intrusive and related fragmental volcanics. In the NE portion of the property, a series

of well hornfelsed to skarnified mafic volcaniclastic sedimentary units are interlayered

with the dominant dacite series of rocks. Glacial till conceals the bedrock in the

western portion of the property and in several east-west trending topographic lows

which transect the property.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 25

Burns Block NI 43-101 Compliant Technical Report January 2014

From south to north, moving down dip through the main lithologic layering and

foliation of the property, the following sequence of rock units occur (Figure 7-2):

1. Upper Dacite Unit. This unit is composed of rounded quartz eye and plagioclase

phyric felsic to intermediate hypabyssal intrusions and related fragmental flows, tuffs

or flow breccias.

2. A complex, interlayered sequence of rare rounded clast, polymictic

conglomerate units, thick, well layered mafic volcaniclastic rocks, thin, 1 to 4 meters,

horizons of finely bedded and strongly sheared graphitic argillites and interbedded

massive pyrite-pryhotite-chert breccias. Near the base of this sequence, multi-meter

thick dacite porphyry units are interlayered with the mafic volcaniclastic units. All

lithological contacts in this lower transition zone are sheared, more strongly foliated

than surrounding rocks, and exhibit slight angular unconformity. The thick mafic

metasedimentary units are highly persistent along strike, but the minor conglomeratic

and graphitic argillite horizons are discontinuous and difficult to reliably correlate

along strike.

3. Lower Dacite Unit. This unit is composed of rounded quartz eye and plagioclase

porphyries of felsic to intermediate composition. These porphyritic units are likely

hypabyssal intrusions and are interlayered with felsic to intermediate fragmental

flows, tuffs or flow breccias. The upper portion of this section contains distinctive,

well layered, siliceous sedimentary units up to 5 meters thick. Lower in the unit,

mafic dikes occur, dominantly lying parallel to the main foliation. Fragmental units

occur within the massive quartz eye dacite unit but are rare and highly discontinuous

along strike. Foliation intensity increases with depth and becomes medium to strong

and persistent approximately 150 meters below the contact with the overlying mafic

dominated rock package. The strongly foliated portion of this unit is widely

mineralized at Burns and is informally called the main zone

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 26

Burns Block NI 43-101 Compliant Technical Report January 2014

Figure 7-3 Property geology

STRUCTURAL FACI NG DI RECTI ON

Drill core from well bedded lithologies throughout the rock section at Burns have

been examined for the presence of graded beds for the purpose of determining

facing direction, or tops. The siliceous sediments within upper portion of the Lower

Dacite unit, in particular, contain some very well developed rhythmic bedding with

very nice individual cm-scale layers. These layers show evidence of both normal

and reverse grading based solely on mineral grain size.

However, all the reverse graded beds are composed of lower gritty sediments that

reverse grade upward into coarser grained pink garnet grains. These garnets appear

to be porphyroblastic crystal growths, not original sedimentary grains. These reverse

graded beds thus appear to be the result of grain size reversal by alteration, not

overturned graded beds.

While the facing direction at Burns has been conclusively answered, the presence of

normal graded beds that do not appear to be the result of alteration or

metamorphism, along with the absence of reliable reverse graded beds, strongly

suggests that the south dip of layered and foliated units at Burns represent steeply

dipping, non-overturned stratigraphy with tops to the south.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 27

Burns Block NI 43-101 Compliant Technical Report January 2014

FAULTI NG, FRACTURI NG, FOLI ATI ON AND SHEARI NG

Brittle, gouged faults at Burns are exclusively confined to the Lower Dacite unit. Cm-

scale, foliation parallel, gouge filled seams occur within the highly foliated portion of

the dacite and are seen in drill core consistently in this position from the west edge of

the property to the east edge. These gouged slip seams occur over very limited

intervals (<2 meters) and in close proximity to mineralization. These appear to be

late, small scale slips confined to limited portions of the highly foliated and sericite

altered Lower Dacite unit.

Well-developed fracture zones are rare at the Burns Block based on core logging

data and RQD data. Several holes near the southwest corner of the property,

including RR10-3 and RR11-1 do contain long intervals (>20 meters) of strongly

fractured rock. More limited fractures zones located below the main mineralized

zone occur in holes RR10-9 and RR10-10, both along the south boundary of the

property. RQD data from core holes in the eastern portion of the Burns property

show very consistent and remarkably non fractured rock, particularly in the lower

dacite unit including the mineralized zone.

