Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

EWS Design Guidelines For PCB Manufacture May 2012

Caricato da

wandai_81Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

EWS Design Guidelines For PCB Manufacture May 2012

Caricato da

wandai_81Copyright:

Formati disponibili

Electronics Workshop

(EWS)

Science 2 Building

N34_-1.17

Nthn !"pus

#$72%&

'esign guidelines (or )!B "nu(cture

This Workshop manufactures single-sided and double-sided boards by either chemical etching or

mechanical milling. We can accept all Protel and some Altium version files. Ignoring the restrictions

below may result in broken or shorted tracks. Ask workshop staff if special requirements eist.

Note: Ask about our in house plated-through-hole connections and overlays. We can also arrange PCBs to

be produced by external providers.

Grid i!e the suggested grid size is 25 mil (1 mil = 0.001)

"ini#u# clearances

$% #il &'.%% ##( bet)een tracks and pads.

Use larger clearances wherever possile to minimise the possiilit! o" short circuits.

Mains potentials to any other copper areas must have 6mm (240mil) minimum clearance (AS3100:2002).

Consier removin! intervenin! pins "rom connectors to increase separation.

All mains volta!e esi!n an manu"acture must #e compliant $ith the %ueenslan &lectrical Sa"ety Act 2002'

an the (ri""ith )niversity &lectrical Sa"ety *olicy 200+. Do not perform this work if you do not hold a

current licence for electrical work. Consult &.,.S. sta"" "or in"ormation on compliance.

*rack )idth 12 mil (0.#mm) minimum.

+se ,' #il &'.-##( or )ider )herever possible$ reducing down to 12 mil (0.#mm)

minimum$ onl! where necessar! (i.e. going etween %.&. pins). 'ee (ale # "or in"ormation on current

carr!ing capacit! verses copper trac) width.

Pad si!e * +2 mil (1.55mm) minimum.

+se ./ #il &,.' ##( or larger )herever possible.

,hen using connector pins$ -. connectors etc.$ use /0 mil (1./0 mm) and "or voltage regulators$ 1*amp diodes

etc$ use /0 mil (2.0 mm)

1ads should e at least 20 mil (0.5 mm) larger than the re2uired hole size. 3"ter the oard is routed$ chec) "or

and modi"! small pads that can e enlarged without causing clearance errors.

Because the holes are not plated-through, beware of connections on the top layer that are under

components and hence cant be soldered to, e.g. multi-pin transition connectors, IC sockets, trim pots

etc. Use vias, or another components pins, to connect top layer tracks to the bottom layer component

pads.

2#0+#//20.doc

Pad 0ole i!es 4dit pads and vias to accommodate stoc) drill sizes "rom (ale 1. 3void using

hole sizes elow 0./mm as the drills rea) more easil!$ and are e5pensive. &hec) that the stoc) lirar! pad

hole sizes are what !ou want drilled. &onsider creating a duplicate lirar! with edited components "or use

while protot!ping 1&6s.

Po)er Plane Connect tyle

+se ,' #il &'.-##( )herever possible$ reducing down to 12 mil (0.#mm) minimum$ onl! i" necessar!.

1ia si!e * Use +2 mil (1.55mm) where possile$ 55 mil (1.7 mm) onl! i" necessar!. (hese have to e

connected top la!er*to*ottom la!er ! inserting a piece o" wire and soldering oth sides$ so minimise their

use. ,here possile$ use an e5isting component lead that can e soldered on oth la!ers to ma)e the

connection.

1ia 0ole i!es * 8a)e via holes 20 mil (0./ mm)

Cut lines or a border must e included on 9eep :ut ;a!er in !our artwor) to indicate "inal

oard size. 8a)e cut lines 10 mil wide.

*ext * (o aid in the handling o" the artwor) in the dar)room when photographicall! processed$ there

#ust be so#e Correct-reading text on each layer when viewed "rom that side o" the oard. (his means

that an! ottom la!er te5t needs to e reversed when viewed "rom the top. 1ossile te5t suggestions are a

uni2ue oard name$ !our initials or name$ the date$ version numer etc.

"axi#u# PC board si!e is 12 5 10 (#00 5 755 mm).

"axi#u# art)ork print si!es are<

A2 *= /.0 5 11.# (1>0 5 20/mm)

A% *= 11.1 5 1+ (202 5 70+mm).

;arger sizes will involve ?oining sheets and should e avoided where possile.

