Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Piping Coordination Systems

Caricato da

farmanali070 valutazioniIl 0% ha trovato utile questo documento (0 voti)

823 visualizzazioni28 pagine1. Plot plans and equipment arrangements are used to determine the positioning of equipment in a process plant by showing their locations relative to a defined plant north.

2. Plot plans can be either overall plans that show the general layout, or detailed plans that show a specific area or floor in more detail. Equipment arrangements also show the equipment layout and elevations.

3. These drawings help with construction planning, safety, permitting, and understanding the layout over the lifetime of the plant. They are reference resources for developing the facility and determining construction methods.

Descrizione originale:

ghdshbdh c hsydbchs dchsd hsbdciusducsd c

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento1. Plot plans and equipment arrangements are used to determine the positioning of equipment in a process plant by showing their locations relative to a defined plant north.

2. Plot plans can be either overall plans that show the general layout, or detailed plans that show a specific area or floor in more detail. Equipment arrangements also show the equipment layout and elevations.

3. These drawings help with construction planning, safety, permitting, and understanding the layout over the lifetime of the plant. They are reference resources for developing the facility and determining construction methods.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

823 visualizzazioni28 paginePiping Coordination Systems

Caricato da

farmanali071. Plot plans and equipment arrangements are used to determine the positioning of equipment in a process plant by showing their locations relative to a defined plant north.

2. Plot plans can be either overall plans that show the general layout, or detailed plans that show a specific area or floor in more detail. Equipment arrangements also show the equipment layout and elevations.

3. These drawings help with construction planning, safety, permitting, and understanding the layout over the lifetime of the plant. They are reference resources for developing the facility and determining construction methods.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 28

Foreword - Location is Relative

An object's location is always given relative to another reference object.

For example, the location of a Heat Exchanger may be described as five blocks from the

General Service Building. To be more specific, the Heat Exchanger is four blocks east

and three blocks south of the General Service Building. With this illustration, a direction

and a distance from the General Service Building has been established.

Several things are assumed to be known, the place to begin (General Service Building),

and understanding of east and south (reference directions), and the length of a block

(unit of displacement). Without consensus on these things, communication of the

location of a Process Plant becomes unclear.

Reference Points

Before beginning with making drawings for a new process plant or building, there must

be determine where the new building in the area will take his place. A coordination

system, which refers to an officially recognized point therefore is necessary.

In the Netherlands, for example, are thousands of official reference points, distributed

across the country ...search on the Internet on geographic coordinate conversion,

triangulation stations, benchmarks, geography or topography. You'll find a lot of

information about how reference points are measured and identified.

Horizontal Reference

Defining a starting point of the site related to the North / South direction, is one of the

first steps in setting up a coordination system.

In principle, with a simple reliable compass the direction of the magnetic north can to

be determined. In the image below the true north is at 18. As a draftsman would work

with the true north coordinates, he will immediately find out that each line from west to

east and from north to south at an angle of 18 must be drawn.

To avoid this, a Plant North will be determined. In the example below, the true north,

18 is reversed, draftsmen and construction contractors will be grateful for it.

General there will be tried, to approach the true north-south coordinates as close as

possible.

A rule is, that the angle between true north and Plant North can not exceed 45. At

50, for example, the Plant North would be on the right side, so on the Eastern side of

the image.

1 = Official reference point

2 = South West angle of new plant

X = East West distance from new plant to reference point

Y = North South distance from new plant to reference point

Vertical Reference

Before starting with any building, the site is leveled (graded), what means that the

ground is made as flat as practically possible. After leveling we talking about "finished

grade", where the highest graded point is termed "high point of finished grade".

This highest point of finished grade refers to an official reference point on which all

vertical measurements are related. In the Netherlands, for example, many vertical

measurement are in relation to the "Normaal Amsterdams Peil" (NAP). If the field

compared to the NAP is 1 meter higher, usually the reference point will not become a

zero start of 1000 mm, but in this case a zero start at zero(0).

On a isometric view of a pipe line elevations are indicated by EL.109665 or EL.99450

etc..

What is meant by this vertical dimensions ?

The first EL.109665 you can read as: centerline of pipe is 9665 mm above zero point

The second EL.99450 you can read as: centerline of pipe is 550 mm below zero point

Well, the vertical zero point in this case is 100 meters (100000 mm), and this has the

advantage that no negative (minus) values on drawings need to be applied

Piping Coordination Systems - Plot Plan & Equipment Arrangement

Foreword

For clarity, as on this website the word Plant is used, then it refers to a Process plant

such as a Chemical plant, Petroleum refinery, Gas Processing plant, Petrochemical,

Pharmaceutical, Textile, Paper, Semiconductor & Cryogenic plants and related

processing plants and terminals. Al these plants fall under the scope of ASME B31.3

Process Piping.

Drawings, which are shown on this page, are fictitious, but they have been drawn a

functional Plot Plan of a Process Plant.

Over the years, I've seen a lot of Plot Plans of several engineering companies. All these

companies show a certain standard in their plans, but the layout and dimensioning is

often quite different. Also sometimes customers or authorities wants to have additional

information on a Plot Plan. For this reason there is no general rule, for a "final" Plot

Plan.

Plot Plan

A Plot Plan is a scale drawing that gives an overview (top view) of the entire plant. All

roads, buildings, units, tank farms, employee entrance etc. will be given on a Plot Plan.

It also listed the true north and Plant north, port address, sometimes prevailing winds,

reference point(s), horizontal references etc..

