Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Casting

Caricato da

Mark Nassef Naguib0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

64 visualizzazioni13 paginecasting

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentocasting

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

64 visualizzazioni13 pagineCasting

Caricato da

Mark Nassef Naguibcasting

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 13

Casting

From Wikipedia, the free encyclopedia

One half of a bronze mold for casting a socketed spear head

dated to the period 1400-1000 BC.

Casting is a process by which a material is introduced into

a mold while it is liuid! allowed to solidify in the shape inside the mold! and then

remo"ed producing a fabricated ob#ect or part. $he finished product is also called a

casting. Casting is often used for creating one or more copies of an original piece of

sculptural %three-dimensional& artwork. 't is also used e(tensi"ely in the automobile

manufacture industry! such as the casting of engine blocks or cylinder heads! or "acuum-

forming of plastics and in the lost core process. $he process! particularly when performed

with molten metals! is also called founding.

Casting may be used to form hot! liuid metals or meltable plastics %called

thermoplastics&! or "arious materials that cold set after mi(ing of components such as

certain plastic resins %e.g. epo(y&! water setting materials such as concrete or plaster! and

materials that become liuid or paste when moist such as clay! which when dry enough to

be rigid is remo"ed from the mold! further dried! and fired in a kiln.

Casting may be used to create artistic sculptures

Lost wax casting process

$he )ost *a( casting process is an ancient practice that is still in widespread use today.

$he process "aries from foundry to foundry! but the steps which are usually used in

casting small bronze sculptures in a modern bronze foundry are as follows+

1. ,culpting. -n artist creates an original artwork from wa(! clay! or another material.

*a( and oil-based clay are often preferred because these materials retain their

softness.

.. /ouldmaking. - mould is made of the original sculpture. /ost moulds are at least

two pieces! and a shim with keys is placed between the two hal"es during

construction so that the mould can be put back together accurately. /ost moulds of

small sculptures are made from plaster! but can also be made of fiberglass or other

materials. $o preser"e the fine details on the original artwork0s surface! there is

usually an inner mould made of late( or "inyl! which is supported by the plaster part

of the mould. 1sually! the original artwork is destroyed during the making and initial

deconstruction of the plaster mould. $his is because the originals are solid! and do not

easily bend as the plaster mould is remo"ed. Often long! thin pieces are cut off of the

original and moulded separately. ,ometimes! especially in the case of large original

%such as life-size& sculptures! many moulds are needed to recreate the original

sculpture.

2. *a(. Once the plaster and late( mould is finished! molten wa( is poured into it and

swished around until an e"en coating! usually about 134 inches think! co"ers the entire

inner surface of the mould. $his may be done in se"eral layers.

4. 4emo"al of wa(. $his new! hollow wa( copy of the original artwork is remo"ed from

the mould. $he artist may reuse the mould to make more wa( copies! but wear and

tear on the mould limit their number. 5or small bronze artworks! a common number

of copies today is around .6.

6. Chasing. 7ach hollow wa( copy is then 8chased8+ a heated metal tool is used to rub

out all the marks which show the 8parting line8 or 8flashing8 where the pieces of the

mould came together. *a( pieces that were moulded separately can be heated and

attached9 foundries often use 8registration marks8 to indicate e(actly where they go.

:. ,pruing. Once the wa( copy looks #ust like the original artwork! it is 8sprued8 with a

treelike structure of wa( that will e"entually pro"ide paths for molten bronze to flow.

$he carefully-planned spruing usually begins at the top with a wa( 8cup!8 which is

attached by wa( cylinders to "arious points on the wa( copy.

;. ,lurry. - 8sprued8 wa( copy is dipped into a ceramic slurry! then into a mi(ture of

powdered clay and sand. $his is allowed to dry! and the process is repeated until a

half-inch thick or thicker surface co"ers the entire piece. Only the inside of the cup is

not coated! and the cup0s flat top ser"es as the base upon which the piece stands

during this process.

<. Burnout. $he ceramic-coated piece is placed cup-down in a kiln! whose heat hardens

the ceramic coatings into a shell! and the wa( melts and runs out. $he melted wa( can

be reco"ered and reused! although often it is simply combusted by the burnout

process. =ow all that remains of the original artwork is the negati"e space! formerly

occupied by the wa(! inside the hardened ceramic shell. $he feeder and "ent tubes

and cup are now hollow! also.

>. $esting. $he ceramic shell is allowed to cool! then is tested to see if water will flow

through the feeder and "ent tubes as necessary. Cracks or leaks can be patched with

thick ceramic paste. $o test the thickness! holes can be drilled into the shell! then

patched.