Arrays o3 boards * %" multiple copies o" the same oard are re2uired$ the! should e arra!ed

with overlapping 10 mill cut lines. 4nsure that the cuts can e made in a logical se2uence on our guillotine$

and that the dimensions aove "or ma5imum pc size aren@t e5ceeded.

2#0+#//20.doc

(ale 1< '(:&9 .A%;; 4BU%C3;4D('

0456 786

&"75(

9:755 786

&##(

,2 '.;

,/ '..

%$ './

%- '.<

%< $.'

2% $.$

2. $.,

-$ $.%

-- $.2

-< $.-

;% $.;

.$ $./

.< ,.'

</ ,.-

$$/ %.'

(ale 2< U'4 (E4 F:;;:,%DG ;3H4A' F:A (E4 A4BU%A4. 1A:&4''

)*+!ESS !,E-.!/001 E2!,E' -.00.N3 -/!,.NE

Top Tet Top !ayer "echanical !ayer #

$ottom Tet $ottom !ayer "echanical !ayer %

Inside &utting "echanical #' % or ( "iddle !ayer #

)utside &utting "echanical #' % or ( *eepout !ayer

+ote #,

,hen oards are to e machine milled$ prepare inside and outside cut lines using la!ers "rom the aove

tale.

8a)e cut lines 10 mils wide and la! them continuous and unro)en at corners.

Use %mperial grid with -snap*to*grid resolution not less than 5 mils.

2#0+#//20.doc

Table (

Stock copper thicknesses re 3$u" (1o4) (or single-sided nd 1%u" (152 o4) (or dou6le-sided

6ords.

2#0+#//20.doc

=:-2 =7B:6G5A 6P4>?-:67N B4N969 5A"7NA*6

G6N6:A5 P6C7=7CA*74N

G6N6:A5:

.ensit!$ gm. I c.c.**************************************************************************** 1.>5

'peci"ic Colume$ in

#

Il***************************************************** 17.#

,eight per s2."t. (125 thic))$ls. ******************************************************** 1.2+

"6C0AN7CA5:

(ensile 'trength$ p.s.i.$ lengthwise*************************************** 70$000

(ensile 'trength$ p.s.i.$ crosswise***************************************** 77$000

&ompressive 'trength$ p.s.i.$ "latwise************************************ +0$000

Fle5ural 'trength$ p.s.i.$ lengthwise************************************** />$000

Fle5ural 'trength$ p.s.i.$ crosswise**************************************** +5$000

8odulus o" 4lasticit! in Fle5ure 5 10

5

;engthwise********************** 15

&rosswise*********************** 12

%mpact 'trength$ %J:. 4dgewise

"t. l.Iin. Dotch$ lengthwise************************** 12.0

"t. l.Iin. Dotch$ crosswise*************************** 0.0

Aoc)well Eardness$ 8 'cale********************************************** 110

6ond 'trength$ ls.********************************************************** 2$#00

656C*:7CA5:

.ielectric 'trength*perpendicular to laminations

'hort time$ CImil. .0+25 thic)****************************** +/0

'hort time$ CImil. .125 thic)******************************* 525

.ielectric 'trength*parallel to laminations

9volts$ step ! step$ 0.125$ &ond. 3************************************ +0

&ond. .70I50******************* 50

.issipation Factor$ 10

+

&!cles$ &ond. 3********************************* .015

&ond. .27I2#*************************** .01+

9ielectric Constant $ 10

+

&!cles &ond. 3****************************** 7./>

N4*6< users have reported that this value is variale$ and closer to 7.1 K 1GEz. Ae2uest a sample e"orehand

i" this is critical and !ou can ma)e !our own determination.

%nsulation Aesistance 8egohm$ &ond. &>+I#5I>0********************* 100$000

3rc Aesistance$ 'ec.******************************************************** 120

P0?7CA5:

(hermal &onductivit!$ &al.I'ec.Icm

2

I

o

&Icm**************************** /.0 5 10

*7

'peci"ic Eeat &alIgmI

o

&*************************************************** 0.#5 * 0.70

Eeat Aesistance

o

F$ 'hort (ime******************************************* #50

&ontinuous******************************************** 250

(hermal 45pansion$ in.Iin.I

o

F 5 10

*5

;engthwise********************************************** 0.>0

&rosswise*********************************************** 0./2

,ater 3sortion L 27 hours

.0+25************************************************** 0.10

.125*************************************************** 0.0/

.500*************************************************** 0.0#

-tock laminate thickness used is #.. mm. )thers thicknesses available on special order.

