Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hot Tap Tools

Caricato da

gshdavidCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hot Tap Tools

Caricato da

gshdavidCopyright:

Formati disponibili

Manual: 224901 Revision: J 5/06

2, 3, 4 & 6

Hot Tap Tools

Operators

Manual

Thank you for purchasing this McElroy product.

McElroy Hot Tap Tools are designed to make hot taps through a

branch saddle into live mains. The tools may be made-up to be

used with a squeeze-off device or a PE ball valve.

With reasonable care and maintenance, this tool will give years

of satisfactory service.

Before operating this tool, please read this manual thoroughly,

and keep a copy with the tool for future reference. This manual

is to be considered part of your tool.

TX01126-9-11-96

World Class Training

This manual is intended as a guide only and does not

take the place of proper training by qualified instructors.

The information in this manual is not all inclusive and

can not encompass all possible situations that can be

encountered during various operations.

McElroy Manufacturing, Inc., offers advanced training

classes to enhance efficiency, productivity, safety and

quality. Training is available at our facility or on site at

your location. Call (918) 836 8611

TX01083 12 10 96

P

H

0

0

9

1

7

-

5

-

1

6

-

9

8

P

H

0

2

4

1

9

-

2

-

1

9

-

0

3

Introduction

Warranty

LIMITED WARRANTY

McElroy Manufacturing, Inc. (McElroy) warrants all

products manufactured, sold and repaired by it to be

free from defects in materials and workmanship, its

obligation under this warranty being limited to repairing

or replacing at its factory and new products, within

3 years after shipment, with the exception of purchased

items (such as electronic devices, pumps, switches, etc.),

in which case that manufacturers warranty applies.

Warranty applies when returned freight is prepaid and

which, upon examination, shall disclose to have been

defective. This warranty does not apply to any product

or component which has been repaired or altered by

anyone other than McElroy or has become damaged

due to misuse, negligence or casualty, or has not been

operated or maintained according to McElroys printed

instructions and warnings. This warranty is expressly

in lieu of all other warranties expressed or implied.

The remedies of the Buyer are the exclusive and sole

remedies available and Buyer shall not be entitled to

receive any incidental or consequential damages. Buyer

waives the benefit of any rule that disclaimer of warranty

shall be construed against McElroy and agrees that such

disclaimers herein shall be construed liberally in favor of

McElroy.

RETURN OF GOODS

Buyer agrees not to return goods for any reason except

upon the written consent of McElroy obtained in advance

of such return, which consent, if given, shall specify the

terms and conditions and charges upon which any such

return may be made. Materials returned to McElroy, for

warranty work, repair, etc., must have a Return Material

Authorization (RMA) number, and be so noted on the

package at time of shipment. For assistance, inquiry shall

be directed to:

McElroy Manufacturing, Inc.

P.O. Box 580550

833 North Fulton Street Tulsa, Oklahoma 74158-0550

PHONE: (918) 8368611, FAX: (918) 8319285.

EMAIL: fusion@McElroy.com

Note: Certain repairs, warranty work, and inquiries may

be directed, at McElroys discretion, to an authorized

service center or distributor.

TX02486-04-06-05

DISCLAIMER OF LIABILITY

McElroy accepts no responsibility of liability for fusion

joints. Operation and maintenance of the product is the

responsibility of others. We recommend qualified joining

procedures be followed when using McElroy fusion

equipment.

McElroy makes no other warranty of any kind whatever,

express or implied; and all implied warranties of

merchantability and fitness for a particular purpose

which exceed the aforestated obligation are hereby

disclaimed by McElroy.

PRODUCT IMPROVEMENT

McElroy reserves the right to make any changes in or

improvements on its products without incurring any

liability or obligation to update or change previously sold

machines and/or the accessories thereto.

INFORMATION DISCLOSED

No information of knowledge heretofore or hereafter

disclosed to McElroy in the performance of or in

connection with the terms hereof, shall be deemed

to be confidential or proprietary, unless otherwise

expressly agreed to in writing by McElroy and any such

information or knowledge shall be free from restrictions,

other than a claim for patent infringement, is part of the

consideration hereof.

PROPRIETARY RIGHTS

All proprietary rights pertaining to the equipment or

the components of the equipment to be delivered by

McElroy hereunder, and all patent rights therein, arising

prior to, or in the course of, or as a result of the design

or fabrication of the said product, are exclusively the

property of McElroy.