10. ?ouring. $he shell is reheated in the kiln to harden the patches! then placed cup-

upwards into a tub filled with sand. Bronze is melted in a crucible in a furnace! then

poured carefully into the shell. 'f the shell were not hot! the temperature difference

would shatter it. $he bronze-filled shells are allowed to cool.

11. 4elease. $he shell is hammered or sand-blasted away! releasing the rough bronze.

$he spruing! which are also faithfully recreated in metal! are cut off! to be reused in

another casting.

1.. /etal-chasing. @ust as the wa( copies were 8chased!8 the bronze copies are worked

until the telltale signs of casting are remo"ed! and the sculptures again look like the

original artwork. ?its left by air bubbles in the molten bronze are filled! and the stubs

of spruing filed down and polished.

12. ?atinating. $he bronze is coloured to the artist0s preference! using chemicals applied

to heated or cooled metal. $his colouring is called patina! and is often green! black!

white or brownish to simulate the surfaces of ancient bronze sculptures. %-ncient

bronzes gained their patinas from o(idisation and other effects of being on 7arth for

many years.& Aowe"er! many artists prefer that their bronzes ha"e brighter! paint-like

colours. ?atinas are generally less opaue than paint! which allows the lustre of the

metal to show through. -fter the patina is applied! a coating of wa( is usually applied

to protect the surface. ,ome patinas change colour o"er time because of o(idisation!

and the wa( layer slows this down somewhat.

On the left is an e(ample of a lost-wa( process mold! and

on the right is the resulting bronze sculpture.

$he lost-wa( process can also be used with any material

that can burn! melt! or e"aporate to lea"e a mold ca"ity.

,ome automobile manufacturers use a lost-foam techniue

to make engine blocks. $he model in this case is made of polystyrene foam! which is then

placed into a casting flask! consisting of a cope and drag! which is then filled with casting

sand. $he foam supports the sand! allowing shapes to be made which would not be

possible if the process had to rely on the sand alone to hold its shape. $he metal is then

poured in! and the heat of the metal "aporizes the foam as the metal enters the mold.

o 5lash animation of lost-wa( casting

Other casting processes used in creating artworks

,and-casting is mainly used for casting flat! relief-like sculptures. -luminum is one

material which is commonly used in sand-casting. $he process starts with a tub filled

with sand. $he sand is wetted! and an ob#ect is pressed into the wet sand! or the sculptor

uses his hands or tools to make the desired design in the sand! which is then dried.

/olten aluminum is carefully poured into the depression and left to cool. $hen the artist

may choose to continue refining the ob#ect by 8chasing8 it or lea"e it with the roughened

surface that is characteristic of sand-cast ob#ects.

Cuttlefish casting using cuttlebone as a mould is a traditional casting method used by

#ewelers and sil"ersmiths for small ob#ects! especially in taking a copy from a metal

original. $he fine grain of the calcium carbonate cuttlebone offers good definition!

although it imparts a characteristic surface te(ture to the cast.

Casting in manufacturing

Casting is a process by which a fluid melt is introduced into a mold! allowed to cool in

the shape of the form! and then e#ected to make a fabricated part or casing. 5our main

elements are reuired in the process of casting+ pattern! mold! cores! and the part. $he

pattern! the original template from which the mold is prepared! creates a corresponding

ca"ity in the casting material. Cores are used to produce tunnels or holes in the finished

mold! and the part is the final output of the process.

,ubstitution is always a factor in deciding whether other techniues should be used

instead of casting. -lternati"es include parts that can be stamped out on a punch press or

deep-drawn! items that can be manufactured by e(trusion or by cold-bending! and parts

that can be made from highly acti"e metals.

$he casting process is subdi"ided into two distinct subgroups+ e(pendable and

none(pendable mold castingBB

Expendable mold casting

7(pendable mold casting is a generic classification that includes sand! plastic! shell! and

in"estment %lost-wa( techniue& moldings. -ll of these in"ol"e the use of temporary and

nonreusable molds! and need gra"ity to help force molten fluid into casting ca"ities.'n

this process the mould is used only once.

Sand casting

Sand casting is a means of producing rough metal castings

that are further refined by any or all of hammer peening! shot

peening! polishing! forging! plating! rough grinding! machine

grinding or machining. ,and castings not further worked by

polishing or peening are readily recognized by the sand-like

te(ture imparted by the mold. -s the accuracy of the casting

is limited by imperfections in the mold making process there

will be e(tra material to be remo"ed by grinding or

machining! more than is reuired by other more accurate

casting processes.

atterns

5rom the design! pro"ided by an engineer or designer! a craftsperson called a

patternmaker produces a master of the ob#ect to be produced! often using wood. -s the

metal to be cast will shrink somewhat between the time it first solidifies and the time it is

cool the master must be made slightly larger than the finished product. $o simplify the

making of the pattern the patternmaker will use an appropriately scaled o"ersize rulerC

called a shrink ruleCspecific to the type

of metal to be cast. -dditional paths for

the entrance of metalCthe sprueCand

the e(iting of gasCthe riserCare added

to the pattern.