Foliation development at Burns is seen in all rock types except for the mafic dike

rocks of the lower dacite unit and in rare granitic dikes intersected throughout the

established rock section. Foliation development is highly variable and is best

developed within the sericite altered lower dacite section and along the margins of

bull quartz veins and veining zones throughout the section.

Contacts between mafic volcaniclastic rocks and quartz eye dacite units in the lower

portion of the complex middle section are moderately to strongly foliated as are all

graphitic argillite sections seen in core on the property. Foliation is weak in less

altered portions of the quartz dacites and is locally hard to recognize in strongly

garnet-chlorite-biotite altered sections of the mafic metasedimentary units where

wavy alteration contacts appear to overprint foliation development.

Shearing of the entire greenstone rock package at Burns, excluding both mafic and

felsic dike sets, is evident from textural features in drill core. Features include

increased foliation and angular unconformities at lithologic contacts, ribboned

textures and discontinuity in fine bedding of graphitic argillite units and the local

presence of cm-scale sigmoidal and J-hook fold features within the strongly foliated

and sericite altered portions of the lower dacite unit.

FOLDI NG AND BRECCI ATI ON

Core logging results from the Burns property document evidence of mm, cm and dm-

scale folding in all rocks except the mafic and felsic dike sets. Folds of several

different forms are seen. Mm-scale crenulation folding of the primary foliation is

commonly seen in highly deformed wall rocks at the contact with bull quartz veins

and veining zones.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 28

Burns Block NI 43-101 Compliant Technical Report January 2014

Sheared ribbon fabrics contain abundant, tight, cm-scale folds developed in fine

laminated primary bedding. Complete dm-scale folds are rare. One example is

logged at 76.5 meters down hole in RR11-97 where a complete fold measuring 14

cm across is developed within foliated and crenulated dacite at a contact with a bull

quartz vein.

Both barren and mineralized, cm-scale quartz-carbonate-sulfide, veinlets are nearly

ubiquitously folded where intersected in drilling right across the Burns property.

These folds are highly asymmetric with long limbs trailing away from tight, bulbose

fold noses. Field orientations done on core by assuming a south dip of the main

foliation have consistently shown steep (55

o

to 65

o

) southwest oriented plunges for

the hinge lines of these folds.

Evidence of larger scale folding at Burns has been identified in the logging of foliation

fans occurring over 10 to 18 meters of core length. In RR13-11W4, the down hole

interval from 454.10 to 472.0 shows three complete swings of foliation angle from 15

o

to 60

o

to the core axis. These foliation fans could be result of the presence of multi-

meter-scale open folds or warps of the primary foliation.

Evidence for larger scale folds, in the 10 to >100 meter range, limb to limb, has not

been documented at Burns. No symmetrical repeats of lithology have been logged

and no large scale foliation fans with foliation reversal have been noted. In summary

it appears that folding at Burns consists of dominantly mm to cm scale asymmetric

folding that is likely related to deformation during foliation development.

Breccia textures in core are commonly logged at Burns. Short intervals, <0.5 meters,

of angular clast breccia are locally seen in quartz eye dacite units. These minor

zones usually have a calcite matrix. Wider zones of angular clast brecciation are

commonly seen within massive py-po-chert iron formation units in the central portion

of the Burns stratigraphy.

Rounded to sub rounded clast breccias are locally seen with high grade mineralized

zones of the lower dacite unit. In the bonanza grade interval of hole RR11-71,

oblong quartz eye dacite breccia clasts are surrounded by poly metallic sulfides,

carbonate minerals and locally abundant visible gold and electrum.

7. 3. 2 ALTERATI ON OF ROCK UNI TS

Bayfield has not under taken any focused, detailed studies of alteration of rock units

at the Burns property. Thus, determination of both precise mineralogy, and attempts

to separate the genesis of mineral assemblages, has not been attempted.