LAW APPLICABLE

All sales shall be governed by the Uniform Commercial

Code of Oklahoma, U.S.A.

Register your product online to activate your warranty:

www.McElroy.com/fusion

(Copy information listed on the machine nameplate here

for your records).

Model No.

Serial No.

Date Received

Distributor

Table of Contents

Safety

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Read and Understand . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Wear Safety Equipment . . . . . . . . . . . . . . . . . . . . . . . 1-2

Gas and Hot Tap Safety. . . . . . . . . . . . . . . . . . . . . . . 1-2

Overview

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Fusion Machines To Use. . . . . . . . . . . . . . . . . . . . . . . 2-1

Tool Make-up

Tool Make-up Measurements . . . . . . . . . . . . . . . . . . . 3-1

Fusion Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2 Hot Tap Tool Using No.2CU Fusion Machine. . . . . . 3-1

2 Hot Tap Tool Using No.14 and Sidewinder

Fusion Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3 Hot Tap Tool Using No.14 and Sidewinder

Fusion Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

4 Hot Tap Tool Using No.14 and Sidewinder

Fusion Machines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

6 Hot Tap Tool using No.28 Fusion Machine . . . . . . . 3-3

Hot Tap Operation

Pressure Test Tool Make-up . . . . . . . . . . . . . . . . . . . . . 4-1

Clamp Tool in Fusion Machine . . . . . . . . . . . . . . . . . . 4-1

Begin Tapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Retract Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Close Valve or Squeeze Off Nipple. . . . . . . . . . . . . . . 4-2

Bleed Off All Pressure . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Cut the Tool Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Fuse Service Line to Branch Saddle Connection . . . . . . 4-3

Open Ball Valve or Remove Squeeze Tool . . . . . . . . . . 4-3

Prepare Tool For Next Tap . . . . . . . . . . . . . . . . . . . . . 4-3

Specifications

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

COPYRIGHT 2006

McElroy Manufacturing, Inc.

Tulsa, Oklahoma, USA

All rights reserved

All product names or trademarks are property of their respective owners.All information,

illustrations and specifications in this manual are based on the latest information available at the

time of publication. The right is reserved to make changes at any time without notice.

TX01807-5-5-00

Equipment Safety

1 - 1

Safety Alerts

This hazard alert sign appears in this manual.

When you see this sign, carefully read what it says.

YOUR SAFETY IS AT STAKE.

You will see the hazard alert sign with these words:

DANGER, WARNING, and CAUTION.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation which,

if not avoided, may result in minor or

moderate injury.

In this manual you should look for two other words:

NOTICE and IMPORTANT.

NOTICE: can keep you from doing something that might

damage the machine or someone's property. It may also

be used to alert against unsafe practices.

IMPORTANT: can help you do a better job or make

your job easier in some way.

TX00030-12-1-92

Read and Understand

Do not operate this equipment until you have carefully read, and

understand the "Safety" and "Operation" sections of this manual,

and all other equipment manuals that will be used with it.

Your safety and the safety of others depends upon care and

judgment in the operation of this equipment.

Follow all applicable federal, state, local, and industry specific

regulations.

McElroy Manufacturing, Inc. cannot anticipate every possible

circumstance that might involve a potential hazard. The warnings

in this manual and on the machine are therefore not all inclusive.

You must satisfy yourself that a procedure, tool, work method, or

operating technique is safe for you and others. You should also

ensure that the machine will not be damaged or made unsafe by

the method of operation or maintenance you choose.

TX00031-12-8-92

W

R

0

0

0

5

1

-

1

1

-

3

0

-

9

2

W

R

0

0

0

5

2

-

1

2

-

1

-

9

2

Equipment Safety

1 - 2

General Safety

Safety is important. Report anything unusual that you notice

during set up or operation.

LISTEN for thumps, bumps, rattles, squeals, air leaks, or unusual

sounds.

SMELL odors like burning insulation, hot metal, burning rubber,

hot oil, or natural gas.

FEEL any changes in the way the equipment operates.

SEE problems with wiring and cables, hydraulic connections, or

other equipment.

REPORT anything you see, feel, smell, or hear that is different

from what you expect, or that you think may be unsafe.