Cope D drag with cores in place on the drag

!olding box and materials

- multi-part molding bo( %known as a casting flask! sometimes referred to as the cope

and drag& is prepared to recei"e the pattern. /olding bo(es are made in segments that

may be latched to each other and to end closures. 5or a simple ob#ectCflat on one sideC

the lower portion of the bo(! closed at the bottom! will be filled with prepared casting

sand or green sandCa slightly moist mi(ture of sand and clay. $he sand is packed in

through a "ibratory process called ramming and! in this case! periodically screeded le"el.

$he surface of the sand may then be stabilized with a sizing compound. $he pattern is

placed on the sand and another molding bo( segment is added. -dditional sand is

rammed o"er and around the pattern. 5inally a co"er is placed on the bo( and it is turned

and unlatched! so that the hal"es of the mold may be parted and the pattern with its sprue

and "ent patterns remo"ed. -dditional sizing may be added and any defects introduced

by the remo"al of the pattern are corrected. $he bo( is closed again. $his forms a 8green8

mold which must be dried to recei"e the hot metal. 'f the mold is not sufficiently dried a

steam e(plosion can occur that can throw molten metal about. 'n some cases! the sand

may be oiled instead of moistened! which makes possible casting without waiting for the

sand to dry. ,and may also be bonded by chemical binders! such as furane resins or

amine-hardened resins.

Chills

'f it is desired to ha"e most of theCiron or steelCcasting in a tough! ductile! state but

with a few surfaces hard! it is possible to introduce! into the mold! metal platesCchillsC

where the metal is to be hardened. $he associated! local! rapid! cooling will form a finer-

grained and harder metal at these locations. $he inner diameter of an engine cylinder is

made hard by a chilling core.

Cores

$o produce ca"ities within the castingCsuch as for liuid cooling in engine blocks and

cylinder headsCnegati"e forms are used to produce cores. 1sually sand-molded! cores

are inserted into the casting bo( after remo"al of the pattern. *hene"er possible! designs

are made that a"oid the use of cores! due to the additional set-up time and thus greater

cost.

$wo sets of castings %bronze and

aluminum& from the abo"e sand mold

*ith a completed mold at the

appropriate moisture content! the bo(

containing the sand mold is then

positioned for filling with molten metal

Ctypically iron! steel! bronze! brass!

aluminum alloy! or "arious pot metal

alloys! which often include lead! tin! and zinc. -fter filling with liuid metal the bo( is

set aside until the metal is sufficiently cool to be strong. $he sand is then remo"ed

re"ealing a rough casting that! in the case of iron or steel! may still be glowing red. *hen

casting with metals like iron or lead! which are significantly hea"ier than the casting

sand! the casting flask is often co"ered with a hea"y plate to pre"ent a problem known as

floating the mold. 5loating the mold occurs when the pressure of the metal pushes the

sand abo"e the mold ca"ity out of shape! causing the casting to fail.

)eft+- Corebo(! with resulting %wire

reinforced& cores directly below. 4ight+-

?attern %used with the core& and the

resulting casting below %the wires are

from the remains of the core&

-fter casting! the cores are broken up by

rods or shot and remo"ed from the

casting. $he metal from the sprue and

risers is cut from the rough casting.

Earious heat treatments may be applied

to relie"e stresses from the initial

cooling and to add hardnessCin the case of steel or iron! by uenching in water or oil.

$he casting may be further strengthened by surface compression treatmentClike shot

peeningCthat adds resistance to tensile cracking and smoothes the rough surface.

"esign re#uirements

$he part to be made and its pattern must be designed to accommodate each stage of the

process! as it must be possible to remo"e the pattern without disturbing the molding sand

and to ha"e proper locations to recei"e and position the cores. - slight taper! known as

draft! must be used on surfaces perpendicular to the parting line! in order to be able to

remo"e the pattern from the mold. $his reuirement also applies to cores! as they must be

remo"ed from the core bo( in which they are formed. $he sprue and risers must be

arranged to allow a proper flow of metal and gasses within the mold in order to a"oid an

incomplete casting. ,hould a piece of core or mold become dislodged it may be

embedded in the final casting! forming a sand pit! which may render the casting unusable.

