Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Calculation Sheet: Esign Xample Esign of A Two Span Trapezoidal Roof Sheeting

Caricato da

ettypasewangDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Calculation Sheet: Esign Xample Esign of A Two Span Trapezoidal Roof Sheeting

Caricato da

ettypasewangCopyright:

Formati disponibili

123

Job No.

R0SU00658

Sheet

1

of

7

Rev

B

Job Title

ECSC Stainless Steel Valorisation Project

Subject

Design Example 3 Design of a two-span trapezoidal

roof sheeting

Made by

AAT

Date

June 2002

Checked by

JEK

Date

June 2002

VTT TECHNICAL RESEARCH

CENTRE OF FINLAND

VTT BUILDING AND TRANSPORT

Kemistintie 3, Espoo

P.O.Box 1805, FIN02044 VTT, Finland

Telephone: + 358 9 4561

Fax: + 358 9 456 7003

CALCULATION SHEET

Client

ECSC

Revised by

JBL/MEB

Date

April 2006

DESIGN EXAMPLE 3 DESIGN OF A TWO-SPAN TRAPEZOIDAL ROOF SHEETING

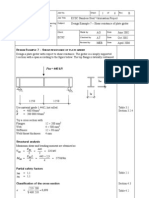

This example considers the design of a two-span trapezoidal roof sheeting. The material is

grade 1.4401 stainless steel and the material thickness is 0,6 mm. The dimensions of the

cross section are shown below.

4 x 212,5 = 850

57 65

70

The example shows the following design tasks:

- determination of effective section properties at the ultimate limit state

- determination of the bending resistance of the section

- determination of the resistance at the intermediate support

- determination of deflections at serviceability limit state.

This example refers to prEN 1993-1-3:2005 and adopts its symbols and terminology.

Reference should be made to prEN 1993-1-3 for a full description of the design

procedures and associated figures.

Design data

Spans L = 2900 mm

Width of supports s

s

= 100 mm

Design load

Q = 1,4 kN/m

2

Design thickness t = 0,6 mm

Yield strength

f

yb

= 240 N/mm

2

Table 3.1

Modulus of elasticity E = 200 000 N/mm

2

Section 3.2.4

Partial safety factor

M0

= 1,1 Table 2.1

Partial safety factor

M1

= 1,1 Table 2.1

Symbols and detailed dimensions used in calculations are shown in the figure below. The

position of the cross section is given so that in bending at the support the upper flange is

compressed.

124

Job No.

R0SU00658

Sheet

2

of

7

Rev

B

Job Title

ECSC Stainless Steel Valorisation Project

Subject

Design Example 3 Design of a two-span trapezoidal

roof sheeting

Made by

AAT

Date

June 2002

Checked by

JEK

Date

June 2002

VTT TECHNICAL RESEARCH

CENTRE OF FINLAND

VTT BUILDING AND TRANSPORT

Kemistintie 3, Espoo

P.O.Box 1805, FIN02044 VTT, Finland

Telephone: + 358 9 4561

Fax: + 358 9 456 7003

CALCULATION SHEET

Client

ECSC

Revised by

JBL/MEB

Date

April 2006

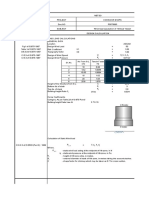

h

0

b

u0

/2

w

0

/2 b

l0

/2

b

sl

/2

b

sl0

/2

b

su

/2

b

su0

/2

h

sl

h

su

Centre line

dimensions

Internal radius of

the corners

mm 70

0

= h

mm 5 , 212

0

= w

mm 65

u0

= b

mm 57

0

=

l

b

mm 20

su

= b

mm 8

su0

= b

mm 6

su

= h

mm 20

s

=

l

b

mm 8

0 s

=

1

b

mm 6

s

=

1

h

mm 3 = r

Angle of the web:

( )

deg 57,1

5 , 0

atan

0 u0 0

0

=

=

l

b b w

h

EFFECTIVE SECTION PROPERTIES AT THE ULTIMATE LIMIT STATE Section 4.4

Check on maximum width-to-thickness ratios:

117 /

0

= t h is less than 336 sin 400 = and Table 4.1

95 /

0

= t b

l

is less than 400. Table 4.1

Location of the centroidal axis when the web is fully effective

Effective width of the compressed flange:

mm 5 , 22

2

su u0

p

=

=

b b

b

966 , 0

000 210

235

5 , 0

y

=

(

(

=

E

f

Section 4.4.1

4 =

k

684 , 0

4 , 28

/

p

p

= =

k

t b

862 , 0

125 , 0 772 , 0

2

p

p

= =

Because , 1 < mm 4 , 19

p u eff,

= = b b

Eq. 4.1a

Reduced thickness of the flange stiffener: Section 4.5.3

mm 849 , 0

2

su

2

0 su su

2

su

su

=

|

.

|

\

|

+

= t

h

b b

h

t

125

Job No.

R0SU00658

Sheet

3

of

7

Rev

B

Job Title

ECSC Stainless Steel Valorisation Project

Subject

Design Example 3 Design of a two-span trapezoidal

roof sheeting

Made by

AAT

Date

June 2002

Checked by

JEK

Date

June 2002

VTT TECHNICAL RESEARCH

CENTRE OF FINLAND

VTT BUILDING AND TRANSPORT

Kemistintie 3, Espoo

P.O.Box 1805, FIN02044 VTT, Finland

Telephone: + 358 9 4561

Fax: + 358 9 456 7003

CALCULATION SHEET

Client

ECSC

Revised by

JBL/MEB

Date

April 2006

2

su su 0 su u eff, s

mm 6 , 26 2 ) ( = + + = t h t b b A

Fig. 4.3

mm 23 , 2

2

2

s

su

su

su su 0 su

s

=

+

=

A

t

h

h t h b

e

( )

4

3

su su

3

0 su

4

2

s

su

su su

2

s su 0 su

2

s

2

s

mm 53 , 159

12

2

12 12

15

2

2

2 ) ( 15 2

=

+ +

|

|

.

|

\

|

+

|

.

|

\

|

+ + =

h t t b t

e

h

t h e h t b e t I

Fig. 4.3

mm 0 , 25

2

2

su0

2

su0 su

2

su s

= + |

.

|

\

|

+ = b

b b

h b

mm 251

3 2

07 , 3

4 / 1

3

s p 2

p s b

=

|

|

.

|

\

| +

=

t

b b

b I l

Eq. 4.9

mm 4 , 83

2

2

0

2

0 0 u 0

w

= + |

.

|

\

|

= h

b b w

s

l

s

b b b + =

p d

2

37 , 1

5 , 0

2

d w

d w

0 w

=

+

+

=

b s

b s

k

Eq. 4.10 and

4.11

b w

3, 01 l s = Because 2

w b

> s l , 37 , 1

0 w w

= = k k

( )

2

s p

2

p

3

s

s

w

s cr,

N/mm 515

3 2 4

2 , 4

=

+

=

b b b

t I

A

E k

Eq. 4.3

683 , 0

s cr,

yb

d

= =

f

Because , 38 , 1 65 , 0 d < <

98 , 0 723 , 0 47 , 1

d

= =

Eq. 4.15

mm 588 , 0

u red,

= = t t

The distance of neutral axis from the compressed flange:

mm 849 , 0

2

sl

2

0 s sl 2

sl

l

=

|

|

.

|

\

|

+

= t

h

b b

h

t

l

mm 714 , 0 sin /

w

= = t t

126

Job No.

