Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Improving Service Quality at Honda

Caricato da

Daniel Nikolas TodeDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Improving Service Quality at Honda

Caricato da

Daniel Nikolas TodeCopyright:

Formati disponibili

Improving Service Quality at Honda

by Wayne Stottler

For all the differences between achieving quality in manufacturing and service environments,

there is at least this important similarity: Both require top quality inputs and processes.

And now for an important difference: Measuring the inputs and processes that create quality

service is a tough challenge. True, you know a good report when you see one, and when

purchase orders are processed in a timely fashion, you get materials faster. But how do you

know the procedures and mental processes used to create the report or procure the materials

were based on quality principlesor were even efficient?

Defects in intangibles such as problem solving, decision making or project management are

much more difficult to spot and correct than defective raw materials or problems on the line. Yet,

these often invisible inputs and processes are just as fundamental to providing high quality

service and support as high quality inputs and processes are to manufacturing.

Critical Questions

Having recognized the need for a quality focus in service and support functions, many

organizations are now confronted with the challenge of developing necessary quality skills. Smart

companies begin by asking themselves a few key questions--the same kind of questions

manufacturing organizations ask and answer about quality training:

What attributes will define quality in these functions?

What skills will most rapidly improve and sustain those quality attributes?

What are the most efficient and effective ways to deliver quality training?

How can quality skills be supported and deepened after training?

How can the organization assess the value of quality training?

And, as organizations look for electronic learning tools and strategies to improve the delivery of

training, assess its value and support the ongoing use of quality processes, heres another

important question:

How can the organization impact the quality of service and support through the use of

electronic learning tools and strategies?

As companies begin to explore these questions, their answers offer interesting insights into

approaches that work, effective methods for achieving and assessing specific results, and

foolproof planning for continuous improvement in the future.

American Honda Example

American Honda Motor Co. is part of Hondas North American operations. Based in Torrance,

CA, American Honda provides information services, purchasing, financial services, leasing

support and a host of sales and marketing related services to Hondas business and

manufacturing units throughout North America.

In 2001, American Hondas associate learning and organizational development group undertook

a broad assessment of its approach to training, looking at what was offered, why, to whom and

how.

One focus of this initiative was to deepen the emphasis on quality, which has long permeated

Hondas manufacturing operations, within the internal support and service portions of the

organization.

The Honda philosophy encourages every individual to continuously expand his or her ability to

identify and impact both internal and supplier quality, says Lou Juneman, manager of associate

learning and organizational development for American Honda. Innovation, branding, customer

satisfaction and efficiency are central to our success; therefore, quality is at the core of

everything we do.

The challenge laid out for the development group was to improve and extend the delivery of

training for employees, reduce their time away from the job for training, take advantage of

expanding technology capabilities and infrastructure and, above all, ensure a tangible transfer of

skills that would take internal service quality to an entirely new level.

It was important to build on what we were already doing well, not replace it, or worse, introduce

problems or barriers in the name of technology enabled learning, notes Juneman.

Hondas approach to service quality improvement through e-learning was focused and

disciplined. First, the company began to use a learning management system (LMS) to schedule,

administer and track training. The system was applied not only to instructor led offerings but also

to pure online training, blended learning (a unique mix of online and instructor led training) and

other offerings.

Using a customized LMS, Honda employees and their managers learned to define and manage

individual training plans as well as enroll in, complete and track their progress courses and

curricula through a learner specific Web portal.

Decisions also had to be made about which programs to offer and which formats would best

support the overall emphasis on growth and quality. We were committed to providing the best

mix of electronic, instructor led and self-paced learning to our employees, explains Juneman.

From the beginning, we focused on blending components whenever possible to meet the needs

of both the learners and the organization.

Blended Learning

One of the programs to which the blended learning approach was applied was problem solving

and decision making. This program sharpens an individuals ability to separate and clarify issues,

identify those that need immediate attention and resolve them using a systematic, rational

problem solving, decision making or action planning process.

These rational thinking skills have been successfully taught at American Honda for many years in

a purely instructor led workshop version. The skills have been critical to establishing and

sustaining quality throughout Honda, in both the manufacturing and service/support areas.