Fas pockets can cause internal "oids. $hese may be immediately "isible or may only be

re"ealed after e(tensi"e machining has been performed. 5or critical applications! or

where the cost of wasted effort is a factor! non-destructi"e testing methods may be

applied before further work is performed.

"ecorati$e use of patterns

Old wood-patterns! once used to make molds for casting machine parts! are sought out

and collected by some for use as interior decorations.

%lternati$e casting methods

,and casting for mass production has largely been superseded by other methods.

/odern mass production methods can produce thin but accurate moldsC

superficially resembling paper mache! such as is used in egg cartons! but that is

refractory in natureCthat are then supported by some meansCsuch as dry sand

surrounded by a bo(Cduring the casting process. Gue to the higher accuracy it is

possible to make thinner and hence lighter castingsCe(tra metal does not ha"e to

be present to allow for "ariations in the moldsCthese thin-mold casting methods

ha"e been used since the 1>:0s in the manufacture of cast-iron engine blocks and

cylinder heads for automoti"e applications.

Earious automoti"e mechanical components are now freuently made of

aluminum! which for appropriately shaped components may be made either by

sand casting or by die casting! the latter an accurate process that greatly reduces

finishing and machining costs. *hile the material and the processing setup is

more e(pensi"e than the use of iron this is one of the most straightforward ways

to reduce weight in a "ehicle! important as a contributor to both fuel economy and

acceleration performance.

,tarting in the early 1><0s! some castings such as automoti"e engine blocks ha"e

been made using a sand casting techniue conceptually similar to the lost wa(

process! known as the lost foam process. 'n this process! the pattern is made of

polystyrene foam! which the sand is packed around! lea"ing the foam in place.

*hen the metal is poured into the mold! the heat of the metal "aporizes the foam

a short distance away from the surface of the metal! lea"ing the molding ca"ity

into which the metal flows. $he lost-foam process supports the sand much better

than con"entional sand casting! allowing greater fle(ibility in the design of the

cast parts! with less need for machining to finish the casting. $his techniue was

de"eloped for the clay mold casting of abstract art pieces and was first adopted for

large uantity commercial production by the ,aturn company. 1nfortunately! this

process burns plastic in an uncontroled way! producing a great deal of smoke.

laster casting &of metals'

?laster casting is similar to sand molding e(cept that plaster is substituted for sand.

?laster compound is actually composed of ;0-<0H gypsum and .0-20H strengthener and

water. Fenerally! the form takes less than a week to prepare! after which a production rate

of 1-10 units3hr-mold is achie"ed with a capability to pour items as massi"e as 46 kg and

as small as 20 g with "ery high surface resolution and fine tolerances.

Once used and cracked away! normal plaster cannot easily be recast. ?laster casting is

normally used for nonferrous metals such as aluminium-! zinc-! or copper-based alloys. 't

cannot be used to cast ferrous material because sulfur in gypsum slowly reacts with iron.

?rior to mold preparation the pattern is sprayed with a thin film of parting compound to

pre"ent the mold from sticking to the pattern. $he unit is shaken so plaster fills the small

ca"ities around the pattern. $he form is remo"ed after the plaster sets.

?laster casting represents a step up in sophistication and reuired skill. $he automatic

functions easily are handed o"er to robots! yet the higher-precision pattern designs

reuired demand e"en higher le"els of direct human assistance.

laster casting &of plaster or concrete'

?laster itself may be cast - either using single use waste molds! multiple use piece molds!

or molds made of fle(ible material such as late( rubber %which is in turn supported by an

e(terior mold&. $he finished product is! unlike marble! relati"ely unattracti"e! lacking in

transparency! and so is usually painted! often in ways that gi"e the appearance of metal.

-lternati"ely! the first layers cast may contain colored sand so as to gi"e an appearance

of stone. By casting concrete! rather than plaster! it is possible to create sculptures!

fountains! or seating for outdoor use.

Shell molding

,hell molding is also similar to sand molding e(cept that a mi(ture of sand and 2-:H

resin holds the grains together. ,et-up and production of shell mold patterns takes weeks!

after which an output of 6-60 pieces3hr-mold is attainable. -luminium and magnesium

products a"erage about 12.6 kg as a normal limit! but it is possible to cast items in the 46-

>0 kg range. ,hell mold walling "aries from 2-10 mm thick! depending on the forming

time of the resin.

$here are a dozen different stages in shell mold processing that include+

1. initially preparing a metal-matched plate

.. mi(ing resin and sand

2. heating pattern! usually to between 606-660 I

4. in"erting the pattern %the sand is at one end of a bo( and the pattern at the other!

and the bo( is in"erted for a time determined by the desired thickness of the mill&

6. curing shell and baking it

:. remo"ing in"estment

;. inserting cores

<. repeating for other half

>. assembling mold

10. pouring mold

11. remo"ing casting

1.. cleaning and trimming.