TX00114-4-22-93

S

A

F

E

1

S

T

-

1

2

-

2

2

-

9

2

Wear Safety Equipment

Wear a hard hat, safety shoes, safety glasses, and other

applicable personal protective equipment.

Remove jewelry and rings, and do not wear loose fitting clothing

or long hair that could catch on controls or moving machinery.

TX00032 4 7 93

W

R

0

0

0

5

3

-

1

2

-

2

-

9

2

Gas and Hot Tap Safety

Explosion hazard. Gas can ignite, causing

explosion, death or serious injury. Tapping into

pipe under pressure can cause severe injury if

safety procedures are not followed.

Follow all applicable federal, state, local and industry specific

regulations and procedures. No person should make a hot tap

unless that person has been properly trained and qualified in the

use of this equipment.

TX01290-3-18-97

W

R

0

0

0

3

4

-

1

1

-

3

0

-

9

2

2 - 1

Overview

Nomenclature

1 Cutter

2 Gland Fitting

3 Bleed Valve

4 Gland End Cap

5 Bearing

6 Cutter Shaft

7 Socket Wrench

TX02100-2-18-03

Fusion Machines To Use

Models No.2CU, Sidewinder and No.28 can be used to fuse a

branch saddle onto a main.

Models No.2CU, No.14 and No.28 can be used to make butt

fusion joints, depending on what size is required.

TX01131-9-30-96

C

D

3

2

6

-

9

-

2

7

-

9

6

C

D

0

0

3

4

0

-

1

1

-

1

4

-

9

6

C

D

0

0

3

4

1

-

1

1

-

1

4

-

9

6

P

H

0

7

8

3

C

-

1

1

-

1

4

-

9

6

P

H

0

0

3

7

5

B

-

1

1

-

1

4

-

9

6

No.28

3 - 1

Tool Make-Up

Fusion Procedures

Use standard facing and fusion procedures from the fusion

machine Operator's Manual, adhering to the pipe manufacturer's

specifications.

IMPORTANT: Make sure the pressure relief valve on the tapping

tool and the ball valve are positioned so that they will be

accessible after fusing tool make-up.

TX01143-11-12-96

Tool Make-up Measurements

The overall tool length is measured from the cap on the gland

fitting, to the center of the concave side of the fitting which butts

against the pipe.

NOTICE: Allowance for face off and bead rollback during fusion

must be added to the measurement.

The make-up length is different for each size tapping tool.

TX01142-11-11-96

2" Hot Tap Tool Using No.2CU Fusion Machine

NO VALVE: Fuse 24" nipple to branch saddle.

Fuse nipple and branch saddle to main.

Measure for tool make-up and cut excess from nipple, leaving

1/4" to 1/2" for face off and bead rollback.

Fuse tool to nipple.

WITH BALL VALVE: Fuse 6" nipple to branch saddle.

Fuse Polyvalve to nipple and branch saddle.

Fuse 12" nipple to other end of ball valve.

Fuse branch saddle and ball valve assembly to main.

Measure for tool make-up and cut excess from nipple, leaving

1/4" to 1/2" for face off and bead rollback.

Fuse tool to nipple.

TX01144-11-12-96

W

R

0

0

0

7

9

-

4

-

1

2

-

9

3

C

D

0

0

3

3

0

-

1

1

-

5

-

9

6

C

D

0

0

3

3

2

-

1

1

-

5

-

9

6

C

D

0

0

3

3

1

-

1

1

-

5

-

9

6

3 - 2

Tool Make-Up

2" Hot Tap Tool Using No.14 and

SidewinderTM Fusion Machines

NO VALVE: Fuse branch saddle to main.

Fuse 24" nipple to gland fitting on tool.

Measure for tool make-up and cut excess from nipple, leaving

1/4" to 1/2" for face off and bead rollback.

Fuse tool make-up to branch saddle.

WITH BALL VALVE: Fuse branch saddle to main.

Fuse 14" nipple to ball valve.

Fuse other end of ball valve to gland fitting on tool.

Measure for tool make-up and cut excess from nipple,

leaving 1/4" to 1/2" for face off and bead rollback.

Fuse tool make-up to branch saddle.

TX01145-11-12-96

3" Hot Tap Tool Using No.14 and

Sidewinder Fusion Machines

NO VALVE: Fuse branch saddle to main.