Determination of the separate effects of several known heat sources is largely

conjectural. During routine logging of drill core it is difficult to discern the

mineralogical changes effected by:

1. Early processes related to the largely igneous formation of the rock package;

2. Effects of later regional metamorphism;

3. Contact effects from intrusion of the Blackhawk stock and,

4. Alteration caused by hydrothermal fluids during mineralization.

Regardless of the exact heat source, robust alteration zones have been identified

during core logging at Burns and a strong case can be made for the presence of

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 29

Burns Block NI 43-101 Compliant Technical Report January 2014

alteration zoning from west to east across the property. Pyrite is an abundant

component of many of the alteration mineral assemblages documented at Burns.

The following well established alteration zones and trends have been documented

from detailed logging of core:

1. Sericite-Pyrite (

+

fuchsite) alteration of the strongly foliated main zone in the

lower dacite unit extends right across the Burns property but is stronger in the west

than in the east. Fuchsite occurs locally in strongly sericite altered fragmental

dacites as complete replacement of isolated clasts in the fragmental volcanic rock.

2. Silica-Pyrite alteration within the main foliation in the lower dacite is weak in the

west and becomes strong in the east. The strong sericite zone in the west becomes

a silica-sericite zone in the east.

3. Kspar-Epidote-Calcite-Magnetite alteration of the lower dacite unit is seen right

across the Burns property in a position above the main sericite to silica sericite

altered foliation zone. This alteration assemblage is weak and sporadic in the west

and is strong and persistent over 40 to 60 meters down hole in the east.

4. Chlorite-Sericite-Calcite-Pyrite alteration of both the upper dacite unit and

portions of the lower dacite unit has been documented across the property. This

alteration is composed of abundant chlorite-calcite-pyrite veinlets and foliation seams

cutting weakly sericite altered dacite. This alteration is best developed within the

lower dacite unit in a position between the Kspar-Epidote-Calcite-Magnetite zone and

the main sericite, or sericite silica zone.

5. Garnet-biotite-chlorite-silica-pyrite-pyrrhotite alteration of mafic volcaniclastic

sedimentary units is seen right across the Burns property and increases in intensity

and thickness from west to east. This skarnoid alteration varies from very garnet rich

alteration with wavy reaction front contacts that cross cut bedding and foliation, to a

finer grained, extremely hard, glassy hornfelse.

The documented alteration mineral assemblages at Burns together point to a trend of

increasing temperature from west to east across the block. The timing of the

development of these mineral assemblages has not been determined, either in a

relative or an absolute since. The overall pattern, however, does suggest that the

Blackhawk stock is a likely candidate as the heat source, and possibly in part the

fluid source for the observed alteration mineral assemblages at the Burns Block

property.

In particular, the Kspar-Epidote-Calcite-Magnetite assemblage that is best developed

in the eastern portion of the Burns property is very similar mineralogically to the

western margin of the stock where higher magnetite and much more abundant Kspar

occurrences when compared to examples from more central positions within the

stock. This thesis is supported by OGS and GSC data which indicate the stock

intruded post district scale metamorphism and deformation of the greenstone wall

rocks. This timing indicates that any changes to mineral assemblages in the wall

rocks surrounding the stock would over-print those from earlier regional to district

scale metamorphism as well as any primary alteration features resulting from

igneous or hydrothermal processes during formation of the rock sequence.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 30

Burns Block NI 43-101 Compliant Technical Report January 2014

7. 3. 3 VEI NS AND VEI NLETS

Economically important quartz-carbonate-sulfide-gold-silver veinlets swarms are one

of the vein related features documented through core logging at the Burns property.

The following vein and veinlet types have been identified:

1. Early bull quartz-chlorite-pyrite veins and veinlets. These veins (and

subordinate veinlets) are concentrated in the Lower portion of the lithologically

complex mafic metasedimentary section and in the upper portion of the lower dacite

unit but are seen locally in all rock types on the property. These veins are generally

massive bull quartz but locally have ribbon textures due to wispy stringers of included

green chlorite. These veins are nearly universally barren of precious metal content

even in rare instances where several percent of sphalerite and chalcopyrite have

been noted. Highly foliated and crenulated wall rocks are a common feature of these

veins and veinlets. Bull quartz veinlets are highly deformed and discontinuous. Both

of these facts suggest the timing of the bull quartz veining event was early and very

likely pre foliation development.