$he sand-resin mi( can be recycled by burning off the resin at high temperatures.

(n$estment Casting

'n"estment casting %lost-wa( process& yields a finely detailed and accurate product! with

e(cellent metallurgical properties.

?olystyrene foam is also used in in"estment castingCsee lost-foam casting.

-fter a "ariable lead time! usually weeks! 1J1000 pieces3hour-mold can be produced in

the mass range ..2J..; kg. 'tems up to 46 kg and as light as 20 g are possible for unit

production.

$he process starts by creating an in#ection die to the desired specifications. $his die will

be used to in#ect wa( to create the patterns needed for in"estment casting. $he patterns

are attached to a central wa( sprue! creating an assembly! or mold. $he sprue contains the

fill cup where the molten metal will be poured into the assembly.

$he wa( assembly is now dipped multiple times in a ceramic slurry! depending on the

shell thickness desired. - layer of fine sand %usually zircon& is added on top of each

ceramic layer. $his process will be repeated until the desired shell is created.

-fter the shell is created to the specifications desired! the wa( must be remo"ed9 this is

normally achie"ed using an autocla"e. $his is where the name 8lost-wa( process8 comes

from. $his lea"es an impression of the desired castings! which will be filled with metal.

Before being cast! howe"er! the shells must be heated in a furnace so they do not break

during the casting process.

=e(t! the desired metal is poured into the hot ceramic shell. $he metal fills each part on

the assembly! and the central sprue ca"ity and fill cup. $he indi"idual parts will be

remo"ed after the mold cools and the shell is remo"ed. $he shell is generally remo"ed

with water-blasting! although alternate methods can be used. *hat remains are the cast

metal parts! but they are still attached to the sprue assembly. $he indi"idual parts are

remo"ed by cold-break %dipping in liuid nitrogen and breaking the parts off with

hammer and chisel& or with large cutoff saws.

$he last step is finishing. 5irst the gate! or the place where the part was connected to the

sprue! must be remo"ed. $he gate is ground off to part specifications. ?arts are also

inspected to make sure they were cast properly! and if not are either fi(ed or scrapped.

Gepending on the in"estment casting facility and specifications! more finishing work can

be done on-site! sub-contracted! or not done at all.

'n"estment casting yields e(ceedingly fine uality products made of all types of metals. 't

has special applications in fabricating "ery high-temperature metals! especially those

which cannot be cast in metal or plaster molds and those which are difficult to machine or

work.

)onexpendable mold casting

=one(pendable mold casting differs from e(pendable processes in that the mold need not

be reformed after each production cycle. $his techniue includes at least four different

methods+ permanent! die! centrifugal! and continuous casting.

ermanent !old Casting

?ermanent mold casting %typically for non-ferrous metals& reuires a set-up time on the

order of weeks to prepare a steel tool! after which production rates of 6-60 pieces3hr-mold

are achie"ed with an upper mass limit of > kg per iron alloy item %cf.! up to 126 kg for

many nonferrous metal parts& and a lower limit of about 0.1 kg. ,teel ca"ities are coated

with refractory wash of acetylene soot before processing to allow easy remo"al of the

workpiece and promote longer tool life. ?ermanent molds ha"e a life which "aries

depending on maintenance of after which they reuire refinishing or replacement. Cast

parts from a permanent mold generally show .0H increase in tensile strength and 20H

increase in elongation as compared to the products of sand casting.

$he only necessary input is the coating applied regularly. $ypically! permanent mold

casting is used in forming iron-! aluminum-! magnesium-! and copper-based alloys. $he

process is highly automated.

"ie*Casting

'n die-casting molten metal is in#ected into a mould at high pressures. ,et-up time for dies

is 1-. hours! after which production rates of .0J.00 pieces per hour-mould are normally

obtained. /a(imum mass limits for magnesium! zinc! and aluminum parts are roughly

4.6 kg! 1< kg! and 46 kg! respecti"ely %though larger machines do e(ist&9 the lower limit

in all cases is about 20 g. Gie in#ection machines are generally large %up to 2 K < m& and

operate at high pressures C 100 megapascals %1000 kgf3cm

.

& and higher! although

aluminum usually is processed at lower pressure. - well-designed unit produces o"er

600!000 castings during the production lifetime of a single mould. *hile the dies used in

the process are uite e(pensi"e! if a "ery large number of castings can be produced!

significant cost sa"ings can be achie"ed when a component is manufactured by die

casting. $he ma#or production step is die construction! usually a steel alloy reuiring a

great deal of skill and fine tooling to prepare. /ostly non-ferrous materials are die-cast!

such as aluminum! zinc! magnesium! and copper-based alloys.