You will understand that a whole process plant, usually can not be given on a readable

drawing. Therefore, a distinction is made between a Overall Plot Plan and a

Detailed Plot Plan.

Overall Plot Plan

A Overall Plot Plan, sometimes this plan called a Site Plan or a Site Master Plan, you can

compare with a city road map. Important buildings, parks and street names are given,

but not the house numbers or the number of rooms in a building.

With the drawing in your hands, you should find a certain process tank farm and a

specific tank, but not a pump or a plate cooler, or heights of buildings, tanks and so on.

That kind of equipment and dimensions are not shown on a Overall Plot Plan.

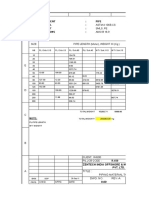

IMAGINARY OVERALL PLOT PLAN

Larger image of a imaginary Overall Plot Plan.

Right down on the drawing you can see the starting point of this imaginary Overall Plot

Plan.

North starting with N - 000.000 coordinate and East with E - 400.000 coordinate.

Both related to an officially recognized reference point, but in practice, the east

coordinates refer often to another reference object, and do not start with the

coordinates E - 000.000.

Right on the top under "Notes" you can see the plant north coordinates and (important

!) starting reference elevation of this plant is EL.100000. (see Reference points)

There are no pipe-bridges, pipelines, pumps or other equipment shown on that

drawing, but the plan gives a good impression of a overall process plant.

Detailed Plot Plan

In contrast with a Overall Plot Plan, a Detailed Plot Plan gives a overview (top view) of a

part of a process plant. Generally it shows a part of a certain area, floor or unit.

As you might have seen on the overall Plot Plan, the process building is largely

equipped with a roof, and only some equipment parts are visible from above.

TOP VIEW 4th FLOOR DETAILED PLOT PLAN at EL.129200

The plan shows the whole 4th floor on a elevation of EL.129200. These elevation are

related to the upper part, Top of Concrete (T.O.C.) of the 4th floor of the FM-AREA, and

indicates a elevation of 29200 millimeters from the starting point (EL.100000) of the

process plant. Furthermore, it shows some equipment, a large pipeline and some

smaller, a staircase and the columns of the steel structure of the building.

Watch out, that all East and North dimensions, starting at the center lines of the

columns.

A major advantage of a proper detailed Plot Plan is that you can determine from your

office, or a new piece of equipment in a certain area, floor or unit, can be placed. That

however only applies to the horizontal dimensions, because you cannot see possibly

obstructions in the vertical level.

What you also cannot see on a Plot Plan, are the elevations of the equipment. That

means that you do not know, or a device on the 4th floor or may be already on the

third floor begins...for this reason, Equipment Arrangements have been considered.

What is a Equipment Arrangement?

Equipment Arrangements are drawings, which show the top and side-view of a part of a

process plant. The top-view is similar to a detailed Plot Plan, except that only

equipment is shown.

Both equipment arrangements shows the equipment in a particular area, and

sometimes a few details around a specific device. With a drawing of a site-view you can

see the elevations of a certain device, and if the device is going through one, or more

floors.

TOP VIEW 4th FLOOR EQUIPMENT ARRANGEMENT at EL.129200

LOOKING SOUTH 3th and 4th FLOOR EQUIPMENT ARRANGEMENT at EL.121900 and EL.129200

Summary

Plot Plans and equipment arrangements are resources to help determine relative and

specific positioning of equipment on a process plant, related to the plant north, that on

the drawings must be shown.

Both help the development of support facilities and are used to determine the most

cost-effective construction sequence and methods. They are also used for operational

needs, such as training and emergency access, and are essential for obtaining permits

and determining environmental and personnel safety. They are the main documents

used in assessing fire protection and if necessary, to obtain government permits..

Plot Plans and equipment arrangements are dynamic documents and evolve further

during the construction phase and the lifetime of a process plant.

Piping Coordination Systems - Piping

Arrangement

Views in Piping Drawings

There are two types of views in hand-drawn piping drawings:

Orthographic - Plans and Elevations

Pictorial - Isometric Views

Orthographic drawings are views (front, side, top etc.) of an piping system, and in

Piping they are called "Piping Arrangements".

An orthographic view shows only one side, and therefore multiple drawings (views) are

necessary to show a complete Piping Arrangement.

In complex systems, where orthographic views do not illustrate the details of the

design, pictorial view in isometric presentation is made for clarity.

Priorities on a Piping Arrangement

Process equipment and piping have priority on the Piping Arrangement. The major

primary beams and secondary beams are also shown, even as Utility stations so that

the most efficient route for utilities can be determined.

Order of importance of pipe lines in a Piping Arrangement:

Alloy steel and other special materials

Large bore piping

High temperature/high pressure piping

Lined piping

Carbon Steel Process Piping

Utility piping

Further (if possible) all equipment, instrument connections, with the tag numbers will

be shown on a Piping Arrangement. Important details are often in a larger scale in the

same drawing shown.

Even as a Plot Plan, a whole process plant usually can not be given on a readable

drawing. Therefore the Piping Arrangement show parts of a process plant.

Types of Piping Arrangement Drawings

Pipelines on a Piping Arrangement are shown by single lines and double lines.

In single line representation only the center line of the pipeline is drawn using a solid

line. In double line representation the actual size to scale is drawn with center line

marked in chain-dotted lines.