2. Chlorite-carbonate-pyrite veinlets and foliation seams. These cm-scale veinlets

and foliation seams are concentrated in the lower dacite unit above the main sericite

altered foliation zone. These are better developed in the western portion of the

property where they occur above and below the sericite foliation zone. The chlorite

in the veinlets and seams is a medium to bright green color and is finely mixed with

fine grained carbonate, silica and pyrite.

3. Epidote-Kspar-Calcite-Pyrite veinlets and fracture fills. These veinlets and local

fracture fills occur in the Kspar-Epidote-Calcite-Magnetite alteration assemblage

which is located in the upper portion of the lower dacite unit.

4. Magnetite veins and veinlets. Very fine grained magnetite veins and veinlets

occur locally within skarnified portions of the mafic volcaniclastic sedimentary

sequence. These are clear cross cutting veins and veins, not bedded features. They

are seen rarely in the western Burns property but have been logged in the vast

majority of holes in the eastern Burns area. Even in the east though, they are a

minor component of the mafic section and never exceed 10 cm in width.

5. Sphalerite stringer veinlets. Sphalerite stringer veinlets are commonly seen in

the sericite altered main foliation zone within the lower dacite unit at Burns. These

stringers are highly deformed and discontinuous and are of mm to cm scale.

6. Quartz-carbonate-sphalerite-pyrite-galena-chalcopyrite-arsenopyrite-gold-

electrum-silver veinlets. These strongly mineralized veinlets are highly deformed and

discontinuous and are of mm to dm scale. These veinlets are highly concentrated

within the strongly sericite and sericite-silica altered, lower dacite unit and are

associated with the majority of assay >10 g/t gold on the property. Local, narrow

occurrences of these veinlets have been logged in sheared contact zones between

mafic volcaniclastic units and quartz eye dacite sections well above the main

mineralized zone. These base metal precious bearing veinlets have a locally well-

developed gauge mineral assemblage of pink rhodonite and purple fluorite. The

presence of these gauge minerals has been shown to be an indicator or lower gold

and silver values and it appears that a zonation of precious metal rich veining is

flanked above and below by weaker gold and silver values within veining containing

the rhodonite and fluorite. Carbonate minerals identified within the mineralized

veinlets include calcite, ankerite and rhodonite. The quartz in these veinlets is

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 31

Burns Block NI 43-101 Compliant Technical Report January 2014

always very fine grained and is commonly smoky grey in color. The sulfide and

gauge minerals in the veinlets occur both as intergrown clotty aggregates and locally

with nicely banded textures. Silver mineralogy in the poly metallic qtz-carb veinlets

has not been identified in detail. Native silver as dendritic growths on foliation and

electrum occur but very high silver numbers have been returned from assays of

mineralized veinlet swarms in dacite without visible native silver and only minor

electrum. Other silver bearing minerals are suspected in the very high grade silver

zones at Burns.

7. Gold-chalcopyrite-galena fracture fills. Hairline to mm-scale fractures filled with

native gold-electrum-chalcopyrite-galena are seen within intervals with deformed

quartz-carbonate-poly metallic sulfide swarms both in west and east Burns. These

fractures are mostly commonly found contained within quartz rich portions of the

mineralized veinlets. The fractures are linear to gently curvilinear and vary in length

from a few centimeters to 20 to 30 centimeters (the observed length appears to be

largely a function of fracture orientation relative core axis). These gold rich fracture

fills can are found both as isolated occurrences within well mineralized zones and as

groups within very high grade sections. The fractures appear late and are

undeformed. The most common orientation is essentially parallel to core axis for drill

holes with north azimuths, thus the fractures appear to have a north-south

orientation. There is wide variability in the proportions of gold, chalcopyrite and

galena in fracture fills, some fractures are nearly completely gold filled, others nearby

may be mostly filled with either the two sulfides. The fractures are usually seen to

end by tapering down to fine point and commonly extend into the dacite wall rocks

away from the main quartz veinlet hosts.

7.4 MI NERAL I Z AT I ON

Drilling on the Burns Block property has confirmed the widespread distribution of gold

and silver within two litho-structural intervals. Both shallow and deeper (below

potential open pit parameters) intercepts reported by Bayfield Ventures along the

strike extension of New Gold's ODM17 deposit clearly shows that high grade gold

and silver mineralization continues onto the Burns Block.

