Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

13 - Minervini

Caricato da

elsaorduna0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni28 pagineTechnology and Engineering Division Development of HTS Cables for DC Power Transmission and Distribution J oseph V. Minervini MIT Plasma Science and Fusion Center Eighth Annual EPRI Superconductivity Conference Doubletree, oak ridge, tennessee. Cable design concepts Chubu-MIT HTS DC cable Collaboration long Length Cooling Current Lead Cooling Potential Near Term Application Conclusions Portions reprinted, with permission, from Massachusetts Institute of Technology.

Descrizione originale:

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoTechnology and Engineering Division Development of HTS Cables for DC Power Transmission and Distribution J oseph V. Minervini MIT Plasma Science and Fusion Center Eighth Annual EPRI Superconductivity Conference Doubletree, oak ridge, tennessee. Cable design concepts Chubu-MIT HTS DC cable Collaboration long Length Cooling Current Lead Cooling Potential Near Term Application Conclusions Portions reprinted, with permission, from Massachusetts Institute of Technology.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni28 pagine13 - Minervini

Caricato da

elsaordunaTechnology and Engineering Division Development of HTS Cables for DC Power Transmission and Distribution J oseph V. Minervini MIT Plasma Science and Fusion Center Eighth Annual EPRI Superconductivity Conference Doubletree, oak ridge, tennessee. Cable design concepts Chubu-MIT HTS DC cable Collaboration long Length Cooling Current Lead Cooling Potential Near Term Application Conclusions Portions reprinted, with permission, from Massachusetts Institute of Technology.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 28

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Development of HTS Cables for DC Power

Transmission and Distribution

J oseph V. Minervini

Leslie Bromberg

Makoto Takayasu

Christopher Miles and Nicholas R. LaBounty

MIT Plasma Science and Fusion Center

Eighth Annual EPRI Superconductivity Conference

Doubletree, Oak Ridge, TN ~ November 12 13, 2008

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Outline

HTS DC Advantages

Cable Design Concepts

Chubu-MIT HTS DC Cable Collaboration

Long Length Cooling

Current Lead Cooling

Potential Near Term Application

Conclusions

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

DC Superconducting Transmission Line

Advantages:

No DC resistive losses

No AC inductive storage

Low or no AC losses

Long range transmission of high currents, including undersea

Very high power ratings including transmission of several GVA

Fault currents limited by fast acting inverters at AC/DC and DC/AC ends

of the line

Low voltage transmission, if desired, limiting the need for high voltage

transformers

Simplified cable design, more amenable to using HTS tape geometry

Cable coolant also used to cool solid state inverters increasing capacity

and reducing high temperature aging degradation

Disadvantages: Invertors can add substantially to cost

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

HTS DC increases efficiency for long distance transmission

Opens other advanced technology opportunities:

Direct connection of alternative low-carbon or carbon-free power

sources:

Wind

Solar PV

Fuel Cell

Microturbine

other

Connection of advanced energy storage devices

Flywheel

Battery

Supercapacitor

Superconducting Magnetic Energy Storage (SMES)

other

HTS DC Applications

}

Grid independence

}

System

Stability and

Power

Quality

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

HTS DC Transmission

Cables

DC-to-AC Power Conversion

Off-Shore Wind Farm Power

Transmission

Using HTS DC Cable

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Solar Photovolatic or Concentrated Solar Thermal

Power Transmission Using HTS DC Cable

Solar PV

CSP

Solar and Wind

DC Power

Transmit DC before conversion?

DC Super c onduc t i ng Pow er

Tr ansmi ssi on Li ne Ex per i ment i n

Chubu Uni ver si t y

&

Col l abor at i on w i t h MI T

Prof. Satarou Yamaguchi

Dept. of Electrical Engineering

yamax@isc.chubu.ac.jp

Center of Applied Superconductivity

and Sustainable Energy Research

(CASER)