-tock copper thicknesses are (/um 0#o12 for single-sided and #3um 0#4% o12 for double-sided boards.

2#0+#//20.doc

Potrebbero piacerti anche

- ABB Medium VoltageDocumento19 pagineABB Medium VoltageMarianella RamírezNessuna valutazione finora

- MVSG Advance SpecificationDocumento19 pagineMVSG Advance SpecificationJason SonidoNessuna valutazione finora

- Qdoc - Tips Electrical Panel Board Project ReportDocumento18 pagineQdoc - Tips Electrical Panel Board Project Reportsampath rajannaNessuna valutazione finora

- SmartFrame Connection DetailsDocumento29 pagineSmartFrame Connection Detailsmeetvinayak2007Nessuna valutazione finora

- Shipbuilding Technology 4th Semester SyllabusDocumento30 pagineShipbuilding Technology 4th Semester SyllabusDiploma in Engineering Shipbuilding TechnologyNessuna valutazione finora

- 74ls04 Not GateDocumento9 pagine74ls04 Not GateVicky LakhwalNessuna valutazione finora

- ARGOS Surface Beacon Asb X User Manual: March 2011Documento7 pagineARGOS Surface Beacon Asb X User Manual: March 2011Reza BabakhaniNessuna valutazione finora

- SWITCHYARDDocumento30 pagineSWITCHYARDKaran TripathiNessuna valutazione finora

- 8.1 - 5 MvaDocumento4 pagine8.1 - 5 MvafaharaNessuna valutazione finora

- Civil WorksDocumento47 pagineCivil WorksAbdulyekini AhmaduNessuna valutazione finora

- ACSR Conductors & Accessories: Our Product RangeDocumento8 pagineACSR Conductors & Accessories: Our Product RangedipenkhandhediyaNessuna valutazione finora

- Ex 9, Punching ShearDocumento4 pagineEx 9, Punching ShearMohafisto SofistoNessuna valutazione finora

- Air Clearance Design of Transmission LineDocumento8 pagineAir Clearance Design of Transmission Lineirshad224100% (2)

- Interni Standard 37 Trajno Dozvoljene Struje Faznih Provodnika Nadzemnih VodovaDocumento8 pagineInterni Standard 37 Trajno Dozvoljene Struje Faznih Provodnika Nadzemnih Vodovacommunist88Nessuna valutazione finora

- 2.5 C - SMUH Electrical Systems - Key Materials & ProductsDocumento6 pagine2.5 C - SMUH Electrical Systems - Key Materials & ProductsmangjuhaiNessuna valutazione finora

- 11281heavy Duty Slide GatesDocumento11 pagine11281heavy Duty Slide GatesZohaib AnserNessuna valutazione finora

- Assignment M.E (Elp) Ept&dDocumento1 paginaAssignment M.E (Elp) Ept&dSyed Asif Ali ShahNessuna valutazione finora

- Catalogueiendt PDFDocumento43 pagineCatalogueiendt PDFNatrajiNessuna valutazione finora

- Tricking Out HF 9x20 LatheDocumento48 pagineTricking Out HF 9x20 LatheCliff Miller100% (2)

- Section Low Voltage Motor Control Centers Part 1 - GeneralDocumento8 pagineSection Low Voltage Motor Control Centers Part 1 - GeneralNardi VallejoNessuna valutazione finora

- In This Article I Will Offer Driver Circuit For 12 VDocumento3 pagineIn This Article I Will Offer Driver Circuit For 12 VPriya JakoonNessuna valutazione finora

- Fabrication Tolerances: Api-Rp-2A (December 2000)Documento2 pagineFabrication Tolerances: Api-Rp-2A (December 2000)dareman_021Nessuna valutazione finora

- MES Central Java - BONNA Technical Note 01#01 Self-Anchoring & Thrust BlocksDocumento7 pagineMES Central Java - BONNA Technical Note 01#01 Self-Anchoring & Thrust BlocksFerdie TolosaNessuna valutazione finora

- Trampa de Onda BPEG - BrochureDocumento8 pagineTrampa de Onda BPEG - BrochureseanwrestlerNessuna valutazione finora

- Presentation CVM Zwick PDFDocumento19 paginePresentation CVM Zwick PDFteacgNessuna valutazione finora

- (Pipes & Fittings)Documento8 pagine(Pipes & Fittings)Santhu MeprathuNessuna valutazione finora