Single lines representation

Flanges are shown as thick lines drawn to the scaled outsite diameter of the flange.

For flanged joints a small gap between dimension lines will be shown to indicate a

gasket.

Valves are shown with identification number and a handwheel is drawn with stem

fully extended. If a valve is lever operated, then the movement of handle position is

given.

Dimensions for flanged valves are given to the flange faces, while non flanged valves

are dimensioned to the center lines of their stems.

Example of a single line Piping Arrangement

The drawing shows 2 pumps, 4 valves (all Handwheel operated and flanged), a pipe line and a column.

The line number CD - PL - 101 - 12 - C300 - T2 - I2 tells something about

the pipe line.

CD

Indicator for plant or system, where the pipeline is located.

PL

Indicator for a service designation.

101

Indicator for the serial number of the pipe line.

12

Indicator NPS, in this case the main pipeline is NPS 12.

C300

Indicator for Pipe Line Class or "Pipe Spec".

C tells that the material is Carbon Steel, and 300 indicates the Pressure Class.

T2

Indicator for E-tracing type.

I2

Indicator for Insulation type.

Above description of the line number is only an example. For line numbers are no

standard definitions, and therefore a customer specification can be different from what

is here defined.

The indication 12-314 (Typ) on the valve told that the valve is 12 inches and 314

indicates the type of valve. The same applies also to the valve near the pump, where

DR indicates a Drain Valve.

Typ stands for Typical and means that there is another ore more valves in that drawing

with the same specification. The advantage of this indicator is, that items with the same

specification only once need to be defined.

Furthermore, the red arrow indicates the flow direction, which perhaps is unnecessary,

because the pipe line is connected to the Suction side of the pump.

Dis. = Discharge, pressure side of a pump

Suc. = Suction, suction side of a pump

An important item is designation TF (Top Flat) which is shown to the eccentric reducer

at the pump. That means that the flat side of the reducer is on the top of de pipe line.

If it was vice versa BF (Bottom Flat), also the elevation to the suction side of the pump

must be given.

Example for the pump suction side:

A eccentric reducer 12 to 8 inch has a center-line difference from 52.4 millimeters.

(12" = O.D. 323.9 mm / 8" = O.D. 219.1 mm / Length = 203 mm / Center-line

difference = 52.4 mm).

If the reducer bottom flat, an elevation round off upwards EL. 100548 must be shown.

Note: The connection to the column is Class 600. This change in Pressure Class is

indicated

by a so-called "Spec break" (change of Piping Class Specification). In this case it

means, that the flange that connect to nozzle C1 also must be have a Pressure Class of

600, and that the material probably not changed.

Another important item is the elevation (given in red) of nozzle C1 from the column.

The elevation EL. 104966 is shown, because the pipe line ends with an eccentric

reducer Bottom Flat (BF). In this case it means, that the vertical centerline from nozzle

C1 is 15.88 mm above the center line of the pipeline.

A eccentric reducer 14 x 12 (355.6 mm x 323.9 mm) has a length of 330 mm and a

center-line difference from 15.88 mm.

Symbols on a Piping Arragement Drawing

On the drawing can be seen that the pipe line(s) from the pumps run up to the column.

The pipeline starts with elevation EL. 100600 at the pump suction site and ends at

elevation EL. 104950 at nozzle "C1" from the column. But without the elevations, the

upward routing is also visible.

For single line representation there are a lot of symbols, which illustrate a directional

change.

The three partly open blue circles in the drawing, indicate three Elbows which are

bending down.

The two blue half-moons around the pipelines/valves indicate that the valves are at the

bottom of the pipeline are located. The two valves are needed to drain the pipeline. By

applying eccentric reducers (Top Flat) in the lowest part of the pipeline, the two valves

make it possible to fully empty the system.

In the main Menu "Docs" the most used drawing symbols can be found.

3-Dimensional View

More and more engineering companies show Plot Plans, equipment and piping

arrangements in a 3D view. Better 3D software has made this possible, and generally

has this way of drawing many advantages.

There are many programs that can be made 3D views, but they are all very expensive.

Large engineering companies often have developed their own software. Some of these

programs make it possible "to walking through a whole plant" in order to find a

particular item. It is very impressive, what is possible with that type of software.

Summary

A standard Piping Arrangement does not exist.

Like a Plot Plan or Equipment Arrangement, in the development phase of a new plant,

the requirements for the drawings will be made by customer and/or engineering

company.

Remark(s) of the Author...

My own experience with 3-Dimensional Views...

Since 1999, I draw many topics in 3D views.

The reason is, that I have noted that a pipefitter or construction worker knows

immediately what he must build. Another reason is, that people who are not able to

read a drawing, also know what I am trying to explain.

For myself, I discovered that it cost me less time, to make different views, because with

acceptable 3D software, each view (what ever you want) in seconds can be displayed

and printed.

My first 3-D drawing

In recent years I have found a combination of both, Orthographic and 3D view. If it is a

simple drawing I show only two or three orthographic views. In complex drawings I

show the necessary orthographicthis views with in the right corner of the drawing, a 3D

view. It works perfectly for those who must carry out the job.

Simple drawing of a 3-Dimensional view from the Piping Arrangement above mentioned.

The 3D view from the Piping Arrangement is simple but it probably shows, for most

users, a direct understandable drawing.