R0SU00658

Sheet

4

of

7

Rev

B

Job Title

ECSC Stainless Steel Valorisation Project

Subject

Design Example 3 Design of a two-span trapezoidal

roof sheeting

Made by

AAT

Date

June 2002

Checked by

JEK

Date

June 2002

VTT TECHNICAL RESEARCH

CENTRE OF FINLAND

VTT BUILDING AND TRANSPORT

Kemistintie 3, Espoo

P.O.Box 1805, FIN02044 VTT, Finland

Telephone: + 358 9 4561

Fax: + 358 9 456 7003

CALCULATION SHEET

Client

ECSC

Revised by

JBL/MEB

Date

April 2006

=

i

e =

i

A

0 t b

u eff,

5 , 0

0 t b

u eff,

5 , 0

= =

2

tot

mm 5 , 87

i

A A

su

5 , 0 h

su su

t h

su

h t b

su0

5 , 0

0

5 , 0 h

w 0

t h

0

h ( )t b b

sl l

0

5 , 0

l

h h

s 0

5 , 0

l l

t h

s s

mm 9 , 34

tot

c

= =

A

e A

e

i i

l

h h

s 0

t b

l 0 s

5 , 0

Effective cross-section of the compression zone of the web Section 4.4.1

006 , 1

c

c 0

=

=

e

e h

1 , 24 ) 1 ( 98 , 5

2

= = k

Table 4.3

mm 4 , 83 sin /

0 p

= = h b

032 , 1

4 . 28

/

p

p

= =

k

t b

630 , 0

125 , 0 772 , 0

2

p

p

= =

Because , 1 < mm 2 , 26

1

p

eff

=

b

b

Eq. 4.1a

Table 4.3

mm 5 , 10 4 , 0

eff 1 eff,

= = b s mm 7 , 15 6 , 0

eff n eff,

= = b s Table 4.3

Effective cross section properties per half corrugation

sin

eff,1 eff,1

s h = sin

eff, eff, n n

s h =

=

i e

e

, ff

=

i

A

, eff

i

I

, eff

0 t b

u eff,

5 , 0 0

0 t b

u eff,

5 , 0 0

su

5 , 0 h

su su

t h

12 /

3

su su

h t

su

h t b

0 su

5 , 0 0

eff,1

5 , 0 h

w eff,1

t h

12 /

3

1 , eff w

h t

) ( 5 , 0

eff, c 0 0 n

h e h h +

w ,n

t h e h ) (

eff c 0

+

12 / ) (

3

, eff c 0 w n

h e h t +

0

h ( )t b b

l l s 0

5 , 0 0

127

Job No.

R0SU00658

Sheet

5

of

7

Rev

B

Job Title

ECSC Stainless Steel Valorisation Project

Subject

Design Example 3 Design of a two-span trapezoidal

roof sheeting

Made by

AAT

Date

June 2002

Checked by

JEK

Date

June 2002

VTT TECHNICAL RESEARCH

CENTRE OF FINLAND

VTT BUILDING AND TRANSPORT

Kemistintie 3, Espoo

P.O.Box 1805, FIN02044 VTT, Finland

Telephone: + 358 9 4561

Fax: + 358 9 456 7003

CALCULATION SHEET

Client

ECSC

Revised by

JBL/MEB

Date

April 2006

sl 0

5 , 0 h h

sl sl

t h

12 /

3

sl sl

h t

sl 0

h h t b

sl0

5 , 0 0

= =

2

i eff, tot

mm 2 , 78 A A

mm 20 , 37

tot

i eff, i eff,

c

= =

A

e A

e

( )

= + =

2 2

i eff, c i eff, i eff, tot

mm 400 8 5 e e A I I

Optionally the effective section properties may also be redefined iteratively based on the

location of the effective centroidal axis.

prEN 1993-1-

3, clause

5.5.3.3(3)

Bending strength per unit width (1 m) Section 4.7.4

4

tot

0

mm 000 549

0,5w

mm 1000

= = I I

3

c

u

mm 800 14 = =

e

I

W

3

c 0

l

mm 800 16 =

=

e h

I

W

Because

l u

W W < ,

3

eff,min u

14 800 mm W W = =

c,Rd eff,min y M0

/ 3, 22 kNm M W f = = Eq. 4.29

DETERMINATION OF THE RESISTANCE AT THE INTERMEDIATE SUPPORT

Web crippling strength Section 5.4.4

Here =

l

a

= s

s

and = 0,15

prEN 1993-1-

3, Eq. 6.19b

and 6.20c

kN 6,2 1

0,5w

mm 1000 1

deg 90

4 , 2 02 , 0 5 , 0 1 , 0 1

0 M1

2

a

yb

2

Rd w,

=

(

(

|

|

.

|

\

|

+

|

|

.

|

\

|

+

|

|

.

|

\

|

=

t

l

t

r

E f t R

prEN 1993-

1-3, Eq. 6.18

Combined bending moment and support reaction

Factored actions per unit width (1m):

35 , 1

G

= 5 , 1

Q

=

Self weight:

2

N/m 70 = G

Section 2.3.2

( ) kN/m 20 , 2

Q G

= + = Q G q Eq. 2.3

128

Job No.