Fuse 25" nipple to gland fitting on tool.

Measure for tool make-up and cut excess from nipple,

leaving 1/4" to 1/2" for face off and bead rollback.

Fuse tool make-up to branch saddle.

WITH BALL VALVE: (Use 2" cutter)

Fuse branch saddle to main.

Fuse 12" nipple to ball valve.

Fuse other end of ball valve to gland fitting on tool.

Measure for tool make-up and cut excess from nipple,

leaving 1/4" to 1/2" for face off and bead rollback.

Fuse tool make-up to branch saddle.

TX01146-11-12-96

C

D

0

0

3

3

4

-

1

1

-

1

1

-

9

6

C

D

0

0

3

3

5

-

1

1

-

1

1

-

9

6

C

D

0

0

3

3

6

-

1

1

-

1

1

-

9

6

C

D

0

0

3

3

3

-

1

1

-

1

1

-

9

6

3 - 3

Tool Make-Up

4" Hot Tap Tool Using No.14 and

Sidewinder Fusion Machines

NO VALVE: Fuse branch saddle to main.

Fuse 31" nipple to gland fitting on tool.

Measure for tool make-up and cut excess from nipple, leaving

1/4" to 1/2" for face off and bead rollback.

Fuse tool make-up to branch saddle.

WITH BALL VALVE: (Use 3" cutter)

Fuse branch saddle to main.

Fuse 6" nipples to each end of the ball valve.

Fuse the ball valve with nipples to branch saddle.

Fuse 8" nipple to gland fitting on tool.

Measure for tool make-up and cut excess from nipple

on tool, leaving 1/4" to 1/2" for face off and bead

rollback.

Fuse tool make-up to ball valve nipple.

TX01147-11-12-96

6" Hot Tap Tool Using No.28 Fusion

Machine

WITH BALL VALVE: (Use 4" cutter)

Fuse 45" nipple to gland fitting on tool.

(For round based saddles, fuse a 3" pup to the branch

saddle)

Place the tapping tool assembly, valve and branch

saddle in line and measure the total length of all

components, adding 1/2" to 3/4" for face off and bead

rollback. After the assembly is fused together, the total

make-up length should be 81" plus allowance for facing

and bead rollback.

Cut excess from nipple on tool.

Fuse components together.

Fuse tool assembly to main.

TX01148-11-12-96

C

D

0

0

3

3

8

-

1

1

-

1

1

-

9

6

C

D

0

0

3

3

9

-

1

1

-

1

1

-

9

6

C

D

0

0

3

3

7

-

1

0

-

7

-

9

8

4 - 1

Hot Tap Operation

Clamp Tool in Fusion Machine

Install proper size jaw inserts, as required. Clamp the bearing

housing on the tool in the movable jaw and the tapping tool in

the fixed jaw.

TX01150-11-18-96

Pressure Test Tool Make-up

Attach hose to the pressure relief valve on the tapping tool. Open

valve and pressure test the tool make-up as required by applicable

regulations.

Relieve all pressure after test is complete and close pressure relief

valve. Remove air hose.

TX01149-11-18-96

Begin Tapping

Attach the ratchet wrench to the hex bar at the end of the cutter

drive shaft.

Using a No.2CU or No.14 machine, apply moderate pressure

on the movable handle and rotate the cutter drive shaft in a

clockwise direction to begin tap.

When using a No.28 machine, shift the selector valve to the

facing mode and reduce the pressure to the lowest setting. Ratchet

the cutter shaft clockwise while activating the carriage control

valve to move in. It may be necessary to shift in and out of neutral

when too much resistance is encountered.

Keep tapping until the bearing housing bottoms out against the

end cap of the tool.

TX01151-11-18-96

P

H

0

2

4

1

5

-

2

-

1

9

-

0

3

P

H

0

2

4

1

6

-

2

-

1

9

-

0

3

P

H

0

2

4

1

7

-

2

-

1

9

-

0

3

P

H

0

2

4

1

4

-

2

-

1

9

-

0

3

Cut the Tool Off

Use standard static charge precautions.

Cut the tool at the bead between the gland fitting and the nipple,

or the gland fitting and the ball valve, whichever was fused to the

gland fitting.

TX01155-11-18-96

4 - 2

Hot Tap Operation

Close Valve or Squeeze Off Nipple

If the tool was made up with a ball valve in line, close the ball

valve.