Experimental Device in Chubu University

Parameters

current > 2.5 kA

voltage > 20 kV

length ~ 20 m

Sumitomo Bi-2223 cable

coolant; LN2

equipped with pump and

cryogenic cooler

72 K - 77 K

SC Cable

made by

Sumi t omo

i nsul at i on l ayer

HTS Tape

f or mer

c opper w i r es

i nner spr i ng

c ent er hol e

f or c ool ant pat h

Phot o of c r oss-sec t i on

40

i nsul at i on

30k VDC

ear t h l ayer

f or mer

c opper w i r es

HTS Tape x 39

Side View

Tape conductor

1st layer; 19

2nd layer; 20

Bi-2223/ 100A

grade

Insulation Volt. DC20kV Insulator, PPPL

Outer radius 40

Center hole 14

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

MIT High Current HTS

DC Cable Designs

Multiple Layers

Triplet

Carpet Stack

Twisted Triplets

Wedge Stack

Twisted

Triplets

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Use Basic Carpet Stack

tapes can be insulated or soldered

Square or rectangular stack

Base element former can be

conducting

non-conducting

Structural

Tape shape requires relatively long twist

pitches

AC losses not an issue for DC applications

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

25 kA at T = 65 K - 77 K

Carpet Stack triplets have highest J

e

Allows for smaller cryostat and lower heat leak

Carpet Stack and wedge base conductors allow many

variations on cable patterns and total tape number

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Potential Opportunity

Data Server Centers

In 2006, electricity consumed by servers in U.S. data

centers (including cooling and auxiliary infrastructure)

represented about 1.5 percent of national electricity

use*.

Internet data center consumes ~ 12 kW/m

2

.

10 MW-50 MW+ total capacity in new centers

DC may be preferred

Minimizes conversion losses

~7-10% energy savings migrating to DC

No reactive power

Power multiplier: for 1 W dissipation saved, 1.5 - 2 W

cooling eliminated

Google datacenter near The Dalles Dam

*Report to Congress on Server and Data Center

Energy Efficiency, U.S. Environmental Protection

Agency, Aug. 2, 2007

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Expected Data Server Center

Power Growth

G. Lawton, Powering Down the Computing Infrastructure, Computer, IEEE, 40, issue 2, p 16-19, Feb. 2007.

DC Distribution Demonstration Developed by

LBNL and Industry Partners

William Tschudi, LBNL

Measured Best in Class AC System Loss Compared to DC

~9-12% efficiency improvement measured by elimination of transformer

and second AC/DC conversion

PSU

ASD

Ballast

AC Distribution

Electronic

loads

Lighting

loads

Motor

loads

AC/DC

AC/DC

VR AC/DC

DC/DC

AC/DC DC/AC

DC/AC

DC/AC

60 Hz AC

480V

AC/DC DC/AC

DC/AC

DC

300-

400V

PV

FC

Benefits of 400Vdc

Slides courtesy of Annabelle Pratt-Intel

PSU

ASD

Ballast

Facility Level

Electronic

loads

Lighting

loads

Motor

loads

AC/DC

AC/DC

VR AC/DC

DC/DC

AC/DC DC/AC

DC/AC

DC/AC

60 Hz AC

480V

AC/DC DC/AC

DC/AC

DC

300-

400V

PV

FC

Benefits of 400Vdc

Slides courtesy of Annabelle Pratt-Intel

X

X

X

X

X

X

X

X

X

X X

X

X

X

X

X

ASD

PSU

Ballast

400V DC facility with DG

60 Hz AC

480V

Electronic

loads

Lighting

loads

Motor

loads

VR

DC/DC

AC/DC

DC

300-

400V

DC/AC

DC/AC

Benefits of 400Vdc

AC/DC

DC/DC

DC/DC

Slides courtesy of Annabelle Pratt-Intel

ASD

PSU

Ballast

400V DC facility with SC Bus

60 Hz AC

480V

Electronic

loads

Lighting

loads

Motor

loads

VR

DC/DC

AC/DC

DC

300-

400V

DC/AC

DC/AC

Benefits of 400Vdc

AC/DC

DC/DC

DC/DC

Slides courtesy of Annabelle Pratt-Intel

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division 4400 Ampere Cable Sizes

1.75Diameter cable

325 A per cable

14 Cables

35 lbs/ft

0.605Diameter cable

133 A per cable

33 Cables

8 lbs/ft

1.75Diameter

up to 30 Conductors

up to 200 Amps per Conductor

1 Cable

2.0 lbs/ft

Copper - Air cooled Copper - Water cooled

HTS- LN2 Cooled

Very High Power Density is

Achievable with Superconductors

x 10 = 4000 A @ 0 Voltage

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Schematic 10MW, 400V, 25 kA

Data Center Layout

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Technology Needed to Implement

SC Distribution

As opposed to transmission, there are a large

number of secondary spurs, with relatively

high density (depending on application)