R0SU00658

Sheet

6

of

7

Rev

B

Job Title

ECSC Stainless Steel Valorisation Project

Subject

Design Example 3 Design of a two-span trapezoidal

roof sheeting

Made by

AAT

Date

June 2002

Checked by

JEK

Date

June 2002

VTT TECHNICAL RESEARCH

CENTRE OF FINLAND

VTT BUILDING AND TRANSPORT

Kemistintie 3, Espoo

P.O.Box 1805, FIN02044 VTT, Finland

Telephone: + 358 9 4561

Fax: + 358 9 456 7003

CALCULATION SHEET

Client

ECSC

Revised by

JBL/MEB

Date

April 2006

kNm 31 , 2

8

2

Ed

= =

qL

M

kN 96 , 7

4

5

Ed

= = qL F

716 , 0

Rd c,

Ed

=

M

M

491 , 0

Rd w,

Ed

=

R

F

21 , 1

Rd w,

Ed

Rd c,

Ed

= +

R

F

M

M

Combined bending moment and support reaction satisfy the conditions:

1

Rd c,

Ed

M

M

1

Rd w,

ed

R

F

25 , 1

Rd w,

Ed

Rd c,

Ed

+

R

F

M

M

prEN 1993-

1-3, Eqs

6.28a-c

DETERMINATION OF DEFLECTIONS AT SERVICEABILITY LIMIT STATE (SLS)

Effective cross section properties

For serviceability verification the effective width of compression elements should be

based on the compressive stress in element under the serviceability limit state loading.

prEN 1993-

1-3, clause

5.5.1(4)

Maximum compressive stress in the effective section at SLS. A conservative

approximation is made based on

u

W determined above for ultimate limit state.

kNm 55 , 1

8

) (

2

ser Ed, y,

=

+

=

L Q G

M

Section 2.3.4

2 ser Ed, y,

ser Ed, com,

N/mm 105 = =

u

W

M

The effective section properties are determined as before in ultimate limit state except that

yb

f is replaced by

ser Ed, com,

and the thickness of the flange stiffener is not reduced.

The results of the calculation are:

Effective width of the compressed flange The flange is fully

effective

Location of the centroidal axis when the web is fully effective e

c

= 34,1 mm

Effective cross-section of the compression zone of the web The web is fully

effective

Effective part of the web The web is reduced

( = 0,88)

Effective cross section properties per half corrugation A

tot

= 86,6 mm

2

e

c

= 34,8 mm

I

tot

= 63 700 mm

4

Effective section properties per unit width (1 m) I = 600 000 mm

4

W

u

= 17 300 mm

4

W

l

= 17 300 mm

4

129

Job No.

R0SU00658

Sheet

7

of

7

Rev

B

Job Title

ECSC Stainless Steel Valorisation Project

Subject

Design Example 3 Design of a two-span trapezoidal

roof sheeting

Made by

AAT

Date

June 2002

Checked by

JEK

Date

June 2002

VTT TECHNICAL RESEARCH

CENTRE OF FINLAND

VTT BUILDING AND TRANSPORT

Kemistintie 3, Espoo

P.O.Box 1805, FIN02044 VTT, Finland

Telephone: + 358 9 4561

Fax: + 358 9 456 7003

CALCULATION SHEET

Client

ECSC

Revised by

JBL/MEB

Date

April 2006

Determination of deflection Appendix C

Secant modulus of elasticity corresponding to maximum value of the bending moment:

1,Ed,ser

=

2

u

ser Ed, y,

N/mm 5 , 89 =

W

M

2,Ed,ser

=

2 ser Ed, y,

N/mm 8 , 90 =

l

W

M

E

s,1

=

2

yb

ser Ed, 1,

ser Ed, 1,

kN/mm 199

002 , 0 1

=

|

|

.

|

\

|

+

n

f

E

E

0 , 7 = n

Appendix C

Table C.1

E

s,2

=

2

ser Ed, 2,

ser Ed, 1,

N/mm 199

002 , 0 1

=

|

|

.

|

\

|

+

n

yb

f

E

E

E

s,ser

=

2 s,2 1 , s

N/mm 199

2

=

+ E E

Appendix C

Check of deflection:

As a conservative simplification, the variation of

s.ser

E along the length of the member is

neglected.

m 22 , 1

16

33 1

=

+

= L x (location of max deflection)

mm 7 , 4 2 3

48

) (

4

4

3

3

ser s,

4

=

|

|

.

|

\

|

+

+

=

L

x

L

x

L

x

I E

L Q G

The permissible deflection is mm 5 , 14 200 / = L , hence the calculated deflection is

acceptable.