If there is no valve, use a squeeze off tool to shut off all line flow.

TX01153-11-18-96

Retract Cutter

Pull the cutter away from the main and as far into the tool as possible.

Stand clear of cutter shaft and loosen the movable jaw enough to

allow the bearing housing to come out of the jaw.

The cutter shaft can move back with force when

unclamped from jaw. Stand clear of shaft travel to

avoid the possibility of injury.

Make sure cutter is as far into the tool as possible.

TX01152-11-18-96

Bleed Off All Pressure

Open pressure relief valve and bleed off all pressure. A short

hose can be attached to direct pressure away from personnel.

Remove fusion machine from tapping tool.

TX01154-11-18-96

P

H

0

0

9

9

6

-

1

1

-

1

9

-

9

6

P

H

0

2

4

1

4

-

2

-

1

9

-

0

3

P

H

0

2

4

1

8

-

2

-

1

9

-

0

3

P

H

0

2

4

1

5

-

2

-

1

9

-

0

3

4 - 3

Hot Tap Operation

Open Ball Valve or Remove Squeeze Tool

Allow the fused service line connection to cool.

Open the ball valve or remove the squeeze tool to allow the

service line to pressurize.

TX01157-11-18-96

Fuse Service Line to Branch Saddle Connection

Fuse the service line to the branch saddle assembly.

TX01156-11-18-96

Prepare Tool For Next Tap

Remove coupon from cutter using a long handled screwdriver.

Cutter edges are very sharp. Avoid injury by

avoiding direct contact with the cutter.

TX01158-11-18-96

P

H

0

0

9

9

6

-

1

1

-

1

9

-

9

6

P

H

0

0

9

9

9

-

1

1

-

1

9

-

9

6

P

H

0

0

9

9

8

-

1

1

-

1

9

-

9

6

4 - 4

Hot Tap Tools

Shipping Lengths:

2 tool: 50 (127 cm)

3 tool: 60 (152 cm)

4 tool: 67 (170 cm)

6 tool: 94 (193 cm)

Shipping Weights:

2 tool: 8lbs (3.6 Kg)

3 tool: 12 lbs. (5.4 Kg)

4 tool: 18 lbs. (8.2 Kg)

6 tool: 26 lbs. (11.8 Kg)

Maximum working pressure: Same pressure rating as pipe being tapped

TX01273-2-27-97

Specifications

About this manual . . .

McElroy Manufacturing continually strives to give customers the best quality products

available. This manual is printed with materials made for durable applications and harsh

environments.

This manual is waterproof, tear resistant, grease resistant, abrasion resistant and the bonding

quality of the printing ensures a readable, durable product.

The material does not contain any cellulose based materials and does not contribute to the

harvesting of our forests, or ozone-depleting constituents. This manual can be safely disposed

of in a landfill and will not leach into ground water.

TX001660-8-19-99

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Consentry Into Sanitary PitsDocumento30 pagineConsentry Into Sanitary PitsgshdavidNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- P&ID SymbolDocumento18 pagineP&ID SymbolBagus Okti100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Crude Oil Properties (Laboratory)Documento15 pagineCrude Oil Properties (Laboratory)gshdavidNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- WWC Technical Data BookDocumento73 pagineWWC Technical Data BookMario BertoneriNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Gap Analysis FinalDocumento2 pagineGap Analysis FinalZetty BlackNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Inspection and Testing of Piping Systems ES-14-602-02Documento44 pagineInspection and Testing of Piping Systems ES-14-602-02Edmund MoraldeNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Dew Point Basics-Compressed Air PDFDocumento4 pagineDew Point Basics-Compressed Air PDFgshdavidNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- PLEATED SS Steam DDPP PDFDocumento2 paginePLEATED SS Steam DDPP PDFgshdavidNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Basket Strainer Intro PDFDocumento4 pagineBasket Strainer Intro PDFgshdavidNessuna valutazione finora

- Worksafe Bulletin: Safe Procedures For Vacuum Truck OperationsDocumento2 pagineWorksafe Bulletin: Safe Procedures For Vacuum Truck OperationsgshdavidNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Why Dry Compressed Air PDFDocumento9 pagineWhy Dry Compressed Air PDFgshdavidNessuna valutazione finora