American Honda worked closely with several vendors to shorten the time spent at the workshop,

produce online learning elements and document results electronically. Since it was important not

to lose the dynamic that occurs when people work together, learn from each other and receive

direct coaching from an instructor, we decided against a completely virtual approach, notes

Juneman.

Rather, we elected to utilize the power of online learning at specific points before and after the

workshop, Juneman continues. This enabled us to increase initial understanding of the topics

and get learners talking to the instructors about their objectives before coming to the session. We

were also able to set the stage for immediate use of the concepts back on the job and provide

learners with online tools to support sustained use over time.

The blended learning approach also enabled American Honda to capture and measure detailed,

useful data about how the problem solving and decision making processes are used to impact

and improve quality in critical service and support areas.

Three Phases

American Honda realized from the beginning that training, by itself, wouldnt lead to quality

improvements. Applying the skills you learn during a training experience regularly and accurately

requires a great deal of practice and support. Enter American Hondas three-phase learning

model (see Figure 1).

Phase one: The first phase takes place online. For two to three weeks, learners access a series

of online modules that introduce the logical processes for effective problem solving and decision

making. Learner progress is essentially self-paced, but since the content is driven from a Web

server, the instructor can follow the progress of each learner and provide ongoing

encouragement and support.

During phase one, learners are also asked to identify situations to which they intend to apply the

techniques so they can focus on these situations when they attend the workshop. This powerful

combination of initial learning and preparation for applying the concepts to real-life issues

ensures the following phase will not only be efficient but also build deep understanding and

significant motivation to use the ideas on the job after training.

Phase two: The second phase takes place at the workshop. Guided by the instructor, learners

spend two days deepening their understanding of the concepts, discussing best practices and

additional techniques for problem solving and decision making, and practicing on detailed case

scenarios.

Since skill transferand resultsoccur most rapidly when you start with the learners on-the-job

issues, a significant portion of the session is spent working on the problems, decisions and plans

identified in phase one. Simultaneously, learners receive coaching and feedback from the

instructor and one another.

Learners leave the session ready to fully apply the concepts and with a plan in hand to move

successfully from the workshop to consistent use of the concepts back on the job.

Phase three: The final phase takes place back online. In the three weeks following the session,

learners resolve the on-the-job issues they began to work on during the workshop. They

document for instructor review, feedback and approval the specific techniques they used to

resolve the issues.

During phase three, learners have access to a host of online support tools and information. They

can contact the instructor with questions at any time.

The goal of this phase is to ensure use of the learned concepts, build confidence, get results and

capture information about how the problem solving and decision making tools impact American

Hondas business--how they create quality and value through their use.

Lessons Learned

We learned a lot about the pros and cons of electronic learning when we began to use this

approach, observes Leon Ronzana, assistant manager, organizational development, at

American Honda. True online learning requires culture change, and like any change, it requires

planning, communication and persistence.

While online learning displaces some workshop timethe session was pared from three days to

twolearners must take time to go online and learn. This requires new behaviors on the part of

learners (who have to find the time and resist distractions), managers (who have to encourage

and protect the time necessary for online learning) and instructors (who become performance

partners and must be available to coach and support learners).

To promote and support the success rate of online learners, American Honda now kicks off each

training session with a Web conference to clarify expectations and provide participants with

practical tips for online learning. In addition, learners managers are brought into the loop and

asked for input into the choice of high priority problems, decisions and plans to be tackled during

the workshop.

Instructors at American Honda have also received additional training to help them effectively

coach online learners and act quickly to intervene with anyone experiencing difficulties. The

company has also created an extensive online library of reference and support materials on

which instructors can draw.

Online learning is not for everyone, especially people whove never learned that way before,

Ronzana points out, so weve made sure learners can print paper versions of most on-line

materials if they learn best in other modes, want to continue learning while traveling or are in a

location without Web access.

These kinds of adjustmentscontinuous improvementshave added up to a performance

environment that better supports the learning experience and promotes the desired outcomes:

problems solved, decisions made and quality protected and improved.

Success Indicators

How has American Hondas learning experiment improved the quality of its support services?

Juneman points to three areas in which the blended learning approach has had a positive

impact: the increased quality of the actual learning experience, the qualityand visibilityof

issues being resolved immediately after training and the increased use of the learned concepts

over time to drive up business results.