$his is the process used in the production of certain toys! notably that of model

automobiles! see+ die-cast toy! /atchbo(

Centrifugal casting

Main article: Centrifugal casting

Centrifugal casting is both gra"ity- and pressure-independent since it creates its own

force feed using a temporary sand mold held in a spinning chamber at up to >0 g %>00

m3sL&. )ead time "aries with the application. ,emi- and true-centrifugal processing permit

20-60 pieces3hr-mold to be produced! with a practical limit for batch processing of

appro(imately >000 kg total mass with a typical per-item limit of ..2-4.6 kg.

'ndustrially! the centrifugal casting of railway wheels was an early application of the

method de"eloped by Ferman industrial company Irupp and this capability enabled the

rapid growth of the enterprise.

,mall art pieces such as #ewelry are often cast by this method using the lost wa( process!

as the forces enable the rather "iscous liuid metals to flow through "ery small passages

and into fine details such as lea"es and petals. $his effect is similar to the benefits from

"acuum casting! also applied to #ewelry casting.

Continuous Casting

Main article: Continuous casting

Continuous casting is a refinement of the casting process for the continuous! high-"olume

production of metal sections with a constant cross-section. /olten metal is poured into an

open-ended! water-cooled copper mould! which allows a 0skin0 of solid metal to form o"er

the still-liuid centre. $he strand! as it is now called! is withdrawn from the mould and

passed into a chamber of rollers and water sprays9 the rollers support the thin skin of the

strand while the sprays remo"e heat from the strand! gradually solidifying the strand from

the outside in. -fter solidification! predetermined lengths of the strand are cut off by

either mechanical shears or tra"elling o(yacetylene torches and transferred to further

forming processes! or to a stockpile. Cast sizes can range from strip %a few millimetres

thick by about fi"e metres wide& to billets %>0 to 1:0 mm suare& to slabs %1..6 m wide

by .20 mm thick&. ,ometimes! the strand may undergo an initial hot rolling process

before being cut.

Continuous casting pro"ides better uality product as it allows finer control o"er the

casting process! along with the ob"ious ad"antages inherent in a continuous forming

process. /etals such as steel! copper and aluminum are continuously cast! with the

largest tonnage poured being steel.

Cooling rate

$he rate at which a casting cools affects its microstructure! uality! and properties.

$he products of sand casting and slurry-mold processes! often large with thick walls!

generally cool slowly. $his increases the metal0s grain size! creating a coarse

microstructure that lowers the strength of the casting. Coarse grains can allow elements

of an alloy to separate! which also weakens the casting. But slower cooling keeps the

casting metal liuid longer! which allows more gases and waste metal to escape! reducing

the "oids and inclusions that can weaken a casting.

Con"ersely! the products of die casting and metal-mold processes generally cool more

uickly! resulting in a fine microstructure with small grain and less alloy segregation but

more trapped gases and inclusions. On the other hand! according to the ?illings Bedworth

4atio! strength of a material is in"ersely proportional to the suare root of its grain size.

?ro"ided de-gassing techniues are used during molten metal preparation! die cast

products may ha"e superior strength when compared with eui"alent sand castings.

Shrinkage

)ike nearly all materials! metal is less dense as a liuid than a solid! and so a casting

shrinks as it cools -- mostly as it solidifies! but also as the temperature of the solid

material drops. Compensation for this natural phenomena must be considered in two

ways.

+olumetric Shrinkage

$he shrinkage caused by solidification can lea"e ca"ities in a casting! weakening it.

4isers pro"ide additional material to the casting as it solidifies. $he riser %sometimes

called a 8feeder8& is designed to solidify later than the part of the casting to which it is

attached. $hus the liuid metal in the riser will flow into the solidifying casting and feed

it until the casting is completely solid. 'n the riser itself there will be a ca"ity showing the

metal which was fed. 4isers add cost because some of their material must be remo"ed! by

cutting away from the casting which will be shipped to the customer. $hey are often

necessary to produce parts which are free of internal shrinkage "oids.

,ometimes! to promote directional shrinkage! chills must be used in the mold. - chill is

any material which will conduct heat away from the casting more rapidly that the

material used for molding. $hus if silica sand is used for molding! a chill may be made of

copper! iron! aluminum! graphite! zircon sand! chromite or any other material with the

ability to remo"e heat faster locally from the casting. -ll castings solidify with

progressi"e solidification but in some designs a chill is used to control the rate and

seuence of solidification of the casting.