At the end of 2008 I had a job for the design of a new 14 inch pipeline from and

between two storage tanks. Normally I had made isometric views from the new pipe

line and orthographic views of the supports. But in that case, for the first time, I made

only 3d views to scale from the pipeline, valves, supports etc.. I gave the pipefitters

and construction workers all possible views...the job is performed without any

problems.

With respect to our "grandfathers", they builded without our current techniques, the

largest plants on earth.

Piping Coordination Systems -

Piping & Instrumentation Diagram

The piping and Instrument Diagram (P&ID) provides a schematic representation of

the piping, process control, and instrumentation which shows the functional

relationships among the system components. The P&ID also provides important

information needed by the constructor and manufacturer to develop the other

construction input documents (the isometric drawings or orthographic physical layout

drawings).

Very large image of a simple Piping & Instrument Diagram (Dim 3000x2146 / 220kb)

The P&ID provides direct input to the field for the physical design and installation of

field-run piping. For clarity, it is usual practice to use the same general layout of flow

paths on the P&ID as used on the system flow diagram.

The P&ID ties together the system description, the system flow diagram, the electric

control schematic, and the control logic diagram. It accomplishes this by showing all the

piping, equipment, principal instruments, instrument loops, and control interlocks.

The P&ID contains a minimum amount of text in the form of notes (the system

descriptions minimize the need for text on the P&ID). The first P&ID in the set for the

job should contain a legend defining all symbols used; if certain symbols are defined

elsewhere, it may be appropriate to only reference their source. The P&IDs are also

used by the start-up organizations for preparing flushing, testing, and blowout

procedures for the piping system and by the plant operators to operate the system. The

correctness and completeness of the SD, SFD, and P&ID drawings are crucial to the

success of the start-up program.

The P&ID should show the following:

Instruments significant to the process piping,

including:

Mechanical equipment

All Valves associated with the process piping

Process pipes

Vents and drains

Special fittings

Sampling lines

Permanent start-up and flushing lines

All size transitions in line:

Reducers and increasers, swages, etc

Direction of flow

Interfaces for class changes

Seismic category

Quality level

Interconnection references

Annunciation inputs

Plant computer inputs

Vendor and contractor interfaces

Identification of components and subsystems by

others

Reference to a vendor drawing for details not

shown

Intended physical sequence of equipment:

Including branch lines, reducers, etc.

Specific information as applicable to job:

Instrument designations

Equipment names and numbers

Pipeline identification

Valve identification

Remark(s) of the Author...

The P&ID for a defined system should be limited to coverage of that system to the

maximum practical extent. Other systems that interface with the subject system are

shown in phantom if such portions are detailed elsewhere.

Whenever a line is broken off as a matter of drafting convenience, both the break and

the continuation are labeled so that one can readily trace the line from both sides of the

break. This applies whether the break and continuation are on the same sheet or on

different sheets of the drawing.

Except for very simple P&ID, the drawing should have the horizontal and vertical

borders marked to permit reference to any small area of the drawing, such as by

"Continued at PG-12".

Piping Isometric

Unlike orthographics, piping isometrics allow the pipe to be drawn in a manner by which

the length, width and depth are shown in a single view. Isometrics are usually drawn

from information found on a plan and elevation views. The symbols that represent

fittings, Valves and flanges are modified to adapt to the isometric grid. Usually, piping

isometrics are drawn on preprinted paper, with lines of equilateral triangles form of

60.

Image of a isometric grid.

The Iso, as isometric are commonly referred, is oriented on the grid relative to the

north arrow found on plan drawings. Because iso's are not drawn to scale,

dimensions are required to specify exact lengths of piping runs.

Pipe lengths are determined through calculations using coordinates and elevations.

Vertical lengths of pipe are calculated using elevations, while horizontal lengths are

caculated using north-south and east-west coordinates.

Piping isometrics are generally produced from orthographic drawings and are important

pieces of information to engineers. In very complex or large piping systems, piping

isometrics are essential to the design and manufacturing phases of a project.

Piping isometrics are often used by designers prior to a stress analysis and are also

used by draftsmen to produce shop fabrication spool drawings. Isometrics are the most

important drawings for installation contractors during the field portion of the project.

Large image of a Hand-Drawn Isometric

How to read a Piping Isometric?

A pipe into a isometric view, is always drawn by a single line. This single line is the

centerline of the pipe, and from that line, the dimensions measured. So, not from the

outside of a pipe or fitting.

The image below shows a orthographic view of a butt welded pipe with three sizes (A,

B, C).

The A size is measured from the front to the center line of the elbow / pipe.

The B size is measured from centerline to centerline.

The C size is like the A size, measured from the front to the center line of the elbow /

pipe.

Orthographic view

(double line presentation)

Isometric view

The image here on the right shows a isometric view of the same pipe as

on the left.

As you can see, this drawing is very simple and quick to implement. The

red lines show the pipe, the black dots are the butt welds and A, B & C

are the dimensions of front to center line and center line to center line.

The simplicity with which a pipe isometric can be drawn is one reason to

made iso's.

A second reason to made isometrics; if a pipe should be drawn in several

planes (north to south, then down and then to the west, etc.),

orthographic views really not an option. In a orthographic view it is not a

problem if the pipe runs in one plane, but when a pipe in two or three

planes to be drawn, a orthographic view can be unclear.

Another reason why isos are preferred, is the number of drawings that

for orthographic views should be made.

For example: for a complex pipeline system, 15 isometrics must be

drawn. I've never tried, but I think for orthographic views maybe 50

drawings are needed to show the same as the Iso's.