Because instructors can track phase one learning progress in real time, they can provide direct

support to individual learners even before they come to the workshop. As a result, the instructor

can tailor the learning experience, minimizing the one-size-fits-all approach that frustrates many

people in traditional training.

After the session, the instructor becomes an on-call coach--tracking progress, providing pointers

and answering questions so learners get personalized support during the critical days following

the workshop, when traditional learners often stumble and give up in frustration.

This adds up to a higher quality learning experience that produces the motivation and support

Juneman believes are key to setting the stage for integrating learned concepts into daily use

long-term.

Training only leads to quality improvements back on the job if people embed new ideas into their

daily routines, Juneman explains, and that only happens if the learner is sufficiently motivated

and supported by the learning experience to consistently use new ideas until they become

second nature.

Ronzana believes the quality, visibility and value of issues learners resolve immediately after the

workshop portion of the training have been greatly enhanced by the new approach. Because

learners now submit online documentation of the issues they have resolved, it is much easier to

see how and where the concepts are being used and evaluate the impact of the training on the

bottom line of the organization.

We have direct visibility into both individual and organizational improvement, notes Ronzana. It

is impressive to stand back and look at 30 or more fully documented decisions made, problems

solved or activities undertaken using clear, rational thinking processes. Sometimes we can

assign clear dollar results to outcomes.

At other times, the results are less tangible, or we choose not to quantify them but to look for

improved systems, reduced barriers or overall employee and customer satisfaction, Ronzana

explains. In either case, we know with certainty our associates are using what theyve learned to

improve the quality of services and, by extension, of the organization.

If you plan to adopt a blended learning approach similar to American Hondas, heres a pivotal

question: What constitutes success? The indicators of success in Figure 2 should serve as

thought starters.

With more than 300 taking advantage of the blended learning opportunity in the last couple of

years, American Honda is happy with the results. Juneman offers an example: When someone

in our dealer support function uses these rational thinking processes to systematically find and

resolve the cause of a longstanding computer systems issue, I know he or she and a number of

other people across the organization will be able to work more efficiently. The quality of individual

output is improved, customers are happier and more efficient, and learners are very likely to use

the problem solving process again and again to achieve similar results.

Although American Honda has not yet studied the long-term impact of blended learning on

quality in service and support functions, Juneman and Ronzana are comfortable the impact is

already there, has added value and will continue to grow.

As Juneman sees it, The fact that our associates talk about decisions, problems and actions

using a common vocabulary and approach and routinely include specific documentation of

results speaks volumes about blended learnings ability to stick over time.

American Honda has found training for service quality improvement works best when it is

multimodal. In blended learning, high touch and high tech converge. It is also where vision and

the basic blocking and tackling of performance management meet to create significant behavior

change and business results.

Kepner-Tregoe, Inc. is a Princeton, NJ-based consulting and training company that works with

organizations worldwide to meet complex business challenges and achieve measurable results.

The renowned Kepner-Tregoe processes for problem solving, decision making, and project

management provide logical and consistent approaches to tough business issues.

Wayne Stottler is a consultant in the Product Engineering and Support Group at Kepner-Tregoe.

His responsibilities include new product design, ongoing product support, product tailoring, and

special project consulting.

Copyright 2005 Kepner-Tregoe, Inc. All Rights Reserved.

Potrebbero piacerti anche

- Training For Improving Service Quality at HondaDocumento5 pagineTraining For Improving Service Quality at HondaFazarizul Hashidi100% (1)

- Value Chain Management Capability A Complete Guide - 2020 EditionDa EverandValue Chain Management Capability A Complete Guide - 2020 EditionNessuna valutazione finora

- Nalugon BSCS - 3A - The Beauty of ConflictDocumento2 pagineNalugon BSCS - 3A - The Beauty of ConflictAlber Kelly NalugonNessuna valutazione finora

- HRM Chapter 5Documento12 pagineHRM Chapter 5Rye FelimonNessuna valutazione finora

- SDRM CaseDocumento3 pagineSDRM Casejawid tabeshNessuna valutazione finora

- Chapter 1 5Documento47 pagineChapter 1 5renz calderonNessuna valutazione finora