130

BLANK PAGE

Potrebbero piacerti anche

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysDa EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNessuna valutazione finora

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDa EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNessuna valutazione finora

- Design Manual For Structural Stainless Steel Design Example 7 enDocumento6 pagineDesign Manual For Structural Stainless Steel Design Example 7 enAl7amdlellah100% (1)

- Calculation Sheet: Esign Xample Esign of A Lipped Channel in An Exposed FloorDocumento8 pagineCalculation Sheet: Esign Xample Esign of A Lipped Channel in An Exposed FloorMoonzeNessuna valutazione finora

- Structural Design For Low Rise BuildingDocumento42 pagineStructural Design For Low Rise BuildingMohammed SumerNessuna valutazione finora

- 750mm X-Beam Calculation To Eurocode PDFDocumento69 pagine750mm X-Beam Calculation To Eurocode PDFapollocradlesNessuna valutazione finora

- 1.0 Rectangular Column-BIAXIALDocumento31 pagine1.0 Rectangular Column-BIAXIALFranklyn P. Genove100% (1)

- RCC11 Element DesignDocumento6 pagineRCC11 Element DesignSovich82Nessuna valutazione finora

- SSB L SectionDocumento20 pagineSSB L SectionMuhammad Azeem KhanNessuna valutazione finora

- Example 4Documento4 pagineExample 4dane05Nessuna valutazione finora

- Design of Steel I-Section (BS5950)Documento6 pagineDesign of Steel I-Section (BS5950)Rachelle C. Abanes50% (4)

- Column Design Subjected To Axial and BendingDocumento4 pagineColumn Design Subjected To Axial and BendingArnel Dodong0% (1)

- Example: Truss/post End Connection: Joint Shear ResistanceDocumento8 pagineExample: Truss/post End Connection: Joint Shear ResistanceRulli RanastraNessuna valutazione finora

- Design of Steel I Section BS5950Documento6 pagineDesign of Steel I Section BS5950amachmouchi100% (1)

- SX019a-En-EU-Example - Column Base Connection Under Axial CompressionDocumento5 pagineSX019a-En-EU-Example - Column Base Connection Under Axial CompressionWNessuna valutazione finora

- Example Beam Simply Supported With Lateral RestraintDocumento11 pagineExample Beam Simply Supported With Lateral RestraintjplezpNessuna valutazione finora

- Testbeams For Ver Pile CapacityDocumento13 pagineTestbeams For Ver Pile CapacitytmssorinNessuna valutazione finora

- 100m3 Design CalculationDocumento23 pagine100m3 Design CalculationgulmstfNessuna valutazione finora

- RCC13 Punching ShearDocumento10 pagineRCC13 Punching ShearSelçuk YanarateşNessuna valutazione finora

- Chapter 24 WexDocumento7 pagineChapter 24 WexCiprian VarlanNessuna valutazione finora

- Shortcol141 DemoDocumento19 pagineShortcol141 DemoterenvanzareNessuna valutazione finora

- Portal Frame Rafter DesignDocumento132 paginePortal Frame Rafter DesignBobor Emmanuel OfovweNessuna valutazione finora

- Column DesignDocumento4 pagineColumn DesignArnel Dodong83% (6)

- 03 1 Weynand Moment Resistant JointsDocumento71 pagine03 1 Weynand Moment Resistant Jointsdeepak_dce_meNessuna valutazione finora

- Oneway Tow Way Slab DesignDocumento12 pagineOneway Tow Way Slab DesignGeorge GeorgianNessuna valutazione finora

- Rcc13 Punching Shear Ver2.6Documento10 pagineRcc13 Punching Shear Ver2.6Hoo Yen HowNessuna valutazione finora

- Design of Anchor BoltDocumento16 pagineDesign of Anchor BoltLaxmikant ChauhanNessuna valutazione finora