The mineralized zones in the Burns Block are contained within a package of south

dipping, strongly foliated, sheared and locally folded dacitic volcanic rock. Pervasive

sericite-silica alteration is characteristic of the zone. The zones of mineralization

occur in felsic metavolcanics within zones of stronger penetrative foliation. The

foliation is near coincident with the strike and dip of the lithologies. Gold and silver

grade appears to be strongly influenced by proximity to the margins of strong sericitic

alteration within the shear system. The zones strike at 120 degrees and dip at around

60 degrees to the southwest on the Burns Block property.

The higher grade mineralization is always accompanied by sulfide mineralization,

predominantly dark brown sphalerite, chalcopyrite, pyrite, galena and arsenopyrite.

Gold and silver mineralization are invariably found together. Ratios of 5 g/t silver to 1

g/t gold are common, while higher grade zones have silver to gold ratios of at least

10 to 1, with ratios of >20 to 1 common. A mineralogical study commissioned by

Rainy River Resources as part of the 2009 technical report on their adjacent property

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 32

Burns Block NI 43-101 Compliant Technical Report January 2014

found that gold and electrum can occur either as inclusions in pyrite, or disseminated

in sphalerite, ankerite or fine grained silicates.

The presence of wide (>30m) low grade mineralized zones on the Burns Block

provides an important indicator for future discoveries. It is possible that these low

grade zones represent the initial mineralization event, but lack the subsequent

secondary enrichment provided by later, deformation event associated quartz veins.

Figure 7-4 Typical mineralization, sulfides in sericitized dacite, local quartz

carbonate veining.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 33

Burns Block NI 43-101 Compliant Technical Report January 2014

8 . 0 D E P O S I T T Y P E

Recent interpretations for the geology and genesis of gold mineralization on the

Burns Block suggest an early, volcanogenic-associated model. Primary rock units in

and around the deposit include dacitic flows and sedimentary volcaniclastic deposits.

Additional data from exploration drilling showed that gold mineralization at the Burns

Block has a strong gold-pyrite association, including ubiquitous sphalerite, and a very

high ratio of silver to gold. These features suggest a transitional epithermal origin. No

significant base metal mineralization or stratiform sulphide lenses have been

encountered to date.

There appear to have been two stages of gold mineralization in the Burns Block. The

first (low to moderate grade) gold mineralization was associated with the

emplacement of sulphide (pyrite-sphalerite-chalcopyrite) as veins and disseminations

in dacitic rocks A later (high-grade) gold mineralization event included the

emplacement of quartz-pyrite/chalcopyrite-gold veins and veinlets. Both events are

post-dated by deformation, when the auriferous quartz veins that post-date the

sulphide stringers and veins and were emplaced.

Several of the larger transitional volcanogenic gold deposits are located in Canada,

including the Hemlo, Troilus, Douay and Dublin Gulch deposits.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 34

Burns Block NI 43-101 Compliant Technical Report January 2014

9 . 0 E X P L O R A T I O N

9.1 AI RBORNE GEOPHYSI CS

In December 2010, Geotech Ltd. carried out a helicopter-borne geophysical survey

over the Burns Block and surrounding areas. Geophysical sensors included a

versatile time domain electromagnetic (VTEM) system, and a cesium magnetometer.

Aircraft positioning was done using a GPS navigation system and a radar altimeter. A

total of 308 line-kilometres of geophysical data were acquired during the survey.

Quality control, quality assurance, and preliminary data processing were carried out

on a daily basis during the acquisition phase of the project. Final data processing

was completed after the end of the survey, and presented to Bayfield in February

2011.

The area was flown in a north to south (0 azimuth) direction with traverse line

spacing of 100 metres. Tie lines were flown perpendicular to the traverse lines at a

spacing of 1000 metres (90 azimuth).

The survey was flown using a Eurocopter Aerospatiale (Astar) 350 B3 helicopter.

The helicopter maintained a mean altitude of 73 metres above the ground with a

nominal survey speed of 80 km/hour.

The electromagnetic system was a Geotech Time Domain EM (VTEM) system. The

VTEM Receiver and transmitter coils were in concentric-coplanar and Z-direction

oriented configuration. The receiver system for the project also included a coincident-

coaxial X-direction coil to measure the in-line dB/dt and calculate B-Field responses.