- Juice Factory Training PlanDocumento38 pagineJuice Factory Training Plansameh mokhtarNessuna valutazione finora

- Activity 3Documento1 paginaActivity 3Sheen CatayongNessuna valutazione finora

- Chapter 11Documento50 pagineChapter 11Randi ZamrajjasaNessuna valutazione finora

- Organizational behavior management A Complete Guide - 2019 EditionDa EverandOrganizational behavior management A Complete Guide - 2019 EditionNessuna valutazione finora

- Prelim Assignment 4 ApuanDocumento2 paginePrelim Assignment 4 ApuanPrimo HorneNessuna valutazione finora

- 1-Nature and ScopeDocumento13 pagine1-Nature and ScopeLopa Manish ShahiNessuna valutazione finora

- Recruitment Policy of A CompanyDocumento3 pagineRecruitment Policy of A CompanyAnonymous zXWxWmgZENessuna valutazione finora

- Log in Sign Up Browse: Answers To The Questions in Question Paper From MBA in TQMDocumento6 pagineLog in Sign Up Browse: Answers To The Questions in Question Paper From MBA in TQMthakur_neha20_903303Nessuna valutazione finora

- Discuss The Concept of Strategic Model. (5 PTS.) : A. Wright, Kroll and Parnell ModelDocumento9 pagineDiscuss The Concept of Strategic Model. (5 PTS.) : A. Wright, Kroll and Parnell ModelMelissa Jane ViveroNessuna valutazione finora

- CRS in Kingfisher FinalDocumento73 pagineCRS in Kingfisher FinalGaurav NathaniNessuna valutazione finora

- Case Study - ABC CorpDocumento2 pagineCase Study - ABC Corpkmilind007Nessuna valutazione finora

- Definition of Logistics ManagementDocumento4 pagineDefinition of Logistics ManagementzamaneNessuna valutazione finora

- Two Major Differences Between Service and Manufacturing OrganizationsDocumento2 pagineTwo Major Differences Between Service and Manufacturing OrganizationsJorge Yeshayahu Gonzales-LaraNessuna valutazione finora

- 10 Decision Areas of Operations Management: Google 'S Human Resource ManagementDocumento2 pagine10 Decision Areas of Operations Management: Google 'S Human Resource ManagementMian RehmanNessuna valutazione finora

- Chapter 1 - IntroductionDocumento4 pagineChapter 1 - IntroductionFrancisco CardenasNessuna valutazione finora

- 69547314Documento3 pagine69547314Jasmin GabitaNessuna valutazione finora

- Human Resource Management Assignment Case Study - Job Analysis at Go-ForwardDocumento11 pagineHuman Resource Management Assignment Case Study - Job Analysis at Go-ForwardHoàng Nam29Nessuna valutazione finora

- Competitivenes AssignmentDocumento3 pagineCompetitivenes AssignmentTristan Zambale100% (1)

- QUESTION: With Relevant Examples, Explain The Product Development Stages. SolutionDocumento11 pagineQUESTION: With Relevant Examples, Explain The Product Development Stages. SolutionKisitu MosesNessuna valutazione finora

- Conceptpaper BDODocumento3 pagineConceptpaper BDOgkzunigaNessuna valutazione finora

- Business Plan 1Documento26 pagineBusiness Plan 1May Chelle ErazoNessuna valutazione finora

- Research (Final Defense)Documento16 pagineResearch (Final Defense)Angela CantigaNessuna valutazione finora

- Capacity Planning ReflectionDocumento1 paginaCapacity Planning ReflectionErinNessuna valutazione finora

- Chapter Five System DesignDocumento46 pagineChapter Five System DesignMikaelaMaeVillaluzNessuna valutazione finora

- Dalumpines Case 3Documento9 pagineDalumpines Case 3Jessa Mae LabinghisaNessuna valutazione finora

- Staffing As A Part of Human Resource ManagementDocumento2 pagineStaffing As A Part of Human Resource ManagementmanichawlaNessuna valutazione finora

- Corporate Social Responsibility SamsungDocumento1 paginaCorporate Social Responsibility SamsungGediya RockyNessuna valutazione finora