Isometric, Plan and Elevation Presentations of a Piping

System

The image below show the presentation used in drafting. The isometric view clearly

show the piping arrangement, but the plan view fails to show the bypass loop and

valve, and the supplementary elevation view is needed.

Isometric views in more than one plane

Below are some examples of isometric drawings. The auxiliary lines in the shape of a

cube, ensure better visualization of the pipeline routing.

The drawing on the left shows a pipeline which runs through three planes. The pipe line

begins and ends with a flange.

Routing starting point X

pipe runs to the east

pipe runs up

pipe runs to the north

pipe runs to the west

pipe runs down

The drawing on the left is almost identical to the drawing above. A different perspective

is shown, and the pipe that comes from above is longer.

Because this pipe in isometric view, runs behind the other pipe, this must be indicated

by a break in the line.

Routing starting point X

pipe runs to the south

pipe runs up

pipe runs to the west

pipe runs to the north

pipe runs down

The drawing on the left shows a pipe that runs through three planes and in two planes

it make a bow.

Routing starting point X

pipe runs to the south

pipe runs up

pipe runs up and to the west

pipe runs up

pipe runs to the west

pipe runs to the north-west

pipe runs to the north

The drawing on the left shows a pipe that runs through three planes, from one plane to

a opposite plane.

Routing starting point X

pipe runs to the south

pipe runs up

pipe runs up and to the north-west

pipe runs to the north

Hatches on a Isometric Drawing

Hatches on isometric drawings being applied, to indicate that a pipe runs at a certain

angle and in which direction the pipe runs.

Sometimes, small changes in the hatch, the routing of a pipe is no longer the east, but

for example suddenly to the north.

The drawing on the left shows a pipe, where the hatch indicates that the middle leg

runs to the east.

Routing starting point X

pipe runs up

pipe runs up and to the east

pipe runs up

The drawing on the left shows a pipe, where the hatch indicates that the middle leg

runs to the north.

Routing starting point X

pipe runs up

pipe runs up and to the north

pipe runs up

The two drawings above show, that changing from only the hatch, a pipeline receives a

different direction. Hatches are particularly important in isometric views.

The drawing on the left shows a pipe, where the hatches indicates that the middle leg

runs up and to the north-west.

Routing starting point X

pipe runs up

pipe runs up and to the north-west

pipe runs to the north

Potrebbero piacerti anche

- Equipment & Piping Layout T.N. GopinathDocumento88 pagineEquipment & Piping Layout T.N. Gopinathhirenkumar patelNessuna valutazione finora

- Coordination Plant LayoutDocumento7 pagineCoordination Plant Layoutvazzoleralex6884Nessuna valutazione finora

- Piping Coordination SystemsDocumento17 paginePiping Coordination SystemsSyed FarhanNessuna valutazione finora

- STRATEGI PENGEMBANGAN USAHATANI PADI SAWAHDocumento12 pagineSTRATEGI PENGEMBANGAN USAHATANI PADI SAWAHAwalMuawan ParkS'HyukEbxNessuna valutazione finora

- Chapter 11 Flow in PipesDocumento34 pagineChapter 11 Flow in PipesTombiruoNessuna valutazione finora

- General Piping and ValvesDocumento184 pagineGeneral Piping and ValvesChiheb KaanicheNessuna valutazione finora

- Design & Construction of Piping SysDocumento114 pagineDesign & Construction of Piping SysPedro Luis Choque MamaniNessuna valutazione finora

- 300# RF Piping Dimensions ChartDocumento148 pagine300# RF Piping Dimensions Chartrerezhassan100% (1)

- Lesson Piping Anciliaries: Sub-ObjectiveDocumento23 pagineLesson Piping Anciliaries: Sub-Objectivemister pogiNessuna valutazione finora

- Piping: Piping Sometimes Refers To Piping Design, The Detailed Specification of TheDocumento5 paginePiping: Piping Sometimes Refers To Piping Design, The Detailed Specification of ThesiswoutNessuna valutazione finora

- Design PipingDocumento412 pagineDesign PipingDavid MestanzaNessuna valutazione finora

- Pipeline Inspection: Pipe RackDocumento4 paginePipeline Inspection: Pipe RackAnushi DahariaNessuna valutazione finora

- Proposal MM IvankovaDocumento89 pagineProposal MM IvankovaYasmeen JafferNessuna valutazione finora

- Volume I Part A Engineering Design PDFDocumento370 pagineVolume I Part A Engineering Design PDFPawan KumarNessuna valutazione finora

- SA-106 GR.BDocumento2 pagineSA-106 GR.BTree TaweeNessuna valutazione finora

- PipingDocumento39 paginePipingKareem ElsayedNessuna valutazione finora

- General Deliverable of Piping Industry All DepartmentDocumento3 pagineGeneral Deliverable of Piping Industry All Departmentsujay Avati100% (1)

- Piping Engineer ResumeDocumento2 paginePiping Engineer ResumeTarkeshwar SharmaNessuna valutazione finora

- Astm A 106B, Cs SMLS, Pe ANSI B 16.9: Component: Pipe Material: Product: DimensionsDocumento137 pagineAstm A 106B, Cs SMLS, Pe ANSI B 16.9: Component: Pipe Material: Product: DimensionsbhupatiNessuna valutazione finora

- SanSimon North Hub BOQDocumento179 pagineSanSimon North Hub BOQMark Roger Huberit IINessuna valutazione finora