Refrigeration losses dominated by leads, not

by distributed cryostat or AC losses

Need to address the problem of

Electrical connections through low-loss leads

Cooling manifolding

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

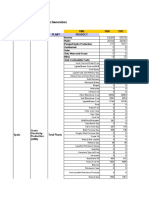

Navigant Consulting costing predictions of SC components in 2008-2012:

http://www.energetics.com/meetings/supercon06/pdfs/Plenary/07_Navigant_HTS_Market_Readiness_Study.pdf

Power Dissipation with Standard Leads (kW)

Summary of Preliminary System Analysis

MIT Energy Initiative Seed Fund - 2008

Current lead loss is 0.05 W/A-lead

Power Loss

HTS +Cu

(2007)

Power Loss

HTS +Cu

(2008-2011)

Power Loss

HTS +Cu

(2012-2016)

Power Loss

All Cu

HTS Leads 10 10 10

HTS Cryostat 0.45 0.225 0.225

HTS Cold

Power Total

10.450 10.225 10.225

Refrigerator

Wall Power

300 177 118

Copper Bus 16 16 16 250

Total Electrical

System Power

316 193 134 250

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Navigant Consulting costing predictions of SC components in 2008-2012:

http://www.energetics.com/meetings/supercon06/pdfs/Plenary/07_Navigant_HTS_Market_Readiness_Study.pdf

Power Dissipation with Optimized Leads (kW)

MITEI Seed Fund Study (contd)

Current lead loss is 0.025 W/A-lead achieved by intermediate cooling stage

Power Loss

HTS +Cu

(2007)

Power Loss

HTS +Cu

(2008-2011)

Power Loss

HTS +Cu

(2012-2016)

Power Loss

All Cu System

HTS Leads 5 5 5

HTS Cryostat 0.450 0.225 0.225

HTS Cold

Power Total

5.450 5.225 5.225

Refrigerator

Wall Power

157 90 60

Copper Bus 16 16 16 250

Total Electrical

System Power

173 106 76 250

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Navigant Consulting costing predictions of SC components in 2008-2012:

http://www.energetics.com/meetings/supercon06/pdfs/Plenary/07_Navigant_HTS_Market_Readiness_Study.pdf

Capital Costs (k$)

MITEI Seed Fund Study (contd)

Capital Costs

HTS +Cu

2007

Capital Costs

HTS +Cu

2008-2011

Capital Costs

HTS +Cu

2012-2016

Capital Costs

All Cu

HTS Tape 2,800 560 112

HTS Cryostat 200 130 44

HTS

Refrigerator

1,050 640 260

HTS Total 4,050 1,330 416

Copper Bus 11 11 11 160

Total Capital

Cost

4,061 1,341 427 160

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Operating Costs of Power ($/Hr)

Electricity cost = $0.10/kW-Hr

MITEI Seed Fund Study (contd)

Operating

Costs

2007

Operating

Costs

2008-2011

Operating

Costs

2012-2016

HTS (standard leads) 31.69 19.27 13.38

HTS (optimized leads) 17.26 10.62 7.61

All Copper 25.07 25.07 25.07

HTS Payback Period

(standard leads)

Never 23 Years 2.6 Years

HTS Payback Period

(optimized leads)

57 Years 9.2 Years 1.75 Years

Portions reprinted, with permission, from Massachusetts Institute of Technology and J oseph Minervini.

Technology & Engineering Division

Summary

Use of HTS could open innovative opportunities in

datacenters for decreased power consumption, flexibility and

easy of construction

Application to data server centers is a near term application

with potential large efficiency gains

Short time scale implementation allows further development

for other MicroGrid applications with similar technology

Establishes technology for:

Bringing large-scale power to land from offshore wind farms

Combining large-scale solar PV or solar thermal systems to the grid

Long distance power transmission and/or grid interconnects

Optimized DC cable, cryostat and current leads require

development program

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Cn1749156a Arc Method For Synthesizing Controllable Single Wall Carbon Nano TubeDocumento7 pagineCn1749156a Arc Method For Synthesizing Controllable Single Wall Carbon Nano TubeelsaordunaNessuna valutazione finora

- Combined PDFDocumento527 pagineCombined PDFelsaordunaNessuna valutazione finora

- 7.5 01 03 03Documento18 pagine7.5 01 03 03elsaordunaNessuna valutazione finora

- 7.5 02 07 03.9Documento17 pagine7.5 02 07 03.9elsaordunaNessuna valutazione finora