- An Evaluation of The Efficiency of Loan Collection Policies and Procedures Among Selected MultiDocumento9 pagineAn Evaluation of The Efficiency of Loan Collection Policies and Procedures Among Selected MultiMariz Lazalita RetolinNessuna valutazione finora

- Local StudiesDocumento55 pagineLocal StudiesMarie0% (1)

- Who Will Pitch It To Win ItDocumento10 pagineWho Will Pitch It To Win ItkonepNessuna valutazione finora

- Factors Affecting RecruitmentDocumento9 pagineFactors Affecting RecruitmentNarayana ReddyNessuna valutazione finora

- Starbucks' Mission: Social Responsibility and Brand StrengthDocumento3 pagineStarbucks' Mission: Social Responsibility and Brand StrengthKAYE JAVELLANA50% (2)

- Employee Selection - Structure ExerciseDocumento11 pagineEmployee Selection - Structure Exerciseshah100% (1)

- OmbudsmanDocumento1 paginaOmbudsmanBOB MARLOWNessuna valutazione finora

- CHAPTER 10 - Quality Teamwork and EmpowermentDocumento40 pagineCHAPTER 10 - Quality Teamwork and EmpowermentJamaica Shaine O. Ramos50% (2)

- Xerox - The Bench Marking StoryDocumento36 pagineXerox - The Bench Marking StoryAman Singh100% (3)

- Senior High SchoolDocumento21 pagineSenior High SchoolKylene Magtibay100% (1)

- Business Communication Assignment - MEMODocumento2 pagineBusiness Communication Assignment - MEMOmanju kakkarNessuna valutazione finora

- Man Science Note 5Documento5 pagineMan Science Note 5Gianelle MendezNessuna valutazione finora

- Work ImmersionDocumento15 pagineWork ImmersionShane Basco Tanyag100% (1)

- Case Study of IBMDocumento4 pagineCase Study of IBMVishek VijNessuna valutazione finora

- Illustrative CasesDocumento9 pagineIllustrative CasesTehmina Qazi0% (2)

- GGSRDocumento21 pagineGGSRAnonymous Pu7TnbCFC0Nessuna valutazione finora

- Research JollibeeDocumento15 pagineResearch JollibeeOMAYOMAYNessuna valutazione finora

- External RecruitmentDocumento2 pagineExternal RecruitmentJovie CabanlitNessuna valutazione finora

- QUIZ 1 Distribution ManagementDocumento1 paginaQUIZ 1 Distribution ManagementDan Navarro100% (1)

- After Reading This Lesson You Should Be Able To:: Module 2: Introduction To Marketing ManagementDocumento9 pagineAfter Reading This Lesson You Should Be Able To:: Module 2: Introduction To Marketing Managementyng hyuna100% (1)

- Behavioral Theory With Reference To Coca Cola CompanyDocumento1 paginaBehavioral Theory With Reference To Coca Cola CompanyRąheel HùssąinNessuna valutazione finora

- Co Op Registration ProceduresDocumento11 pagineCo Op Registration ProceduresmwangikyNessuna valutazione finora

- HRM Activity 1Documento8 pagineHRM Activity 1jackihNessuna valutazione finora

- QM - Training For Employees of HondaDocumento3 pagineQM - Training For Employees of HondaPhương Anh NguyễnNessuna valutazione finora

- Multimedia Fusion A Complete Guide - 2020 EditionDa EverandMultimedia Fusion A Complete Guide - 2020 EditionNessuna valutazione finora

- Education Programs A Complete Guide - 2020 EditionDa EverandEducation Programs A Complete Guide - 2020 EditionNessuna valutazione finora

- Economic Review English 17-18Documento239 pagineEconomic Review English 17-18Shashank SinghNessuna valutazione finora

- Hidrl1 PDFDocumento7 pagineHidrl1 PDFRajesh Kumar100% (1)

- Miguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Documento22 pagineMiguel Augusto Ixpec-Chitay, A097 535 400 (BIA Sept. 16, 2013)Immigrant & Refugee Appellate Center, LLCNessuna valutazione finora

- Health Post - Exploring The Intersection of Work and Well-Being - A Guide To Occupational Health PsychologyDocumento3 pagineHealth Post - Exploring The Intersection of Work and Well-Being - A Guide To Occupational Health PsychologyihealthmailboxNessuna valutazione finora