Linear Shrinkage

,hrinkage after solidification can be dealt with by using an o"ersized pattern designed for

the rele"ant alloy. ?attern makers use special 8shrink rulers8 to make the patterns used by

the foundry to make castings to the design size reuired. $hese rulers are . - : H

o"ersize! depending on the material to be cast. 1sing such a ruler during pattern making

will ensure an o"ersize pattern. $hus! the mold is larger also! and when the molten metal

solidifies it will shrink and the casting will be the size reuired by the design.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- ZF 2092.033.009 Eccom 1.8 2017Documento43 pagineZF 2092.033.009 Eccom 1.8 2017Oskars RozefeldsNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Surface Preparation and Protective Coating: Norsok StandardDocumento28 pagineSurface Preparation and Protective Coating: Norsok StandardTeck Tiong Huan100% (1)

- Quiz 3 MDPS370Documento1 paginaQuiz 3 MDPS370Mark Nassef NaguibNessuna valutazione finora

- Assignment 2Documento2 pagineAssignment 2Mark Nassef NaguibNessuna valutazione finora

- Quiz 3bDocumento1 paginaQuiz 3bMark Nassef NaguibNessuna valutazione finora

- Primary 4 ReportDocumento3 paginePrimary 4 ReportMark Nassef NaguibNessuna valutazione finora

- Applsci 10 08918 v4 PDFDocumento31 pagineApplsci 10 08918 v4 PDFMark Nassef NaguibNessuna valutazione finora

- CALS 1st Floor Vending Area - 9.93 - ENLARGED OFFICE COMMUNAL SPACE - Rev.4 - REFERENCEDocumento1 paginaCALS 1st Floor Vending Area - 9.93 - ENLARGED OFFICE COMMUNAL SPACE - Rev.4 - REFERENCEMark Nassef NaguibNessuna valutazione finora

- Practical Mid-Year Exams - ICT & Science - 2021-2022Documento1 paginaPractical Mid-Year Exams - ICT & Science - 2021-2022Mark Nassef NaguibNessuna valutazione finora

- CVI FormDocumento1 paginaCVI FormMark Nassef NaguibNessuna valutazione finora

- MDPN262 Lecture 1Documento48 pagineMDPN262 Lecture 1Mark Nassef NaguibNessuna valutazione finora

- INSPECTION REQUEST and Mateiral Approval AquaDocumento2 pagineINSPECTION REQUEST and Mateiral Approval AquaMark Nassef Naguib100% (1)

- Solid & Dry Lubricants: InroductionDocumento7 pagineSolid & Dry Lubricants: InroductionMark Nassef NaguibNessuna valutazione finora

- Pinching-Off of PE Gas PipesDocumento1 paginaPinching-Off of PE Gas PipesMark Nassef NaguibNessuna valutazione finora

- Common Errors and Warnings in Convergence Problems PDFDocumento2 pagineCommon Errors and Warnings in Convergence Problems PDFMark Nassef NaguibNessuna valutazione finora

- Tribological Problems and How To Reduce ThemDocumento4 pagineTribological Problems and How To Reduce ThemMark Nassef NaguibNessuna valutazione finora

- Church and StateDocumento10 pagineChurch and StateMark Nassef NaguibNessuna valutazione finora

- Access Control Notes MarkDocumento1 paginaAccess Control Notes MarkMark Nassef NaguibNessuna valutazione finora

- Print Close WindowDocumento1 paginaPrint Close WindowMark Nassef NaguibNessuna valutazione finora

- IT RackDocumento1 paginaIT RackMark Nassef NaguibNessuna valutazione finora

- Chiller Base: Item Description Unit QTY Rate Amount L.E. L.E. Option 1 - No Connections in The I - BeamsDocumento1 paginaChiller Base: Item Description Unit QTY Rate Amount L.E. L.E. Option 1 - No Connections in The I - BeamsMark Nassef NaguibNessuna valutazione finora

- Client: DR - Hosam Zaki Project: Ganin Fertility Center. PROECT NO.: 452 DATE: 15 AUG, 2011 REV.: 0 PACKAGE (II) : MEP & Finishings - Main BuildingDocumento1 paginaClient: DR - Hosam Zaki Project: Ganin Fertility Center. PROECT NO.: 452 DATE: 15 AUG, 2011 REV.: 0 PACKAGE (II) : MEP & Finishings - Main BuildingMark Nassef NaguibNessuna valutazione finora

- CR 10-16Documento5 pagineCR 10-16Mark Nassef NaguibNessuna valutazione finora

- GeneratorDocumento4 pagineGeneratorMark Nassef NaguibNessuna valutazione finora