- Column Design Examples EBCSDocumento7 pagineColumn Design Examples EBCSMesfin Derbew89% (28)

- RCC Design SheetsDocumento40 pagineRCC Design Sheetsashuswara84% (25)

- RCC13 Punching ShearDocumento10 pagineRCC13 Punching ShearlianduNessuna valutazione finora

- Scaffold Estimation - CD 5 Post TADocumento5 pagineScaffold Estimation - CD 5 Post TAPazhani RamNessuna valutazione finora

- Access Steel - SX023a - Effective Section Properties of Steel Lipped Channel in CompressionDocumento10 pagineAccess Steel - SX023a - Effective Section Properties of Steel Lipped Channel in Compressiongianniorlati1972Nessuna valutazione finora

- UK Afternoon WorkshopDocumento50 pagineUK Afternoon WorkshopanhkhoacgNessuna valutazione finora

- Load Calculation As Per IS CodeDocumento14 pagineLoad Calculation As Per IS Coderonnie_syncinNessuna valutazione finora

- Baseplate Biaxial MZDocumento26 pagineBaseplate Biaxial MZD SRINIVAS100% (1)

- NC11-1100X500 - (30th-Roof StyDocumento4 pagineNC11-1100X500 - (30th-Roof StyJONHCENA13Nessuna valutazione finora

- CFD Design TemplateDocumento5 pagineCFD Design TemplateEm MarNessuna valutazione finora

- Cold Formed BendingDocumento8 pagineCold Formed BendinggeorgeispasoiuNessuna valutazione finora

- Geometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear CapacityDocumento7 pagineGeometry Materials: Link Light Rail - Ds 720 YP Mcclellan Station Column Shear Capacitydicktracy11Nessuna valutazione finora

- Acuity Base Frame Anchorage July 3, 2008Documento7 pagineAcuity Base Frame Anchorage July 3, 2008GoswandiNessuna valutazione finora

- Pile CAP Design Example + 2 PilesDocumento3 paginePile CAP Design Example + 2 PilesTharanga Pradeep100% (1)

- Microsoft Word - Design of Precast and Prestressed Double Tee Beam in EC2 in EsteemCADDocumento20 pagineMicrosoft Word - Design of Precast and Prestressed Double Tee Beam in EC2 in EsteemCADLim Wee BengNessuna valutazione finora

- Tutorial 7 - Connections - Part ADocumento28 pagineTutorial 7 - Connections - Part ACyrus HongNessuna valutazione finora

- Steel Beam Design Calcsheet v.0Documento4 pagineSteel Beam Design Calcsheet v.0Olusegun S. Ajibola100% (1)

- Manual Beam DesignDocumento14 pagineManual Beam DesignRonald Kaaku50% (2)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationDa EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNessuna valutazione finora

- Functional and Physical Properties of Polymer NanocompositesDa EverandFunctional and Physical Properties of Polymer NanocompositesAravind DasariNessuna valutazione finora

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDa EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNessuna valutazione finora

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsDa EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsNessuna valutazione finora

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesDa EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNessuna valutazione finora

- Solution Manual for 100 Genesys Design Examples: Second EditionDa EverandSolution Manual for 100 Genesys Design Examples: Second EditionNessuna valutazione finora

- MOS Integrated Circuit DesignDa EverandMOS Integrated Circuit DesignE. WolfendaleNessuna valutazione finora

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsDa EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNessuna valutazione finora

- Process Intensification for Sustainable Energy ConversionDa EverandProcess Intensification for Sustainable Energy ConversionNessuna valutazione finora

- British Commercial Computer Digest: Pergamon Computer Data SeriesDa EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNessuna valutazione finora

- Pressure Vessel and Stacks Field Repair ManualDa EverandPressure Vessel and Stacks Field Repair ManualValutazione: 4 su 5 stelle4/5 (4)

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesDa Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNessuna valutazione finora

- Module 10 Lecture 2 WorkabilityDocumento12 pagineModule 10 Lecture 2 WorkabilityettypasewangNessuna valutazione finora

- Introducing The GEK Gasifier Systems - Rev3Documento18 pagineIntroducing The GEK Gasifier Systems - Rev3ettypasewangNessuna valutazione finora