- Piping and Piping Components (Iso 10628) : Date of Print: 11/30/2021Documento12 paginePiping and Piping Components (Iso 10628) : Date of Print: 11/30/2021pipingNessuna valutazione finora

- Review of Engineering Design and Standard Procurement Documents (SPD)Documento81 pagineReview of Engineering Design and Standard Procurement Documents (SPD)Gbolahan Salam100% (1)

- ATIF Yasin CV Piping EngineerDocumento12 pagineATIF Yasin CV Piping EngineeryasiriftikharNessuna valutazione finora

- Book Reviews LeadershipDocumento14 pagineBook Reviews LeadershipAnonymous KsBupZlyVNessuna valutazione finora

- Madhusoodan Singh 9140672026 / 9042862377: Proessional ReviewDocumento4 pagineMadhusoodan Singh 9140672026 / 9042862377: Proessional Reviewmadhusoodan singhNessuna valutazione finora

- Piping Designers Vessel OrientationDocumento13 paginePiping Designers Vessel OrientationkazishidotaNessuna valutazione finora

- Co ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionDocumento2 pagineCo ., LT D.: ASME A-106/A-106M - 2019 EDITION Material Verification The Original Markings On ProductionBalaji SelvarajNessuna valutazione finora

- Syracuse University - School of Education Formal Doctoral ProgramDocumento4 pagineSyracuse University - School of Education Formal Doctoral ProgramLaura Knieser ReederNessuna valutazione finora

- Piping Design Engineer Interview QuestionsDocumento5 paginePiping Design Engineer Interview QuestionsDayo IdowuNessuna valutazione finora

- Review of Reactor Piping Systems - R1 To R2 Piping Report PDFDocumento37 pagineReview of Reactor Piping Systems - R1 To R2 Piping Report PDFChristopher Brown0% (1)

- Steps For The Procurement of Piping / Mechanical ItemsDocumento2 pagineSteps For The Procurement of Piping / Mechanical ItemsSanjeev KumarNessuna valutazione finora

- Model Review Process X5axp5bsDocumento8 pagineModel Review Process X5axp5bsNadi Jothidan KLNessuna valutazione finora

- Sr. Piping Designer Ali Azzam CVDocumento5 pagineSr. Piping Designer Ali Azzam CVAli AzzamNessuna valutazione finora

- PG Diploma in Piping Design and Autocad Training CourseDocumento4 paginePG Diploma in Piping Design and Autocad Training CourseWin LinnNessuna valutazione finora

- Implementation of Expansion LoopsDocumento13 pagineImplementation of Expansion LoopsSSSNessuna valutazione finora

- Piping Engineering.nDocumento6 paginePiping Engineering.nAjay KumarNessuna valutazione finora

- Career After Chemical EngineeringDocumento14 pagineCareer After Chemical EngineeringUtsav patelNessuna valutazione finora

- Guidelines For Piping Design & ErectionDocumento55 pagineGuidelines For Piping Design & ErectionKartik Varma Namburi100% (2)

- Flare Line Stress AnalysisDocumento7 pagineFlare Line Stress AnalysisdhurjatibhuteshNessuna valutazione finora

- PipingDocumento11 paginePipingAshley JacksonNessuna valutazione finora

- C1 The Basic of Plant Layout Design - Process Plant Layout and Piping DesignDocumento81 pagineC1 The Basic of Plant Layout Design - Process Plant Layout and Piping Designdung100% (1)

- Distillation Column Nozzle Location Guidelines PDFDocumento21 pagineDistillation Column Nozzle Location Guidelines PDFShyam MurugesanNessuna valutazione finora

- PIPING PROCEDURESDocumento9 paginePIPING PROCEDURESippon_osotoNessuna valutazione finora

- 07 ValvesDocumento33 pagine07 Valvesshiva_ssk17Nessuna valutazione finora

- VaksinasiDocumento7 pagineVaksinasiROS SHAHNessuna valutazione finora

- P&ID drawing symbology guideDocumento36 pagineP&ID drawing symbology guideSterling GordianNessuna valutazione finora

- Overview Part 1 PDFDocumento65 pagineOverview Part 1 PDFKim NamjoonNessuna valutazione finora

- Flange FacingDocumento6 pagineFlange FacingDurjoy ChakrabortyNessuna valutazione finora

- Chapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deDocumento21 pagineChapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deezeabrilNessuna valutazione finora

- ENG2068 SampleofcontentsDocumento10 pagineENG2068 SampleofcontentsKlich77Nessuna valutazione finora

- Chapter 8 Steam PipingDocumento14 pagineChapter 8 Steam PipingChen WsNessuna valutazione finora

- Pipe RoutDocumento10 paginePipe Routghkashyap1Nessuna valutazione finora

- Example Pumps PresentationDocumento31 pagineExample Pumps PresentationsonpvmsNessuna valutazione finora

- 5-Plant Design - Material Handling Part 1Documento86 pagine5-Plant Design - Material Handling Part 1MrHemFunNessuna valutazione finora

- Mechanical Engineering Drawing: SR KaleDocumento22 pagineMechanical Engineering Drawing: SR KaleAdnan RanaNessuna valutazione finora

- 2015-Xii. P&id PDFDocumento71 pagine2015-Xii. P&id PDFFitria Nur HayatiNessuna valutazione finora

- Piping Coordination Systems and Engineering Standards (Macmac)Documento67 paginePiping Coordination Systems and Engineering Standards (Macmac)Mark Joseph Nambio Nieva100% (1)