- 7.5 02 07 03.9Documento17 pagine7.5 02 07 03.9elsaordunaNessuna valutazione finora

- Regulatory: GuideDocumento7 pagineRegulatory: GuidetingpaduNessuna valutazione finora

- CFR 2012 Title10 Vol1 Part50 Appb PDFDocumento5 pagineCFR 2012 Title10 Vol1 Part50 Appb PDFelsaordunaNessuna valutazione finora

- España AieDocumento14 pagineEspaña AieelsaordunaNessuna valutazione finora

- Pub1159 WebDocumento115 paginePub1159 WebRodolfo RodriguezNessuna valutazione finora

- Epri TR1002159Documento214 pagineEpri TR1002159elsaordunaNessuna valutazione finora

- CN 103293186Documento11 pagineCN 103293186elsaordunaNessuna valutazione finora

- Pub1157 - Web Periodic Safety ReviewDocumento62 paginePub1157 - Web Periodic Safety ReviewelsaordunaNessuna valutazione finora

- CN 103293186Documento11 pagineCN 103293186elsaordunaNessuna valutazione finora

- Kr20130041572 Complex Condition Diagnosis Device and Method For Induction Motor Using On-Line TechniqueDocumento15 pagineKr20130041572 Complex Condition Diagnosis Device and Method For Induction Motor Using On-Line TechniqueelsaordunaNessuna valutazione finora

- Us 2011002774 A 1Documento13 pagineUs 2011002774 A 1elsaordunaNessuna valutazione finora

- 05 - WeberDocumento22 pagine05 - WeberelsaordunaNessuna valutazione finora

- Pub1376 - Web Severe AccidentDocumento83 paginePub1376 - Web Severe AccidentelsaordunaNessuna valutazione finora

- CN102543422 Technology For Improving Insulation Resistance of Dry Transformer Iron Core and Online MonitoringDocumento6 pagineCN102543422 Technology For Improving Insulation Resistance of Dry Transformer Iron Core and Online MonitoringelsaordunaNessuna valutazione finora

- HVDCDocumento30 pagineHVDCelsaordunaNessuna valutazione finora

- Chapter 3 Phasor Estimation at Off-Nominal PDFDocumento31 pagineChapter 3 Phasor Estimation at Off-Nominal PDFelsaordunaNessuna valutazione finora

- KR101035497 Method For Total Monitering On-Line Health of The GeneratorDocumento20 pagineKR101035497 Method For Total Monitering On-Line Health of The GeneratorelsaordunaNessuna valutazione finora

- Kr101035496 System For Total Monitering On-Line Health of The GeneratorDocumento18 pagineKr101035496 System For Total Monitering On-Line Health of The GeneratorelsaordunaNessuna valutazione finora

- Kr101035496 System For Total Monitering On-Line Health of The GeneratorDocumento18 pagineKr101035496 System For Total Monitering On-Line Health of The GeneratorelsaordunaNessuna valutazione finora

- Us8455145b2 - Arturo Solis H - Photoelectrochemical MethodDocumento8 pagineUs8455145b2 - Arturo Solis H - Photoelectrochemical MethodelsaordunaNessuna valutazione finora

- Chapter 3 Phasor Estimation at Off-Nominal PDFDocumento31 pagineChapter 3 Phasor Estimation at Off-Nominal PDFelsaordunaNessuna valutazione finora

- CN202230145 Distribution Transformer Remote Wireless Monitoring SystemDocumento4 pagineCN202230145 Distribution Transformer Remote Wireless Monitoring SystemelsaordunaNessuna valutazione finora

- CN101294856 Transformer Device On-Line Multi-Parameter Monitoring Device Based On Optical Fiber Sensor TechnologyDocumento7 pagineCN101294856 Transformer Device On-Line Multi-Parameter Monitoring Device Based On Optical Fiber Sensor TechnologyelsaordunaNessuna valutazione finora

- ART - Reinjection Into Geothermal ReservoirsDocumento21 pagineART - Reinjection Into Geothermal ReservoirselsaordunaNessuna valutazione finora

- Transfomer FmeaDocumento58 pagineTransfomer FmeaPartha Sarathi GangulyNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Adenariwo AdepojuDocumento225 pagineAdenariwo AdepojustarykltNessuna valutazione finora

- Electrical Trade Theory N2: National CertificateDocumento48 pagineElectrical Trade Theory N2: National CertificateAdriaan MyburghNessuna valutazione finora