- GAP AnalysisDocumento4 pagineGAP AnalysisTushar PareekNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- M146content PDFDocumento90 pagineM146content PDFgshdavidNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Drying PDFDocumento11 pagineDrying PDFgshdavidNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Mesh Size EquivalentsDocumento2 pagineMesh Size EquivalentsFrancisco Chavez ContrerasNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 007 UTube CleaningDocumento2 pagine007 UTube CleaninggshdavidNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hot Tapping: Typical Hot Tap ApplicationDocumento1 paginaHot Tapping: Typical Hot Tap ApplicationgshdavidNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- Distillation - How It WorksDocumento8 pagineDistillation - How It WorksOmar KallufNessuna valutazione finora

- Hot Tapping GuideDocumento3 pagineHot Tapping GuidegshdavidNessuna valutazione finora

- MSC Prac 30500Documento8 pagineMSC Prac 30500gshdavidNessuna valutazione finora

- P&ID DiagramDocumento6 pagineP&ID DiagramMejdi Sylas ToudjiNessuna valutazione finora

- Benzene Methods 2520of 2520productionDocumento4 pagineBenzene Methods 2520of 2520productionHưng LucaNessuna valutazione finora

- Hot Tap ProcedureDocumento21 pagineHot Tap ProcedureImanuel Sitepu100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Hot Tapping GuideDocumento3 pagineHot Tapping GuidegshdavidNessuna valutazione finora

- Avoid Syn Gas Catalyst Mal-Operation WSVDocumento48 pagineAvoid Syn Gas Catalyst Mal-Operation WSVgshdavidNessuna valutazione finora

- 2008 Midwest Regional Heard Catalyst PassivationDocumento23 pagine2008 Midwest Regional Heard Catalyst PassivationgshdavidNessuna valutazione finora

- Catalyst in Refining PetrochemicalsDocumento5 pagineCatalyst in Refining PetrochemicalsgshdavidNessuna valutazione finora

- Mesh Size EquivalentsDocumento2 pagineMesh Size EquivalentsFrancisco Chavez ContrerasNessuna valutazione finora

- BAT Production of Urea and Urea Ammonium NitrateDocumento44 pagineBAT Production of Urea and Urea Ammonium NitrateTTaddictNessuna valutazione finora

- IMRANADocumento4 pagineIMRANAAji MohammedNessuna valutazione finora

- 2022 AUSL Purples Notes Criminal Law and Practical ExercisesDocumento305 pagine2022 AUSL Purples Notes Criminal Law and Practical ExercisesNathalie Joy Calleja100% (6)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Case View With Rajat Gandhi - P2P Lending in India: Delivering Disruptive Innovation in Alternate Lending SpaceDocumento16 pagineCase View With Rajat Gandhi - P2P Lending in India: Delivering Disruptive Innovation in Alternate Lending SpaceETCASESNessuna valutazione finora

- European Green Party 11th COUNCIL MEETING Malmö, 16-18th October 2009Documento1 paginaEuropean Green Party 11th COUNCIL MEETING Malmö, 16-18th October 2009api-26115791Nessuna valutazione finora

- In Bengal, Erosion Leads To Land Loss: Shiv Sahay SinghDocumento1 paginaIn Bengal, Erosion Leads To Land Loss: Shiv Sahay SinghRohith KumarNessuna valutazione finora

- Dorfman v. UCSD Ruling - California Court of Appeal, Fourth Appellate DivisionDocumento20 pagineDorfman v. UCSD Ruling - California Court of Appeal, Fourth Appellate DivisionThe College FixNessuna valutazione finora

- A Practical Guide To The 1999 Red & Yellow Books, Clause8-Commencement, Delays & SuspensionDocumento4 pagineA Practical Guide To The 1999 Red & Yellow Books, Clause8-Commencement, Delays & Suspensiontab77zNessuna valutazione finora

- AWS D14.1 - 1997 Specification For Welding of Industrial and Mill Crane and Material Handling EqDocumento141 pagineAWS D14.1 - 1997 Specification For Welding of Industrial and Mill Crane and Material Handling EqRicardo Contzen Rigo-Righi50% (2)

- Tech Refresh & Recycle Program: 2,100PB+ of Competitive GearDocumento1 paginaTech Refresh & Recycle Program: 2,100PB+ of Competitive GearRafi AdamNessuna valutazione finora