- Plot Plan & Equipment LayoutDocumento6 paginePlot Plan & Equipment LayoutTejas PatelNessuna valutazione finora

- LOCATION RELATIVE - ESTABLISH REFERENCE POINTSDocumento3 pagineLOCATION RELATIVE - ESTABLISH REFERENCE POINTSTejas PatelNessuna valutazione finora

- Plot Plan Equipment LayoutDocumento6 paginePlot Plan Equipment LayouttisyaNessuna valutazione finora

- Lesson 13Documento14 pagineLesson 13farmanali07Nessuna valutazione finora

- Timeline of The Certification ProcessDocumento1 paginaTimeline of The Certification Processfarmanali07Nessuna valutazione finora

- Lesson 8Documento29 pagineLesson 8farmanali07Nessuna valutazione finora

- ASTM Standards For Steel PlateDocumento4 pagineASTM Standards For Steel Platefarmanali07Nessuna valutazione finora

- Overview of AutoFillDocumento6 pagineOverview of AutoFillfarmanali07Nessuna valutazione finora

- Overview of AutoFillDocumento6 pagineOverview of AutoFillfarmanali07Nessuna valutazione finora

- Piping Shop Fabrication SpecificationDocumento18 paginePiping Shop Fabrication Specificationfarmanali07100% (1)

- PreDocumento4 paginePrefarmanali07Nessuna valutazione finora

- Lesson 6Documento30 pagineLesson 6farmanali07Nessuna valutazione finora

- Factors Affecting Pipe Spool FabricationDocumento7 pagineFactors Affecting Pipe Spool FabricationtkarasonNessuna valutazione finora

- Lesson 4Documento21 pagineLesson 4farmanali07Nessuna valutazione finora

- Comparing and Evaluating Values in Excel with Logical and Comparison OperatorsDocumento6 pagineComparing and Evaluating Values in Excel with Logical and Comparison Operatorsfarmanali07Nessuna valutazione finora

- ExpressionsDocumento17 pagineExpressionsfarmanali07Nessuna valutazione finora

- Shop FabDocumento8 pagineShop Fabfarmanali07Nessuna valutazione finora

- Pipeline ProcedureDocumento26 paginePipeline ProcedurekeronsNessuna valutazione finora

- Data Entry With NumbersDocumento13 pagineData Entry With Numbersfarmanali07Nessuna valutazione finora

- Double Pipe Heat ExchangersDocumento27 pagineDouble Pipe Heat ExchangersRiki MandolNessuna valutazione finora

- 100 Industry Piping FormulasDocumento2 pagine100 Industry Piping Formulasfarmanali07Nessuna valutazione finora

- MCQ CH 3 FSC Part1 NaumanDocumento2 pagineMCQ CH 3 FSC Part1 Naumanfarmanali07Nessuna valutazione finora

- Comparison ASME KTADocumento7 pagineComparison ASME KTAAndres_Pastor1987Nessuna valutazione finora

- ForewordDocumento2 pagineForewordfarmanali07Nessuna valutazione finora

- Numerical Significance: Ladle Steel MillDocumento2 pagineNumerical Significance: Ladle Steel Millfarmanali07100% (1)

- English Proficiency CertificateDocumento1 paginaEnglish Proficiency Certificatefarmanali07Nessuna valutazione finora

- BS 10 Flange Dimensions and Pressure Ratings for Stainless Steel FlangesDocumento6 pagineBS 10 Flange Dimensions and Pressure Ratings for Stainless Steel Flangesfarmanali07Nessuna valutazione finora

- British Standard Pipe FlangesDocumento1 paginaBritish Standard Pipe Flangesfarmanali07Nessuna valutazione finora

- Open Source Content Management Systems (CMS) in JavaDocumento1 paginaOpen Source Content Management Systems (CMS) in JavaorionNessuna valutazione finora

- Mapeh 1 With TOSDocumento7 pagineMapeh 1 With TOSMary roseNessuna valutazione finora

- Mini Critique: by Galo and CasiñoDocumento9 pagineMini Critique: by Galo and CasiñoAngela GaloNessuna valutazione finora

- AOCS DB 2-48Documento1 paginaAOCS DB 2-48Asadulhaq Ali HamidiNessuna valutazione finora

- Persian Music Meets West: A Bachelor Thesis on Persian Musical Traditions and Their Expression on Western InstrumentsDocumento37 paginePersian Music Meets West: A Bachelor Thesis on Persian Musical Traditions and Their Expression on Western InstrumentsAmirreza Sadr100% (1)

- Mythical Heroes: Elf BowmanDocumento1 paginaMythical Heroes: Elf BowmanBoz Boz100% (1)

- Hungarian PhotographsDocumento3 pagineHungarian PhotographsAnchy013Nessuna valutazione finora

- Rules for reading Sri Sri ChandiDocumento2 pagineRules for reading Sri Sri Chandiviky24100% (1)

- David B. Gray - Tantra and The Tantric Traditions of Hinduism and Buddhism - 2016Documento34 pagineDavid B. Gray - Tantra and The Tantric Traditions of Hinduism and Buddhism - 2016sumel666100% (2)

- Materials Overwing Aircraft NozzlesDocumento3 pagineMaterials Overwing Aircraft NozzlesLucio Falbi FernandezNessuna valutazione finora