- Midea Split Heat PumpDocumento4 pagineMidea Split Heat PumpDarryl de LangeNessuna valutazione finora

- MidtermI 11012010 SolutionDocumento11 pagineMidtermI 11012010 SolutionRolf WangNessuna valutazione finora

- Schumann ResonancesDocumento11 pagineSchumann ResonancespuretrustNessuna valutazione finora

- Ecosystem Threats WorksheetDocumento2 pagineEcosystem Threats WorksheetDareNessuna valutazione finora

- Ernst Mayr What Evolution Is PDFDocumento2 pagineErnst Mayr What Evolution Is PDFKayla0% (1)

- Mollier Diagram - Spirax SarcoDocumento14 pagineMollier Diagram - Spirax Sarcolj0000100% (1)

- CHEE 3369 Fall 2018 HW#4 - SolutionsDocumento5 pagineCHEE 3369 Fall 2018 HW#4 - Solutionsjmoh100% (1)

- Bosworth Et Al 2015 Jurassic Rifting WD Egypt PDFDocumento36 pagineBosworth Et Al 2015 Jurassic Rifting WD Egypt PDFMohamed HaboNessuna valutazione finora

- Elutriation: R K, Essen, GermanyDocumento14 pagineElutriation: R K, Essen, GermanyRay CNessuna valutazione finora

- Production of Biogas From Kitchen Waste and Cow DungDocumento13 pagineProduction of Biogas From Kitchen Waste and Cow DungEkeh Victor ChibuezeNessuna valutazione finora

- Bubble Point of Liqued PropaneDocumento128 pagineBubble Point of Liqued PropaneKhalil RehmanNessuna valutazione finora

- Sunny Schools Assembly IdeasDocumento2 pagineSunny Schools Assembly IdeasRahulNessuna valutazione finora

- 6KW Fire Station SLDDocumento1 pagina6KW Fire Station SLDB . G STUDIONessuna valutazione finora

- Atomic Numbers, Protons, Neutrons and Electrons: Name DateDocumento1 paginaAtomic Numbers, Protons, Neutrons and Electrons: Name Datenoob noobNessuna valutazione finora

- PDFDocumento148 paginePDFBurak Hamdi İldemNessuna valutazione finora

- Assignment 1Documento2 pagineAssignment 1Stephen TabiarNessuna valutazione finora

- WebquestDocumento10 pagineWebquestapi-3300500950% (1)

- Small Hydropower Plants in Generation in The Rural Area of The West and Southwest of Paraná State-BrazilDocumento13 pagineSmall Hydropower Plants in Generation in The Rural Area of The West and Southwest of Paraná State-BrazilJoão VítorNessuna valutazione finora

- 物化1Documento37 pagine物化1鄭伊媗Nessuna valutazione finora

- 02 Activity Sheet 1 NSTP (Dela Peña)Documento2 pagine02 Activity Sheet 1 NSTP (Dela Peña)Princess Diane Dela PeñaNessuna valutazione finora

- State of Matter Teacher's Guide/chemistry Form 4 / SimulationDocumento7 pagineState of Matter Teacher's Guide/chemistry Form 4 / SimulationYulianaNessuna valutazione finora

- Fundamentals of Physics 9th Edition Halliday Solutions ManualDocumento25 pagineFundamentals of Physics 9th Edition Halliday Solutions ManualDaleQuinnwnbx97% (61)

- Life Cycle Cost Estimate For 2 ENERGY STAR Qualified Room Air Conditioner(s)Documento11 pagineLife Cycle Cost Estimate For 2 ENERGY STAR Qualified Room Air Conditioner(s)selisenNessuna valutazione finora

- Test Unit ME HOD NO.: C Lorific Val e A TM D2 0 18 0 5 Kin. Vi Osity 122° P C T A M D445Documento1 paginaTest Unit ME HOD NO.: C Lorific Val e A TM D2 0 18 0 5 Kin. Vi Osity 122° P C T A M D445Yogesh ChaudhariNessuna valutazione finora

- Chapter 10 Properties of GasesDocumento69 pagineChapter 10 Properties of GasesAdi Febrianto50% (2)

- NCSC Activity Guide BookDocumento202 pagineNCSC Activity Guide BookAMIT AGARWAL100% (3)

- CP3 NT Natural ResourcesDocumento20 pagineCP3 NT Natural ResourcesANUSHKA PRAKASHNessuna valutazione finora

- Problem Set 3Documento1 paginaProblem Set 3engineerNessuna valutazione finora