- Project Report: On Analyze Submerged Arc Welding (SAW) With Respect To MIG Welding (GMAW)Documento32 pagineProject Report: On Analyze Submerged Arc Welding (SAW) With Respect To MIG Welding (GMAW)Rama Krishna Reddy DonthireddyNessuna valutazione finora

- Control Panel LayoutDocumento15 pagineControl Panel Layoutreddylogin100% (2)

- Matching A Centrifugal Fan To A Chosen Model SizeDocumento5 pagineMatching A Centrifugal Fan To A Chosen Model SizelesteradimNessuna valutazione finora

- Microstrip Patch Antenna With Defected Ground Structure & Offset Feed in The Field of CommunicationDocumento4 pagineMicrostrip Patch Antenna With Defected Ground Structure & Offset Feed in The Field of CommunicationUpendraSinghNessuna valutazione finora

- Form 2 Designform Locked MasterNewDocumento11 pagineForm 2 Designform Locked MasterNewkoklenderNessuna valutazione finora

- ATR720C Install Oper EngDocumento14 pagineATR720C Install Oper EngDarko FvzdNessuna valutazione finora

- Applicationguides 4Documento4 pagineApplicationguides 4Jacques DeroualleNessuna valutazione finora

- Double Cut LP JRDocumento34 pagineDouble Cut LP JRRXillusionist92% (12)

- Pspice Tutorial Discusses Text-Based Pspice EntryDocumento5 paginePspice Tutorial Discusses Text-Based Pspice EntryRobertDumitruNessuna valutazione finora

- RYO Optodist Assembly ManualDocumento14 pagineRYO Optodist Assembly ManuallistentomerijnNessuna valutazione finora

- Techair Industries (M) SDN BHD Product CatalogueDocumento3 pagineTechair Industries (M) SDN BHD Product Catalogueshahrul_dmNessuna valutazione finora

- Boring Bar ManualDocumento41 pagineBoring Bar ManualPranjal Chakraborty100% (1)

- 11 KV SwitchgearDocumento24 pagine11 KV SwitchgearMD Zakirul Islam SarkerNessuna valutazione finora

- The LH1000: Low Head Propeller TurbineDocumento16 pagineThe LH1000: Low Head Propeller TurbineRaymond KatabaziNessuna valutazione finora

- Radial Air Core Alternator FunDocumento5 pagineRadial Air Core Alternator FunMiguel CabreraNessuna valutazione finora

- 11th Physics Practical HSCDocumento7 pagine11th Physics Practical HSCABHAY SHINDENessuna valutazione finora

- Lathe Project - Cannon Barrel (TMJ 209)Documento7 pagineLathe Project - Cannon Barrel (TMJ 209)sanu7blyNessuna valutazione finora

- 230529Documento8 pagine230529thanh_79Nessuna valutazione finora

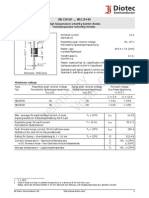

- SB12H30 ... SB12H40: High Temperature Schottky Barrier Diodes Hochtemperatur-Schottky-DiodenDocumento2 pagineSB12H30 ... SB12H40: High Temperature Schottky Barrier Diodes Hochtemperatur-Schottky-DiodenselocaNessuna valutazione finora

- Busbar Stabllity Test Procedure and CalculationDocumento8 pagineBusbar Stabllity Test Procedure and CalculationRitesh Jaiswal0% (1)

- IC TDA-11115, TDA-11145 Service Manual enDocumento24 pagineIC TDA-11115, TDA-11145 Service Manual enJeank Rivadeneyra50% (2)

- Isolated Footing Design (IS 456-2000)Documento12 pagineIsolated Footing Design (IS 456-2000)Divya TadepalliNessuna valutazione finora

- Aft Fuselage Jig Process Sheet-2Documento7 pagineAft Fuselage Jig Process Sheet-2asderbvaNessuna valutazione finora

- The Deputy Manager 220kv GIS G/S Ravi LahoreDocumento9 pagineThe Deputy Manager 220kv GIS G/S Ravi LahoreJavaid IqbalNessuna valutazione finora

- The University of Asia Pacific: Trainer Board 2Documento5 pagineThe University of Asia Pacific: Trainer Board 2sabitavabiNessuna valutazione finora

- Learning of Etabs Software ProblemDocumento32 pagineLearning of Etabs Software ProblemRamilArtatesNessuna valutazione finora