The EM bird was towed at a mean distance of 35 metres below the aircraft. The

magnetic sensor utilized for the survey was Geometrics optically pumped cesium

vapour magnetic field sensor mounted 13 metres below the helicopter. The sensitivity

of the magnetic sensor is 0.02 nanoTesla (nT) at a sampling interval of 0.1 seconds.

A Terra TRA 3000/TRI 40 radar altimeter was used to record terrain clearance. The

antenna was mounted beneath the bubble of the helicopter cockpit. The navigation

system used was a Geotech PC104 based navigation system utilizing a NovAtels

CDGPS (Canada-Wide Differential Global Positioning System Correction Service)

enable OEM4-G2-3151W GPS receiver, Geotech navigate software, a full screen

display with controls in front of the pilot to direct the flight and an NovAtel GPS

antenna mounted on the helicopter tail. As many as 11 GPS and two CDGPS

satellites may be monitored at any one time. The positional accuracy or circular error

probability (CEP) is 1.8 m, with CDGPS active, it is 1.0 m.

A combined magnetometer/GPS base station was utilized on this project. The base

station was installed 200 metres from landing spot (4906.5557 N, 93 55.3997 W);

away from electric transmission lines and moving ferrous objects. A Geometrics

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 35

Burns Block NI 43-101 Compliant Technical Report January 2014

Cesium vapour magnetometer was used as a magnetic sensor with a sensitivity of

0.001 nT. The base station recorded the magnetic field together with the GPS time at

1 Hz on a base station computer.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 36

Burns Block NI 43-101 Compliant Technical Report January 2014

Figure 9-1 VTEM B-Field Z component profiles

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 37

Burns Block NI 43-101 Compliant Technical Report January 2014

Figure 9-2 VTEM B-Field Z component channel 38

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 38

Burns Block NI 43-101 Compliant Technical Report January 2014

9.2 DI AMOND DRI L L I NG

Early drilling by Rainy River resources was largely in the footwall of the known

mineralization. Bayfield began drilling the deposit in 2010, and have drilled 103,044

in 310 diamond drill holes and 8 wedged holes to date. Diamond drilling has been

the primary method of exploration on the property. More details of their drilling

program are provided in section 10.

Drill core analysis and assaying is being conducted by ACT Labs in Thunder Bay,

Ont. The lab is ISO/IEC 17025:2005 (CAN-P-4E) certified.

The drill core is split and sampled in 0.5 metre to 1.5 metre intervals. The core

samples were analyzed for gold by 30-gm fire assay with AA finish. Samples over

5,000 ppb we re-assayed with a gravimetric method. In addition, screened total

metallic assays are being performed on samples assaying over 5,000 ppb.

The core samples were analyzed for silver by Ag Aqua Regia with an ICP finish. Ag

Fire Assay-Gravimetric assays are conducted on samples greater than 100 ppm Ag.

Bayfield has implemented a quality assurance and quality control program to ensure

that the sampling and analysis of all samples is conducted in accordance with the

best possible practices.

RiverbendGeologicalServicesInc.

Bayfield Ventures Corp. 39

Burns Block NI 43-101 Compliant Technical Report January 2014

1 0 . 0 D R I L L I N G

10.1 RAI NY RI VER RESOURCES

Rainy River Resources (RR) began drilling the Burns Block in 2008. There were 10

holes that were either collared on the Burns Block, or drilled through portions of the

property. Hole NR08283 was one of those holes, collared 100 meters S of the SW

corner of the Burns Block, and drilled north onto the Burns Block. This hole

intersected strong gold mineralization from 501.5 to 507.5 meters down hole, and is

considered the discovery hole on the Burns Block. The 6 meter interval returned

5.76 g/t Au and 6.0 g/t Ag.

10.2 BAYF I EL D VENT URES

In 2010, Bayfield began a 19,354 metre 54 hole drilling program on the Burns Block.

The objective of this program was to extend the limits of the gold and silver

mineralization that had been identified on the adjacent New Gold (previously Rainy

River Resources) property, east onto Bayfield's Burns Block property. The Burns

Block drill program focused on delineation drilling of the gold-silver zones on the

western portion of the Burns Block, and the exploration towards the eastern portion

of the Burns Block, through a series drill fences. This drilling on the Burns Block

defined a continuous gold-silver zone across the property, and outlined a significant

tonnage of gold-silver mineralization.