- Module 5 Extrusion-Lecture 3Documento9 pagineModule 5 Extrusion-Lecture 3udaygwlNessuna valutazione finora

- Module 10 Lecture 2 WorkabilityDocumento12 pagineModule 10 Lecture 2 WorkabilityettypasewangNessuna valutazione finora

- Module 7 Sheet Metal-Forming Lecture 1Documento9 pagineModule 7 Sheet Metal-Forming Lecture 1ettypasewangNessuna valutazione finora

- 160 Work BookDocumento111 pagine160 Work BookettypasewangNessuna valutazione finora

- Mechanics ContentsDocumento2 pagineMechanics ContentsettypasewangNessuna valutazione finora

- Building Low Cost Autonomous RobotsDocumento10 pagineBuilding Low Cost Autonomous RobotsPiyush Shukla0% (1)

- Matlab DC Motor ControlDocumento52 pagineMatlab DC Motor ControljofrefoNessuna valutazione finora

- Weatherwax Grewal SolutionsDocumento94 pagineWeatherwax Grewal SolutionsettypasewangNessuna valutazione finora

- Introduction To RoboticsDocumento31 pagineIntroduction To RoboticsnkruškoNessuna valutazione finora

- Design of Crane Steel BeamsDocumento134 pagineDesign of Crane Steel Beamsshak54383% (6)

- Introduction To System Modeling: Dynamic System Input U (T) Output y (T)Documento19 pagineIntroduction To System Modeling: Dynamic System Input U (T) Output y (T)ettypasewangNessuna valutazione finora

- Building Low Cost Autonomous RobotsDocumento28 pagineBuilding Low Cost Autonomous RobotsPiyush Shukla100% (1)

- Mod 6Documento41 pagineMod 6ettypasewangNessuna valutazione finora

- Mechanics Ch4Documento22 pagineMechanics Ch4ettypasewangNessuna valutazione finora

- Mechanics Ch5Documento24 pagineMechanics Ch5ettypasewangNessuna valutazione finora

- Structure Introduction BestDocumento46 pagineStructure Introduction BestAbraham JyothimonNessuna valutazione finora

- Mechanics Ch2Documento38 pagineMechanics Ch2Reeja MathewNessuna valutazione finora

- Mod1 Mechatronics and Manufacturing Automation PDFDocumento17 pagineMod1 Mechatronics and Manufacturing Automation PDFthebetterman0511Nessuna valutazione finora

- GoodnessDocumento10 pagineGoodnessSandeep PachipulusuNessuna valutazione finora

- Tut 101 GPKDocumento14 pagineTut 101 GPKettypasewangNessuna valutazione finora

- Mechanics Ch8Documento16 pagineMechanics Ch8ettypasewangNessuna valutazione finora

- Mechanics Ch5Documento24 pagineMechanics Ch5ettypasewangNessuna valutazione finora

- Tut 003 VehicleGearboxWithPlanetaryDifferential EDocumento35 pagineTut 003 VehicleGearboxWithPlanetaryDifferential EettypasewangNessuna valutazione finora

- Dynamics of CranesDocumento46 pagineDynamics of CranesGogyNessuna valutazione finora

- Design of Crane Steel BeamsDocumento134 pagineDesign of Crane Steel Beamsshak54383% (6)

- Topic C: Energy - Examples SPRING 2014: V V V V e 0.0 e 0.5 e 1.0Documento9 pagineTopic C: Energy - Examples SPRING 2014: V V V V e 0.0 e 0.5 e 1.0ettypasewangNessuna valutazione finora

- Examples MomentumDocumento9 pagineExamples Momentumettypasewang0% (1)

- Principles of Foundation Design D.BDocumento4 paginePrinciples of Foundation Design D.BDavid BaltazaryNessuna valutazione finora

- Chapter4 MECE5104Documento17 pagineChapter4 MECE5104CedricNessuna valutazione finora

- Tutorial 1 SolutionDocumento10 pagineTutorial 1 SolutionSu YiNessuna valutazione finora

- Calibration of Flow Meters Lab Report PDFDocumento10 pagineCalibration of Flow Meters Lab Report PDFsaasNessuna valutazione finora