- Useful Websites and LinksDocumento6 pagineUseful Websites and Linksapi-306276137Nessuna valutazione finora

- Irregular Verbs TestDocumento1 paginaIrregular Verbs TestJonathan Noriega100% (1)

- Cultural CriminologyDocumento25 pagineCultural CriminologyArturo LunaNessuna valutazione finora

- MainDocumento204 pagineMainDebby TeniNessuna valutazione finora

- Angiosperm or GymnospermDocumento2 pagineAngiosperm or Gymnospermtuti_ron_007100% (1)

- Saint Bingo CardsDocumento30 pagineSaint Bingo CardsShower of Roses100% (3)

- Indus ValleyDocumento37 pagineIndus ValleySwati Shukla100% (1)

- Basics and Techniques of American Kenpo KarateDocumento4 pagineBasics and Techniques of American Kenpo Karatenear600Nessuna valutazione finora

- House Arrest Teacher GuideDocumento4 pagineHouse Arrest Teacher GuideChronicleBooksNessuna valutazione finora

- Drifter OP - Guitar Tab Full - AndrosDocumento3 pagineDrifter OP - Guitar Tab Full - AndrosSahrul AgustianNessuna valutazione finora

- T5u4hDocumento10 pagineT5u4hJ.ROMERO100% (4)

- Cause and Effect EssayDocumento1 paginaCause and Effect Essayapi-511984734Nessuna valutazione finora

- English 393B: Environmental CriticismDocumento4 pagineEnglish 393B: Environmental CriticismLuis RomanoNessuna valutazione finora

- TaweezDocumento2 pagineTaweezbasyll73Nessuna valutazione finora

- A Bibliography On Christianity in EthiopiaDocumento105 pagineA Bibliography On Christianity in Ethiopiafábio_homem100% (2)

- AccordionDocumento12 pagineAccordionDante SallicopNessuna valutazione finora

- Marketing Galeri Luxton Layout Plans 3D Perspectives Furniture DimensionsDocumento16 pagineMarketing Galeri Luxton Layout Plans 3D Perspectives Furniture DimensionsYustisia KatriniNessuna valutazione finora

- Kings, Farmers and Towns: By: Aashutosh PanditDocumento27 pagineKings, Farmers and Towns: By: Aashutosh PanditIndu sharmaNessuna valutazione finora

- Presentation: On Industrial Visit of NOMAN WEAVING MILLS LTDDocumento30 paginePresentation: On Industrial Visit of NOMAN WEAVING MILLS LTDMehzabeen ShahidyNessuna valutazione finora

- Boundary Wall Estimate Comparision Sheet S.No Sor No. Decription Boundary Wall Total Qty Unit Rate AmountDocumento6 pagineBoundary Wall Estimate Comparision Sheet S.No Sor No. Decription Boundary Wall Total Qty Unit Rate AmountInterns 2020Nessuna valutazione finora

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDa EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNessuna valutazione finora

- Highest Duty: My Search for What Really MattersDa EverandHighest Duty: My Search for What Really MattersNessuna valutazione finora

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDa EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestValutazione: 4 su 5 stelle4/5 (28)

- The Fabric of Civilization: How Textiles Made the WorldDa EverandThe Fabric of Civilization: How Textiles Made the WorldValutazione: 4.5 su 5 stelle4.5/5 (56)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (241)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDa EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureValutazione: 5 su 5 stelle5/5 (124)

- Pale Blue Dot: A Vision of the Human Future in SpaceDa EverandPale Blue Dot: A Vision of the Human Future in SpaceValutazione: 4.5 su 5 stelle4.5/5 (586)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Da Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Valutazione: 4 su 5 stelle4/5 (21)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationDa EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationValutazione: 4.5 su 5 stelle4.5/5 (46)

- Sully: The Untold Story Behind the Miracle on the HudsonDa EverandSully: The Untold Story Behind the Miracle on the HudsonValutazione: 4 su 5 stelle4/5 (101)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesDa EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesNessuna valutazione finora

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseDa EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseValutazione: 3.5 su 5 stelle3.5/5 (12)

- The Future of Geography: How the Competition in Space Will Change Our WorldDa EverandThe Future of Geography: How the Competition in Space Will Change Our WorldValutazione: 4.5 su 5 stelle4.5/5 (4)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraDa EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraValutazione: 3 su 5 stelle3/5 (10)

- Packing for Mars: The Curious Science of Life in the VoidDa EverandPacking for Mars: The Curious Science of Life in the VoidValutazione: 4 su 5 stelle4/5 (1395)

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsDa EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsNessuna valutazione finora

- Reality+: Virtual Worlds and the Problems of PhilosophyDa EverandReality+: Virtual Worlds and the Problems of PhilosophyValutazione: 4 su 5 stelle4/5 (24)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDa EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellValutazione: 4.5 su 5 stelle4.5/5 (80)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- The Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsDa EverandThe Mushroom at the End of the World: On the Possibility of Life in Capitalist RuinsValutazione: 4 su 5 stelle4/5 (139)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNessuna valutazione finora

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsDa EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNessuna valutazione finora

- Inventor of the Future: The Visionary Life of Buckminster FullerDa EverandInventor of the Future: The Visionary Life of Buckminster FullerValutazione: 4 su 5 stelle4/5 (10)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- Artificial Intelligence: A Guide for Thinking HumansDa EverandArtificial Intelligence: A Guide for Thinking HumansValutazione: 4.5 su 5 stelle4.5/5 (30)