- A Recurrent Quest For Corporate Governance in India Revisiting The Imbalanced Scales of Shareholders' Protection in Tata Mistry CaseDocumento17 pagineA Recurrent Quest For Corporate Governance in India Revisiting The Imbalanced Scales of Shareholders' Protection in Tata Mistry CaseSupriya RaniNessuna valutazione finora

- Mathematics: Textbook For Class XIIDocumento14 pagineMathematics: Textbook For Class XIIFlowring PetalsNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Social media types for media literacyDocumento28 pagineSocial media types for media literacyMa. Shantel CamposanoNessuna valutazione finora

- Applied Crypto HardeningDocumento111 pagineApplied Crypto Hardeningadr99Nessuna valutazione finora

- Sunrise Conveyors Maintenance OfferDocumento3 pagineSunrise Conveyors Maintenance OfferRampwalker ConveyorNessuna valutazione finora

- Customer Based Brand EquityDocumento13 pagineCustomer Based Brand EquityZeeshan BakshiNessuna valutazione finora

- Final Activity 4 Theology 1. JOB Does Faith in God Eliminate Trials?Documento3 pagineFinal Activity 4 Theology 1. JOB Does Faith in God Eliminate Trials?Anna May BatasNessuna valutazione finora

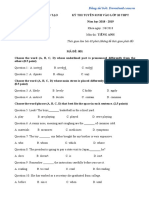

- Đề thi tuyển sinh vào lớp 10 năm 2018 - 2019 môn Tiếng Anh - Sở GD&ĐT An GiangDocumento5 pagineĐề thi tuyển sinh vào lớp 10 năm 2018 - 2019 môn Tiếng Anh - Sở GD&ĐT An GiangHaiNessuna valutazione finora

- Northern Nigeria Media History OverviewDocumento7 pagineNorthern Nigeria Media History OverviewAdetutu AnnieNessuna valutazione finora

- Charity Extends Help To Seniors: Donating Is Made EasierDocumento16 pagineCharity Extends Help To Seniors: Donating Is Made EasierelauwitNessuna valutazione finora

- Edsml Assignment SCM 2 - Velux GroupDocumento20 pagineEdsml Assignment SCM 2 - Velux GroupSwapnil BhagatNessuna valutazione finora

- тест юніт 1Documento3 pagineтест юніт 1Alina BurdyuhNessuna valutazione finora

- Asset To LiabDocumento25 pagineAsset To LiabHavanaNessuna valutazione finora

- Working While Studying in Higher Education: The Impact of The Economic Crisis On Academic and Labour Market Success (Preprint Version)Documento22 pagineWorking While Studying in Higher Education: The Impact of The Economic Crisis On Academic and Labour Market Success (Preprint Version)Vexie Monique GabolNessuna valutazione finora

- E-Mobility - Ladestation - Charging Station in Thalham - Raspberry Pi OCPPDocumento8 pagineE-Mobility - Ladestation - Charging Station in Thalham - Raspberry Pi OCPPjpcmeNessuna valutazione finora

- 3.1.bauer Martin-Resistance To New Technology Nuclear Power, Information Technology and Biotechnology 1995Documento436 pagine3.1.bauer Martin-Resistance To New Technology Nuclear Power, Information Technology and Biotechnology 1995Anonymous 2o0az0zOJNessuna valutazione finora

- PPAC's Snapshot of India's Oil & Gas Data: Abridged Ready ReckonerDocumento40 paginePPAC's Snapshot of India's Oil & Gas Data: Abridged Ready ReckonerVishwajeet GhoshNessuna valutazione finora

- Invoice FANDocumento1 paginaInvoice FANVarsha A Kankanala0% (1)

- IB English L&L Paper 1 + 2 Tips and NotesDocumento9 pagineIB English L&L Paper 1 + 2 Tips and NotesAndrei BoroianuNessuna valutazione finora

- Meeting Consumers ' Connectivity Needs: A Report From Frontier EconomicsDocumento74 pagineMeeting Consumers ' Connectivity Needs: A Report From Frontier EconomicsjkbuckwalterNessuna valutazione finora

- SodaPDF Converted DokumenDocumento4 pagineSodaPDF Converted Dokumenzack almuzNessuna valutazione finora