- Acmee 2018Documento6 pagineAcmee 2018Ishu AroraNessuna valutazione finora

- Ak-90le SuezDocumento1 paginaAk-90le Suezinversiones del peruNessuna valutazione finora

- Mech Control of Corrosion On Underwater PilesDocumento14 pagineMech Control of Corrosion On Underwater PilesBalaji GuruNessuna valutazione finora

- Lube Oil Replenishment Procedure Air CompDocumento3 pagineLube Oil Replenishment Procedure Air CompGulraiz ShaukatNessuna valutazione finora

- Spec Product PertaminaDocumento8 pagineSpec Product PertaminaErik AlfiandyNessuna valutazione finora

- Mcnally Sayaji Engineering LimitedDocumento54 pagineMcnally Sayaji Engineering LimitedUtpalSahaNessuna valutazione finora

- AM Industry - Steel PrequalificationDocumento63 pagineAM Industry - Steel PrequalificationAbdul RaqeebNessuna valutazione finora

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape Metal (Fox Chapel Publishing) Over 400 Step-by-Step Photos to Help You Learn Hands-On Welding and Avoid Common Mistakes - Andrew PearceDocumento6 pagineFarm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape Metal (Fox Chapel Publishing) Over 400 Step-by-Step Photos to Help You Learn Hands-On Welding and Avoid Common Mistakes - Andrew Pearcecazikoce0% (1)

- Kerala Electrical and Allied Engineering Co. LTD (KEL), Mamala UnitDocumento45 pagineKerala Electrical and Allied Engineering Co. LTD (KEL), Mamala UnitVishal VsNessuna valutazione finora

- Universal Rutile Electrode: Tip ColourDocumento1 paginaUniversal Rutile Electrode: Tip Colourmohamed AdelNessuna valutazione finora

- APL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResDocumento48 pagineAPL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResarrsshaNessuna valutazione finora

- Company Profil CV - Citra Harapan Jaya All CustomerDocumento6 pagineCompany Profil CV - Citra Harapan Jaya All Customersutrisno00Nessuna valutazione finora

- Toyo - Heat Exchanger-1Documento70 pagineToyo - Heat Exchanger-1alokbdas100% (1)

- Top Grades Tags: Home About Us Product E-Stock Selling List Contact UsDocumento3 pagineTop Grades Tags: Home About Us Product E-Stock Selling List Contact Usarief setiawanNessuna valutazione finora

- BHELDocumento56 pagineBHELAjay Kumar100% (1)

- Praxair Oxygen EnrichmentDocumento2 paginePraxair Oxygen EnrichmentsyamNessuna valutazione finora

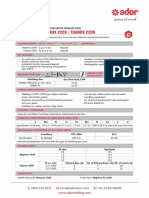

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocumento1 paginaMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNessuna valutazione finora

- PULL OFF TEST - Adhesion TestingDocumento6 paginePULL OFF TEST - Adhesion TestingAlsonChin100% (2)

- Fixture (Tool) - Wikipedia, The Free EncyclopediaDocumento4 pagineFixture (Tool) - Wikipedia, The Free Encyclopediaचन्दनप्रसादNessuna valutazione finora

- Triumph Twist Drill CatalogDocumento64 pagineTriumph Twist Drill CatalogCarbide Processors IncNessuna valutazione finora

- JSW Cold Rolled Brochure PDFDocumento22 pagineJSW Cold Rolled Brochure PDFJaison JacobNessuna valutazione finora

- Langmuir-Hinshelwood Kinetics - A Theoretical Study: K. Vasanth Kumar, K. Porkodi, F. RochaDocumento3 pagineLangmuir-Hinshelwood Kinetics - A Theoretical Study: K. Vasanth Kumar, K. Porkodi, F. RochaAmanda PontesNessuna valutazione finora

- Introduction To /hydrogen Induced Cracking (HIC)Documento5 pagineIntroduction To /hydrogen Induced Cracking (HIC)Raghvendra SinghNessuna valutazione finora

- Wrought IronDocumento28 pagineWrought IronDurham bryleyNessuna valutazione finora

- HSC 7450 8230Documento2 pagineHSC 7450 8230HINDUSTHAN SPECIALITY CHEMICAL LTDNessuna valutazione finora

- How To Make Fake - 20 NotesDocumento4 pagineHow To Make Fake - 20 NotesPaulo ExtoNessuna valutazione finora

- Casing Integrity TestingDocumento1 paginaCasing Integrity TestingKim MissonNessuna valutazione finora

- Me137l - Shopreport - No. Quenching and TemperingDocumento10 pagineMe137l - Shopreport - No. Quenching and TemperingJag MasterNessuna valutazione finora