- PROBLEM 13.14: SolutionDocumento1 paginaPROBLEM 13.14: SolutionNattamon PetchkeawNessuna valutazione finora

- Concentrating On The System: 3.5 The Helmholtz and Gibbs EnergiesDocumento42 pagineConcentrating On The System: 3.5 The Helmholtz and Gibbs EnergiesAnnaLynYepesNessuna valutazione finora

- Aerodynamics Question BankDocumento39 pagineAerodynamics Question BankSeeandgrow ByabdulsamadNessuna valutazione finora

- Seismic Analysis of Steel StructureDocumento9 pagineSeismic Analysis of Steel Structureminn ko ko kyawNessuna valutazione finora

- SM 04 Spring Short PDFDocumento2 pagineSM 04 Spring Short PDFdddddddddNessuna valutazione finora

- Dynamic System Modelling and ControlDocumento761 pagineDynamic System Modelling and ControlDr-Nancy Ahmed100% (1)

- 13.6 Work-Kinetic Energy Theorem: W F DX MVDocumento3 pagine13.6 Work-Kinetic Energy Theorem: W F DX MVsreejitha KNessuna valutazione finora

- Slide CLTDocumento28 pagineSlide CLTleoNessuna valutazione finora

- A1 Batch NKC Sir Heat Thermodynamics KTG 1637843224143Documento57 pagineA1 Batch NKC Sir Heat Thermodynamics KTG 1637843224143Harsh SinghNessuna valutazione finora

- International Standard: Test Code For Machine Tools - Determination of The Noise EmissionDocumento11 pagineInternational Standard: Test Code For Machine Tools - Determination of The Noise EmissionAnonymous 2SQDbt2Nessuna valutazione finora

- Appliedmechanics00poorrich PDFDocumento264 pagineAppliedmechanics00poorrich PDFNileshNessuna valutazione finora

- Punjab College Arifwala List of Books Available in Department (Physics) Library Book Number Book Title AuthorDocumento18 paginePunjab College Arifwala List of Books Available in Department (Physics) Library Book Number Book Title AuthorAamir JavedNessuna valutazione finora

- UT Dallas Syllabus For Phys2325.001.10f Taught by Jason Slinker (jds107020)Documento6 pagineUT Dallas Syllabus For Phys2325.001.10f Taught by Jason Slinker (jds107020)UT Dallas Provost's Technology GroupNessuna valutazione finora

- Cruise Flight: 1 Equations of MotionDocumento3 pagineCruise Flight: 1 Equations of MotionSyafiq KamilNessuna valutazione finora

- Fluidsummary 180610171918 PDFDocumento190 pagineFluidsummary 180610171918 PDFsing_r100% (1)

- Introduction To SensorsDocumento17 pagineIntroduction To SensorsHossam AbdelmoneimNessuna valutazione finora

- Cold Formed Steel DesignDocumento2 pagineCold Formed Steel DesignkiplingkipNessuna valutazione finora

- .In-Deduction of Gas Laws From Kinetic TheoryDocumento2 pagine.In-Deduction of Gas Laws From Kinetic TheoryMridul BhaskarNessuna valutazione finora

- The Calculation of The Bending of Star Light Grazing The Sun.Documento4 pagineThe Calculation of The Bending of Star Light Grazing The Sun.sipora1Nessuna valutazione finora

- PhysicsDocumento12 paginePhysicsPeter Paul RecaboNessuna valutazione finora

- CU Quantum Social Science 1107012821 PDFDocumento306 pagineCU Quantum Social Science 1107012821 PDFBreilla ZanonNessuna valutazione finora

- General Expressions For Flow Through Beds in Terms of Carman-Kozeny EquationsDocumento6 pagineGeneral Expressions For Flow Through Beds in Terms of Carman-Kozeny Equationsحاتم غيدان خلفNessuna valutazione finora

- C9789810694364SM PDFDocumento34 pagineC9789810694364SM PDFJohnrey FlandezNessuna valutazione finora

- Chapter 1 Jan2013Documento30 pagineChapter 1 Jan2013enteryourname5Nessuna valutazione finora

- Bluebook (EN1993 1 1, HyperBeam, 17 Dec 2013)Documento138 pagineBluebook (EN1993 1 1, HyperBeam, 17 Dec 2013)Peyman MznNessuna valutazione finora