- Systems Analysis and Design in A Changing World, Fourth EditionDocumento41 pagineSystems Analysis and Design in A Changing World, Fourth EditionKoko Dwika PutraNessuna valutazione finora

- Intellirent 2009 CatalogDocumento68 pagineIntellirent 2009 Catalograza239Nessuna valutazione finora

- Patrick Meyer Reliability Understanding Statistics 2010Documento160 paginePatrick Meyer Reliability Understanding Statistics 2010jcgueinj100% (1)

- Literatura Tecnica 3Documento10 pagineLiteratura Tecnica 3Christian PerezNessuna valutazione finora

- Kazon Greater Predator MothershipDocumento1 paginaKazon Greater Predator MothershipknavealphaNessuna valutazione finora

- ChatGpt PDFDocumento19 pagineChatGpt PDFsanx2014100% (1)

- Cloud Comp PPT 1Documento12 pagineCloud Comp PPT 1Kanishk MehtaNessuna valutazione finora

- Quarter 1 - Module 1Documento31 pagineQuarter 1 - Module 1Roger Santos Peña75% (4)

- Chapter 2Documento13 pagineChapter 2Kumkumo Kussia KossaNessuna valutazione finora

- Case CapsuleDocumento8 pagineCase CapsuleLiza BulsaraNessuna valutazione finora

- Rifle May 2015 USADocumento72 pagineRifle May 2015 USAhanshcNessuna valutazione finora

- CV & Surat Lamaran KerjaDocumento2 pagineCV & Surat Lamaran KerjaAci Hiko RickoNessuna valutazione finora

- 22 Khan S.Documento7 pagine22 Khan S.scholarlyreseachjNessuna valutazione finora

- 1 in 8.5 60KG PSC Sleepers TurnoutDocumento9 pagine1 in 8.5 60KG PSC Sleepers Turnoutrailway maintenanceNessuna valutazione finora

- Recitation Math 001 - Term 221 (26166)Documento36 pagineRecitation Math 001 - Term 221 (26166)Ma NaNessuna valutazione finora

- Friction: Ultiple Hoice UestionsDocumento5 pagineFriction: Ultiple Hoice Uestionspk2varmaNessuna valutazione finora

- Antena TelnetDocumento4 pagineAntena TelnetMarco PiambaNessuna valutazione finora

- Aleutia Solar Container ClassroomDocumento67 pagineAleutia Solar Container ClassroomaleutiaNessuna valutazione finora

- The Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermannDocumento15 pagineThe Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermanngeorgiescuNessuna valutazione finora

- Speech On Viewing SkillsDocumento1 paginaSpeech On Viewing SkillsMera Largosa ManlaweNessuna valutazione finora

- Perancangan Crushing Plant Batu Andesit Di PT Nurmuda Cahaya Desa Batujajar Timur Kecamatan Batujajar Kabupaten Bandung Barat Provinsi Jawa BaratDocumento8 paginePerancangan Crushing Plant Batu Andesit Di PT Nurmuda Cahaya Desa Batujajar Timur Kecamatan Batujajar Kabupaten Bandung Barat Provinsi Jawa BaratSutan AdityaNessuna valutazione finora

- Cambridge IGCSE™: Information and Communication Technology 0417/13 May/June 2022Documento15 pagineCambridge IGCSE™: Information and Communication Technology 0417/13 May/June 2022ilovefettuccineNessuna valutazione finora

- Fds-Ofite Edta 0,1MDocumento7 pagineFds-Ofite Edta 0,1MVeinte Años Sin VosNessuna valutazione finora

- ყვავილები ელჯერნონისთვისDocumento348 pagineყვავილები ელჯერნონისთვისNia NorakidzeNessuna valutazione finora

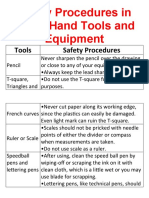

- Safety Procedures in Using Hand Tools and EquipmentDocumento12 pagineSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezNessuna valutazione finora

- 2022 WR Extended VersionDocumento71 pagine2022 WR Extended Versionpavankawade63Nessuna valutazione finora