- Low Voltage Colloidal Silver Generator With Motorized StirringDocumento2 pagineLow Voltage Colloidal Silver Generator With Motorized Stirringgicu123Nessuna valutazione finora

- Building Drifts in EtabsDocumento9 pagineBuilding Drifts in EtabsnsutharNessuna valutazione finora

- Labor Units Manual: Electrical Contractor'sDocumento14 pagineLabor Units Manual: Electrical Contractor'sBNessuna valutazione finora

- British Commercial Computer Digest: Pergamon Computer Data SeriesDa EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNessuna valutazione finora

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityDa EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNessuna valutazione finora

- British Commercial Computer Digest: Pergamon Computer Data SeriesDa EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNessuna valutazione finora

- Alert Based Monitoring of Stock Trading SystemsDocumento3 pagineAlert Based Monitoring of Stock Trading Systemswandai_81Nessuna valutazione finora

- Online Stock Trading Touted: Home Search Alerts News Pages Companies/MarketsDocumento1 paginaOnline Stock Trading Touted: Home Search Alerts News Pages Companies/Marketswandai_81Nessuna valutazione finora

- PID Algorithm in Matlab M FileDocumento2 paginePID Algorithm in Matlab M FilejagateesanNessuna valutazione finora

- Assignment 2 - Progress Report 2Documento1 paginaAssignment 2 - Progress Report 2wandai_81Nessuna valutazione finora

- Student Health and Safety Declaration FormDocumento1 paginaStudent Health and Safety Declaration Formwandai_81Nessuna valutazione finora

- What Should Be The Return On Public-Sector Investment?: Policymakers Need To Be Mindful of Opportunity CostsDocumento5 pagineWhat Should Be The Return On Public-Sector Investment?: Policymakers Need To Be Mindful of Opportunity Costswandai_81Nessuna valutazione finora

- Assignment 1leesaDocumento2 pagineAssignment 1leesawandai_81Nessuna valutazione finora

- 3304ENG-7517ENG - Risk AssessmentDocumento1 pagina3304ENG-7517ENG - Risk Assessmentwandai_81Nessuna valutazione finora

- Financial AffidavitDocumento1 paginaFinancial Affidavitwandai_81Nessuna valutazione finora

- Gu Edu AuDocumento36 pagineGu Edu Auwandai_81Nessuna valutazione finora

- Health and Safety RequirementsDocumento1 paginaHealth and Safety Requirementswandai_81Nessuna valutazione finora

- KkcitymapDocumento1 paginaKkcitymapsmksplNessuna valutazione finora

- Pro MetricDocumento3 paginePro Metricwandai_810% (1)

- Jsu 7 April 2013-Adtec KulimDocumento2 pagineJsu 7 April 2013-Adtec Kulimwandai_81Nessuna valutazione finora

- Format - OBE Circuit TheoryDocumento12 pagineFormat - OBE Circuit Theorywandai_81Nessuna valutazione finora

- African American Theme GardenDocumento2 pagineAfrican American Theme GardencdslicNessuna valutazione finora

- Kertas Penerangan (H-175-04-05-LE4-IS3) : Institut Latihan Jabatan Tenaga Manusia Kementerian Sumber Manusia MalaysiaDocumento14 pagineKertas Penerangan (H-175-04-05-LE4-IS3) : Institut Latihan Jabatan Tenaga Manusia Kementerian Sumber Manusia Malaysiawandai_81Nessuna valutazione finora

- Page 1 of 2 Substation Test Equipment - Powerpoint Engineering LTD - Official Megger Distributo..Documento2 paginePage 1 of 2 Substation Test Equipment - Powerpoint Engineering LTD - Official Megger Distributo..wandai_81Nessuna valutazione finora

- 14.electrical SafetyDocumento30 pagine14.electrical SafetyZulkarnaenUchihaNessuna valutazione finora

- Biomass & Solar TechnologyDocumento2 pagineBiomass & Solar Technologywandai_81Nessuna valutazione finora

- TECHNICAL WRITING TIPSwDocumento3 pagineTECHNICAL WRITING TIPSwwandai_81Nessuna valutazione finora

- Wiki BisoprololDocumento6 pagineWiki Bisoprololwandai_81Nessuna valutazione finora

- gr2 ExpDocumento32 paginegr2 Expwandai_81Nessuna valutazione finora

- MotorDocumento116 pagineMotorRutvi Vishal Vaghela100% (1)

- Chapter 1 Introduction: CAD Tools (Brunvand09), Covers Practical Details of Using The Leading Industrial CADDocumento1 paginaChapter 1 Introduction: CAD Tools (Brunvand09), Covers Practical Details of Using The Leading Industrial CADCarlos SaavedraNessuna valutazione finora

- Optimization and Control of HydroponicsDocumento88 pagineOptimization and Control of HydroponicsDeepak KNessuna valutazione finora

- TestDocumento25 pagineTestsubha4studyNessuna valutazione finora

- ARM Based ESD UNIT 2BDocumento18 pagineARM Based ESD UNIT 2BManu ManuNessuna valutazione finora

- Photoluminescence For Defect Detection On Full-Sized Photovoltaic ModulesDocumento11 paginePhotoluminescence For Defect Detection On Full-Sized Photovoltaic ModulesADITYA BHALEGHARENessuna valutazione finora

- Samsung SF 830 and 835P Service ManualDocumento189 pagineSamsung SF 830 and 835P Service ManualwcualumniNessuna valutazione finora

- "ZNR" Transient/Surge Absorbers (Type D)Documento4 pagine"ZNR" Transient/Surge Absorbers (Type D)Eduard BuseNessuna valutazione finora

- Crystal Defect PresentationDocumento22 pagineCrystal Defect PresentationMani Charan Manicharan100% (1)

- ISL6612, ISL6613: Advanced Synchronous Rectified Buck MOSFET Drivers With Protection FeaturesDocumento12 pagineISL6612, ISL6613: Advanced Synchronous Rectified Buck MOSFET Drivers With Protection FeaturesAnonymous oyUAtpKNessuna valutazione finora

- Sodium Ion BatteriesDocumento29 pagineSodium Ion Batteriesarjmandquest100% (2)

- Quanta jm3Documento37 pagineQuanta jm3CADASEDANessuna valutazione finora

- Excitation SystemDocumento13 pagineExcitation SystemKVVNessuna valutazione finora

- Gas Metal Arc Welding (GMAW)Documento16 pagineGas Metal Arc Welding (GMAW)Akmal Bin Saipul AnuarNessuna valutazione finora

- Solidpractices: Thermal Management: Using Electronics Cooling ModuleDocumento14 pagineSolidpractices: Thermal Management: Using Electronics Cooling Modulemlik borhenNessuna valutazione finora

- Final Year Project of SsuetDocumento59 pagineFinal Year Project of SsuetMuhammad Yousuf SaleemNessuna valutazione finora

- Boost Interleaved Buck Boost ConverterDocumento7 pagineBoost Interleaved Buck Boost ConverterSrikanth PolisettyNessuna valutazione finora

- 12 PhysicsDocumento26 pagine12 Physicsqadeer03038185164Nessuna valutazione finora

- ETAP IEC Short Circuit Calculation MethodsDocumento7 pagineETAP IEC Short Circuit Calculation Methodshizbi7Nessuna valutazione finora

- AC Vs DCDocumento17 pagineAC Vs DCKhalid UsmanNessuna valutazione finora

- LAB 2aDocumento5 pagineLAB 2aguntadiNessuna valutazione finora

- 01 - Introduction To Multilevel InvertersDocumento53 pagine01 - Introduction To Multilevel Invertersp09el860Nessuna valutazione finora

- 555 Timer Setup MannualDocumento3 pagine555 Timer Setup MannualMitochiNessuna valutazione finora

- (Lertffi Y: (Typ - I) Iffi "Eq0Documento6 pagine(Lertffi Y: (Typ - I) Iffi "Eq0supremeNessuna valutazione finora

- Physics ProjectDocumento14 paginePhysics ProjectAkhilesh Soni100% (1)

- Andervol: Resistors CapacitorsDocumento1 paginaAndervol: Resistors CapacitorsNilson Gomes Jr.Nessuna valutazione finora

- LM324 PDFDocumento4 pagineLM324 PDFAlexinGriNessuna valutazione finora

- Unit 1 Notes TopperDocumento33 pagineUnit 1 Notes TopperShashank BakshiNessuna valutazione finora

- Infineon IKY75N120CH3 DS v02 - 02 EN PDFDocumento16 pagineInfineon IKY75N120CH3 DS v02 - 02 EN PDFnithinmundackal3623Nessuna valutazione finora

- 89C51Documento15 pagine89C51Bhasker GurramNessuna valutazione finora

- Taiwan Semiconductor: Description FeaturesDocumento7 pagineTaiwan Semiconductor: Description FeaturesjicoelhoNessuna valutazione finora